Topic

Aluminum vs Carbon Fiber Tent Poles

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › Aluminum vs Carbon Fiber Tent Poles

- This topic has 99 replies, 36 voices, and was last updated 6 years, 3 months ago by

Roger Caffin.

Roger Caffin.

-

AuthorPosts

-

Jan 10, 2018 at 12:09 am #3511559

Hi Daryl

I am always interested in reports of breaking CF tubing. What sort of tubing was it (source?) and what did the break look like? Square break across the tube or lengthwise split?

Cheers

Jan 10, 2018 at 1:00 am #3511570Roger,

(1) tent pole break =Fberplex custom made-to- replace aluminum pole on clip Flashlight tent. Small end of tent hoop snapped when hoop ends were drawn together to fit into grommets of tent. Square break. Wrapped tubing. Aluminum elbows of tent pole weren’t correctly angled. Company gladly replaced. Part of the trial and error process. No complaint with Fibraplex. .

(2) pack break=thin walled wrapped tubing used for vertical sides of myog frame pack. Both went at once. Square breaks. Load was too heavy. Pack was 10 years old. No problems before.

(3) test breaks-Skyshark 400s. These are strong wrapped tubes that can easily carry 40 pounds vertically. Concentrated pressure on the tubing sides, however, will snap them like a twig. For example carelessly hanging the carbon fiber top-bar of a heavily loaded frame pack on a nail or hook could result in sudden and complete breaking of the top bar.

MYOG folks usually know what the weak points are and can avoid problems and/or fix them. Others sometimes don’t know what to avoid and/or how to fix problems that do occur.

Jan 10, 2018 at 1:41 am #3511576Hi Daryl

Square breaks on Fiberplex CF tubing? Indeed! Overload.

Pack frame breaks – also interesting. Thank you.

carelessly hanging the carbon fiber top-bar of a heavily loaded frame pack on a nail or hook could result in sudden and complete breaking of the top bar.

Ah yes, I know.

My summer pack has an Easton Al tubing frame, and I took it to the Pyrenees after minimal (=inadequate) testing. The curved bottom cross bar kept breaking loose from the verticals. I kept reglueing it in place. The glueing would only last about one day.Eventually, at about 1,500 m on an early afternoon, I sat down and actually LOOKED at what was happening. The load from the shoulder strap was going onto the curved cross bar, creating torque around the joint. The joint was not designed for that. I thought of trying to bolt the joint together, then realised that the real problem lay in trying to put the load onto the cross bar.

I did some inspired alterations to the design of the suspension right there (at 1,500 m, while my wife waited for dinner): I moved the strap connections from the cross bar to the bottom ends of the verticals. 5 or 10 years later the cross-bar joints are still holding.

The lifting loop on the top of the pack goes to the bag, not the frame. At least I got that right.

So yeah – understood.

Cheers

Jan 10, 2018 at 5:54 am #3511610My experience goes along Roger’s for the weight savings. My CF poles are about half the weight of the aluminium they replace. I use carbon arrow shafts (usually) which is lighter then the Carbon FX.

Jan 10, 2018 at 8:49 pm #3511700I agree that greater weight savings are possible, especially for a MYOG approach.

I guess Easton positioned the Custom Carbon poles as a Carbon Fibre version of the 0.355″ poles, with similar stiffness but increased strength and reduced weight. I imagine all the much lighter MYOG poles would be either less stiff, or less strong – both could be OK if the user is experienced and careful. I guess that Easton wanted a decent factor of safety to cover extreme weather, accidents, misuse & worse.

I also compared the weight of a straight pole: Compared to an Easton Aluminium 0.380″ pole, the Custom Carbon was 62% (saving 38%). But then the 0.380″ pole is quite burly, stiffer than the Custom Carbon pole.

I find the Syclone idea interesting – a pole that will bend a lot, but won’t break. I imagine the poles are much less stiff than the Custom Carbon poles, and how much fun the concept would be in high winds might depend on the tent design and intestinal fortitude of the occupants. “Bending like a reed in the wind” is all very well, but some disadvantages became apparent to two of the little pigs.

Roger, the arch connectors (elbows) are standard Easton 0.340″ aluminium, each adds 50mm to the length of the pole. No doubt you’ve seen them: I expect both the poles and elbows are heavy by your standards.

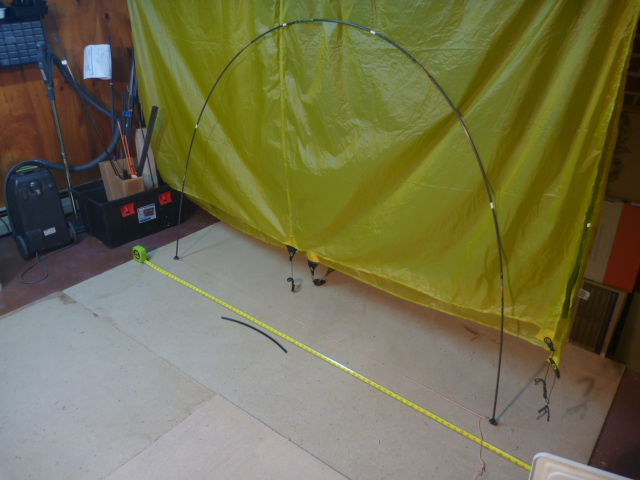

Since Roger asked so politely for a picture… The front pole has 6 sections, 3 elbows, the other has 7 sections, 4 elbows. Along the top of the tent there are no creases, even with the different positions of elbows. There are a couple of diagonal creases in the vent cover (bottom of the picture). This is partly due to the cut of the vent, not just the elbow. The tent was designed for standard poles, not these.

Cheers

Jan 10, 2018 at 9:37 pm #3511711Hi Will

Very interesting photo, thank you. The front pole with the peak at the top and the vent looks very much like my tents. The middle pole with the flat region on top is different. I avoided having a flat top on mine because past experience showed that snow tends to accumulate on flat tops, and that was something I wished to avoid.

I would love to see the rest of the tent, if that is possible? Have you had it in the snow? MYOG or commercial?

Yes, my CF poles are a less stiff than the Easton .355 poles, but they have held my tent up in 100 kph winds with snow with no flapping. We slept through the night. On the other hand, they are just over half the weight of the 355 poles, so there is considerable benefit. I took advantage of the reduced pole weight to go to 4 poles for my winter tent, and I do not regret that choice at all.

Cheers

Jan 11, 2018 at 7:19 pm #3511869Hi Roger

I’ve read a lot about your tent designs on this site. All looks well thought out and tested. Making the arches all at the top is a good idea regarding snow, and with such lightweight poles, a 4 hoop tunnel makes a lot of sense.

The tent in the picture is not aimed to be as light as your designs, and is developed with carbon poles as an alternative to pre-bent aluminium. Some other design factors mean that the poles are not all the same length; the partly flat top in the photo was not a design goal! However, I have other solutions in place to help handle snow loading; these have been effective in the testing I have done so far. Always more things to test, as you know.

Yes, it is a commercial project, there should be something available in Europe sometime in April this year.

Cheers

Jan 11, 2018 at 8:51 pm #3511890Hi Will

Details, please!

Either here or by email, whatever. I have long wanted to get my tents into commercial production, but so far I have had two failed attempts.Cheers

Jan 11, 2018 at 9:10 pm #3511898Yes, I was one of many who followed the saga of trying to get your designs into production, and I do hope all those eager people can get their hands on one sometime in the future.

It’s not easy making a tent from scratch by hand – getting one into production is also hard!

Jan 13, 2018 at 9:15 pm #3512257I heard recently that Easton alloy poles age harden, and therefore have a definite and limited life; is this true? If so do Carbon fibre poles suffer from the same affliction?

Jan 13, 2018 at 9:22 pm #3512258I heard recently that Easton alloy poles age harden, and therefore have a definite and limited life; is this true?

It’s complicated. First off, the 7178 alloy is kinda brittle, and i think Easton have discontinued it. It can shatter.

If the 7075 poles are given the correct pre-bend then I don’t think there is any problem. You have to stay within certain elastic limits, and Easton can even advise you on that. They have tables of data.If so do Carbon fibre poles suffer from the same affliction?

Not in my experience.

Caution: I am talking here about the genuine 2D wrap poles. The wrapped-fabric poles should be similar, just slightly less stiff. The pultruded variations are a total disaster and will fail any time.Cheers

Jan 14, 2018 at 1:56 am #3512318Broken Fibraplex pole (top pole) on my MSR Hubba HP. Snapped at the joint. Got a stouter (and heavier) MSR Carbon Reflex top pole to replace it.

Jan 14, 2018 at 1:29 pm #3512370I heard recently that Easton alloy poles age harden, and therefore have a definite and limited life; is this true? If so do Carbon fibre poles suffer from the same affliction?

MD, “age hardening” (also called precipitation hardening) is one of the heat treatment steps that you go through to take 7075 from its raw form to the T6/T9 temper – you hold it at ~120 degC for 24h. Metals don’t age just sitting around. If you repeatedly plastically deform metals they work harden, but then you have deformed tent poles that need replacing anyway.

I have never heard of composites degrading without being subject to UV, oil, chemicals, or high temperatures.

Jan 14, 2018 at 8:30 pm #3512410Cherian somebody was trying to persuade me not to buy some NOS Easton precurved pole sections locally, that was one of the arguments he used.

I had not ever heard of the phenomenom so I thought I’d ask via the forums collective wisdom.

I’m still trying to decide on the purchase or whether to go to CF poles and joiners and try and make my own tent

Jan 14, 2018 at 8:40 pm #3512413that was one of the arguments he used.

Whoever it was sounds seriously incompetent. Easton are not stupid: they sell pre-curved pole sections for a very good reason.It’s funny stuff, 7075. 7178 is even stranger. You can put a significant curve into a section, once, and it will last ‘forever’. Leave it straight and repeatedly flex it to a similar curvature and it will work harden and snap. Been there, done that, had to repair in the field.

Cheers

Jan 14, 2018 at 9:28 pm #3512426Perhaps he was pushing for me to purchase one of his tents.

You know the person I am referring to I am sure and I’d not personally call him incompetent

I won’t mention his name in public but feel free to discuss via PM

Jan 15, 2018 at 8:49 pm #3512608Assuming I were to make carbon fibre poles (with elbows) for a commercially available tent coming with aluminium poles, would I learn the hard way it is a silly thing to do, or is this a perfectly viable strategy (assuming I can make good carbon fibre poles)?

Jan 15, 2018 at 11:15 pm #3512650Hi Federico

That would depend ENTIRELY on the tent. Generalities are generally useless.

If the tent is a pop-up with long bendy poles – could be a balancing act to get the right stiffness.

If the poles have pre-curved section – tricky, because you cannot pre-curve CF poles at all.I have tried putting CF poles with elbows into a tunnel tent made for elbow-free Al poles, but it was not a good solution. The fabric creased the wrong ways.

Btw – CF poles may be glamorous, but they are not cheap.

Cheers

Jan 16, 2018 at 6:35 am #3512711Hi Roger, I am specifically thinking of a Hilleberg Nammatj 2, which has pre-bent poles — hence why I was thinking of putting elbows in the CF replacements. I accept that it might be a feasible thing to do!

Jan 16, 2018 at 8:32 am #3512713The main body would probably be fine, but the end bells would have some very obvious puckers in the fabric.

In any event, you would need to have quite a few elbows to get any decent sort of appearance. I did try it on a Macpac Olympus, and the wrinkles did not look all that good.Cheers

Jan 16, 2018 at 8:58 am #3512715Damn — I really like the look of your tents, BUT realistically making a tent myself is just not going to happen in the foreseeable future. Also I though swapping poles for CF is a simple and achievable way of making the tent lighter.

Cheers

Jan 20, 2018 at 9:43 am #3513384As in the photo above, I’ve put Easton CF poles with arch connectors (elbows) into a tent designed for prebent aluminium poles and in my opinion it looked fine. I think that how acceptable it looks depends on:

1) how elastic the tent fabric is and

2) how perfect you want the tent to look.In the photo earlier in this thread, the fabric was silnylon, and this produced (IMO) a good result. A PU coated and/or polyester fabric might have more creases. To be honest the tent is likely to be just as functional regardless of how it looks.

Jan 20, 2018 at 9:50 am #3513385how elastic the tent fabric is

Could be. Silnylon is ‘stretchy’.Cheers

Jan 21, 2018 at 1:52 am #3513467Roger and folks,

Re:

“That would depend ENTIRELY on the tent. Generalities are generally useless.

If the tent is a pop-up with long bendy poles – could be a balancing act to get the right stiffness.

If the poles have pre-curved section – tricky, because you cannot pre-curve CF poles at all.I have tried putting CF poles with elbows into a tunnel tent made for elbow-free Al poles, but it was not a good solution. The fabric creased the wrong ways.

Btw – CF poles may be glamorous, but they are not cheap.”

PLEASE NOTE that both the beefier Victory and Gold Tip shafts I referred to ante will arc very well. Here are pics of them that were posted sometime ago on a BPL gear thread:

The white on the shafts are just strips of white tape used to hold the shaft sections on ferrules for the photos. The carbon tubes readily absorb this flexion without being stressed to anywhere near the breaking point.

Easton alloy poles, or any other of consistent construction, will have the same arc if they are the same length with the tips the same distance apart. Hence a tunnel or dome that uses straight alloy poles should work with carbon poles. The stiffer the poles (the Victory are slightly stiffer) the less lateral movement, or sway, they will have when arced as in the pics. However, the Easton T9 tempered poles, such as the .340, will resist lateral movement and yield less to winds hitting a tunnel on the sides. If the tent uses alloy poles with longer prebends at some location, one would have to use a long prebent alloy section at the same spot in a carbon pole. Similarly, if the prebends are short, or elbows, alloy elbows would have to be used on poles that are carbon in their straight sections. I’ve not found anything difficult about replacing alloy poles with carbon in this fashion. Note that the staking of vestibules on a side entry tent will also add more lateral stability, but guying is essential as discussed below.

What can be a problem is use of alloy for prebends, elbows, or even straight ferrules on otherwise straight carbon poles, as the heavier alloy is usually stronger, and when the pole is flexed into an arc, especially when wind further distorts it, there is a greater likelihood of breakage of the carbon portion, particularly at the points where carbon joins the alloy elbows. On Roger’s and other tents, the carbon is reinforced at the joints with short pieces of tubing. Archers run into the same problem, so use ‘Bulldog nock collars’ where the shafts connect to the arrow points for this purpose. Some of these will fit nicely over the end of the Victory or Gold Tip shafts.

A better solution is to design the tent to use poles with no prebends, such as a simple tunnel or dome, and to use carbon ferrules of similar elasticity and strength to join the sections. My impression was that Roger used the elbows at least partly to create more room in his tunnel tents. For a solo tent, the arcs provide plenty of space. Guess this is a matter of preference. Another approach is to use less stiff fiberglass tube for the middle sections of the otherwise carbon pole. This makes a tunnel, for example, more vertical on the sidewalls, and more hooped at the top, which may be desirable for both roominess and snow shedding. Years ago I did this with A16 alloy pole sections on the sides and Early Winters Omnipotent FG sections on the top, and it worked very well with a sleeved tarp:

I’ve never had a problem putting straight carbon poles into a tent sold with straight alloy poles, because as stated above, they will flex to equal arcs if of equal length. So am not sure how this occurred for Roger. However, carbon poles used for tunnels and domes will not take as much flexion as Easton .340 alloy without breaking, so cannot be safely flexed as much as the alloy. (Note that if you are thinking of carbon poles touted in pics with them bent into a circle with a small radius, please consider that the pole bent to such a small radius will be greatly stressed or broken if it is in a tent that is assaulted by high winds, or a pet, or someone inebriated.) As a result, carbon poled tents, even more than alloy, must be guyed out to prevent excessive flexion of the poles in high winds. This is true of tunnels, as Roger has often noted. With dome-shaped tents, this often will not require more stakes, as the tension applied by the corner guys also keeps the bottom corners of the tent separated & in place:

Please forgive me that the image has deteriorated a bit over time in the PC, but at least one of the guys should be visible. No bottom corner stakes are needed when the corner guylines are staked.

Lastly, there is the issue of cost. I’ve not purchased any Victory or Gold Tip shafts lately, but when I did, they were much cheaper, making 2 pole sections from a 31-32″ shaft, than alloy or carbon pole sections from Quest and other suppliers.

Jan 21, 2018 at 2:47 am #3513477Hi Sam

Hum …. maybe I need to return to testing CF poles? It’s been a long while, and I admit I was a bit conservative with my designs as far as bending went.

I do reinforce the ends of my CF pole sections, but I don’t have to. The CF tubing is quite strong enough to handle the bending, provided it is good 2D wrap stuff. rather, I do it to limit what we might call ‘bruising’ at the ends of the walls, which can be a small problem (not a big one) after many years of hard use.

You are right about the elbows giving us more head-space inside the tents. That was definitely one reason for the use of the elbows. But it is not ‘absolute’: it may be possible to come quite close without the elbows.

Yes, I found that arrow shafts were MUCH cheaper than most other sources. Archery enthusiasts buy them, by the dozen (literally), and the markups are much less. Custom mfrs and gear distributors have bigger markups.

Cheers

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.