Topic

Evolution of a Stove System for HX pots: Chapter 1

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Evolution of a Stove System for HX pots: Chapter 1

- This topic has 5 replies, 3 voices, and was last updated 4 years ago by

Jon Fong / Flat Cat Gear.

Jon Fong / Flat Cat Gear.

-

AuthorPosts

-

Feb 2, 2021 at 6:32 pm #3697033

Evolution of a Stove System for HX pots: Chapter 1

I decided to define and focus my efforts on a stove system for HX pots. The initial thread can be found here (Chapter 0).

https://backpackinglight.com/forums/topic/a-diy-version-of-teh-jetboil-stash/

What I may have discovered in an effective way to efficiently heat water in an HX pot. JetBoil has been actively trying to reduce the weight of some of their cooking systems to reach the UL market: The Stash being the latest effort. The first impression is that they seem to have gone backwards with a “traditional” canister topped stove with built in notches to support he stove. Performance in the wind has not been evaluated and JetBoil claims that the performance will be similar to ordinary Canister topped stoves. To me, that means that you get the 20% efficiency increase due to the HX design and the normal fuel efficiency degradation when the wind blows.

As I own a number of canister topped stoves, I have been wanting to experiment with HX pots and purchased a Sterno Inferno for about $22. Additionally, I have a FireMaple 300t which lends itself to easy modifications. The first prototype provided good results, the second prototype was similar, but closer to a real prototype.

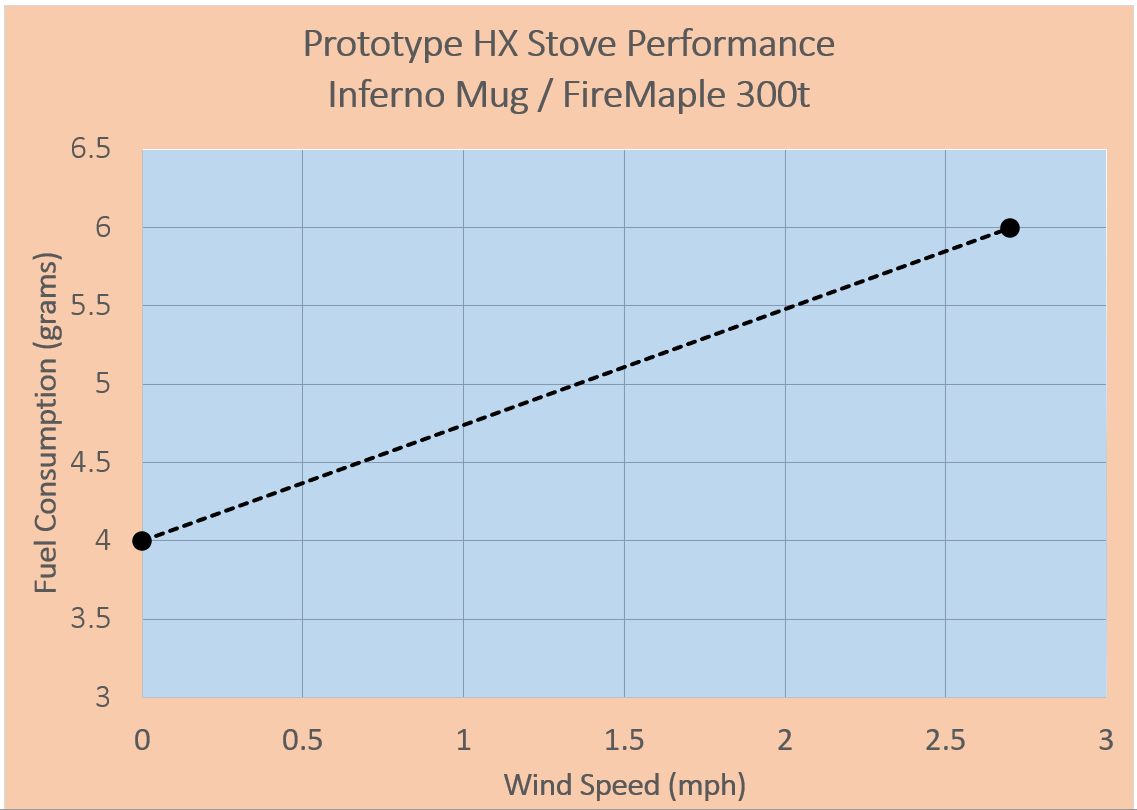

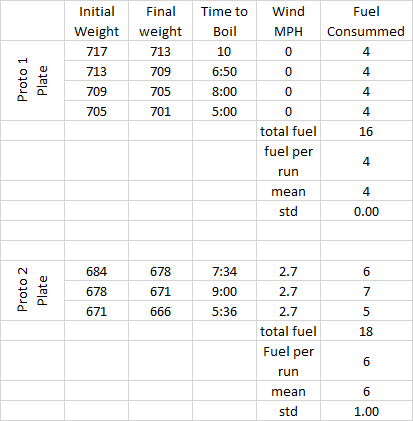

All of this is moot if the system had ordinary performance in the wind. I set up my wind tunnel and obtained the following data. All testing was done using 2 cups of 70 F water. The stove/canister was measured before and after testing. Keep in mind that my scale has a 1-gram resolution. In general, I look at the initial and final weight of the system after all of the runs have been completed. At least 3 runs were conducted at each state with cool down times between each run.

Raw data

Basically, the burner plate and Fire Maple 300t achieved good fuel efficiencies at calm conditions: 4 grams of fuel to boil 2 cups of water. With the wind speed of 2.7 mph, the fuel consumption increased by 50% to 6 grams to boil 2 cups of water.

Why I think it works.

- Unlike a lot of other systems, the bottom of the HX is completely covered and the air inlets are perpendicular to the direction of the wind

- The air inlet ports probably choke some of the available air flow

- The radial configuration of the HX fins block the wind

- The net positive pressure of the burnt gasses probably push air out of the fins thereby keeping the flame coupled to the pot

I had an interesting observation. I was trying to obtain a couple of “fast” boils and was unable to do so as the flames from the Fire Maple would lift off of the stove. I am using a brand new 16 oz isobutane canister and the pressure may be high. I have observed this before when using a propane canister with a Lindal Valve adapter. In the long run, this may be a good thing as I am interested in efficiency and not speed.

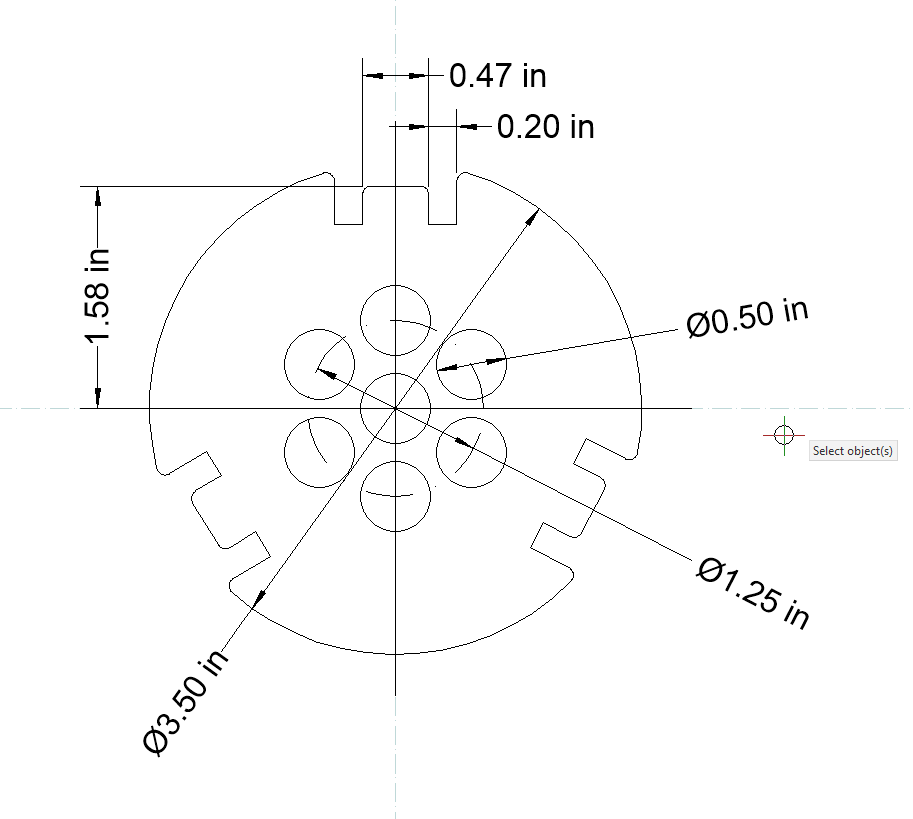

My plan is to keep this as a DIY project as mainstream users are probably not ready to modify their stoves. Currently, the burner plate is made of 0.012” SS. IT may make sense to switch to a thicker aluminum plate, but this is the material that I have on hand. As the design stabilizes, I plan to share the physical dimensions of the plate. As I said in the previous thread, if you would like to see a design for other HX pots, I will need the following dimensions. If it works out, I may waterjet some prototype parts for people who want to experiment withthe design.

- OD of the base of the pot

- ID of the bottom opening

- Distance between the bottom of the mug and the bottom of the HX Assembly

Best regards,

Jon

Feb 3, 2021 at 2:01 pm #3697166Wow,

All of the images on the last post are now missing! Ok, I’ll repost some and provide more information.

Prototype 2 plate

Wind Tunnel set up

Wind Tunnel Results: 2 cups 70F water

4 grams in calm conditions / 6 grams at 2.7 mph

Raw Data

Evolution of a Stove System for HX pots: Chapter 2

Well, this project is about to be wrapped up! I think that I have meet my initial goal of creating a DIY stove system for HX pots (well, at least for the Sterno Inferno). Fuel consumption to boil 2 cups of water (moderate) is 4 grams, in 2.7 mph steady wind – 6 grams.

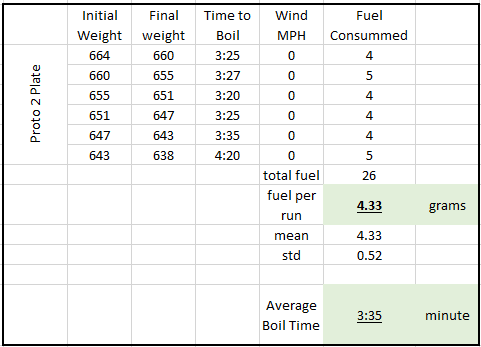

I collected the latest series of test data this morning by running the Fire Maple 300t on high.

Six test runs were conducted using 2 cups of 70 F water. The stove was lit and the flame turned up to as much as possible to keep the flames from lifting off of the burner head.

The key take away was the average fuel consumption on high was 4.3 grams with an average time to boil of 3:35 minutes

Kit as is, (no lid) 5.6 oz.

The kit would consist of the Sterno Inferno pot ($25): keep the other parts if you want to revert back to alcohol.

Fire Maple 300t ($32)

Dan may still be making lids for this pot.

Home Made Burner Plate: I used 0.012” Stainless Steel. Slightly thicker aluminum should work fine

Unscrew the stove, remove the lower brass nut, unscrew the upper nut and remove the support arms. Insert the burner plate, add and tighten the upper brass nut and screw the stove body together. The stove and burner plate will nest inside of the mug. Have Fun!

Feb 3, 2021 at 4:40 pm #3697211Good information Jon–thanks for posting.

Feb 12, 2021 at 4:38 pm #3699082Final video

Boils 2 cups 70 F using 4 grams of fuel; 6 gram consumption in the wind

Total weight – 176 g / 6.2 oz

Cost – about $60 (with lid) not including the DIY Plate

Feb 12, 2021 at 6:00 pm #3699098

Feb 12, 2021 at 6:00 pm #3699098That looks like a really system, Jon.

Feb 12, 2021 at 6:13 pm #3699102Thanks, If I can get people to send me the dimensions of a JetBoil, I can see if I can design a Universal plate. I need the ID of the bottom openning, the OD of the bottom of the mug and the depth (distance) from the bottom of the HX to the bottom of the mug.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

HAPPENING RIGHT NOW (February 11-21, 2025) - Shop Hyperlite Mountain Gear's Biggest Sale of the Year:

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.