Topic

Cuben – The 422 mm hydrostatic head dirty little secret

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › Cuben – The 422 mm hydrostatic head dirty little secret

- This topic has 330 replies, 84 voices, and was last updated 4 years, 12 months ago by

Henry Shires / Tarptent.

Henry Shires / Tarptent.

-

AuthorPosts

-

Nov 16, 2017 at 8:21 pm #3502443

Roleigh MartinBPL Member

Roleigh MartinBPL Member@marti124

Locale: Founder & Lead Moderator, https://www.facebook.com/groups/SierraNorthPCThikersJoe Valesko does not let Zpacks do custom upgrades anymore. He wouldn’t replace the tent floor with their thickest CF fabric (1.43 oz sq ft), but he did agree to put in a new 1.0 oz sq ft floor underneath the old floor–they will inspect the existing floor and tape any tears. So my repaired Triplex will have the equivalent of a 2.0 oz sq ft floor but unfortunately in two layers which means if water gets between, it may pose a difficulty of how to get it out of the tent. If it happens, I’m thinking of having a “release hole” of about 1/4″ diameter on the inner (inward) floor fabric where I can plug the hole with CF Tape. Any ideas where you’d think the release hold could be made? I’m figuring I can delay worrying about it until I get in the field, but just bring some CF tape with me. PS, Joe said he could remove the existing floor or put in the new floor above or beneath the old floor; we decided beneath was better. The tent is about 3 years old.

PS, I use the tent each summer now for about 6-7 weeks of backpacking in the High Sierra on the PCT (or close to the PCT), been hiking those grounds (slight variations) since 2000 each summer now. Prior to 2016, I could only spend 25-30 days a year there; as of 2016, I’m spending about 7 weeks a summer out there.

The super viscous hail storm that brought out the tent floor problem is shown here:

https://drive.google.com/open?id=0B7L_TrVYTWZRcmU5ZGtpYzJ6MlUPicture of the tent (outside, does not show the floor, bummer).

Nov 17, 2017 at 4:42 am #3502537Geoff,

Yes, you were one of the two folks I was thinking of. Regret I did not recall your name. We have differed on the relative merits of nylon and polyester fabrics before, so will not rehash. One point I don’t recall mentioning is that for myself and many others, the UV issue is not too important when the tent is only going up at dusk until dawn. For that reason, none of my silnylon tents has shown any UV damage. In any event, this should not be a big issue for a floor, which is protected from sunlight by the tent.

Nov 19, 2017 at 9:25 pm #3502953Sam, I did not mention anything about polyester being stronger than nylon. Not sure where this came from…I am not recommending generic polyester fabrics, I simply recommended Silpoly PU4000 over silnylon for a floor because:

- It has a high measured HH (both new and after simulated aging)

- The sil coating on the outside helps with abrasion

- The PU coating on the inside helps reduce me sliding around

- The PU coating on the inside makes it more difficult for sharp things, like cactus needles or stray pine cone needles, to poke through the floor and puncture my inflatable sleeping pad (what I call “puncture resistance”)

I’ve used a floor made of this material for almost 2.5 years with good results. Silnylon definitely works as a floor, but in my opinion, Silpoly PU4000 is better.

It is the elasticity of nylon, especially silcoated, that deters puncturing and abrasion, not by pins, but by less sharp objects under the tent floor. And the demonstrations on RBTR with puncturing and tearing the Mountain Silnylon are persuasive, and illustrate greater strength than any polyester of similar weight that I’ve seen.

The tests by RBTR on Mountain Silnylon are not very relevant for a floor. Floors do not experience very high loads, so they don’t need high tear strengths. I have a sample of Mountain Silnylon – it is extremely strong and hard to tear and would make a bomber tarp. It would also probably work fine as a floor, but I still think PU4000 is a better choice.

Nov 19, 2017 at 11:35 pm #3502974John, you make an excellent case for polyester tent floors. I was responding to a post from Geoff Caplan on the previous page of this thread. But I do think floors experience high loads when elbows etc. push into soft, soaked ground (or wet snow) as I mentioned in an earlier post on this thread. It is also the example editor Roger Caffin gives to illustrate water pressure on floors (also mentioned above). Add to that the abrasion from all manner of ground cover, and I think the inherent strength and durability of the fabric, as well as its HH, becomes an issue.

My difference with Geoff involved the strength issue on another thread, and despite his reference to the the credentials and expertise of someone he consulted, I remain unconvinced that polyester fabrics are more durable than 6,6 nylon. As stated on another thread this is simply based on observations of the comparative durability of nylons and polyester fabrics over long periods of hiking and backpacking use; not to mention the opinions of folks who are more fabric savvy, although taken with a grain a salt, given the hazards often presented by ‘the best and the brightest’ in any field.

Right now, I’m wrestling with whether to use sil/pu coated polyester or nylon for the front and rear vestibules of a dome-type tent, because the polyester is much less prone to expand and sag when exposed to wet and cold; whereas the nylon, while lighter, and stronger (IMO), can be more of a wrinkly and drippy nuisance when unzipping the outer door and entering or leaving the tent in, or even after a rainstorm. Even with a tent designed to minimize the effects of nylon sag, this remains a tough choice. While there is no perfect tent, there are so many trade-offs to be made with both materials and design, that choices are not always easy.

Nov 20, 2017 at 12:18 am #3502992If you leave out the UV factor, nylon is definitely stronger than polyester, and Geoff says as much in his post above. I think the question is whether nylon’s extra strength is necessary. For most tents under most conditions, I don’t think it is.

I got the Mountain Silnylon sample to help me decide on a fabric for a small pyramid tarp I will be sewing. While it’s incredibly strong, I’m 90% sure I’ll go with RBTR’s 1.1oz Silpoly (non PU4000) due to the lack of sagging when wet/cold. I think with good tie-out and peak design, the fabric will work fine. If I was making a tent for Alaska or Scotland (or wherever Roger Caffin camps), then maybe I would choose the Mountain Silnylon.

Mar 11, 2019 at 1:50 pm #3582878The first post in this thread was updated, in August of 2011 to provide a link to the results of the testing of various product samples. However, that link is no longer a valid link (it just gets redirected to the forums index). Does anybody know the current link URL? Or can anybody provide instructions for how to manually modify the URL so that it becomes valid, again?

Mar 11, 2019 at 2:45 pm #3582895 Roleigh MartinBPL Member

Roleigh MartinBPL Member@marti124

Locale: Founder & Lead Moderator, https://www.facebook.com/groups/SierraNorthPCThikersI tried to find that Hydrostatic Head Test paper and you’re right it’s gone from the forum thread. I looked in archive.org and Google Cache but it’s not there. Two more options. Did you try and message Richard Nisley who posted the original entry? What about UBL’s technical support, perhaps they may have a cache of it somewhere.

Mar 11, 2019 at 3:47 pm #3582911Thanks, I sent a PM to Richard, asking if he knows the current URL.

Mar 11, 2019 at 5:27 pm #3582935Mar 11, 2019 at 6:42 pm #3582955Thanks Richard! Very interesting!

Mar 27, 2019 at 11:03 pm #3585821I was recently talking to someone and they said cuben hasn’t changed all that much from this original post, showing cuben with a HH of ~422mm. But I’m confused, Tarptent on their website is calling their Aeon Li “Fully taped and waterproof: 8,000mm+ hydrostatic head pressure rating.” I assume they’re using modern 0.51oz/yd weight DCF.

See here https://www.tarptent.com/product/aeon-li/

So which is it these days, an awful 422mm HH or an amazing 8,000mm HH?

Was hoping to hear from <span class=”profile-data”>@richard295</span>

Mar 27, 2019 at 11:15 pm #3585824IMO real world trumps lab testing. I’ve had misting with woven fabrics. Of all the cuben shelters I’ve made in the last three years, I’ve never had misting. It could’ve changed/improved around the time I started MYOG a few years ago, but since that time I’m absolutely sure, based on real-world use, that Cuben has a higher HH than the typical 1.1oz WP woven materials available these days. YMMV…

Mar 28, 2019 at 5:43 am #3585892What are the weights of Dyneema fabric used in various brands of tents now on the market? Is this weight related directly to hydrostatic head numbers?

I understand Tarptent uses one of the lightest weights of Dyneema. Is this true?

Mar 28, 2019 at 5:53 am #3585894Matthew,

8 years ago, when I tested Cuben, some samples of the .8mil Mylar versions, but not all samples, had low HH. Based on the field reports since then, I think it is safe to assume they corrected that problem.

Mar 28, 2019 at 4:44 pm #3585945No more dirty little secret? Worlds Collide! Dogs and Cats Sleeping Together! Hallelujah! 3,000+ days and its settled. Maybe the OP will now be radically changed to reflect the correct Information…

Apr 3, 2019 at 4:29 am #3586778Richard,

If the qualities of cuben/dcf have improved, and I say if because I don’t know that they have, then your testing and reporting on BPL was the reason.

Thank you again for your service to us MYOG folks.Apr 3, 2019 at 6:11 pm #3586836Anecdotal evidence (field reports) that the issue has been corrected? Seriously? Is that the standard that should be used?

I have a 0.51oz cuben shelter (https://backpackinglight.com/forums/topic/75909/#post-1301652), fabric purchased from zpacks, that mists during a hard rain (large drops falling from overhanging tree). Feeling the inside of the tarp when this is happening, no moisture was felt. Is that the kind of anecdotal evidence that should be used to say that this is still an issue?

Was there ever a second test of the material, or of different weights of the material, or of different ages of the material?

If we are considering anecdotal evidence, lets all fill up our DCF stuff sacks (that are seam sealed) and see how much water passes through. I know mine leak like sieves after they have wear.

Apr 3, 2019 at 7:40 pm #3586852One possible explanation for why the HH may have improved is that seemingly DSM changed the type of mylar used in DCF.

I don’t know all the details, but 0.5oz DCF used to be CT1K.08 whereas now it is CT1E.08, where K and E are different versions of mylar. I’m not sure exactly when this happened, but I think back around 2011 pretty much everything was K, whereas today all the lighter DCF variants use the E mylar. I’m told the E stuff is more stretchy, so it may be less prone to micro cracking than older DCF (of course this is hearsay and could be mistaken)..

If you look at DCF offerings today, only the thicker (“0.18”) mylars have the K. So seemingly they changed the type of mylar used for the thin mylar layers, but kept it the same for the much thicker mylar layers.

Apr 4, 2019 at 1:59 am #3586907It would be great to have some 2019 data points.

@mountainlaureldesigns (I think you have this machine ??) and @richard295 can you do some testing please! I’m not trying to stir up anything, I’m just a numbers guy.Apr 4, 2019 at 4:02 am #3586925Dan,

That’s especially interesting because I once bought some 3/4 oz Cuben from the original vendor, the one that would sell only with a signed NDA in hand. They sent me a roll of nice light green stuff that was labelled with the E. I inquired and they said the E was better, so not to worry. Got the same response from the fabric mavens on BPL. But never knew what the E signified, so thank you for that. Maybe I’ll send a swatch to Richard for testing, but of course there is no longer a link possible to the original seller to complete the protocol.BTW, what’s with the sarcasm and profanity in some recent posts. Is this what I keep hearing goes on in “social media.” Glad I don’t do any of it, and stick to email, phones, in-person and PBS for contacts and news. As Roger has often reminded us, this is a “family” website. Hope we all can keep it that way.

Apr 4, 2019 at 6:36 am #3586939A little history that MAY shed some light on why E Mylar was created. During the time period of my testing, the original manufacturer did not specify the HH value nor did they even test for it. That was not unreasonable since the material was designed for racing sails, not shelters. Furthermore, they required OEM buyers to sign an NDA as a requirement of use. It said, in part, that if the OEM purchaser conducted any tests, they were expressly prohibited from disclosing the test results to any one other than the manufacturer. The only reason I could legally disclose my test results publicly was that I wasn’t an OEM. In addition to publishing my results to BPL, I also sent my test results to their engineering department to assist them in problem resolution.

I was able to discover what was happening, at the time, only because a few OEMs and many DIY people sent me different Cuben samples.

If anyone wants a current 8 mil Mylar scrap tested, I suggest they request that Stephen S. test it for them He has the HH equipment to test with and may have the time, which I currently do not.

Apr 5, 2019 at 11:11 pm #3587233In fact, I do. If someone wants to send me samples to test, send me a PM. I will review the procedure that the testers created for this issue so we can be on the same wavelength, including the preconditioning that was done by the person sending the sample. If you want the sample back, I request that a paid shipping label be included with anything you send.

Apr 15, 2019 at 4:49 pm #3588877Steve B makes a good point about using anecdotal experiences. re: misting inside during a heavy rain. The general humidity when it rains is 100% plus the drops. Inside a tent our humid breath condenses on the cold tent like the beads on a water glass (we know this)- but what’s actually happening?

So yeah, maybe fill up your water proof backpacks. I had the bright idea to wear my SealSkinz gloves while sea kayaking. They filled up with water, my hands froze. It was awful. I was absolutely convinced they weren’t waterproof–no way could that much water seep in around my wrists. I loved the socks which is why I bought the gloves. At home after they were dry, I tested them and the socks in a bucket of water. Bone dry. Physicist Richard Feynman said, “The easiest person to fool is yourself.”

This is a great exchange, above my qualifications, but terrific to follow. I’m already rethinking how I think about DIY/MYOG tents and tarps and ponchos.

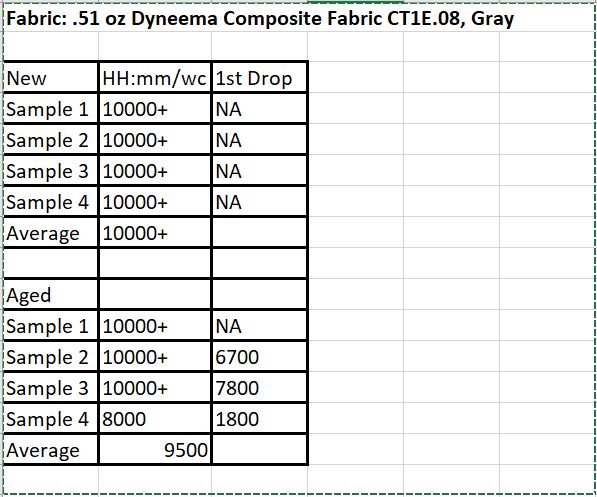

Apr 27, 2019 at 11:54 pm #3590648Matthew S has sent me a Cuben sample on which to perform a Hydrostatic Head Pressure Test. The table below shows the results:

The test device at present is limited to 10000 mm/wc. It is clear that the fabric can achieve higher HH before leaking. I may modify the device to reach higher HH values. If so, I will retest if higher values are relevant to the community. Also, I have now installed a digital pressure gauge capable of displaying in excess of 30000 mm/wc, so the next round of tests will have greater precision in the readings.

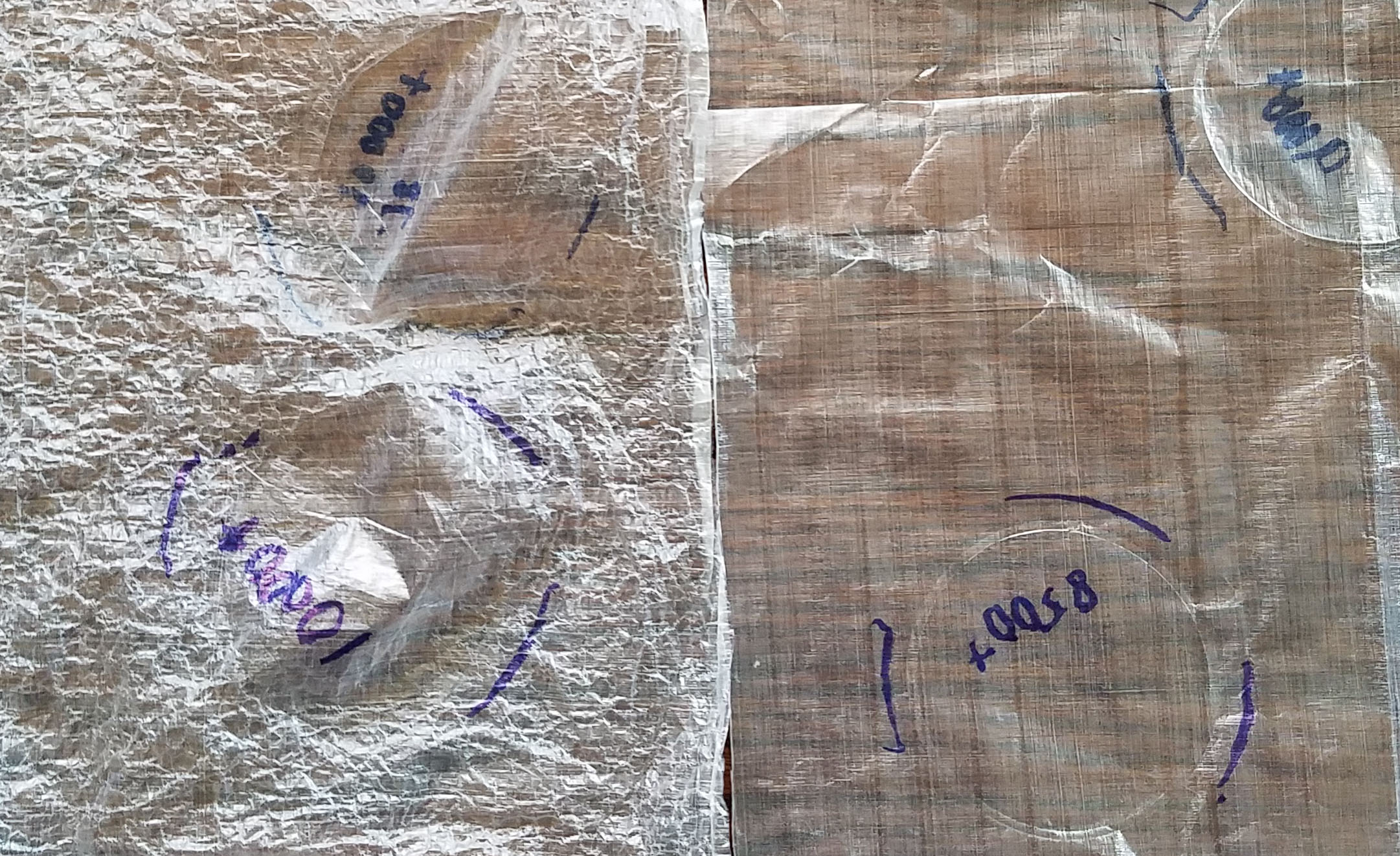

The sample was aged by the procedure developed by Richard Nisley. The photograph below shows the aged (left) vs new (right) sample. The aging process takes a visual toll on the fabric. However, the wrinkles produced by aging more or less disappeared at the test locations as the result of the test pressure.

For the new sample tests, no leaks occurred up to the pressure limit of the test device.

For the aged samples, drops occurred in three of four samples. In two samples, only a single drop was produced. After the drop developed and pressurization continued, the single leaks in these samples actually stopped flowing water. Under the criteria of ISO 811, these leaks do not constitute a failure. Failure occurs at 3 drops. In the fourth sample, the first drop appeared at around 1800 mm/wc. Two additional drops developed at around 8000 mm/wc.

The test results indicate that the performance of .51 oz Dyneema Composite Fabric is significantly improved over the results from prior studies.

Apr 28, 2019 at 2:18 am #3590655I know it’s only 1/2 yard sample of 1, but this test is great. Thank you for doing this. If you want to re-calibrate I would be happy to buy another sample from RSBTR and have it sent directly to you. Makes you wonder what 0.74 is capable of.

You followed Richard Nisleys aging protocol, what is the simulated age?

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.