Topic

Catenary vs Conic Curve — Does it matter?

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Catenary vs Conic Curve — Does it matter?

- This topic has 19 replies, 7 voices, and was last updated 5 months, 1 week ago by

Sam Farrington.

Sam Farrington.

-

AuthorPosts

-

Aug 9, 2024 at 11:24 am #3816161

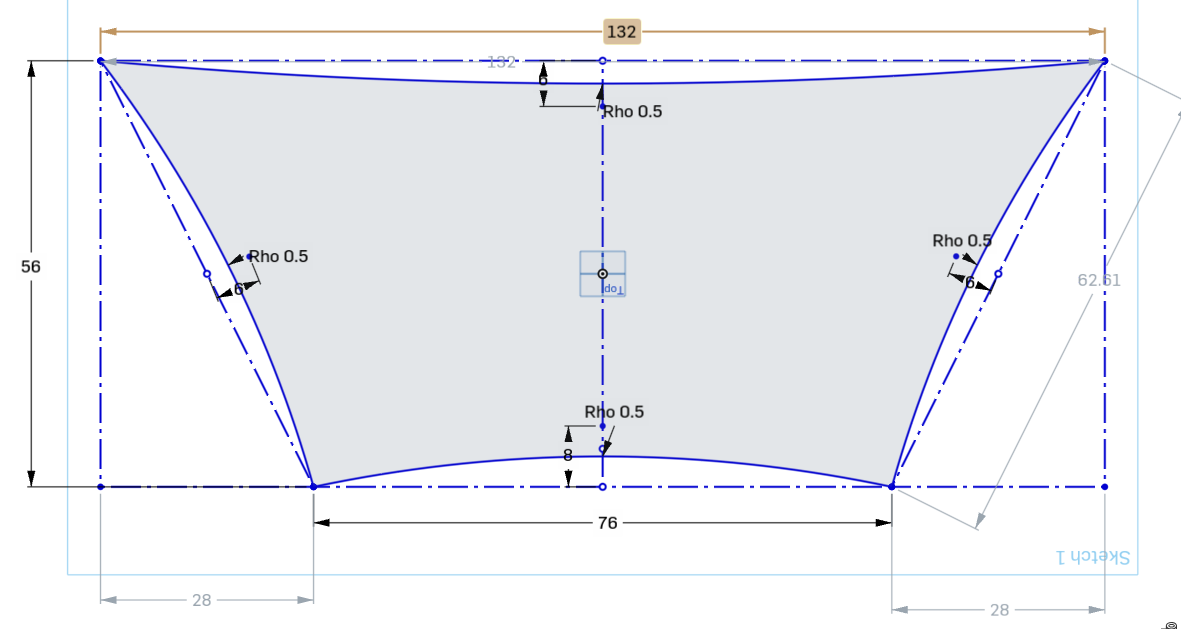

I started designing an 11′ hammock tarp last night using on-shape, and since they don’t have an easy way for me to create catenary curves I just used the conic curve tool with a rho of 0.5 on all my curves. However, I realize these the geometry of these two curves are not the same. I intend to make this using 0.77 oz MTN Silnylon 6.6 (Sil/Sil Nylon). I am new to MYOG and have never done this before, and I am not sure if in practice the result would matter or not. Would it be “close enough,” or should I spend the time to create true catenary curves in my design?

For added context, this is my current design:

Aug 9, 2024 at 12:02 pm #3816163

Aug 9, 2024 at 12:02 pm #3816163I don’t think it matters. The fabric will stretch a bit to whatever curve is best anyway

Are you talking about a ridge or the edges?

Catenary on the ridge makes it pitch better.

I’m skeptical it makes any difference on the edges.

Aug 9, 2024 at 12:03 pm #3816164Roger has an excell spreadsheet to calculate catenary curve. That’s what I’ve used

Aug 9, 2024 at 12:28 pm #3816169Are you talking about a ridge or the edges?

Both.

I don’t think it matters. The fabric will stretch a bit to whatever curve is best anyway

Presumably, the MTN Silnylon 6.6 will sag to some degree with stretch and condensation/moisture. Does the curvature geometry have any impact on the slack in the fabric? I currently share your sentiment, and am a little skeptical that using specifically a catenary versus some other curvature matters so much for such lightweight materials. Nevertheless, the engineer in me just wants to know, “Why catenary, and why nothing else?”

As I understand it, catenary curves help prevent sil nylon fabrics from flapping around a lot in windy conditions. Asking Google what a catenary curve is used for comes back with, “The curve’s shape is determined by the balance between the tension and weight of a chain or cable, and the distance between two points.” So in with this in mind, it makes sense this curve would be used.

Roger has an excell spreadsheet to calculate catenary curve.

My intention is to use my CNC to cut out a template/pattern from dollar-store foam board and tape it together so that I can trace it easily. I looked at the spreadsheets, but I am not sure how to translate the resulting data into a 2D design in onshape. Granted I am over-thinking the problem as well. I probably will end up just cutting the ridge line from the template by hand, as it will be far less effort than coding a custom onshape “featurescript,” but it is nice to be able to resize the design and have the software magically adjust it for me.

Aug 9, 2024 at 1:06 pm #3816191I made my first tarp over the winter and used catenary curves on all edges. I also used a cat-curve on the ridgeline of the bugnet I made. For the tarp, I started with a kit from Ripstop by the Roll and modified it to the size I wanted. They have a link to a catenary curve generator spreadsheet. Start in their “DIY Kits” section and then go to instructions for one of their tarps to find the link.

The curve generator worked pretty well. My only complaint is that it gave dimensions in decimals. I made a conversion page and formatted Excel to output the dimensions in 1/16″ to make it easier to mark out. I stretched out a tape measure on the edge I was modifying (x-axis) and then used a measuring square to measure the y-axis. I made a mark on the tarp with chalk about every 2″ and then free-handed the curve between the points. This seemed to work pretty well and I’m happy with how the tarp holds its shape on the edges.

Aug 9, 2024 at 1:52 pm #3816212I have modified spreadsheet to output in fractions.

But then I modified it to output in decimal mm. (That is, I set the “rho” value from FA’s diagram above to 15 or whatever, then used mm ruler). Inches aren’t fractional, inch rulers are what’s fractional, mm rulers are decimal.

I do the same thing – make a straight line along the ridge, make a mark every 2 inches, then measure perpendicular the distance for that point. Maybe I make straight lines between each point, or maybe I just sew through the points.

I’ve tried making a template but it didn’t seem more accurate when I was done. It doesn’t take that long to measure out a point every 2 inches.

If I was making tents for a living, I’d figure out how to make a template and a process to get it accurately transferred to the fabric. A laser cutter would be good.

Aug 9, 2024 at 2:30 pm #3816218But then I modified it to output in decimal mm.

Yeah, I fully intend to change the dimensions to round numbers in metric before I finalize this. I can’t even tell you the number of times I have incorrectly measured stuff with imperial mesurements… metric is way easier, and why we still use imperial measurements is beyond me.

A laser cutter would be good.

I fully agree. I intend to bond the ridgeline, but something I haven’t figured out is how to ensure the ridgeline doesn’t fray. I am hoping it won’t matter with the adhesive, but I can see weather impacting this over time. I think a laser cutter would help solve this since it would heat seal the cut lines, but that’s a BIG laser cutter.

Aug 9, 2024 at 2:57 pm #3816220Flat felled seam will prevent fraying. Having 5 layers of fabric adds strength.

I think we should make the rest of the world use the superior U.S. system. Spreadsheets should default to fractional. Etc… (attempt at humor)

Aug 9, 2024 at 5:36 pm #3816224“I think we should make the rest of the world use the superior U.S. system.”

damn straight! Umm, I mean damn catenary.

https://kinolorberedu.com/film/the-cat-and-the-canary-blu-ray

Aug 9, 2024 at 5:51 pm #3816225All kidding aside I still have the open question, does the curvature geometry have any impact on the slack in the fabric from stretch and condensation/moisture?

Adding to this, are there any other performance impacts I am not considering?

Aug 9, 2024 at 6:43 pm #3816226I’ve never liked the looks of the zpacks duplex tent because the top catenary curve seemed to create a ‘bowl’ in the long sides/walls of the tent. That bowl has always struck me as being a potential issue in weather. Note that I ‘ve never used a duplex!!

Still, contrast the way the Zpacks catenary curve top line effects the way that tent’s long sidewall hangs versus, say, the Tarptent’s Notch li’s side wall. the Notch li appears to have a much less pronounced curve up top, and as a result–perhaps!!–the side walls remain more taught and straight.

Several caveats here: I’m mostly comparing the Notch li solo tent (be still, my heart) to the Zpacks Duplex. Comparing a solo ultralight tent to a two person ultralight tent isn’t fair. But even given that, from pictures it would seem that a less pronounced curve up top may result in a more taught and wind resistant side wall on a tent.

I may be way off on this! I’d very much like to hear how a cat curve up top effects side wall geometry. I could be wrong; always happy to learn!

Aug 9, 2024 at 7:33 pm #3816228With some better digging on the forums than I did the first time, I found some really great older posts on the subject.

I think this post does a really good job of answering the original question I had about catenary vs conic curves: https://backpackinglight.com/forums/topic/108009/#post-2233501

And this post does an excellent job of going into details about the catenary curve and variants, and how they affect performance: https://backpackinglight.com/forums/topic/1543/#post-1344249

Aug 9, 2024 at 7:51 pm #3816230I glanced at those

I think when you sew along a line, catenary or whatever, then you’ll have 1/8th inch error if you’re really good. And the deviation between different types of curves will probably be about the same. Like they talked about on those threads.

So it doesn’t matter which curve you use.

But you need to really carefully lay out the lines, make sure the two pieces of fabric line up, along the line and perpendicular, and you precisely sew along the line.

Or there will be wrinkles and things when you pitch the tent

Aug 9, 2024 at 8:27 pm #3816231But you need to really carefully lay out the lines, make sure the two pieces of fabric line up, along the line and perpendicular, and you precisely sew along the line.

Or there will be wrinkles and things when you pitch the tent

Since I plan to bond the ridgeline, it might be a little less forgiving than sewing as well. I need to look and see how they do this sort of shape when bonding DCF, because the principals are probably similar.

I’ll try a bonding a small-scale conic curve cut with some scrap first just to see if I need to do something more complex. I might be able to do interlocking differential cuts to ensure it doesn’t wrinkle… but that feels like a bad idea due to complexity and adding failure points.

Aug 11, 2024 at 11:28 pm #3816310“… they don’t have an easy way for me to create catenary curves.”

“But even given that, from pictures it would seem that a less pronounced curve up top may result in a more taught and wind resistant side wall on a tent.”

As noted by several above, these issues have often come up in the past on BPL, and address ‘parabolic’ curves that increase the curve as it approaches the curve center. This was said to maintain a taut roofline, and as the OP notes, seems logical.

But what about the weave of the fabric, important to maintain elasticity in order to keep a taut canopy. DCF and TNT have little stretch, are rigid, and have little elastic. In good weather the best silnylon may do well; but does not hold its shape when soaked, so is the most vulnerable in nasty weather.This leaves an evenly woven polyester, or silpoly. But the quality varies greatly, which led me to borrow from Yama tarps; or from the slightly heavier Extrem Textil silpoly to handle heavier winds.

And to make a tarp frame, as the OP’s diagram shows, it is not just the roofline that may need to be curved. As your diagram shows, there will be slanted edges from peak to ground. If you are using trekking or end poles, you could pin the peaks, fix and erect the tarp, stake out the corners, and see how taut the leading edges are. If too loose, you can create a curved template from a slightly curved rod, and use it to mark, cut and sew the indentations shown on your diagram.

Aug 14, 2024 at 4:34 pm #3816433Complete guide to making catenary curves:

https://backpackinglight.com/myog_tech_note_catenary_curves/Cheers

Aug 15, 2024 at 6:24 pm #3816470Hi Roger, What a great thread. Thanks for reposting it.

What do you think about using flexible narrow tubing to make templates to mark fabric before cutting (with seam allowances of course). Do you think it would be worth the time experimenting?

Thanks, Sam

Aug 16, 2024 at 5:57 pm #3816516Hi Sam

A catenary curve (hanging chain held at both ends) and a parabolic curve (which one would get from bending a rod) are mathematically different. On the ground, in the context of a tent ridge line, there would probably not be much difference though.

Yeah – experiment!

Cheers

Aug 17, 2024 at 9:19 am #3816558My first template I used an actual chain hung from nails and a piece of heavy vinyl truck tarp fabric for the template. To quote Barbie, sometimes “math is hard”.

Some use a curve formed by a long yardstick shaped piece of wood bent between the two points to approximate the curve as well.

Like said, the cutting, sewing or glueing/taping precision will matter as much.

Aug 17, 2024 at 6:12 pm #3816592Roger and Dave,

Thank you for the responses.

Yes, think I will experiment with the frame design in mind.

With a view to making a template or templates for cutting fabric panels.

Sam -

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.