Topic

Another Ultralight Saw Idea

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Another Ultralight Saw Idea

- This topic has 26 replies, 10 voices, and was last updated 1 year, 9 months ago by

David Gardner.

David Gardner.

-

AuthorPosts

-

Apr 28, 2021 at 9:26 am #3710658

Hey guys and gals,

I recently went to purchase a replacement blade for my silky saw and the saw the price for one. WOW! $30!

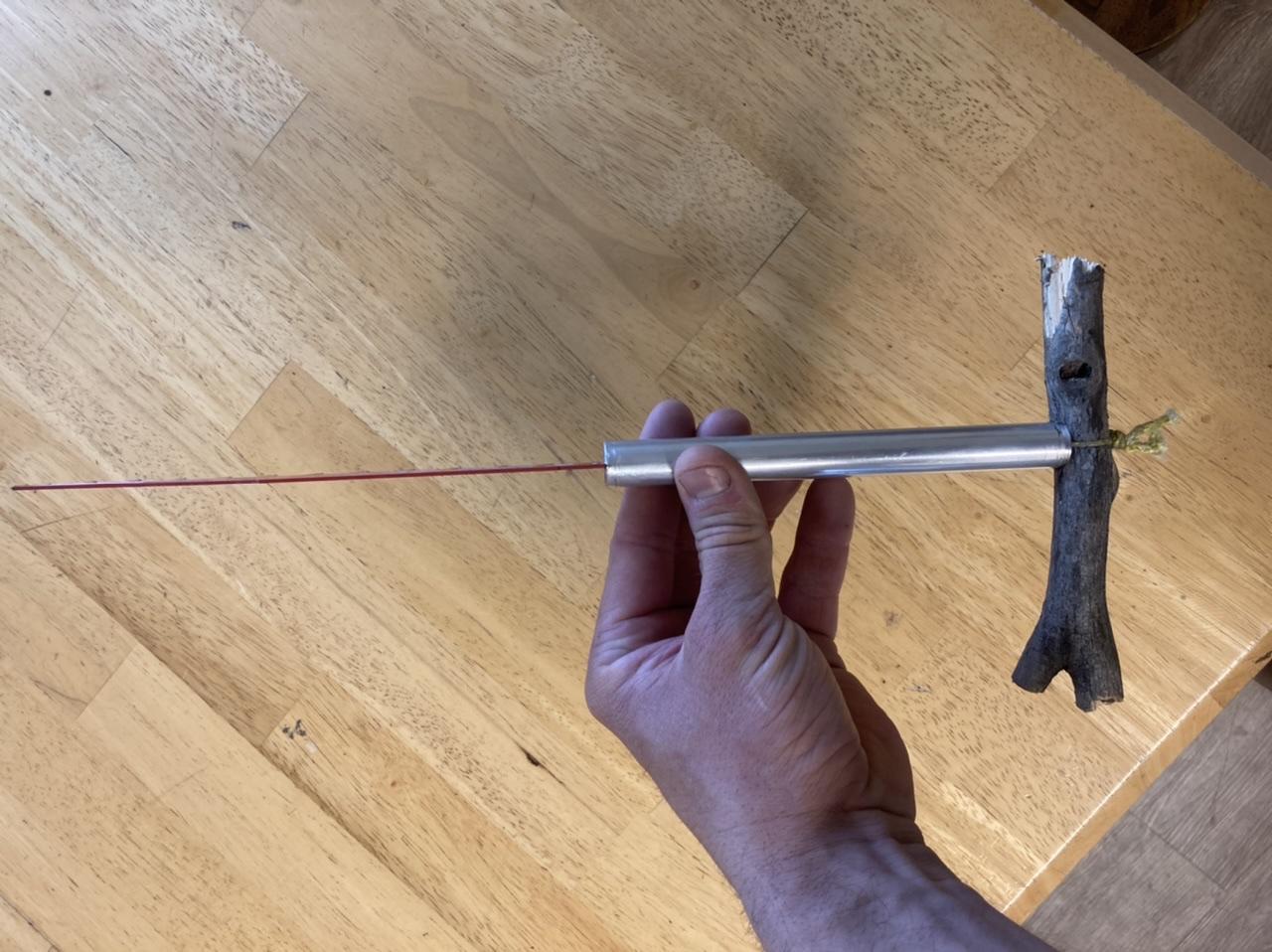

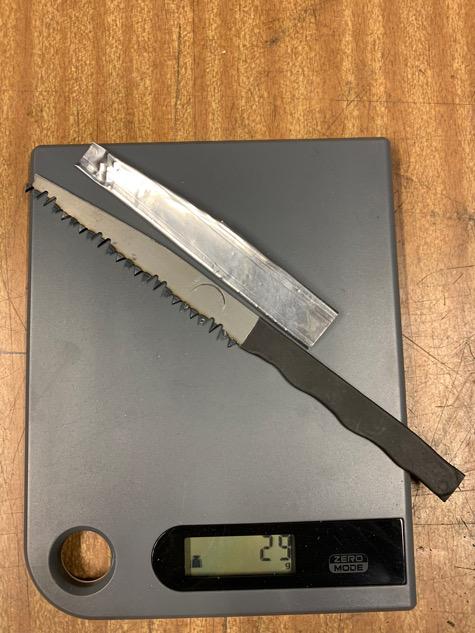

This led me to try my hand at making my own ultralight saw. I got the idea from a YouTuber (knifepointgear). He has them for sale made out of carbon fiber. I made mine out of hardened aluminum, a 9” coarse carbide tipped blade, cotter pin, and some dyneema cord. To tighten the blade in you just find a stick on the ground about the width of your thumb, and twist to tighten. It’s an extremely solid system, and have cut a lot of wood with it already. One of the most important parts in my testing is having the I.D. of the tube within .001” of the blade so it fits perfectly.

If you want to see some videos how it works checkout “knifepointgear” YouTube channel. My favorite part about this saw is how you can just go down to the hardware store and get a replacement blade, cheap. Also, the carbide tipped blades last far far longer than my silkys. Another added bonus is the stick on the end acts as a t-handle and is quite comfortable. You can get any blade length/teeth that suits your fancy, and it works with the aluminum handle.

Apr 28, 2021 at 12:08 pm #3710682

Apr 28, 2021 at 12:08 pm #3710682Very cool. I also like how you can carry and easily swap out different blades for different types of cutting: fine tooth for hardwood, bone, and antler, coarse teeth for green and soft wood. Is the weight 2.6 oz or 0.26 of an lb?

Apr 28, 2021 at 12:41 pm #37106852.6 oz

Apr 28, 2021 at 1:52 pm #3710691Nice! Will have to make one of these for a friend. He brought some sort of chain saw blade with him on our last trip. Looked heavy and tiring to use.

Apr 28, 2021 at 6:27 pm #3710720<p style=”text-align: left;”>Love my Silky F180, but this setup weighs half as much and I love using a carbide blade! Thanks so much for posting!</p>

Jul 17, 2021 at 8:21 pm #3722227Inspired by this thread to try a similar design with PVC. This is 1/2″ pipe. If you use 3/4″ I think it is big enough to be able to store the blade in the pipe. You can also make this floatable if you screw cap both ends. This weighs 2.9 oz although I can gram weenie it a bit more and I think I may go with a shorter blade.

Jul 17, 2021 at 8:22 pm #3722228

Jul 17, 2021 at 8:22 pm #3722228 Jul 17, 2021 at 8:22 pm #3722229

Jul 17, 2021 at 8:22 pm #3722229 Jul 17, 2021 at 8:23 pm #3722230

Jul 17, 2021 at 8:23 pm #3722230 Jul 18, 2021 at 8:33 am #3722240

Jul 18, 2021 at 8:33 am #3722240I think storing the blade inside is a big plus. Nice idea.

Jul 18, 2021 at 10:19 am #3722327A couple of quick tidbits for those that don’t know:

The pruning sawzall blades with the teeth designed for green or dry/soft wood – as pictured by Brian – tend to be a bit thinner and lighter per given length than the construction blades. They also tend to cut limbs faster, in my experience, and the non-carbide ones can be sharpened with a fine diamond file/stone/lap. This is also true for Silky blades, incidentally…even the impulse-hardened models, although these are not easy to work with due to the complexity of the tooth shapes.

For those that prefer the tube/sawzall configuration, here’s a thought: nest a smaller-diameter piece of tubing inside the main handle to act as the tensioner bar. This way you don’t have to find a sturdy piece of wood, and the weight gain would be very minimal.

(As an aside: my 6-ish” Silky with a carbon handle is 2.6 ounces, as well.)

Apr 1, 2022 at 4:58 am #3744979Suggestions ( apologies for mixed metric-imperial units) – and ive bought an actual from knifepoint saw too, with my own money, the handle is brill but i think the 12 in blade is overkill and the teeth aretoo coarse for efficient cutting in the aussie bush:

use the 9” or 6” red diablo demon blade and get the finer 6/9tpi – the finer teeth work better forsingle habded short blade cutting on the pull, and the shorter length is lighter. But the shortest 6” is plenty long enough for packing use, cuts 2”-3” poles well for camp and easy for tent stakes etc

for the handle, i used 5” of aluminium tube and put heat shrink tube over it. it needs to just belong enough for your hand. Result : Weight is only 51g total.

if you grind the top edge a little to put a slight burr on it, as the diablo demon is carbon steel, it casts a good spark off a ferro rodI used pie tin foil to make a blade sleeve to carry it in and protect my gear, with blue painters tape holding the folds of the pie tin together. It weighs than 1g.

alternative – refer ultralighthiker.com:

Try the 9” steel uncoated diablo pruning blade (5 tpi) and grind the back section down for a handle, cover with heat shrink and padding. Weighs about 22-25g and provides a fixed length saw with usable blade. See steves site for instructions and pics.

This particular 9” diablo blade is about half the weight of the equivalent in 9” red coated demon blades before any mods or grinding (21g vs 42g). My store only had it in the 9 and 12” lengths, not 6”. I live in victoria australia too.Apr 1, 2022 at 10:34 am #3744999Excellent. I really like the ability to choose the blade you want for specific applications, like coarse TPI for soft, green wood, finer for hard, dry wood, and finest for bone and antlers, as well as the length, like longer for large branches or small logs, shorter for small stuff. And the weights are fantastically low.

“Brill” – short for brilliant? Would be great to see pics of your saw and sheath. Does it use twisted dyneema cord to hold the blade in the 5″ aluminum tube handle, similar to the Knifepoint saw? Would also be cool if you could post a link to the ultrahiker.com idea you mentioned.

Apr 1, 2022 at 6:25 pm #3745039 Thanks david

Thanks david

– I did mean “brilliant.

– Cord – I couldn’t get the dyneema cord that knifepoint saw use so had to use dyneema cuttings from my rapid ridge lines (zpacks dyneema). The cord is important – unless dyneema most will break under tension as you tighten and get a lot of force in there. The knifepoint dyneema is better and holds the twist which helps with take down set up.

– Ultralighthiker reference : https://www.theultralighthiker.com/2018/09/09/how-to-carry-a-saw/my knifepoint saw handle is pure class (carbon with stainless steel ends) and sized for 2 handed cutting. If you want the best these are it. Im not as strong as the young guys who make these, so my diy are one handed and use shorter finer toothed blades as I only cut small diameter poles or stakes for camp set up or small fires when out on walk about. I have a suluk46 and my own diy bow saw for the large stuff, along with silkys and hand and petrol chainsaws, but that’s car carry.

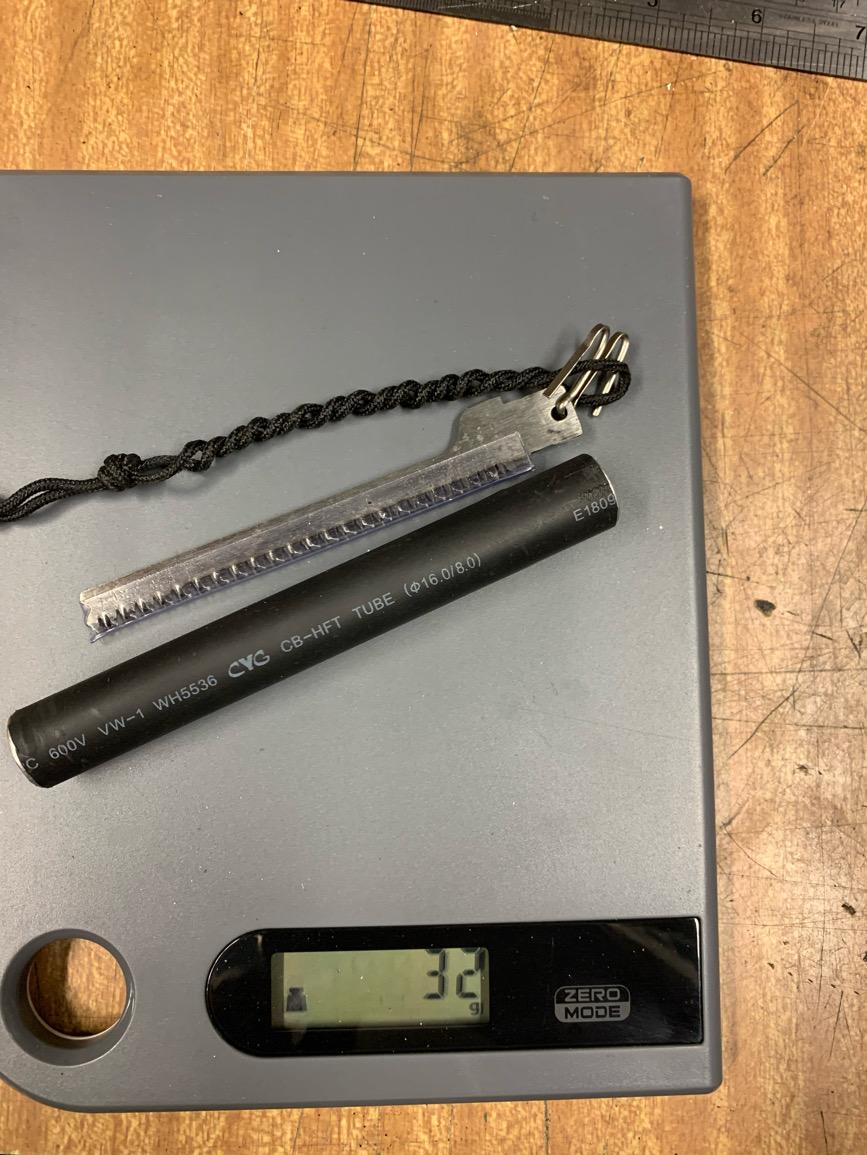

Pic of my spare diy one shown. It has a longer 6” handle and uses the heavy stainless steel cottle pin. I orginally made the handle same length as blade for wrapping with the blade. My current working version uses a 4” handle and a light gauge steel ring for attaching the dyneema.

The heat shrink over the al tube really helps grip. I really prefer the finer tooth and shorter blade. This cuts 3 inch poles even dried hardwood pretty good. Being able to dismantle or reassemble with a few twists means I carry this when out. Also shown is a bit of stick I last used as the toggle – cut with a small knife.Ultralighthiker has inspired me and when my shoulder gets better (re tore the rotator cuff again) I will get out the angle grinder on the red demon 6” blade. And I will make one of his fixed length ones with the steel 9” blade.

Apr 16, 2022 at 3:00 am #3746605HOW LIGHT CAN YOU GO?

much lighter apparently.

I focussed on the

Diablo blade, it’s “heavy” duty.

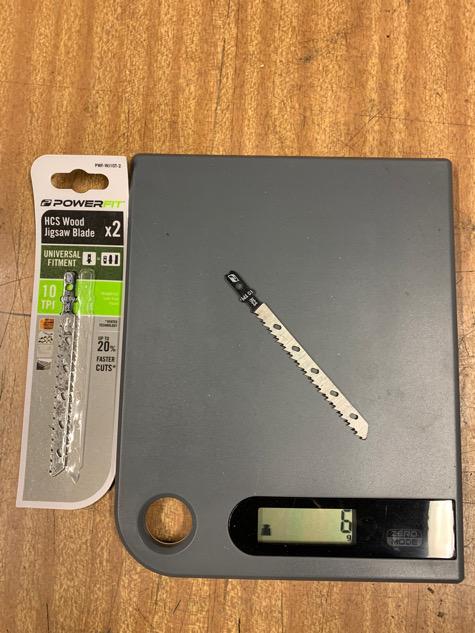

I found a lighter blade a bit smaller length but still usable. And even though teeth per inch is smaller than I’d like (13tpi cf Diablos 6-9tpi the sweet spot for greens and dries) it still cuts Aussie eucalyptus hardwoods.herein my latest evolutions – I found a pack of scroll blades with same size ends as the Diablo reciprocating blade ends

And bonus- the scroll blades come with a plastic tooth protector!

packet cost me $AUD7.60-ish (Bunnings) so each blade $AUD3.70-ish (cf Diablo 6” recip blade $AUD18)

so –

blade weight (w/teeth cover) 11g (Diablo 6” blade weighs 30g alone!)

cottle Pin 1g

Al tube handle covered in heat shrink tube 11g

<b>Total saw pack weight 32g</b>I will post pics in a separate response as the website isn’t compatible with apple iOS and won’t let me use my iPhone to insert a reduced pic from my photo library (Ryan et al?)

Apr 16, 2022 at 3:23 am #3746606worked out how to post pics, sorry my bad – needed to turn the iPhone to landscape to see the rhs

and apologies, a correction – the 6” heavy duty Diablo blade weighs 22g (not 30g). So the new blade is about half that weight.

I made the saw ala the knifepoint design with a much lighter cottle pin (1.2g cf 2.5g).

of interest (to me at at least!) I tried a few saltwater tackle connectors to see if I could replace the cottle pin with these as they are less than half the weight (so I could save a massive 1/2 gram!). When I tensioned them they ALL broke, even though they are rated at 60kg and 100kg. Wow! The tension one can build when twisting the cord to tighten the blade in the handle! No wonder I needed to use dyneema!

“the scales do not lie”

and first pic shows cut of fully dried eucalyptus hardwood stick 1” diam. I wouldn’t want to try to cut a larger stick than this with this tiny blade, it becomes hard work!

now – to reduce the “massive” weight of the aluminium tube handle (a staggering 11g) but still have a usable tool ……

Apr 16, 2022 at 5:30 am #3746608Brian,

That’s a great idea for being able to store the blade as well instead of a separate sheath

Apr 18, 2022 at 12:42 pm #3746797Excellent. Very cool. What brand of scroll blades? Alternatively, what brand(s) of scroll saws will the blades fit? I hope they are available “up over” here in the US!

Apr 19, 2022 at 12:39 am #3746932Ozito pic attached

Apr 19, 2022 at 10:42 am #3746966

Apr 19, 2022 at 10:42 am #3746966Thank you!

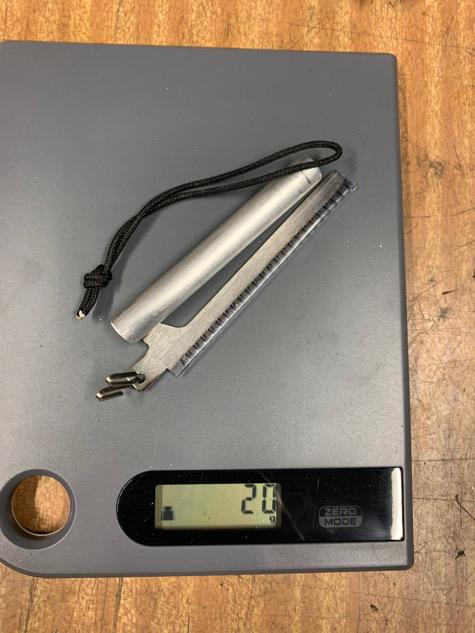

Apr 20, 2022 at 4:36 am #3747020Back in the workshop today – latest evolution as shown, using a smaller diameter aluminium tube, total weight 20g. Covering the handle with heat shrink tube will add about 2g.

i dont think i can go much lighter and still have a reliable usable handsaw.but then perhaps there is something i could do with this:

Apr 20, 2022 at 4:41 am #3747021

Apr 20, 2022 at 4:41 am #3747021And here’s one made with the angle grinder shaped 9” blade ala http://Www.theultralighthiker.com – Saw weight 26g, heat shrink tube on the handle added 2g, knife sheath 1g.

Apr 20, 2022 at 4:48 am #3747022

Apr 20, 2022 at 4:48 am #3747022Heres the collection – all of the blades are high carbon steel and will draw a decent spark off a ferro rod using the flat spine back, even more so if you grind the spine square and leave a fine burr on the strike side…

(the smaller diablo silver coloured blade in the middle which says 9” was a 9” blade that I cut down to 6” with an angle grinder, interchangeable withe the ozito scroll blade, diable 6” and 9” blades)

Apr 21, 2022 at 1:07 am #3747142Putting aside the joking, I’ve tested these today on dried and green Aussie yellowbox and stringybark

there are at least 3 fatal errors in here, I will detail as follows – correspondingly there are some design choices that I would not rely on in the bush AND DO NOT RECOMMEND – you should make up your own mind before doing so. This is where shaving grams can reduce the effectiveness or even possibly cause injury and is stupid. It was fun to try but I will be frank here.

In summary I will only recommend and use the original design saws (heavier gauge red blades, heavy duty split pins and longer larger handles). They weigh a whopping 20-30g (about an ounce) more than the lightest but are safe, effective, reliable, and actually easier to use.

The flaws and my observations are:

1. all tensioning designs using the knifepoint system – I tried lighter split pins to drop a gram but this is a fatal mistake, you need the strength of the 3.2mm or even 4mm gauge pins. It only makes a 1g difference – yes, 1g! these pins when bent are the crucial lateral stability for the blades, critical for safety and also reducing effort in sawing as you can relax and focus on the cut.

2. I cut down the split pins and again, this a mistake – full length is better (remember they provide the lateral stability) -longer is better

3. the ozito scoll saw blades are very light because they are thin gauge- and unfortunately (and somewhat predictably) have reached the point where they flex slightly in a hand held diy saw. After all they are designed for a high speed electric reciprocating saw, not a human arm. They don’t flex as much as the coghlans folder saw blade (which is why I don’t want to rely on that in the real bush situation, I’ve busted one doing so and that’s it). But also the final straw was that the blade has very fine teeth (tiny length and 10th I count) and it’s not enough even for dried hardwood sticks – it does cut them, but too much effort. (The original designs using even a 6” blade with 6 tpi and longer teeth are like a hot knife and butter). I will not be using these scroll blades in real life situations.

4. the thinner shorter tube handle is ok and can work but is a safety hazard and tires the hand faster – I prefer the large one for grip and safety – and a larger diameter works better with the toggle system for tensioning the blade. I will stick with the larger longer ones.

5. the fixed blade saw ala theultralighthiker design is very hard on the hand with just tape or heat shrink tube and needs a grip added, plus I feel very unsafe using it as I could slip down onto the teeth if tired and forgot – the saw teeth are just too deadly, and the handle is just too short (and can’t be longer or you lose blade saw length) – you need about another inch between top finger and the saw teeth (or a guard) – I just don’t like having to constantly be so careful to avoid a catastrophic hand injury out in the bush for the sake of the weight out a mouthful of water. The teeth on this saw are deadly also. I won’t be using this one for real either.

so – I WILL be using the heavier gauge Diablo blades with larger diameter longer Al tube or original carbon knifepoint handles and heavy duty pins for real everyday use, but with the finer tpi red Diablo blades which still cut just fine and don’t have the deadly sharp teeth (general purpose and wood, 6/9tpi) – these finer blades are also easier on my older joints. I will limit using the pruning teeth blades to a full length bowsaw (also in the car along with the axe, for when the chainsaw runs out of petrol or jams). Not for backpack fishing.

Here’s an example of a small pile of wood that I cut while it was green (tree came down in a storm, used a chainsaw for the trunk – not show- and used these tensioning saws with the 6” and 9” red 6/9tpi blades one morning about 6 weeks ago – it gave me a couple hours of saw time in controlled conditions to test and prove out the original designs so I know I can rely on them (and they are safer when you get tired when cutting the stuff the thickness of your wrist ):

</p>

</p>

Apr 21, 2022 at 3:59 am #3747147Chuckle.

The trade-off between UL bling and functionality.

Well done!Cheers

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.

Thanks david

Thanks david

</p>

</p>