Topic

Tarp fabric resistant to hail and extreme weather

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › Tarp fabric resistant to hail and extreme weather

- This topic has 114 replies, 24 voices, and was last updated 2 years, 3 months ago by

Sam Farrington.

Sam Farrington.

-

AuthorPosts

-

Nov 12, 2022 at 1:24 am #3764852

Roger’s reminder perfectly explains why the HH of the 15D and 20D silpoly finally ended up higher than that of the 40D fabric after prolonged exposure.

Nov 12, 2022 at 10:50 am #3764868From Rex’s interview with Mike

For instance, if you have a ripstop, it’s a little bit lumpy. And if you use blade coating like everyone does, you are going to have thin spots at the top of every [ripstop thread]. Those thin spots are going to form a grid pattern.

We are buying 20 denier ripstop polyesters from Korea. And they’re not unusual in that they are flat. Making flat ripstop is old technology. But the manufacturer or the factory has to be smart enough to make sure that they’re getting flat weave. Now it comes down to what kind of consistency and what kind of process are they using. Some people have gotten extremely good at finishing.

It sounds like what Mike is saying is that ripstop can be made, or finished, in a way that reduces the gaps that Roger was talking about.

Nov 12, 2022 at 1:53 pm #3764875The bit I do not understand is why one should even bother putting in any ripstop threads when the fabric will be silicone-coated. They add cost and do nothing (as in zero) to add any strength. Why bother? Omit the ripstop threads and get a higher longer-lasting HH, with no loss of strength.

I should perhaps add here that having ripstop threads in an old-fashioned PU-coated fabric (especially the old single-sided coating) does make some sense. The PU coating on the surface of the fabric is known to seriously reduce the strength of any fabric (due to stress concentration), so having a heavier thread to block a tear makes some sense. But who uses a PU coating like that these days?

Cheers

Nov 12, 2022 at 11:10 pm #3764899Why ripstop? Maybe marketing that comes back to bite you.

Company: Ripstop is a great name, let’s call it that!

Consumer: Ripstop sounds like a great idea, I’ll buy that!

(time passes)

Company: Ripstop sucks, but we can’t stop selling it, customers demand it. At least, “that’s the perception.” (See that section in Mike’s interview.)

— Rex

Nov 12, 2022 at 11:40 pm #3764901Rex is SO right.

CheersNov 13, 2022 at 1:11 am #3764904William, is that chart the same one you posted sometime ago? Just wondering, but since then I’ve seen charts on BPL that are all over the walk. So doubt that there will be anything scientific that resolves the comparisons of polyester and nylon in tent fabric. For starters, there are different nylons, and even more polyesters.

But there are a few helpful approaches. One is to build prototype canopies for the type of tent you want (tunnels, mids, A-Frames, single cross as well as double cross pole wedges, and the most common, the lengthwise hoops that are supported by hubbed struts at each hoop end. While the latter may require the least pole length to make a tent self-standing, they do not appear to have any inherent stability. The tent walls are still what hold the tent upright and in place, and in that respect are no better than an A-Frame.

Having settled on a design, the next step is to place a prototype canopy outside in severe weather and see what happens. With silnylon, that turned out to be a disaster. While the self-standng canopy was sheltered by a leaky deck roof and high concrete walls surrounding a walk-in cellar entrance, the blowing rain reduced the strength of the whole structure to almost nothing, and in the open it would certainly have been blown flat much like photos sometimes posted by Roger Caffin. The nylon simply loses its shape when wet, and will not support any kind of tent, even one using a couple trekking poles. Yet, when sunny weather returns, the nylon canopy again becomes able to support a well designed prototype rigidly in place. Unfortunately, mother nature is having none of that, and in the mountains she more often than not combines winds with rain.

So having become convinced that silnylon is a poor choice of fabric for withstanding the weather, the next issue is whether there is a good choice. Unfortunately, polyesters cannot be catagorized so easily as 6.6 Dupont silnylon, and similar tests on a whole variety of polyesters appears daunting.

But plastic embroidery loops that require only a square foot of a fabric can be useful in comparing polyester fabric with nylons. In my case, the differences were stark, but it remains to see how the polyesters resist punctures, rips and abrasion. And whether they have a mini-ripstop that Richard Nisley spoke so well of on this site.

And guess what, black Friday sales are a great time of year to see if some of the light silpoly tarps on the market show promise in rigidly supporting a shelter in a storm. Even better, there is no need to pretend to any scientific expertise. I’ll pick out the fabrics that do best in the loops, and apply some simple tests to see how durable and strong they are. When I meet the ones I trust, I’ll know it, just as we do in everyday life.

Also, tents can be designed with ultra light flies of limited size so they can be readily replaced when the fly wears out. That’s quite a bit less hassle and expense compared with replacing a DCF tent. A bathtub floor might also be designed for easy replacement. It is the single wall vestibules, or beaks though, that may need to be more durable, since they often supply the tension that most supports a tent; and R&R for those could also be quite a chore.

Just some thoughts that might help to save another 4 years of academia in the attempt to build better tents.

Nov 13, 2022 at 1:21 am #3764906“The bit I do not understand is why one should even bother putting in any ripstop threads when the fabric will be silicone-coated.”

Roger, when you have spent some time with “membrane” silpoly, as I have with Stephen Seeber’s help, you will have the answer.

Nov 13, 2022 at 1:28 am #3764907The nylon simply loses its shape when wet, and will not support any kind of tent, even one using a couple trekking poles.

I suggest that might be more a matter of poor design for that fabric.

As so many of my photos have shown, my silnylon tents do NOT collapse in the rain. Never. I claim that is because I play to the strengths of silnylon in my designs.But please enlighten me: is there a good clear definition of ‘membrane silpoly’? I get the poly bit of course, but not the membrane bit. I had thought that ‘membrane’ meant something like GTX, where there is a distinct membrane bonded to the fabric. This is very different from a silicone-coated fabric, where the coating goes right through the fabric. Hum … I sometimes find it easier to think of silnylon (and silpoly) as being a fabric-reinforced silicone film.

And, chuckle, I see that the ‘membrane silpoly’ that RipstopByTheRoll are selling is a PLAIN WEAVE, and NOT a ripstop. It would seem that Kyle has ‘seen the light’ on HH.

I also note from Searches that the term seems to be largely the preserve of RBTR anyhow.Cheers

Nov 13, 2022 at 1:51 am #3764908Does anybody have any references to peer-reviewed research to back up the assertions being made here?

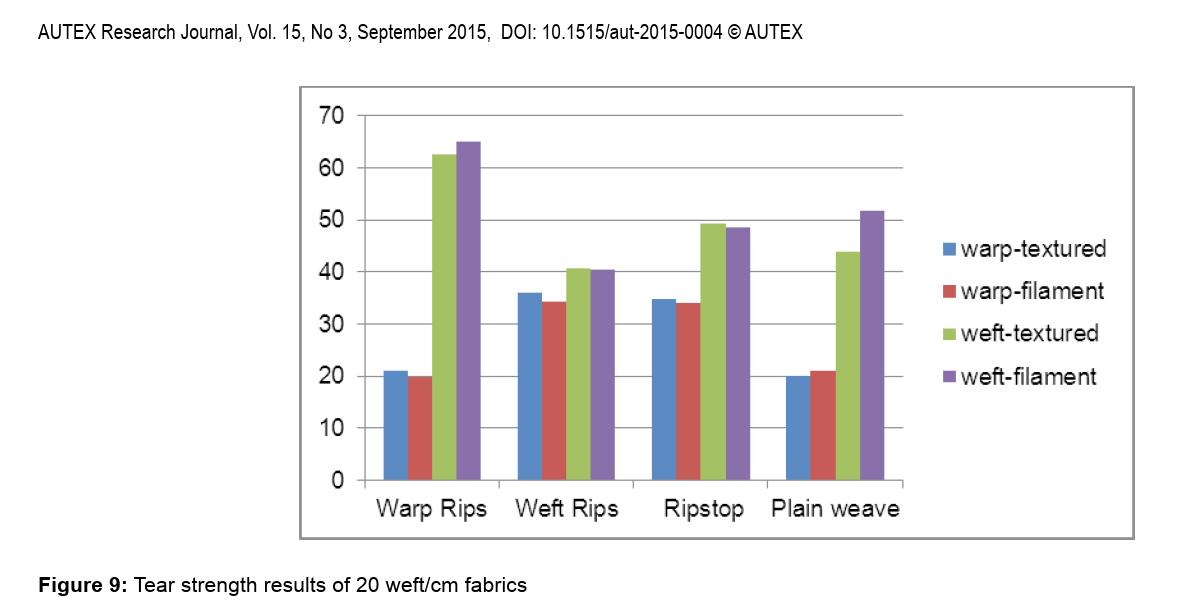

I’m no expert but a search easily returned this article, The Effect Of Weave Construction On Tear Strength Of Woven Fabrics.

This article includes an informative comparison of plain weave and ripstop (also apparently called “basket”) weave on tear strength.

The tear strength performance of a ripstop fabric appears to be generally superior to that of plain weave fabric. True, ripstop on the weft doesn’t add anything but on the warp it adds 50% to the tear strength compared to plain weave fabrics. Hence, this article at least debunks the idea that ripstop “contributes nothing (zero)” to the tear strength.

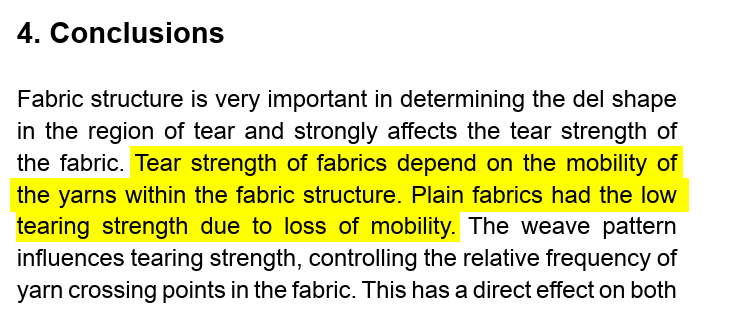

The conclusions are interesting, too:

It is well known that silicone coatings enhance the mobility of yarns within a fabric while PU coatings reduce that mobility. The problem is that an increase in tear strength gained by enhanced yarn mobility (achieved through a ripstop weave) might come at the expense of water resistance over time. This article does not explore the correspondence between the two.

Nov 13, 2022 at 2:36 am #3764909Roger, please forgive me, but it is late on this side of the planet. I’ll respond as soon as I have the opportunity. -Sam

Nov 13, 2022 at 1:27 pm #3764975It is an interesting subject – so to speak.

We have to recognise that there are (at least) four different materials to consider:

Uncoated plain weave fabric

Uncoated ripstop weave fabric

PU-coated fabric of either sort

Silicone-coated (or impregnated) fabric of any sortIn uncoated fabrics the tear strength will depend on the threads: thicker threads => more strength. No problems there. If the threads are a bit elastic, like nylon, then the tearing force will be distributed across the next few threads.

In PU-coated fabrics we find that the coating causes the stress to focus very much on the next thread only. This means that PU-coated fabrics will tear more easily than uncoated fabrics, and this could be a good reason for having heavier ripstop threads in the weave.

In silicone-coated fabrics the dynamics are significantly changed. The silicone coating spreads the load across more fibres, so that the tear strength is actually increased above what you might get with an uncoated fabric. This too is well-known.

I have done tear tests on silnylon and photographed the tear boundary under load. The distribution of load across many threads was visible. There was little difference in behaviour between the ordinary threads and the heavier ripstop threads: both stretched. The ripstop threads added little to the tear strength.

All this ignores the effect of the thread thickness on hydrostatic head. HH testing shows very clearly the way the silicone coating fails at the heavier ripstop threads. I have photos showing this – somewhere. I can’t find them right now.

My main points are that silnylon using a plain weave fabric is plenty strong enough for a tent in a storm, but that having a ripstop thread in the weave seriously reduces the HH, and time makes this worse.

Cheers

Nov 13, 2022 at 1:53 pm #3764976Right. I get that. But that’s totally different from saying that ripstop contributes nothing, nada, zero, zilch. That’s how internet myths get started. What you’re really saying is that the difference is irrelevant or not meaningful as far as siliconized fabrics are concerned. Wouldn’t it be nice, though, to have a quantifiable idea of what irrelevant means?

FWIW, the ripstop in the blue fabric pictured above looks to my untrained eyes like it’s doing its job there. The lower extension of the tear basically ends on the grid.

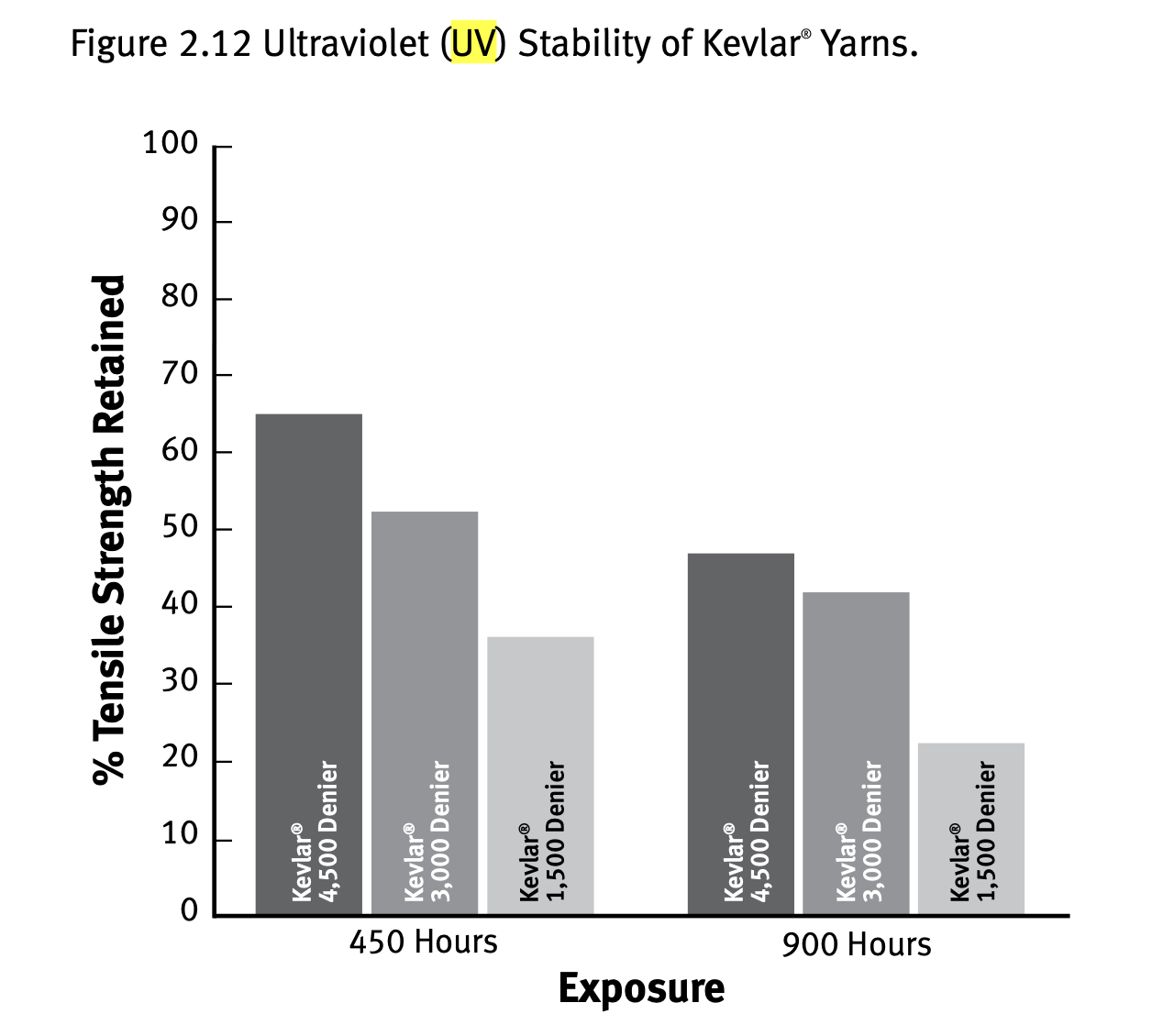

Nov 13, 2022 at 2:48 pm #3764979While I think it is well established that polyester is more UV resistant than nylon, I agree there are many other important factors including coatings and denier, so polyester vs nylon shouldn’t be blown out proportion and can be moot when certain coatings are present. That is why high altitude tents were dominantly polyester prior to the availability of UV inhibiting coatings, but now are most often nylon.

For denier, DuPont has some nice data that is for Kevlar but it isolating the variable of denier to show that thicker threads do retain a greater percentage of their strength:

“You have sil (inorganic) and PU/PE (organic). Organic coatings probably aren’t going to fare well in response to UV exposure. Inorganic should be “more OK”.”

This is an interesting hypothesis for sure. It does sound plausible, although it is hard to say how much of PU/PE degradation is from UV versus the other things it is more susceptible to (e.g. hydrolysis). Would be a neat test.“….we know that sil/sil coatings preserve fabric integrity over long periods even with Nylon…..but poly + Sil/PE or Sil/PU or PU or PE/PU – we already know these fabrics degrade rapidly in sunlight.”

Are talking about blends when you mention Sil/PE or Sil/PU? I can see a Sil/PU blend degrading faster than pure Sil under UV, whereas if a Sil/PU tent is sil (outside) and PU (inside) then it seems like it would have the same UV benefits as sil/sil (if sil is really better).

Nov 13, 2022 at 3:15 pm #3764980FWIW, the ripstop in the blue fabric pictured above looks to my untrained eyes like it’s doing its job there. The lower extension of the tear basically ends on the grid.

I have to disagree quite strongly.

First of all, thanks to the silicone coating there is no clear point where the tear ends. The damage extends way below the ripstop line you mention, and does not stop at any ripstop thread. This photo shows the area in more detail:

In fact, this is a good photo for showing how the load is spread with a silicone coating.

The ripstop thread did create secondary damage: it pulled somewhat out of the fabric to the right, disrupting the weave. This is partly visible in this photo, and more visible in my previous photo.

But that’s totally different from saying that ripstop contributes nothing, nada, zero, zilch

I stand by that statement. The ripstop thread does not add any extra strength, but it does seriously reduce the HH rating of the fabric. In the context of a tent, that means no benefit. No, this is not an internet myth: it is hard observation and science.It would of course be nice to be able to provide actual strength measurements. That needs a Tensile Tester such as an Instron. Unfortunately I do not have the gear for that at present.

As for UV resistance – well, my blue silnylon tent is by now over 12 years old and has seen a lot of use. So far, so good. But I should mention that the dye used in the fabric is also important, very important, but seems to have been ignored. I once had an MYOG tent made with panels of blue fabric and yellow fabric. It spent a lot of time in strong sunlight. Eventually the yellow fabric went paper-like, while the blue fabric stayed strong. It would seem the blue dye molecules protected the nylon fibres.

Cheers

Nov 13, 2022 at 4:07 pm #3764982

This photo shows clearly that the tear is contained between the square formed by the parallel lines A and B in the ripstop weave. If tear strength is defined as the resistance to crack propagation, then the basket weave in this fabric pictured above is having an effect that is minimal but not negligible.

The fact that the effect is minimal does not mean that there is no effect. Observation is critical to science, but observation in itself isn’t “scientific.” There’s a huge literature on the subject.

I would be really interested to know the response of the Korean manufacturer of Hilleberg’s triple coated silicon ripstop fabric, Kerlon, to Roger’s assertions. Maybe it is all a marketing ploy but think of how difficult it would be to enforce that ploy across a diverse and competitive global supply chain. Why wouldn’t a Taiwanese competitor just come out with data and ad copy showing that fabrics with elastomeric coatings don’t need ripstop and are actually better with plain weave (“better” because they are just as strong or stronger than basket weave siliconised fabrics and also have an advantage in HH durability)? Occam’s razor suggests this explanation isn’t the definitive one.

Nov 13, 2022 at 4:27 pm #3764983Roger, I’ve spent the day re-reading this thread, and find that the longer it goes, the more variables are thrown into the mix. Ryan J may have savored this when he brought this thread forward a while ago. In any case, I’m going to post several comments, and then try to address some of the comments you’ve made.

Nov 13, 2022 at 4:29 pm #3764984“As for DCF, in the past Ron Bell at MLD would only supply the 0.5 at the owner’s risk, but his current Fabric Mojo has softened a bit and he’s now prepared to recommend it for 3.5 season use, though he warns of shorter life. Personally, in areas with risk of hail or big winds I’d prefer to go up a weight and reduce the risk of very expensive damage…”

Geoff, is he kidding us? 3.5 out of 4 seasons includes plenty of opportunity for the most life threatening weather. Indeed, I’d rather be out in the coldest half season in the dead of winter than face the frightful mountain weather we’ve had this year in NH, with at least one death to its credit and numerous rescues.

Nov 13, 2022 at 4:32 pm #3764985“I’ll toss in a counter point on this topic. Standardizing for other factors (e.g. weave, denier, coatings etc) the tensile strength of nylon isn’t that different from poly.”

Thank you, Dan, for bringing us back to earth. It’s not poly’s limitations that concern me, it’s the failure of nylon to hold a shelter taut and upright when it becomes soaked. I think ‘membrane’ has given poly a bad name. As Stumphges said, “I once saw a Keron 3 tunnel, set up nice and taut, sag more than any shelter I’ve ever seen as dusk fell. No rain, only a slight drop in summertime temps, presumably to the dewpoint, and the thing transformed into a sharpei puppy.” If that’s what happens to a nylon shelter in typical weather, what’s going to happen when it really gets nasty.

Nov 13, 2022 at 4:36 pm #3764986“Clear as mud. Must be other confounding factors.” For sure, Rex. Even different roles from the same manufacturer can behave far differently. Found that out when asked Stephen Seeber to test RBTR’s membrane silpoly. Michael B submitted some membrane that tested OK; but the stuff from two separate later orders both dropped to around 400mm HH after simulated aging. And as Roger Caffin has noted, the silnylon he acquired before regulations affected quality, perform much better than the current silnylon. Also, the various manufacturers use different quality raw fabric, different quality coatings, and those can change over time. The bottom line is that I now will only make a tent from fabric that has been tested, due to QC (quality control) issues. It is a sad state of affairs, especially for retail buyers. Guess all they can do is buy from tentmakers with the best reputations for QC and hope.

Nov 13, 2022 at 5:00 pm #3764987Hi Jon

I have not a lot of problem with line B at the top, but I do not accept the position of line A as representing the bottom of the ‘tear’. Looking carefully at the source photo suggests to me that line A should be 4 – 6 threads lower, below the ripstop thread.

But part of the problem here is that what the photo is showing is not a traditional ‘tear’. It bears no resemblance to a tear in a sheet of paper (for instance) with a clear discontinuity. So trying to say where the tear point is can be a futile exercise: the tear is over a region.

Why wouldn’t a Taiwanese competitor just come out with data and ad copy showing that fabrics with elastomeric coatings don’t need ripstop and are actually better with plain weave

My limited experience in dealing with the coating companies in Asia is that they are running on a different commercial model. They are not weaving the fabric: they are just coating it. They are not selling the fabric: they are coating the fabric to the customer’s specification. And that is being done on a contract basis rather than as a commercial product line.Understanding this helps to explain why every company seems to have a different fabric for their tents: they are indeed different fabrics. In fact, my understanding is that each production run (for a single customer) is essentially unique.

What about the silicone coating then? My understanding, from a large international vendor of silicone polymers, is that there are hundreds of different polymers available (or more), and that in many cases the polymer supplied to a customer is made up to that customer’s specifications. Cost, viscosity, cure time, emissions, tenacity, you name it: they are all variables.

So, coming back to the start point: why does ‘ripstop’ fabric persist? Because the eventual customer (tent vendor?) has specified it, based on that customer’s perception of the market demand. And that ‘demand’ is really based on what the marketing department thinks it knows about the market place.

RBTR originally sold only ripstop fabrics, but as the market becomes a bit more educated about HH at both the consumer level and the company level, so the ‘demand’ is changing. They now sell coated plain weave at the top end.

Cheers

Nov 13, 2022 at 5:44 pm #3764989For me, the main takeaway is Roger’s point that ripstop threads reduce HH while offering very little benefit to compensate.

In my correspondence with leading lightweight tent designer Mike Cecot-Scherer he said that many mills now produce ripstops with a much smoother surface. I guess the idea is that you can still exploit the marketing benefits of ripstop while minimising the actual disadvantages. He says that these smoother ripstops are generally what he specifies for a technical lightweight shelter.

So the differential in denier between the body threads and the ripstop grid is another factor to consider.

I do feel that within reason the tear-strength debate is a bit of a red herring, at least if we are talking about normal lightweight shelter fabrics in the 20D – 40D range. (Extreme 10D or 15D fabrics are another matter – I’ve seen catastrophic failures on YouTube and I personally wouldn’t consider them above the treeline).

To reiterate – according to Mike, who has access to the labs of many of the top manufacturers, the quality of coating from batch to batch can affect the tear strength more than the differences between silnylon and silpoly. He says that the skill of the fabric finisher who applies the coating is often not fully appreciated. Plus the differences vary with age, because of silpoly’s better UV resistance, so after a few weeks in the field nylon very likely loses its strength advantage.

So given that nylon doesn’t have any major strength advantage over the best silpoly Mike emphasises the lower stretch that silpoly can offer, which he points out enables panels to retain their proper shape and performance in cold, damp and wind.

As I wrote above, in his experience tear strength is almost never the cause of failure as reported by manufacturer repair services. And when tears are experienced, it’s unlikely that any lightweight fabric would have survived as the differences between them are so marginal. So outside of extreme expedition use the differences are likely to be irrelevant provided stress points are properly reinforced.

So for a small MYOG shelter that could potentially experience extreme wind and hail, my preference would be a quality silpoly such as the ExtremTextil 40D. It should function at least as well as anything else on the MYOG market – and probably better. Plus it’s reportedly relatively easy to sew.

Nov 13, 2022 at 6:19 pm #3764991So Roger, I’ll join Rex’s protest. It is futile to make stabs at consumer protection when so many variables are present. Reminds me of a couple of occasions when I was taking medications and the insurer switched to generic. It wasn’t just that the medicine no longer worked, but also that the side effects blew out of control. On a lesser scale, I think the quality of tents is subject to similar outcomes.

But specifically, re your comment about poor design, and not silnylon allowing tents to fail; that was the reason I built a prototype canopy. It was solid as a rock in my dry basement, but when subjected to the freezing rain outside, but protected from wind, it became a sharpei puppy, to use Stumphges’ expression, and would have blown over without the wind protection.

The situation with your tunnels is different. You use several elbowed hoops, with guylines supporting the hoops on each side of the tunnel. No doubt that keeps you secure, and is a kudo to the tunnel design. However, there are benefits to self-standing designs as well, if they are also well supported by a framework. And, they also can be built to be very light.

With respect to ripstop, please the note the failures mentioned above of ‘membrane’ silpoly, possibly due to a lack of quality control. However, I’ve tested some other ~one ounce silpolys, and found their waterproofness as well as strength and durability to be outstanding. One good example is the 20 denier fabric used by Yama Mountain Gear that weighs nearly a quarter ounce per square yard less than the RBTR product. This also indicates that denier may not be a sole determinant of fabric weight, as was mentioned earlier on this thread.

You also have raised issues also with mini-ripstop weaves. These weaves were noted by Richard Nisley in evaluating the 7D Rockywoods silnylon, and reported at:

https://backpackinglight.com/forums/topic//108230In that thread, Richard stated that, “In addition to using a very-high quality sil/PU coating, this fabric has periodic increased thread density, rather than larger threads, to create a ripstop effect. … It is a very effective way to increase the tear resistance without reducing the HH [due] to having bigger threads the coating knife has to jump over.” While I cannot attest to that mini-ripstop being the same as the one used on the Yama fabric, they appear very similar to the naked eye, and the Yama has similarly increased tear strength and water resistance compared to similar RBTR and Dutchware products.

Because of that, I believe the mini-ripstops I’ve looked at are an excellent way to insure that the strength and water resistance of silpoly is more than adequate without increasing the fabric weight to the point that consumers feel the need to pay high prices for a DCF laminate that raises a number of concerns not present with woven fabric. Even if you do not agree with me, I hope you can see where I’m coming from.

PS: Rolls was spelled “roles” in an earlier post about this. Maybe I was hungry.

Nov 13, 2022 at 8:15 pm #3765000according to Mike, who has access to the labs of many of the top manufacturers, the quality of coating from batch to batch can affect the tear strength more than the differences between silnylon and silpoly. He says that the skill of the fabric finisher who applies the coating is often not fully appreciated.

I can well believe that. It is worth remembering.The situation with your tunnels is different. You use several elbowed hoops, with guylines supporting the hoops on each side of the tunnel. No doubt that keeps you secure, and is a kudo to the tunnel design.

Yes, I do use sideways guylines, but they are not the main source of stability. In fact, I have had cases where the side-guys were either not effective or actually missing/failed (sheet rock can be tricky). But the tents survived just fine – – – because the lengthwise tension was retained and that is the main source of strength in a tunnel.To be technical: the tension over the top of the arches stops them from distorting by pressing down onto the arch, and diagonally down near the peak on each side. Yes, that does mean a lot of care for the end anchors. In the snow I use ‘deadman’ anchors which are too big to displace. On sheet rock I use a lot of heavy rocks at each end, on long sticks. See below. Rocks are red, stick is green, sideguys are missing.

So what would I do if I found myself on smooth sheet rock with no spare loose rocks to use as anchors? Bluntly, I would keep moving to a better site. The above site in our Alps was reached at dusk when there were NO alternatives, but there were rocks and sticks.

Cheers

Nov 13, 2022 at 11:36 pm #3765006“Bluntly, I would keep moving to a better site.”

So would I in Colorado or Northern New England, because it is easy to find places to camp that are better than a rock slab. But from reading BPL, there may be places where that is not the case. Did have my eye on a couple off-trail slabs or ledges on Mount Chocorua nearby, possibly to test a tent’s performance overnight and take some photos; but there were enough bushes to anchor the tent with guylines.

With respect to the side-guylines on your tunnels, surely they are there for a purpose. It’s only ‘when things go wrong,’ that such things become critical. The rest of the time there are features we don’t need. But to have the capability, you have to carry the extra stakes. There’s the rub.

Nov 13, 2022 at 11:57 pm #3765007With respect to the side-guylines on your tunnels, surely they are there for a purpose. It’s only ‘when things go wrong,’ that such things become critical.

It is better to have some extras and not use them than to need them and not have them.

Yes, this may appear to be at some odds to the BPL philosophy, but it avoids the ‘Stupid UL’ moves.But to have the capability, you have to carry the extra stakes.

Fine – I carry them. The weight of a few more Ti wires is offset by the idea of sleeping peacefully through a storm. I should add that we can have severe storms right through the middle of summer in our mountains. Bad hailstorms twice so far at the peak of summer.Cheers

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Trail Days Online! 2025 is this week:

Thursday, February 27 through Saturday, March 1 - Registration is Free.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.