Topic

Dyneema Tent Fabric Distorting; Normal?

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › Dyneema Tent Fabric Distorting; Normal?

- This topic has 28 replies, 15 voices, and was last updated 1 year, 6 months ago by

Dan @ Durston Gear.

Dan @ Durston Gear.

-

AuthorPosts

-

Sep 27, 2022 at 10:09 pm #3760876

For quite some time I noticed that the front of my MLD DCF Duomid along the long length door side, the fabric has always been a little “loose” or somewhat stretched out along the bottom and never could get it tight regardless of pitch, where as the other sides were always pretty tight and straight. Never could understand what was going on and just kind of forgot about it as it didn’t affect the function/use, until I noticed after having rubbed a spot on the back panel with my finger to remove a dirt spec, the fabric seemed to have deformed like a stretched dents; repeating it and again the fabric deformed. Began to wonder if that explained the two extended bumps on the back wall, which I think now may have been caused from kneeling on it while folding it up on a carpet at home.

My question is does DCF distort from such pressures, or is this something that happens with age, as I notice small holes and fabric micro “shearing/tearing” at certain areas. The tent hasn’t been used that much, and pretty delicately aside from a good hand washing in the tub. Is there such a thing as over-tightening the guy lines for a tight pitch, causing the distortion on the front door panel bottom? Is Dyneema that sensitive to pressure against it that it distorts its shape?

Just trying to understand the nature of this material and what to expect from it as time goes on, and how to treat it in the future when I purchase another one.

Sep 28, 2022 at 7:59 am #3760888I had an HMG Ultamid 4 that distorted along the entire perimeter. With the rest of the tent taut, the bottom 4-6” would be loose and wrinkly. This happened slowly over time (maybe 30-50 nights?). When I looked into this phenomenon, it seemed like there were reported cases of permanent distortion from overstretching the tent (like during wind events), and others thought that stuffing a tent (as opposed to folding/rolling) could cause this. It seems to be a “dirty little secret” of DCF and has led to me being a bit less enamored with it as a tent fabric. I’m curious what others will have to say.

Sep 28, 2022 at 10:49 am #3760891There are quite a few threads on this topic if you search the forum. I can try to look for them if you can’t find them. Also, it would probably be helpful if you could post photos.

Edit: Here is one from last year: https://backpackinglight.com/forums/topic/how-did-your-dcf-shelter-age-and-expire/

Sep 28, 2022 at 3:17 pm #3760904It will be nice to see some pictures. I have seen many MLD Duomid DCF pictures where the bottom is not straight. Though folks claimed it happened after a long time of use. But some folks claim it is brand new or used very few nights and I see the squiggly perimeter – on ebay and other reddit etc. I have 32 nights in my Zpacks Altaplex in 0.55osy and it is pretty straight still. Maybe the sides of the pyramid (Duomid, Ultamid) are too long while in the Zpacks Altaplex, the sides are short between guy out points and hence tends to be straight rather than wrinkly?

Sep 28, 2022 at 4:20 pm #3760907That’s not common in my experience… depending on manufacturer. I own a DCF MLD Solomid, Duomid (my second one), and Supermid. I have both generations of the T@rptent @eon Li (DCF). I have a Zpacks Alt@plex. A Seek Outside DCF Redcliff and DCF Cimmaron. Aside from the Alt@plex which I have pitching issues with, all the others pitch nice and taut with very little or no flappy/looseness at the perimeter hem. 4 of my friends have HMG Ulatmid 4s and all of them have loose/flappy perimeter hems. That is why I would never own a HMG shelter. We have a number of other DCF shelters in our group like 2 other DCF Redcliffs, a Ti Goat Lone Peak, etc. They are all good. Note that the Seek Outside shelters have ‘sod skirts’ so there is not a defined hem between the perimeter Line-locs.

The only times I have noticed deformation in DCF fabric is in our shelters that we use with wood stoves. When sparks land on the DCF fabric and melt holes, we take small discs of DCF repair tape or Ten@cious tape and apply them to the fabric and then rub them in place with medium pressure from a finger to get the adhesive to engage. Sometimes it results in a little dimple in the fabric when it is in a hard to reach location and we cannot use another finger as pressure on the opposite side of the fabric. But this seems to go away after a while.

At 3:40 in this video we wake up to strong winds on the morning of the 3rd day of a hike across Kodiak Island. The 2 white shelters are Ultamid 4s and the green one is my Supermid. It’s only one data point, but pretty representative of my experiences.

Sep 28, 2022 at 4:27 pm #3760908Mylar is prone to a mechanical property known as “creep” – the elongation (without recovery) of the mylar film placed under high tension loads for “long” periods of time (hours to days depending on how much tension). In our experience with DCF-mylar fabrics used in tents, sometimes we see it, sometimes we don’t. It’s not consistent among brands, tent models, or fabric ID’s. It manifests as small “puckers” or a change in panel shape across a few square inches or elongation (sagging) of edges (common since they can have lots of tension imparted to them). The fabric manufacturer doesn’t like to talk about this, but at least some tent manufacturers do.

Sep 28, 2022 at 4:48 pm #3760910Here is my Zpacks Altaplex pitched drum tight….it has about 32 nights. I pitched this with the 4 corners of the rectangle first and then pole and the back center mid point. This pitching strategy seems to make the Altaplex pitch always great. And you can see the bottom which is straight…not squiggly.

Sep 28, 2022 at 4:49 pm #3760911

Sep 28, 2022 at 4:49 pm #3760911 Sep 28, 2022 at 5:57 pm #3760919

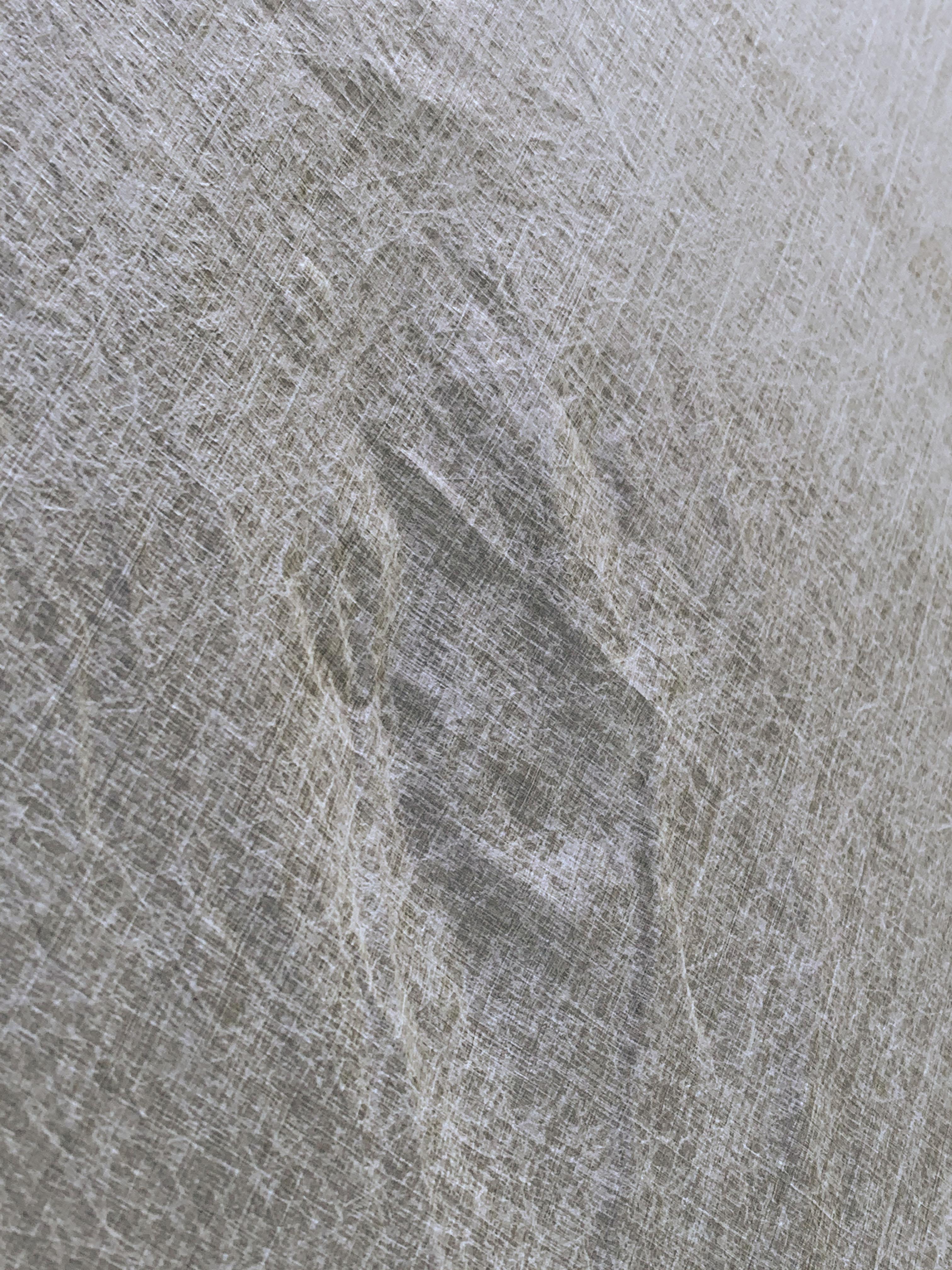

Sep 28, 2022 at 5:57 pm #3760919Here are a couple of photos from today. I notice that I can EASILY distort the fabric just by rubbing my hand across it while it’s set up, or even a finger rubbing it back and forth with little pressure while removing a piece of dirt. It’s not like I’m using a lot of force or pressure; frightening how little it takes to create this distortion. Strange! I fold then roll and into a silylon bag that came with the Duomid and avoid stuffing.

I have hand washed it in a tub and not sure if stressing it by hand agitation or the weight of pulling it up out of the water and it’s weight would have anything to do it.

Tent was purchased new between 2018 / 2019. A couple of trips a year (3-5 nighters) but it’s not used for every trip, and most of them in the high Sierra lakes at a base camp so not a whole lot of packing and unpacking.

Front panel with distortion (above), while the rear and sides are drum tight around the perimeter (below)

Sep 28, 2022 at 6:37 pm #3760921

Sep 28, 2022 at 6:37 pm #3760921Yeah, that looks pretty weird and not to code.

Sep 28, 2022 at 7:37 pm #3760922I have limited experience with DCF. I tried it. It has a place. Had had a flat tarp and a 1P single wall shelter from two different vendors. The tarp faired along well enough but showed signs of fatigue at the tie points. The 1P showed unexpected deformation similar to Mark J’s pics while wiping down inside condensation. Same bummer as getting that first dent in your new car. I take notice of the fragile mylar but hoped the dyneema strands would make the end product a lot more robust. Stronger than steel?The caveat is both were 0.51. If I go heavier, I’ll stick with sils or polys, for increased shade if nothing else. I think I might be done with DCF as a shelter. Just some thoughts. ymmv.

Sep 29, 2022 at 4:44 am #3760927I can’t really tell why the bottom edge isn’t taut, if it was like that from the beginning, perhaps the panels just weren’t cut exactly right. However, those little dents do look like some damage to the fabric. I don’t know if they are serious and will cause any functional problems, but I haven’t noticed that on my DCF tent, which has apparently seen a lot more use than yours. I don’t think that you should damage it by kneeling on it on a carpet, or by rolling it up. That all seems pretty normal and common unless you were somehow unusually rough with it, and it doesn’t sound like you were. Maybe I should be embarrassed to admit this, but I can’t recall ever washing a tent; however, that also doesn’t sound particularly stressful as long as you didn’t use detergent or very hot water. I wonder if you somehow unknowingly exposed it to something hot, either in the field or at home. Otherwise, I suppose they could just be some defective parts of the fabric. Sorry that this happened to your tent, but maybe it’s still usable.

Sep 29, 2022 at 7:45 am #3760929The loose front was there from the beginning and drove me a bit crazy trying to figure out what I was doing wrong regarding my pitch that might have been causing it and never could achieve a taut line as the other panels. After a while I wrote it off to the way it was made and forgot about it as it wasn’t affecting the use of the tent. Only recently upon noticing the easy deformation that my attention returned to it as another part to the sum. Emailed Ron and he mentioned that about that time I purchased the tent (mid 2018) they went to a new mylar E film vs. older K film and that the weave has gotten better in the last few years. Could explain things, or at least I’d like to think so. I do like the material in shelters for its obvious characteristics (waterproof, weight, rigidity) especially having experienced PU breakdown in tents (talking to you NorthFace and your “lifetime warranty”???) but given this experience, I’m beginning to think I could probably get by just fine with silnyon.

Sep 30, 2022 at 8:01 am #3760994I have a feeling that the zipping/un-zipping adds and relieves enormous stress to the front fabric compared to the other sides which can explain the front lower ends not being taut.

Here is a picture of Zpacks Duplex for sale on reddit which has done a PCT thru. The bottom edges seem fine as Duplex doesn’t have any zippers. And the doors do not see enormous stretching stresses that the Duomid has due to the zipper zipping/un-zipping.

That is just my theory:-)

Sep 30, 2022 at 3:20 pm #3761041yeah, dyneema can be very prone to distorting unfortunately. While it’s not technically a woven material, it suffers many of the same problems as them in terms of bias stretch. It just doesn’t spring back again the same way as a woven material because of how it is made. Other than in one specific sense, it’s not actually a very durable material.

As I’m sure you know, it is made of a loose grid of UHMWPE strands, laid out in a criss-cross grid, that are sandwiched in-between two sheets of plastic film.

If you pull at the material in the direction of the strands, either straight up and down or straight side to side, then the Dyneema strands are taking the strain of that force. And they are VERY strong of course, and it’ll tension well and be fine, hold it’s shape no problem.

However if you pull it at any sort of angle, you’re then starting to not pull so much on the strands, you’re pulling increasingly on the plastic film that simply binds the strands and hold them in place. It’s not very strong at all, especially at the kind of thicknesses that are used to try and keep things ultralight. It doesn’t have much of any bounce back, so it very easily stretches and deforms just as you’ve shown.

Tent companies do their best to get round it by cutting the panels that make the tent in specific directions, placing seams in specific places etc, all designed to place the forces as much as possible in the direction of the ‘grain’ or to minimise the stretch problems. Some do it pretty well and minimise the problems, and obviously the exact type of plastic film used and construction will be a big factor. But its never perfect.

It’s also not very durable against abrasion or puncture from the sides either, against the side of the material, as again you’re then pretty much bypassing the Dyneema fibers and just applying the force to the plastic film.

So yeah, other than specifically pulling in the two directions that the fibres run, its not actually a very durable material at all. Many people just think the sacrifices are worth it to save the extra bit of weigh, take care of it as much as they can, and accept that a tent or backpack made of it will only have a limited shelf life compared to a tent made of a woven material.

Oct 1, 2022 at 11:28 am #3761074The Ultamid is very finicky. Any un-even surface gave me logistical issues with a tight proper pitch. Plastic de-forms with heat and pressure easily. I have no doubt DCF deforms from the constant use and strain it gets from setting up. If it’s deforming new, I found getting the geometry correct solved most or all of these deformations. Again, finicky.

Oct 1, 2022 at 11:54 am #3761080

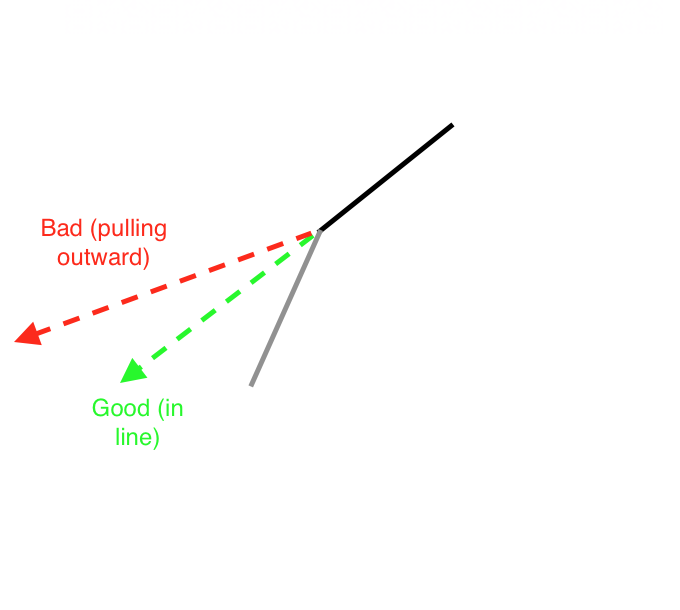

Oct 1, 2022 at 11:54 am #3761080DCF deformation primarily occurs when you are not pulling in line with the dyneema fibers. The fibers are layed out at 0 and 90 degrees. If you are pulling diagonally to the fibers then it pulls the fibers apart and stretches the mylar. Eventually the mylar can begin to crack. On a well designed DCF tent the main forces will be in line with the fibers as much as possible, and then when that is not possible there will be DCF backed tape added on those lines to bears the load and stop the deformation.

As mentioned, mid-panel guyouts can also be a problem. This deformation occurs if you are not pulling on the same plane as the material. This becomes increasingly bad as the guyout is positioned increasingly perpendicular to the material. Mid-panel guyouts will always be somewhat perpendicular the material, so they are problematic. What I do is use side panel guyouts that are not located mid-panel but rather at a seam where the wall steepens below that point. Here, the side panel guyout can be angled along the same plane as the upper panel (basically as an extension of the upper panel) so it is pulling in line with the fabric. If it is also square to the fibers, then you can get a side panel guyout that won’t cause deformation.

The sketch below shows this. Black and grey lines are the normal shape of the tent panels (not being pulled out) and then the green line is a side panel buyout that is in-line with the upper panel so it’s not going to deform the upper panel.

Oct 2, 2022 at 6:50 pm #3761191

Oct 2, 2022 at 6:50 pm #3761191FWIW, here’s a photo of how my Ultamid 4 deformed around the perimeter:

These wrinkles formed fairly early on in the tents life. When contacted about this, HMG customer service responded:“I also have an Ultamid that is quite old (2013) and it did end up developing this issue over time. We have found that DCF can wrinkle enough to the point where it may not lay flat without holding it back in place for a considerable amount of time. I found when I stowed my shelter by shoving it into the stuff sack it worsened this problem, and got better when I folded it neatly each time I put it away. This reduces the amount of times it wrinkles itself thus keeping it smoother for longer. At home, try to hold these areas into place with something weighted overnight and this should help it keep its shape.”

The wrinkling sure seemed permanent to me, but in all fairness, I never tried what was suggested.

Oct 2, 2022 at 9:06 pm #3761200” ,,, does DCF distort …?’ (From the original post)

Here is an excerpt 0f a 2/20/18 BPL post by Roger Caffin, an expert on both fabric matters and making his own tents:

“I was sent some Cuban (sic), way back then, and experimented with it. I noticed the lack of stretch or elasticity, which worried me. So I ran up some small sewn test panels and worked them over. At the same time I made up some silnylon test samples and worked them over. I very quickly came to the conclusion that Cuban was not suitable for a tunnel tent, as the panels on a tunnel need to stretch a bit when it is erected.

“Also I noticed that the needle holes in Cuban tended to grow quite a bit under tension. This would be problematic with a tunnel tent in a storm unless you use very wide tapes with a permanent bond adhesive. I tested this too, and the problem I found there was that the taped joints tended to be rather stiff.

“After that there were at least two other people who made up tunnels out of Cuban using my patterns. I did warn them beforehand about the problems I could foresee. After they had tested them a bit in the field they confirmed what I had been thinking.”

Having the above in mind, I used a high strength adhesive to bond several swatches of Cuben and DCF. Each swatch was folded and bonded to itself, given at least 72 hours to cure, and leaving plenty of room to grasp the swatches and pull them apart. The fabrics tore, ripping off the mylar in places, and allowing physical examination of the dyneema close up.

What I found was that the dyneema threads that appeared to be woven, were not woven together; but rather just placed over each other. And in some places, the threads slipped out of place, stressing the outer mylar layers that were very thin and easily ruptured. I do not know what adhesive, if any, had been used to hold the threads in place; however, where the mylar was ruptured, the threads going in one direction, or weft, could easily be lifted of the threads situated at right angles or warp. Both Cuben Tech. and its successor have claimed that the threads are bonded in the mylar sandwich by heat, with no mention of an adhesive, which would greatly add stiffness.

Because the dyneema threads are not elastic, and because they are not woven together like a fabric, the result is no elasticity, as Roger noted. The term “elasticity” is used to note that a substance will return to its usual shape when tension is released, as distinguished from “stretch,” which may alter the shape of the fabric permanently.

It is therefor easy to see what will happen to the mylar exterior of the DCF sandwich when the interior fibers, not woven in place, are stretched. They will permanently distort and/or rupture the mylar, the latter opening the material up to penetration by moisture.

A number of tentmakers have made valiant efforts to make inelastic material into shelters. And no doubt there are many techniques that will help to produce and maintain a taut canopy, as Dan D’s previous post suggests; and the products of several other tentmakers attest. However, there is no getting past the characteristics of DCF that make it less than ideal for shelters that need to be able absorb severe winds and rain, not to mention hail, and remain durable and taut.

Another factor that enters into fabric performance is quality control in manufacturing, as I’ve learned to my dismay from reports posted here on BPL. So why are folks still paying such high prices for DCF. The answer may be, ‘If you build it the will come,’ as the saying goes.

Those who are looking for elastic tent materials may take some solace from the fact that not all of the lighter weight of some DCF tents results from the use of DCF. Rather, some DCF tents are designed to use less fabric, the price being less spaciousness inside. Taking a cue from that, I’ve tried to develop designs that will lighten a tent by other means, reducing the use of zippers and other fixtures, and making interiors more spacious where really needed, while allowing less space above head, feet and gear storage, where it is not as needed. This approach can also be designed to make a tent shape more aerodynamic, by eliminating canopy surfaces that present obstacles to wind and storms.

But a very light woven spectra or dyneema fabric, with the recently improved coatings, would be a boon to backpackers who want to go light with a shelter that is also durable. There is a woven material, Ecopak Ultra 100, that uses this fabric, but it is laminated with a heavy waterproof material, and weighs about 3 oz/sq/yd. Might make a pack from it.

Oct 3, 2022 at 9:00 pm #3761245I should mention I do fold mine, taking extra care that the bottom edges are folded flat. Time will tell how long that technique will hold its shape though.

Oct 4, 2022 at 7:41 am #3761252I have done nothing special with my Duplex, simply folding and rolling and actually storing it that way. I see absolutely no difference in the fabric (0.74) than the day it was new. No idea if this has anything to do with shelter design, usage patterns or differences in types/production runs of DCF. Just another data point.

Oct 4, 2022 at 1:27 pm #3761264General Care and Use Rules for DCF Mids and most similar tents.

1: Fold and Roll – Don’t stuff tight. Store at home loosely folded.

2: Don’t stand, kneel or put heavy stuff on the fabric or pressure compress the tent in stuff sack.

3: Protect from heat. Car storage can for sure be too hot. Stuff sack in hot direct sun can get hot. If whatever conditions makes you skin feel hot, DCF feels hot. Ground temps under a collapsed DCF tent left in the sun can get quite hot. Don’t do that. Hot tenting? You are on your own!

4: Mids: Stake out the corners medium tight. Don’t be superman.

5: Stake out the mid panel loops very gentle. Use bungee. Should not change shape of the shelter to try to add more room inside.

6: Stake out any other ground level guypoints lightly. The corners of the mid should carry the majority of the main force. All other points are only backup for big wind.

7: Don’t leave DCF shelter set up out in the sun, especially in hot sun unless there is a good reason.

8: If it needs a bit of cleaning. Pitch it and use mild detergent and a soft sponge + gentle water rinse. Do not wrastle it in a tub, pickle bucket or washer. Don’t use a dryer. Yes, I had to say that…

Follow these rules and you will prevent, or at least significatly delay, many posted “problems” of DCF.

Oct 4, 2022 at 4:09 pm #3761270What is the need for rolling after folding? Why can’t one just fold? if folding is causing problems, then we have already folded before rolling….

Simulacra – your tarp looks great even at the bottom.

Homemade Wanderlust recently posted a video saying how she was wrong to just stuff her DCF tent – that was painful to watch. Even her Duplex XL tent with the strut rod – she stuffs the tent, then pushes the rod into the stuff sock ever so gently to make room for more of her tent. If that’s what she was doing on her original Duplex, it survived a thru’ hike and more. She also used her tent as groundsheet once:-)

Oct 6, 2022 at 6:43 pm #3761379Plastic deformation of DCF along the bias is the dirty little secret of UL gear.

If you’ve not ever had your hands on a piece, even a swatch, it might be hard to imagine. All these shelters doing all these miles; they can’t possibly be all deforming. But get a swatch and pull it along the orientation of the Dyneema strands. Strong as hell. But then pull it along the diagonal and you find zero tensile strength and immediate, permanent distortion. Just a little force, ounces, applied this way and your swatch will be a permanent little pucker that will never, ever lie flat again.

I’m amazed that these structures even exist. That they do is a testament to the art of the guys making them. But every DCF shelter I’ve owned has deformed. They have deformed along the biases in areas of high stress – adjacent to zippers, resulting in wavy zippers; along the hems when pitched with a little too much perimeter tension; and in the middles of the panels when pitched with a too little hem tension. And they have also deformed in the denting fashion pictured Mark J’s post above.

My dog walked into a DCF pyramid just after I’d pitched it for the first time and rubbed against the back wall. He hadn’t figured out the dimensions yet, or maybe was fooled by the semi-transparency. Anyway, he just walked in and turned around, didn’t bound or jump and ram into the wall. But his back put a nice big dent that was forever a saggy part of that panel.

DCF is, in my opinion, not suitable for tents. It was Henry Shires who said, in a BPL podcast, that we’d all be laughing ten years from now that we even used this stuff.

I’m not laughing yet, but I will not buy another DCF shelter until the bias instability issue is fixed. And it’s so easy to fix! Back in 2015 or so, “high bias” or HB DCF was actually a thing. Then, it cost less than twice as much to produce. Last I heard, from Dan Durston, it was ten times as much. So no one uses it.

They used to make, and had in their product sheets, an HB variant that weighed about the same as 0.8 DCF that’s used today, but half the Dyneema was oriented at 0 and 90 degrees and the other half at 45 and 135 degrees. They could make it again, whoever “they” are nowadays. It could and should be the standard product in their line, and in our tents.

Sorry to say it, but DCF is stupid light.

Save your money. A 20d silnylon Duomid is stronger, will last longer, will not deform, is far more forgiving to pitch and will cost you 3 ounces.

Oct 6, 2022 at 9:31 pm #3761383Yeah – I am coming to the same conclusion that even if it is a half a pound hit – it is not a big deal. Half a pound is nothing – that is like 8 ounces of water – couple of big gulps:-) I know people get obsessed about ounces – how you die by a thousand cuts. Ounces here, there etc. I usually don’t care about half a pound or a pound increase to my base weight. It will not kill me – and I use a frameless.

My Zpacks Altaplex tarp in 0.8 will be 9.5 oz’s and a ground sheet for that is around 5.5 oz’s – which comes to 15 oz’s (the tent version in 0.8 is 17.25 or so). A x-mid sil-poly fly is 17.5 plus same groundsheet will be 23 or so. Half a pound for no worries – I may go to a smaller groundsheet as there is lots of space in x-mid and all sides can be pitched to the ground which will make it 21 oz’s. I have a silnylon Duomid (older 30d model) and it is around 21 oz’s. With a smaller groundsheet, I can have a 24.5 system.

If half a pound extra is going to break the camel’s back, then I should not be backpacking.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.