Topic

Thoughts on Orientation of Woven Fabrics Relative to Shelter Orientation

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Thoughts on Orientation of Woven Fabrics Relative to Shelter Orientation

- This topic has 12 replies, 7 voices, and was last updated 8 years, 10 months ago by

Kyle.

Kyle.

-

AuthorPosts

-

May 2, 2016 at 10:31 am #3399209

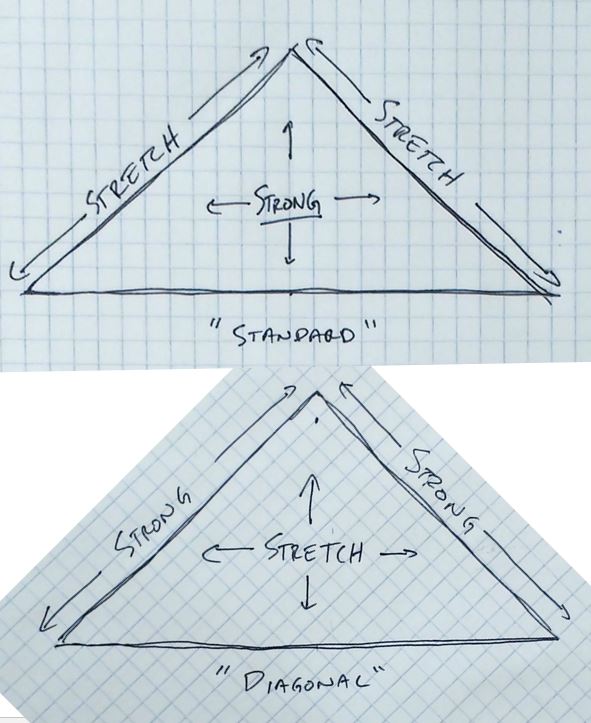

I’m working on building a mid shelter right now, and just copied everyone else when it came to orientation of the weave of my base material relative to the shelter (“standard” in photo). But it got me wondering, is there any advantage of orienting the fibers 45 degrees off from the “standard” layout (“diagonal” in photo)? It seems it would have a great effect on how the shelter stretches, and would also allow for larger shelters to be built for a given width roll of material. Anywho, any words of wisdom would be appreciated, especially if someone has made a shelter like this in the past! As always, thanks for the knowledge~

May 2, 2016 at 10:57 am #3399215

May 2, 2016 at 10:57 am #3399215Interesting idea. I wonder how that would work. If you had a square mid, it would stretch down the middle of each panel, so it would sort of turn into an octagon which would be fine. I do conventional orientation and the middle of each side is up in the air a little, extra couple inches gap between ground and tent.

One way to get bigger mid is to run the fabric sideways rather than up/down. Then there’s a sideways seam a foot or so down from the peak.

May 2, 2016 at 11:13 am #3399219I think in general a little stretch on the fabric is welcome when it comes to shelters as it will help the fabric cope better with gust winds before reaching catastrophic failure.

Not sure what fabrics and seams are you planning to use, but even if you use a material as stretchy as silnylon if you sew your panels with a flat felled seam it will be quite strong where is needed. (i.e 3 layers of fabric)

May 3, 2016 at 3:47 pm #3399593Cut for the most efficient use of material and don’t lose sleep over orientation.

May 3, 2016 at 3:54 pm #3399597I think it would be bad to have two pieces that are sewn together, one with the weave, and the other on the bias. When you set it up under tension it won’t look right.

May 3, 2016 at 3:57 pm #3399598yea – i think you want them all oriented the same – for sure on that. this was just more of a theoretical question – although i’m not convinced that the “standard” way is the best….

May 5, 2016 at 10:44 pm #3400337Looked at a variety of quality tents to see how the grain was oriented on differently shaped fabric pieces. And some things are obvious – you don’t want bias stretch along the base of a tent wall. The stitches or bonding on the hems prevent it anyway, so you get loose material above the hem.

But why worry about it when engineers have addressed it with more knowledge than I’ll ever have, and I can just go and look at the better tents in the stores.

May 6, 2016 at 11:30 am #3400423thanks for the info, sam, i will definitely keep that in mind! i’m not really worried about anything, just curious =P also, i think the engineers out there designing tents for mass consumption are far more constrained than folks in the MYOG community. thus, i don’t put it past us MYOGers to create products superior to those in the retail space. for example, we can customize everything, not have to worry about mass production efficiency, and also not have to skimp on materials, which i think is a pretty good start…

May 6, 2016 at 2:06 pm #3400452I think the traditional way is probably better because the stretchy edges curve outside of the 2D plane. This results in a saddle shape, so your fabric is pulled in to a form w/ 2 axis of curvature (in contrast, a bowed piece of paper has a single axis of curvature). Compound curves are more rigid than simple curves – this is why birds eggs are so strong for their weight.

In contrast, the alternate orientation puts the non-stretchy edge on the curved seams, so the panel won’t deform beyond a single axis of curvature. The stretchy edge is the free edge which has nothing to pull it out of the plane, such as an adjoining piece of fabric at a different angle.

A contributing factor in this is that the traditional way orients the fibers in the middle of the panel radially, so they go from the pole tip to the middle of the free edge. As the seams stretch, the straight fibers won’t. This makes them want to short cut the bowed surface defined by the seams w/ a straight line and pull the free edge in to an arc (you get a cat cut hem for free). This results in the saddle shape that gives mids a more rounded cross section towards the top and a smidge more internal volume.

You don’t get this with the alternate. The mid-panel fibers connect the seams with the stretchy free edge, so there’s nothing pulling them in to a straight line, away from the bowed surface. I would expect you’d see much less rounding in the cross section in this case.

The standard way may also be easier to pitch because the stretch is radial which gets deformed by raising the center pole. The alternative stretches around the circumference which requires tightening all the guy lines. So, taller vs. wider.

But this is all just theory. I made a large mid out of poly tarp for Burning Man, but I haven’t experimented with the form in anything like to 30D nylon.

May 6, 2016 at 3:03 pm #3400482woah – thanks for the detailed reply, rene. gunna have to let this one sink in for a while =P

May 6, 2016 at 8:03 pm #3400554Yeah, a little complicated :)

Here’s a more direct way to approach it:

Get a square piece of fabric. Orient it in the traditional way, w/ fibers parallel to the edges. Hold 3 corners down to a table or floor and lift the 4th. You’ll find that it behaves much like a piece of paper, folding on the diagonal. If you move the two corners on that fold closer together a bit and then repeat the experiment, you’ll find you can get a fold in the opposite direction. But again, it’s like folding a piece of paper. You don’t get a saddle shape. This is equivalent to the proposed alternate alignment for a ‘mid.

Now rotate the fabric 45 degrees and try it again. This is equivalent to the standard mid arrangement. Think of your hand lifting the corner as the pole tip. Threads run from that corner straight through the middle of the panel. When you try the experiment this time you’ll see that no crease forms, tension goes through the middle of the panel and it forms a shallow saddle shape.

May 9, 2016 at 6:40 am #3401098I think it’s a good idea and it will make subjectively more spacious pyramid. I suppose that the “traditional” layout is used mainly because it’s simpler and more efficient way to cut the fabrics.

I made a traditional mid with fabrics cut on diagonal on the corner seams and I have observed how this affects the shape of the mid. When it is pitched taut, the corner seams stretch a lot and they are much more curved than what was the catenary cut in the design. Because of that, the cross-section higher above the ground is quite close to a circle. At the ground level, the corners are so low that there’s not much useful space.

If the corner seams were not as stretchy, the shape will be closer to a rectangular pyramid and there will be more useable space in the corners. I think this is where the extra space matters – having steeper walls in the corners would provide more space to a sleeper lying along the wall.

I agree that the corner seams may be loaded more in this design, and I would consider reinforcing them somehow.

May 9, 2016 at 11:41 am #3401161Thanks for the comment Jan! I think I will just have to make another mid one of these days to figure out the answer. I bet the guys over @ MLD, HMG, and Oware have given this more thought than us, and their product seems to suggest the answer is the standard orientation, but I’m in agreement with you that I can see advantages of the diagonal config…

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Trail Days Online! 2025 is this week:

Thursday, February 27 through Saturday, March 1 - Registration is Free.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.