Topic

Dynamic Reinforcement Patch Testing

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Dynamic Reinforcement Patch Testing

- This topic is empty.

-

AuthorPosts

-

Jan 1, 2012 at 6:37 pm #1283600

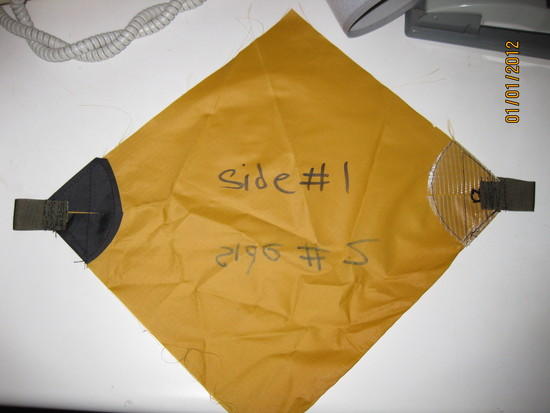

I performed a dynamic breaking strength test of two reinforcement patches that wrapped around opposing corners of a puke yellow colored piece of 1.9 ounce uncoated ripstop nylon parent fabric.

Photos using my recently acquired $100,000 super-high speed (explosion analysis certified) camera* are shown below:

Details,

(1)In one corner, wearing black trunks, is a wrap around patch made of two inch wide adhesive backed insignia cloth with stitching added.

(2)In the other corner, wearing nearly clear trunks(yuk) is a wrap around patch made of two inch wide strapping tape with stitching added.

(3) Third photo shows testing mechanism. A forty pound bag of lime is in the bucket. Lime bucket was lifted approximately 1 foot and dropped during test.

(4) Fourth photo shows what happened.Conclusions/Findings

This was really fun! I'm sooooooo happy to be retired and to have the time to do this sort of thing.Other things being equal and given only two choices I would use adhesive backed insignia cloth for corner reinforcements instead of strapping tape.

This concludes my analysis (line stolen from Mr. Bean)

No rights reserved. No copywrite. No patent pending.

*Just kidding about the camera.Jan 1, 2012 at 8:19 pm #1818482Hmmm…To me it looks like the parent fabric failed at the seem and not the actual patches or tie outs.

The failure was at the seam created by the stitching, why it failed on the strapping tape vs the insignia cloth could be due to a lot of factors. I'd wager the strapping tape is fairly rigid while the adhesive cloth stretches similar to the silnylon.

Thus you could reason that the stiffer tape concentrates the fall force onto the seem between the fabrics and doesn't distribute the load as well, but you'd need more trials to verify.

I'd conjecture that this result probably does not apply to cuben fiber, which has very little stretch. With cuben, assuming the parent fabric also fails before the patches themselves, you'd probably see little difference in which patch fails…the failures relying more on the uniformity of the seem stitching than the fabrics used.

Jan 2, 2012 at 8:04 am #1818616Dustin,

What you say makes sense to me.

Daryl

Jan 2, 2012 at 9:35 am #1818647I just tested two adhesive backed insigna cloth reinforcement patches on 1.9 ounce uncoated ripstop parent fabric.

One patch has straight edge on both sides of parent fabric. Other patch has a strait edge on one side of the parent fabric and a rounded edge on the other side of the parent fabric.

Winner = the one with a rounded leading edge on one side.

I also did several more tests with strap tape and insignia cloth always won. Strap tape has been sent back to the minor leagues.

Observation: Dropping a 40 pound weight makes a heck of a wallop. I can see why gallows are very effective.

Jan 2, 2012 at 9:39 am #1818649"I can see why gallows are very effective."

;-)

Jan 2, 2012 at 10:47 am #18186876

Jan 2, 2012 at 11:36 am #1818711Timothy,

You said "It just depends where you want your tarp to fail".

I like David Olson's shear pin idea to control where the failing occurs. I could, for example, put a loop of cord on the grossgrain loops that breaks before everything else fails. That cord loop would be easy to replace in the field.

One source I found said the grossgrain has a breaking strength of about 1000 lbs.

Daryl

Jan 2, 2012 at 11:38 am #1818712This test matched adhesive backed insignia cloth with a patch made from the parent fabric. Parent fabric won.

Jan 2, 2012 at 11:52 am #1818724

Jan 2, 2012 at 11:52 am #1818724d

Jan 2, 2012 at 12:38 pm #1818745Daryl,

You are getting similar results when I tried such.

It reminds me of fancy steel bike frames where tubes are double or triple butted at the

stress points of the end.Jan 2, 2012 at 1:26 pm #1818770Daryl, try a test where both corners are made equally – in the same way. Then, when one corner tears, what conclusion can be made?

Jan 2, 2012 at 1:45 pm #1818775It tears at the near end to the force applied.

Jan 2, 2012 at 2:05 pm #1818785I haven't seen the test of a star or finger reinforcement.

Jan 2, 2012 at 4:55 pm #1818851Dan,

Good point. If they were the same construction I guess one would have to look for subtle differences between the two to explain why one broke. I'm only interested in gross differences at this point. Still have a couple more ideas that I'd like to try.

Your packs are so well built we'd probably have to drop small cars to test your reinforcement patches.

Daryl

Jan 2, 2012 at 8:39 pm #1818955Daryl, the packs are not the point but I did test things in the 70s with my Chevy Corvair and a tree. I never did break the early 70s Chouinard carabiner, although I broke many others. The Chouinard seemed like it would hurt my car if I pressed it.

The point of my prior post is that the testing as is may not be showing much besides random 50/50 failure. The differeces between the loads that are breaking the corners may be statistically insignificant. The differences need to be measured to matter. Gradually loading the test sample will show where the different patches begin to fail before they do, which is something you can do with the same setup. Also, patches like these are meant to absorb a wide angle of force rather than one focused in a narrow range like in the test.

After I posted this I looked up some of your older posts and did not realize this is an ongoing thread series. :>)

Jan 3, 2012 at 8:57 am #1819111Dan,

"may not be showing much besides random 50/50 failure"

Sounds like a line from one of my performance reviews before I retired.

OK, now I get it. Time for me to pause and reflect on this project.

Daryl

Jan 3, 2012 at 9:39 am #1819127Dan- Pickup truck, large tree, logging chain. Sewed my own runners and harness for awhile. A hydraulic jack with lots of padding work for slow mo. Wear safety glasses.

Daryl- Now you can start testing other factors.

Increase the size of the patch or change stitch length. Try different thread or size needle. At some point you will start having failures places other than the leading

edge of the reinforcement.Jan 3, 2012 at 10:45 am #1819159David,

Thanks for the tips.

Can I borrow your pickmeup truck?

Daryl

Jan 5, 2012 at 10:56 am #1820176If the failure is at the sewn seam (circumferential), why not change the sewing to radial lines from the attachment point? It might cause the tie-out to tear into strips, but this might at least have some strength.

You might have to finish the edges of the sewn-on patch first to stop it fraying.

I'm also wondering about how realistic the test is when the rest of the sheet isn't tensioned (as it would be in a more realistic application, e.g. tent or tarp tie-out). It may well be that the puckering that occurs causes stress concentrations along the seam that wouldn't occur with a 'normally' set up tie-out.

BTW, good work as always, Daryl.

Jan 5, 2012 at 11:35 am #1820191Kevin,

Yes, I think radial lines(maybe) and finished edges(for sure) would strengthen the patch. I also think the puckering of my test system could be contaminating some of my tentative conclusions.

My "drop the bucket" testing system has been fun but the feedback and my own reconsideration of it says it isn't a very good way to test patches. I think Steve Evan's testing system is much much better.

I've learned a lot about reinforcement patches as I've blundered through this, however.

Daryl

Jan 5, 2012 at 1:25 pm #1820285I am going to point out what has been done with cuban sails again because I notice that everyone's patches are quite small.

Also If you take note of modern sail design the shape of the patches are longer on the on the leech side and shorter on the foot of the sail not just perfect half circles.

The longer edge of the leech has more force against it than the shorter foot so the patch has more area on that side. Also note the type of stitching used and how it is placed in graduating semi circles.And hey, if you really want to impress, have a titanium corner piece added!

Additional info here:

http://usfoilingmoths.blogspot.com/2008/10/north-sails-new-moth-mainsail-designs.htmlJan 6, 2012 at 6:53 am #1820669The other thing I thought of last night is the use of zig-zag stitching, rather than a simple straight seam. Anything to break up that line of weakness. Zig-zag stiching is commonly used in load-bearing swen items. A good source of examples of attachment methods is probably to be found in sailmaking, and I think radial, zig-zag stiching predominates (not that I've given it too much study…)

Then there's the method of attaching the tape loop; this could simply be folded back on itself, and sewn through on either side of the base fabric. Alternatively, the tape could be folded across at an angle, and one end sewn to the base fabric at an angle, and the other end sewn at the opposite angle (i.e. a 'V' attachment). This spreads both the sewing, and provides some reinforcing, radial load-spreading from the attachment ring (assuming a ring is sewn into the loop).

I guess the problem with the stitching is due to the fact that the base material is trying to stretch under load, but the patch stops it (consider it as a single spring pulling against two doubled-up springs; the spring constant is double). So the stitches hold the fabric fibres back, opening gaps in the fabric, and putting the warp/weft fibres under concentrated stress until they break.

This is probably a similar pheonomenom to the fact that coated fabrics are generally weaker than the uncoated base fabric, because the coating prevents the weave fibres from moving over each other to absorb/spread loads.

Jan 6, 2012 at 8:15 am #1820724Kevin,

Thanks for the suggestions.

My new strategy is to mimic the technique used on the reinforcement patches of my Hubba Hubba HP tent. I figure the engineers at MSR must know what they are doing.

Daryl

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.