Topic

850 or 950 for a winter bag

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › 850 or 950 for a winter bag

- This topic has 32 replies, 15 voices, and was last updated 7 years ago by

Roger Caffin.

Roger Caffin.

-

AuthorPosts

-

Jan 16, 2017 at 6:23 am #3445382

Price aside, what volume of down would yall choose for a winter quilt? I’ve heard that lower fill power could potentially be more resistant to moisture degradation, but I’m not certain if there would be a big difference in the field. Most of my winter trips for the foreseeable future will be 5 days or less. I’m also thinking if I went with 950, I’d get a bag with 21 oz, of down (-10 degree according to EE), but if I got 850 I’d only go with 20 oz (0 degree). Any thoughts?

Thanks!

Jan 16, 2017 at 6:32 am #3445384oh, and I’ve been using a katabatic sawatch with 16 oz of 850 down (narrower) the past few years. I also sleep in a down parka, pants and down booties.

Jan 16, 2017 at 7:58 am #3445395My thought process when making a similar decision was based on just how much more expensive the 900 or 950 was relative to lesser rated down for an extremely minute savings in weight. Nothing to add concerning moisture resistance but anecdotally I’ve read the same conclusions, so I went with the 850 for my EE quilt and have been quite happy.

Jan 16, 2017 at 8:15 am #3445398I’m a cheapo…. 850 for me and no regrets.

Jan 16, 2017 at 8:18 am #3445400I don’t have any scientific data behind, but my intuition tells me the following. Higher fill power will have a higher pitfalls. I believe that wet down will compress to the same loft no matter the previous fill power. If this is correct 20 oz of 950 and 20 oz of 850 would be equal when wet. The problem with higher loft is when you compensate higher fill power for less down. So, if price isn’t an issue and you would go with the same weight in down I guess 950 would just give you that extra warmth without any other downside (pun intended) than price and the possibility of being too warm in warmer conditions.

Jan 16, 2017 at 9:41 am #3445413I believe Ryan Jordan put forth the idea that really high loft down (e.g. 950) may be more susceptible to moisture, and thus provide little real world advantage. I think this was in a SUL article a couple years ago, which was the first I’d heard of it. I don’t think RJ presented any evidence for this, just suggested the possibility. And to be clear, the idea was that 950 down would still be better than 850 in high humidity, it would just have a smaller advantage, as it might drop to 850, while 850 down drops to 800 etc, and thus be a relatively expensive way to save a little weight.

It’s worth noting that 950 down isn’t some extra fragile down cluster, but rather a higher proportion of down clusters rather than feathers. 800-850 down is about 10% feathers, whereas 950 down uses better sorting to get closer to 0% feathers. So susceptibility to humidity might increase at higher fill powers – this seems reasonable in theory – but the same argument could be used to argue for 700 over 800, or skipping down entirely and just bringing a 100% feather bag. Really all that’s being said here is that feathers outperform down clusters in mega wet conditions, which may be true but without knowing how important this is in the real world, we can’t know if the ideal amount of feathers is 100%, 50%, 10% or 0%.

So we need to know if any correlation between loft loss and fill power is meaningful in the field. Based on my experiences using 800-900 down bags/quilts, I suspect any difference in resistance to humidity is trivial. I don’t notice 900fp quilts lose more loft than 800 quilts. And I virtually never have any issues with losing loft in general, even in winter conditions in the PNW where I live. Admittedly this is a crude analysis and I’d love to see a quality BPL on article, but I am confident the ideal amount of feathers is close to 0%. I think packing feathers intentionally is just another form of packing fears. Arguments about loft loss in wet/humid conditions have always seemed like paranoia to me, unless you’re the kind of hiker that is grossly irresponsible with your gear.

Also, I have heard that the advent of treated down has really changed the situation. I spoke with Tim from EE recently and asked him this exact question. He said that even if this was true for regular down, it would be much less true for treated down because it’s far less susceptible to humidity. So treated 950, which is the OP is considering, should certainly provide a sustained advantage over 850 in any humidity you’re likely to encounter in the field.

Loft aside, 950 has other advantages. Since there are much fewer feathers, you’re much less likely to get feathers poking out of the bag. And it will pack smaller. So my take is that the loft advantage of 950 does translate into the field, especially with treated down, and it’s the best way to go if you can afford it. Whether this is a wise purchase depends on your finances and where you’re at in your lightweight journey. Many hikers will could find more effective ways to save weight, but down quilts do last for a very long time so if you pony up for 950, you’ll get a smaller packing, lighter and less feather loss prone quilt for decades.

Jan 16, 2017 at 10:33 am #3445421yeah, RJ said something about studying this more and reporting back but I don’t remember seeing any more

Jan 16, 2017 at 1:44 pm #3445461This month I received a backordered LL Bean -20 F. down bag with 750 fill. My WM Megalite 3 season bag has 800 fill so is nearly the same.

Yes , a 750 fill winter bag will not compress as much as an 850 or even 950 fill bag but for $269. (limited sale price) I’m very happy with a bag that is better constructed than an Eddie Bauer 850 bag I returned for a very poorly designed collar. My LL Bean winter bag came with a $419. price tag on it so I know it was a legitimate sale.

The 750 fill beneath me will not compress as much as a bag higher fill down and that may be a good thing on sub zero nights. :o)

The important thing in my LL Bean winter bag is that the down is DWR treated with Down Tek to keep the down much drier (and the bag warmer) over a week long trip.

Eric B.

Jan 16, 2017 at 4:03 pm #3445487What’s the aim of changing quilts? If it’s to increase warmth then the -10F quilt with 950 fill is going to make a bigger difference than the 0F quilt with 850, which might not be that much warmer than your Katabatic Sawatch.

In my experience the 950 fill down does perform well and gives a small advantage over the 850 fill down. It comes down to the individual as to whether the small advantage is worth the extra cost.

Jan 16, 2017 at 4:24 pm #3445490Thanks for the replies everyone. My thoughts line up with yours, Dan, and was curious to see if anyone had experience to sway me.

As much as I value RJ’s insights, I think its a problem with the format how quickly conjecture and opinion can become part of an online communities beliefs. I think of the overblown response to one persons issue with their cuben shelter.

I should be more of a cheapo based on income, but I think the extra warmth and compressability for the weight seems worth it to me. I use my gear a lot. Part of the reason I wouldnt just go with extra 850 fill is because I know even a few oz (as trivial as that is) will make me less likely to take the quilt out in the shoulder seasons.

Anyway, so I’ve basically justified it to myself, but please share if anyome has related experience.

Jan 16, 2017 at 8:34 pm #3445535Regarding Ryan Jordan’s article, it was incomplete. I personally believe that for a few days out, say up to 5 depending on conditions, your body heat will force any dampness in the down to leave the down, soo, you end up with a greater insulating value/weight from the 950fp, than the 850. However, in very cold conditions, (like 0F and below) you could move the frost line into the down, so, it gets wetter each night. Since the air is dry at cold temps (say above 0F at night,) I wouldn’t worry about external moisture too much, if at all. Even when I have been out for a day from base-camp and the bag is covered in spindrift, I just shake it off and put it back on the pads for use. I believe that your body heat will dry the down quicker than it picks up moisture from insensible perspiration as long as the condensation/frost line is outside of the bag (assuming it isn’t wet to start.) One of the reasons VB liners aren’t worth much until things start getting below 0F.

Go for the higher fill…Jan 16, 2017 at 11:11 pm #3445550take it as you will …

Ryan Jordan

( ryan – BPL STAFF – M)Locale:

Greater YellowstoneNEW Re: Re: Re: Introduction to Outdoor Retailer Summer Market 2008 on 08/10/2008 08:04:56 MDT

Bill et al.,

I spoke at length with IDFL yesterday about down testing.

None of their tests stimulate real world testing. 900 fp in a test is going to be a pipe dream in the field, because they steam wash and dry the down to nearly zero humidity before doing the test. Ironically, this most recent iteration of test methods was designed to determine the maximum possible fill power for down rather than what it will look like in the field.

Interestingly as a side note, we did some 900 fp testing of down a few years ago on two manufacturer’s 900 bags. We cut the bags open and sent them to IDFL. Neither made the claimed 900 spec (they tested 830-870 using the steam method). What was more dramatic was that when each down (which clearly came from different sources as evidenced by visual inspection) was subjected to 50% humidity, the differences were pretty dramatic. One bag tested at 770 fp, the other at 680 fp. It seems that at least these two sources of 900 down had feathers in it that were not resilient in response to humidity.

The kicker is that we ran the same test next to down taken from a manufacturer’s 750 fp bag. at 50% humidity, the fp was 720. Why? It had more feathers that were stiff enough to preserve the loft in moist conditions.

https://backpackinglight.com/forums/topic/39920/

other folks have posted research saying theres no real effect of humidity ..

though i think no one would argue that if a bag got significant condensation (actual moisture) the down would be affected

to further muddy the waters … DWR down might make it a relative non issue

;)

Jan 17, 2017 at 1:12 am #3445562Thanks for posting eric. Yeah, so not really conjecture at all, but also not experience. The other factor is that I will be in the rockies for every forseeable winter trip, where the air is quite dry, and most days offer oppurtunities to dry my bag out in the sun. I have experienced loft degredation on multi-day trips, but nothing bad enough that I cant compensate with extra layering, fatty foods and warmup skinnning before bed.

Another factor which I’m curious about but I’ll never get the chance to quantify is breathability of fabric. EE’s 10d fabric is by far the mist breathable downproof fabric I’ve found. This for sure helps with drying, both from air drying in the daytime and drying with body heat or a nalgene from the inside.

The only time I’ve ever totally soaked a bag was one with average fill power in the winter of 2001 near the top of mount mitchell in NC where its basically a rainforest. I spent a night in my sierra designs clipflashlight basically inside of a rain/snow cloud hovering right around 32. The next night I put hot water in my nalgene and a thru hiker lent me his bivy. The bag dried up fine. Thats mainly to say that for colorado ski trips, conditions are pretty damn different, and for the most part more favorable. Unfortuantely, less and less 0 degree nights too.

Jan 17, 2017 at 2:01 am #3445565The IDFL steam treatment was developed solely for marketing purposes. If you get your down tested at IDFL you can claim a higher fill power. The IDFL tests and numbers are usually ignored by any European mfr, as they are crap.

Cheers

Jan 17, 2017 at 3:03 am #3445568The IDFL tests and numbers are usually ignored by any European mfr, as they are crap.

Well, I have the impression that quite a big lot of European mfrs do quote the fill power number coming out of this test for the sole purpose that it is higher. I always try to find which method is being used and if the steam one is mentioned or no method is being mentioned at all so I assume it’s the steam method, I always convert it to the non-steamed number.

Jan 17, 2017 at 8:03 am #3445586serge …

as long as you can worship the sun god itll be fine … and i suspect that EEs DWR down will help out as well

i had an EB DWR down vest which ive since given away to a family member … when i used it in the rain it got damp of course, but once it stopped raining it dried out quite well with body heat … not quite synth, but milder dampness it worked quite fine

my favorite climbing partner had a marmot xenon DWR down which she used in the canadian rockies last year where amazingly it rained for a week straight … the DWR down did its job managing the condensation even though there was little sun

there was a series of articles on packrafting in BPL where they used some EE DWR down in damp conditions as they mentioned in the comments

fabric makes a large difference as you noted as well … years ago BPL did a test which some folks use to try to prove that down dries faster than synth … what they forget to say as well is that it was in warm conditions (not cold rain) … and that it was really the WM flash that dried faster because it had a more permeable fabric as BPL noted in the article …

the MB with much less permeable fabric dried quite a bit slower

;)

Jan 17, 2017 at 1:14 pm #3445639the MB with much less permeable fabric dried quite a bit slower

Wet down in a plastic bag dries extremely slowly (OK, rate of zero), while wet down in a mossie netting bag dries at a reasonable rate.

It’s air flow which dries the down, and that is controlled by the fabric (and the wind). The DWR is not all that significant.Cheers

Jan 17, 2017 at 1:43 pm #3445645Roger, I beg to differ with you on the significance of “down DWR”. I think you need to give DWR treated down a fair trail. I’ve found that it is very useful for retaining loft in down garments in damp weather and sweaty climbs. Soon I’ll find how well it works in my -20 F. winter bag.

All this “fill power” sleight-of-hand by marketers shows yet again how important a good down DWR treatment can be in real world situations. Retaining loft in actual use over many days in less than ideal conditions, such as cold and/or damp weather, is more important than initial loft in dry conditions.

SO… which down DWR, Dri Down, Down Tek or Patagucci’s proprietary down DWR version will be proven to be the the best and most durable? Or will another new advancement down DWR prove to be “the one”?

Jan 17, 2017 at 2:12 pm #3445654BPL should really do a comparison of these different treatments. That would be BPL gold.

Serge: I believe EE’s 10d fabrics test at about 10 CFM, which seems about optimum. Higher would lose feathers and heat, while lower would dry slower. 10CFM is similar to a good windshirt, with a plastic feeling windshirt probably under 1 CFM.

Jan 17, 2017 at 2:29 pm #3445660Hi Eric

We will have to differ here. For a start, wearing down on a ‘sweaty climb’ strikes me as being fundamentally wrong.

But the whole ‘retaining loft’ idea is also wrong. Down comes from ducks (and geese etc). In its natural environment (on a duck’s body) it is NOT ‘dry’. Down can retain loft while holding a moderate humidity. What ducks do to control the dampness of their insulating down is to protect it with a layer of water-repellant outer feathers. Fine – so what we need to do is to protect the down with a good outer fabric – a water-repellant fabric.

A really amusing thing you can try is to take a bag of down (assuming a good fabric), dunk it in a bucket of water for a moment, then haul it out and see what has happened. IF it was a good fabric, you will find the down remains dry: only the outer surface of the fabric gets wet.

A lot of very technical down gear mfrs have publically said that they will pass on the DWR idea. They can’t see any benefit.Basically, the DWR is either ineffectual (far too little coating to do anything), OR it makes the down far too heavy. In other words, it is a great bit of marketing spin with very little real justification – a bit like Nike’s arch supports. To be sure, the quality of the down matters, but too many people pay far too little attention to the fabric on the surface. In part that is because the mfrs of down gear keep fairly quiet about the fabric they use – and which in many cases is their own custom material. It’s their ‘secret sauce’.

Cheers

Jan 17, 2017 at 2:32 pm #3445661for down clothing i can say that the DWR down does make a significant difference

i had the old original EB downlight vest, which they eventually replaced with a new version with DWR down … so ive used the same garment with treaded and non treated down

they both get damp and wet in enough rain … the difference is that the DWR one keeps the loft longer when damp and more important DRIES quicker

you wouldnt want to get either totally soaked, but for milder damp conditions its fine

of course i can only speak for this particular down treatment … the IDFL put out a paper a few years ago where they said quite a few DWR treatments dont do crap, sadly they didnt ID which ones they were

as to the DWR of the surface fabric … that wont do diddly against condensation from the INSIDE

;)

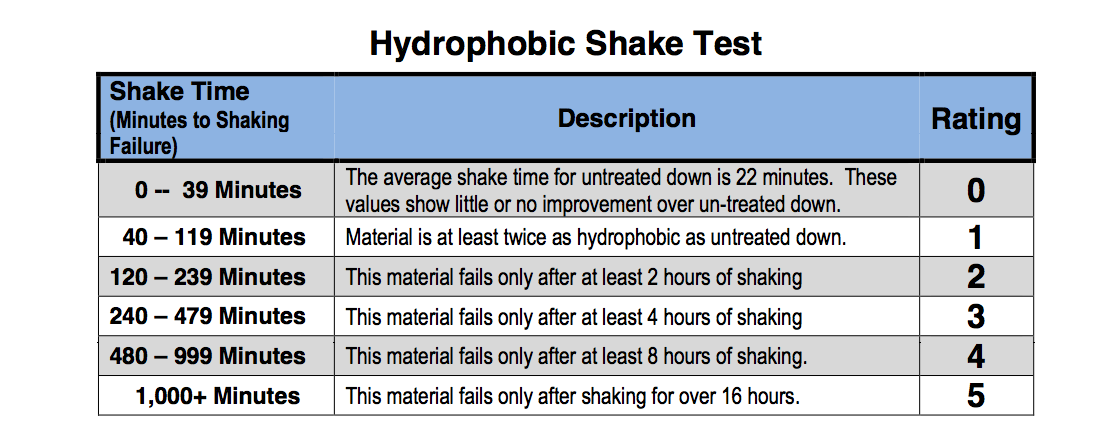

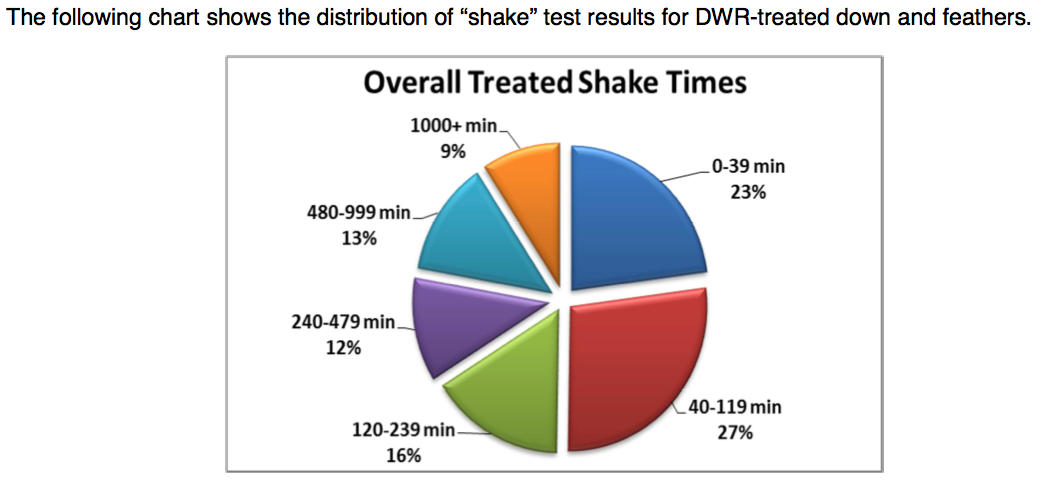

Jan 17, 2017 at 2:40 pm #3445667DFL has received over 1,000 samples for DWR testing. The samples include different treatments from

different suppliers using different application procedures and varying qualities of down.DWR data has yielded many surprising results:

• Natural down is very hydrophobic without treatments.

• Untreated down averages 22 minutes of shaking until failure.

• Some DWR material has yielded over 1000 minutes of shaking before failure.

• Polyester did much worse than expected in absorption rates and hydrophobic shake testing.

• Polyester and other synthetics can also be treated with DWR. In some cases, the results show

great improvement in hydrophobicity for polyester fillings.IDFL’s research on down performance before and after DWR treatment:

• More than 50% of DWR treatments have a positive effect on Fill Power.

• Generally, the DWR treatments slightly increase down cluster percent and decrease fiber percent.

• The oil & fat content percent increases by an average of 0.6% after DWR treatments.

• DWR treatments slightly improve the cleanliness test results of down and feathers.

http://www.idfl.com/media/pdfs/IDFL%20DWR%20Info%20Sept%202014.pdf

Jan 17, 2017 at 3:34 pm #3445678Well there it is…. 40 years of backpacking and all I’ve been missing is “hydrophobicity”. Who knew? I gotta get me some of that!

Edit- Actually I have 2 down quilts and both are treated with dwr, however, I don’t have a direct comparison to a non-treated quilt.

Jan 17, 2017 at 7:01 pm #3445709I agree with Roger. The big deal about down warmth is staying dry. Iff I let my down bag get that wet, I will have more trouble than just being wet. And it doesn’t really matter whether it is treated or not…it’s wet. At cold temps, it doesn’t make any difference because it would never get all that wet. It would be snow. Nor will DWR coatings of any type stop condensation/ice build-up in your down bag. Based on experience, at around 25F and above, wet stuff becomes a significant concern. But, I would not subject my bag to a water bath in the first place. Hell, I go out of my way to AVOID wet spots. Again, the IDFL is testing stuff, getting results, reporting it, but, it has nothing to do with the objective of camping. Who cares? I would not sleep in a mud puddle anyway, soo, why would I care how long it takes to wet out? Real World Conditions. Sorry, the test is interesting but mostly meaningless in our context. The only difference would be how long it takes to dry the next day. Sorry, I suspect I would be of little concern by then.

Jan 17, 2017 at 7:22 pm #3445713Eric,

Thanks for that enlightening (to open-minded backpackers;o) info on DWR treated down. I went to the linked site and printed out the info.

Roger, you may benefit by looking at that site and digesting the info. I know you’ll look at it with a gimlet eye but at least look.

Eric, I have had similar experiences with an EB untreated jacket and a newer EB treated vest. Both were the First Ascent models.The untreated jacket wetted out in a wet snow that struck suddenly when skiing at Snowbird, UT.

My EB Dri Down vest got a similar wetting last winter in my local Spring Mountains in a sleet storm at 8,500 ft. but remained lofty and, later at home, dried much quicker. No, the two conditions were not the same but were similar enough for me to see the difference in the two garments’ down.

BTW, Rog, ducks and geese use “natural DWR” by constantly preening their down under feathers with their bills which have oils from their tail area. This oil is is replenished by the waterfowl through daily preening.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

UPDATED August 2024: See our recommendations for lightweight gear at REI »

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.