Topic

DCF X-Mid Clone

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › DCF X-Mid Clone

- This topic has 56 replies, 15 voices, and was last updated 1 year, 7 months ago by

R L.

R L.

-

AuthorPosts

-

Apr 29, 2021 at 7:20 pm #3710872

Hey everybody,

As mentioned in a recent thread, I’m taking the plunge and attempting to replicate the notorious Durston X-Mid 1P in DCF. Here are the highlights:

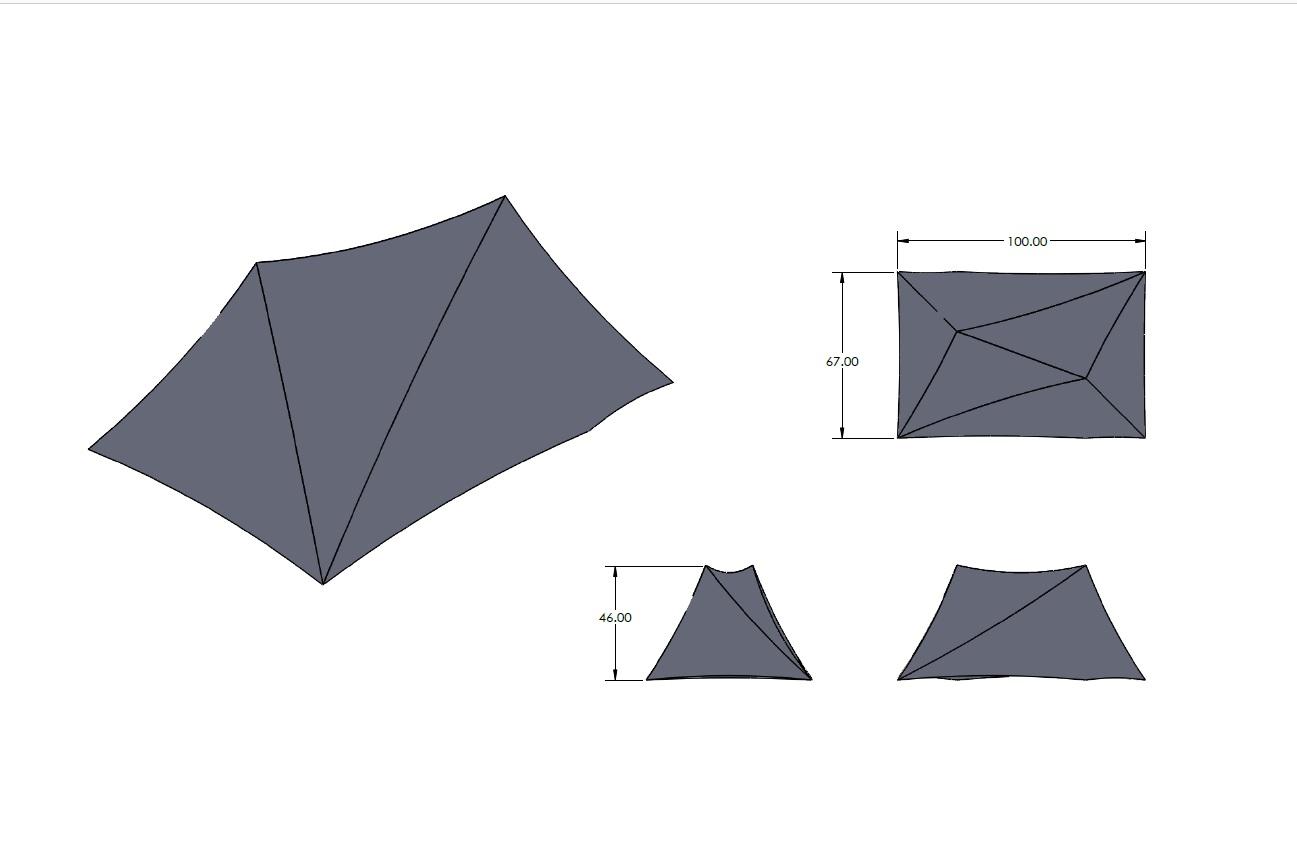

– 100″ x 67″ footprint

– 46″ peak height

– CT2E.08 (0.8 osy) for the main body; CT2K.18 (1.0 osy) for tie out reinforcements; CT5K.18/wov.32c (2.92) for peak reinforcements

– Estimated weight: ~12.5 oz with guylines (2mm Glowire). I tried to account for body fabric, seam tape, tie outs, and reinforcements. We’ll see how close I get…

Everything but the DCF itself is either here or on order. I’m getting patterns for the main panels laser cut by RBTR and they are sending me a final quote any time now. Pretty excited about that part. All the DCF is from RBTR, zippers from OWFINC, 3M 9482PC tape from McMaster-Carr, Clamcleat CL266’s from eBay (Thanks, Roger).

A few notes in no particular order:

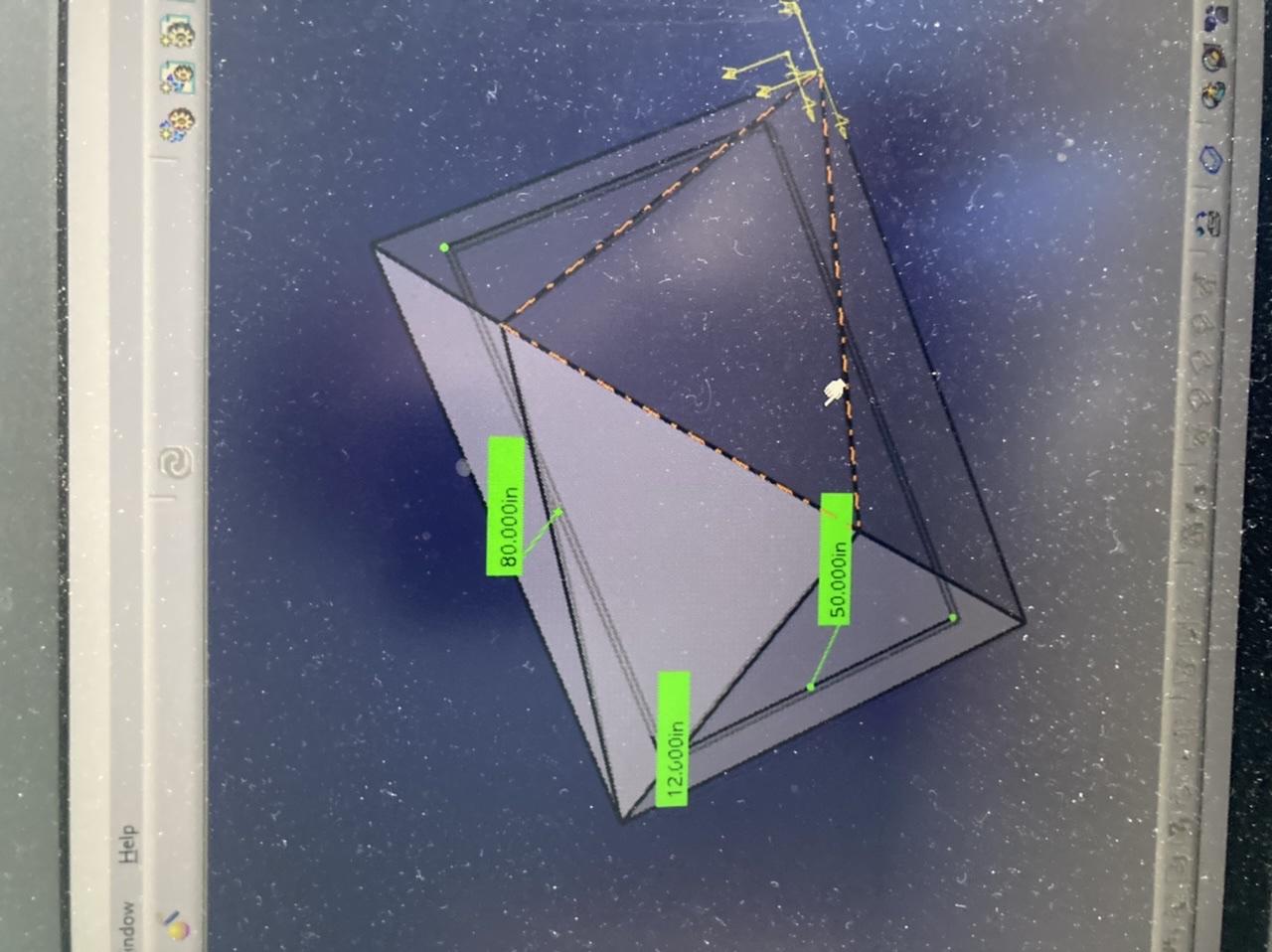

– I used SolidWorks to make the design and create full-sized digital patterns, including curved seams and seam allowance. I went with 2″ deflection along the ridgeline, 1.5″ along the other structural seams, and 1″ along the hem. My gut feeling is that might be a bit much given given the seam lengths, but I really appreciate a nice tight pitch and would rather have too much than not enough.

– Per RBTR I’ll need ~10 yards of the main body material to laser cut it, but I was able to nest the patterns onto 8.5 yards. So if someone were to cut patterns themselves they could save a substantial amount if you include the laser cutting service.

– Speaking of laser cutting, that is going to be somewhere around $200 including some one-time setup costs and the extra material. At this point it’s worth my time to have the patterns cut for me. We just added twins to the family (!!!) so time is at an absolute premium. I’ll probably get in trouble for posting this. :) Cutting these patterns in the future should be MUCH more affordable, so if this whole thing is successful and someone else wants to give it a try, hit me up.

– Total cost, including the one-time stuff, shipping, tax, extra material due to minimum quantities, etc. is (hope you’re sitting down) about $630. I know what you’re thinking…”Well shoot, that’s less than an Ultamid 2!” I totally agree. :)

– I reached out to 3M regarding ideal tape for this application – thin, flexible, low surface energy material bonded to itself in a temperature range of roughly 0 – 120F. Guess what they suggested? Yep, 9482PC. Their other recommendation was 9471LE, as it is specifically designed for low surface energy base materials. But that stuff is hard to come by and they mentioned it was in very limited supply due to pandemic-related supply chain issues. 9482PC on the other hand, is relatively easy to find and more than strong enough for the task. Take a look at Steve Evans’ recent video testing DCF tie out reinforcements for some supplemental info.

– Speaking of supplemental info, a particular shout out to Craig B @kurogane, Eric Blanche @eblanche, and Lawson Kline @mountainfitter for seriously good information on construction techniques. I got inspiration/information from many others, but these three seem to have it pretty dialed. Got me motivated to finally do this myself.

Happy to answer any questions or share any info, patterns, etc. Will post progress as it occurs.

Apr 29, 2021 at 7:28 pm #3710873

Apr 29, 2021 at 7:28 pm #3710873Right on Eric. Congratulations on the twins! 🎈🍾🎉

Looking forward to your progress reports and the final product. About the tent.

Apr 29, 2021 at 8:16 pm #3710877Thanks, David! Hope all is well.

I believe I still owe you a prototype DCF dome tent as well. I haven’t forgotten! Shoot me an email and we can reignite that one if you wish.

Apr 29, 2021 at 10:21 pm #3710892I look forward to seeing this. I went the much cheaper route with membrane silpoly and plotting my own patterns. With other projects and kids, the fabric and patterns are just sitting in the corner of my office. I’ll get to it eventually though. Twins sound like fun, congratulations.

Apr 30, 2021 at 7:56 am #3710928$630?, $630???, are you serious?????? (just riffing on your theme about sitting down)

that should end up being a really nice tent, I’m waiting to see pictures

I sometimes take a while to complete projects. I’m working on a quilt/bivy. Will take several months before I’m done.

Apr 30, 2021 at 9:19 am #3710940Thanks, Jerry. :)

$630 certainly isn’t chump change, but IMO it’s a reasonable price to pay for the whole experience. And really it’s in the ballpark of comparable, already-made DCF shelters – not counting my labor, of course!

It will probably take me awhile, although I feel like most of the hard work (the patterns and cutting them accurately) will be done. I just have to not get a panel backwards…or get them all backwards. :)

Apr 30, 2021 at 12:47 pm #3710975Cool! So this is just the fly, correct? If so, do you plan to add an inner (double wall) or attach a floor (single wall)? KISS and just throw down a groundcloth? Looking forward to pictures.

Apr 30, 2021 at 1:01 pm #3710979Correct – just the fly.

KISS method for now. I just use a SOL emergency blanket for a groundcloth and 2 yards of NS50 to drape over myself to keep skeeters at bay. I’m leaning toward whipping up a bug/wind bivy at some point, or turning the NS50 I have into a wearable half bivy. That might be the jam.

Apr 30, 2021 at 1:13 pm #3710981Thread drift…interested in your bivy thoughts. I have some DCF and nu-see-um from RBTR, a 60″ #3 zipper, and some PSA tape coming from Dave at Oware that I’m planning to make into a bivy. Have some ideas but no final design yet.

Apr 30, 2021 at 2:50 pm #3711006If I were to do a full bivy, I’d probably go with a silpoly floor, and I’d love to try some of that Monolite mesh that Yama is using on their bivies. Actually, I’d pretty much make their wind bivy. The side entry option is inspired.

For the wearable half bivy, I would just make a tube of NS50 that goes down to about upper thigh with a draw cord around the bottom edge. No zipper. I can tie it out above my face or use a length of PE tubing as a sort of UL hoop pole. probably around 3 oz total.

I’m leaning toward the latter for simplicity and low weight. And I already have the material.

Apr 30, 2021 at 3:46 pm #3711020Can’t wait to see the final product!! Thanks for the shout out!

Also, no, ”Well shoot, that’s less than an Ultamid 2!” was not my first thought. My first thought was “yikes!” I then read the rest of the post and understand. I am incredibly jealous that you are having this laser cut by rsbtr. Super expensive (and cost prohibited, in my case) but the results will likely be perfect. I assume you are having cat cuts in the pattern?? making the cost of laser cutting more reasonable…

Edit: yes, i see the cat cuts in the pattern now.

PUBLIC SERVICE ANNOUNCEMENT for those not in the “know:” Dyneema Composite Fabric is going UP in price very soon. This and other dcf projects prices will be less reasonable. Some already think the cost of dcf is too much…Time for the next “super high end future of fabrics” to come out…lol

*Also, David, imo dcf for floor or bivy is only reasonable (cost/durability) when using 1oz dcf. And at that weight, silnylons/silpoly would still be a better material. I think the properties of sil coated nylons and polyesters make them a better choice for a floor touching the ground.

Apr 30, 2021 at 4:10 pm #3711025If I was buying material now I’d probably go for the 0.93 oz membrane silpoly, but I’ve had 2 yards of 0.67 camouflage DCF sitting around for a year and nothing better to do with it. I know it’s not the most puncture and abrasion resistant, but I’m going to use it to make either a bathtub floor for a bug net-tent to fit my Hexamid pocket tarp or a bivy with bug net top. Haven’t decided, but a bivy would weigh less, probably be easier to make, and be usable for “cowperson” camping too.

Apr 30, 2021 at 4:59 pm #3711033Erik, are you giving any thought to orientation of the DCF “bias” with respect to the way your pieces will be cut? DCF is highly unstable on the bias – very little force is required to permanently deform a piece if tensioned at 45 degrees to the selvedge edge.

Does the bonding tape provide tensile strength along those ridgelines that have been cut along the bias of the DCF roll? Otherwise, I would think those ridgelines would be prone to deformation sooner or later. (I have no experience working with DCF myself, this is just a question I’ve had for a while.)

Apr 30, 2021 at 5:39 pm #3711036Good question – I have thought about it, but to be honest I am not optimizing the orientation relative to the bias. Based on my experience and understanding, the combination of high-strength bonded seams and very little stretch in any direction make it a minor concern. Using the 0.8 osy (as opposed to the 0.51 osy) variant with double the Dyneema fibers certainly helps too. I don’t know that any of the major gear makers are taking this into consideration – I’d guess they’re all optimizing for material usage. That said, my panels will be oriented the same way most manufacturers appear to do it – with Dyneema fibers oriented at 0 and 90 degrees relative to horizontal. Unless RBTR does something funky with nesting the patterns for the laser, which I think is unlikely.

Apr 30, 2021 at 6:07 pm #3711039Hi Erik, hmmm I wonder if the 3M tapes are quite stiff. That would make it less important.

I recently grabbed a DCF stuff sack and pulled along the bias and was shocked how easily the DCF deformed in this dimension.

Apr 30, 2021 at 6:21 pm #3711040You should pay for them to cut two, then sell one to make back your laser cutting costs :) I am pretty sure someone would take you up on the offer.

Apr 30, 2021 at 7:20 pm #3711048How much would you charge for a second one in 0.51 DCF?

Apr 30, 2021 at 7:39 pm #3711051Food for thought: It took me approx. a days worth of printing, taping, tracing, and then cutting out my pattern to exact specs. This time does not include “frustration factor” as I call it.

I would charge at least that amount of work at whatever rate you deem reasonable.

Apr 30, 2021 at 8:36 pm #3711059Let’s see how this one goes, but it would be interesting to see how much lighter it would be in 0.51 DCF. At a minimum I could order another set of patterns at a reduced cost. With enough of a group buy, I know I can get a pretty sweet deal on a full roll of DCF cut up into patterns…

Apr 30, 2021 at 9:06 pm #3711062MLD Duomid is a good reference for potential weight savings potential of various materials:

20D silnylon: 18 ounces

0.75 DCF: 15.5 ounces

0.5 DCF: 14 ounces

From here: https://mountainlaureldesigns.com/product/duomid/

Apr 30, 2021 at 10:46 pm #3711069Erik, I’ll be curious to see what RBTR quotes you for the laser cutting. Their setup fee was too steep for me to consider it for just one shelter, I’d think at least 4 or five sets of patterns would be a minimum for me to buy back my cutting time. I plotted my patterns on 36” wide paper, so I still had to piece together some parts, but it was fine. I believe I am in the 14 oz range estimate for my xmid style 2P sized shelter with Membrane silpoly and #5 zips if I recall correctly. It is not a carbon copy as the 2P wasn’t out when I modeled this up, plus I wanted my ridgeline to be nice and straight when viewed in plan form.

May 1, 2021 at 12:37 pm #3711128

May 1, 2021 at 12:37 pm #3711128Sorry, last thread drift…

Given the anticipated DCF price hike I’m going to save the (apparently) discontinued 0.67 camo for some use to which it is more suited, perhaps a hooded poncho and chaps , and get 0.93 membrane silpoly for the bivy floor.

May 19, 2021 at 2:38 pm #3713620Ok…main panels are ordered! I’m told I got the last 10 yards of RBTR’s 0.8 DCF :)

Should be here in a couple of weeks. All other materials have arrived. I plan to make a couple of test pieces for tie out reinforcements, and want to see how well the 3M tape sticks to a water resistant zipper – I wonder if it will be strong enough without any stitching there. I know I read at least one MYOG report of a bonded zipper somewhere on here.

May 26, 2021 at 4:27 pm #3714671Hey Erik, thanks for the shout out! I’m a little jealous RSBTR was responsive to your lasercutting request. When I was making my tent early last year, I tried like hell to get them to lasercut my panels, but they were totally unresponsive, I think because they were making PPE for the pandemic on their equipment. Lasercutting will definitely save you a lot of time and headache! (if you can stomach the cost of course, which apparently you can). Good luck!

Sep 10, 2021 at 8:11 pm #3727125Sam, I’d missed your post. The bias instability of DCF has been mentioned several times on this forum, including by Dan Durston, and so this thread seemed a good place to bring it up. Dan mentioned at one point that he’d looked into a DCF variant with Dyneema filaments running in more than two directions so as to provide bias stability. I’m curious whether the X-Mid Pro will feature this type of DCF variant. I would not be surprised. Afterall, another fabric designed as sailcloth, XPac, has an X-shaped grid overlay expressly to stabilize the bias and prevent panel deformation under load.

I’ve owned several DCF tents and each one has deformed on the bias. Radially symmetrical pyramids tend to deform near the tieouts, such that the corners of the mid gradually get longer. The result is that the mid must either be a) pitched wider and shorter than normal to get tight hems, with a bell shape with exagerated cat curves being the overall geometric result, or b) pitched normally, resulting in loose and flappy hems. Take a look at photos of DCF Duomids in the wild – you’ll see lots of loose hems flapping in the wind.

You and I have had discussions about bias stretch. I think your hypothesis that silnylon tent designs that tension the bias particularly well are somehow resistant to “silnylon sag,” is probably right. Such designs made with DCF will, I submit, permanently deform on the bias.

I recently got some swatches from RBTR and compared the effect of bias tension on 1. 0,5 DCF, 2. 30d MTN silnylon, 3. 20d silpoly (double-sided sil variant). Several firm tugs on the bias left the MTN sil much as it was to start, whereas the silpoly was puckered and no longer wanting to lie flat, while the DCF was so badly deformed it could not, would not lie flat.

Most mids have panels oriented such that their ridges are cut about 20-30 degrees from selvedge, so about 15-25 deg from the bias and therefore subject to creep of the mylar layers – which are really the only thing providing any bias stability in DCF, and possessed of extremely low stiffness and tensile strength. It’s possible that the stitching and overlying DCF reinforcement stabilizes the ridges and prevents plastic deformation in DCF shelters built with “traditional” construction.

But bonding-only construction is becoming popular, with only some adhesive between two DCF edges holding the seam together. Unless the glue or tape has some tensile strength and stiffness of its own, I would expect these ridgelines to elongate over time.

In my opinion, this type of construction would be stabilized with the application of ~1 inch DCF tape (typically available in thickness equivalent to 0.8 DCF) to the underside of the ridge seams. Reinforcing all the seams this way should provide dramatically improved dimensional stability with very little weight increase. Doing all the seams on a Duomid-sized shelter might add 1-2 ounces.

The issue of bias deformation at the corners of a mid is trickier to counter, IMHO. I think the best way is to leave the hems slightly undertensioned in relation to the ridges. This tends to minimize the tension on the panels diagonal to the tieouts (directly on the panel biases).

Getting back to poled tents, like your dome, I think that building it with DCF would be a disaster. A pole structure designed to tension fabric on the bias would quickly deform the DCF. I could be wrong, but it might be that this deformation issue is an even bigger one than the problem of getting DCF cut just so to match the complex 3D curves of a domed structure. Even if you get those panels cut perfectly, they would quickly lose their shape and bag out. The horror.

In my opinion, the resilience of silnylon maintains its position as the best overall shelter material, despite it’s well-known drawbacks. It’s well known that nylon, as a material, is more resistant to creep and stress relaxation than polyester or UHMWPE. It think it’s that elasticity, combined with the elasticity of silicone (as compared to PU or TPU, which I also think are vulnerable to “bagging out”) that allows silnylon shelters to hold their shape over time (but unfortunately tending to lose their shape overnight).

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.