Topic

Sterno Inferno Olicamp Stove Adaptor Plate

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Sterno Inferno Olicamp Stove Adaptor Plate

- This topic has 46 replies, 4 voices, and was last updated 3 years, 5 months ago by

DAN-Y.

DAN-Y.

-

AuthorPosts

-

Aug 25, 2021 at 7:35 pm #3725823

Hi Dan

I would think that if there was CO/gas vapor coming of it would ignite.

Life is never that simple. There is always a barrier between to be overcome before two atoms can join or burn. Those little flames may not be enough.For a start, the oxygen molecule O2 has to be broken in half (dissociation) into 2-off free oxygen atoms, and that takes energy. Then two atoms have to overcome the mutual electrostatic repulsion due to the surrounding electron clouds, before they can be close enough to share electrons. That requires a high atom velocity, aka temperature, for them to collide.

Reminds me a little of courting . . .

With a normal flame, it is the energy given off by the current ‘burning’ atoms which provides the free energy for the dissociation of the next set of molecules.

When you look at a flame you normally see two different blue colours: light blue and darker blue. These represent different chemical processes. The first set involves free hydrogen burning, as it can be broken off from propane and butane molecules more easily. Only later on at a higher temperature are the carbon-carbon bonds broken to allow carbon-oxygen bonds to form.

So how do you get a flame in the first place? If you are using a piezo igniter, it is the glowing flint spark which starts the process. The glowing spark comes from mechanical action, steel on flint. But if there is not enough fuel in the gas mix, or if there is too much fuel in the gas mix, the energy barrier can be too high and the spark dies. That is why piezos often do not work at high altitude: the mix is ‘wrong’. Matches? Mechanical friction between the match head and the side of the match box.

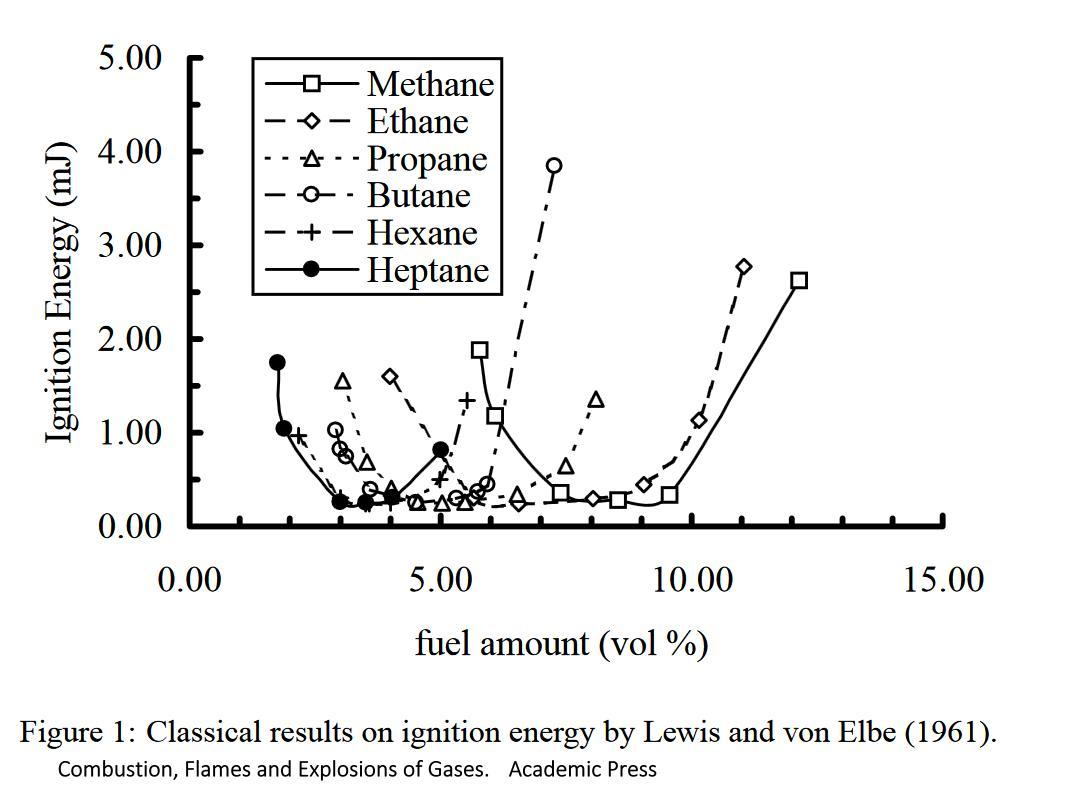

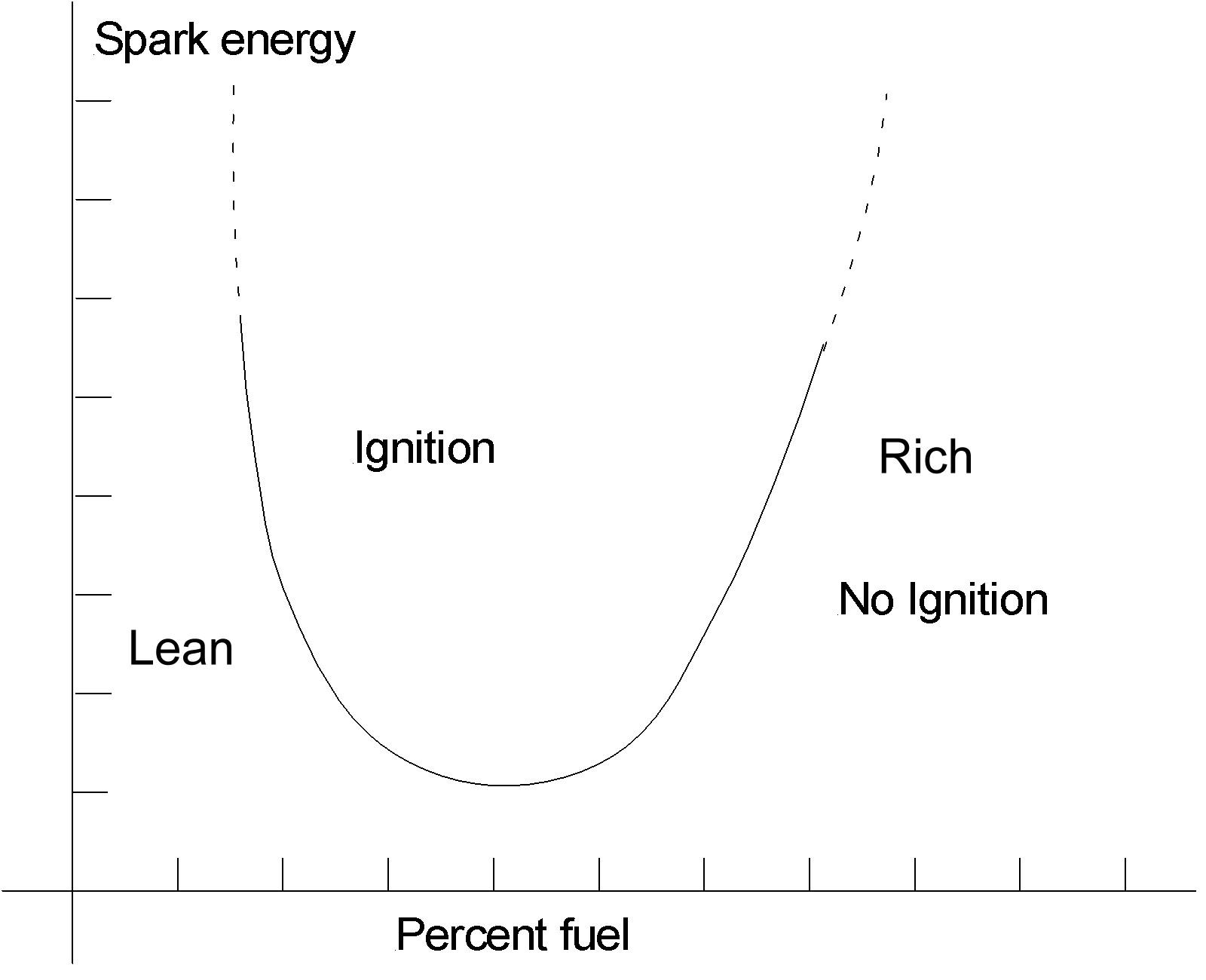

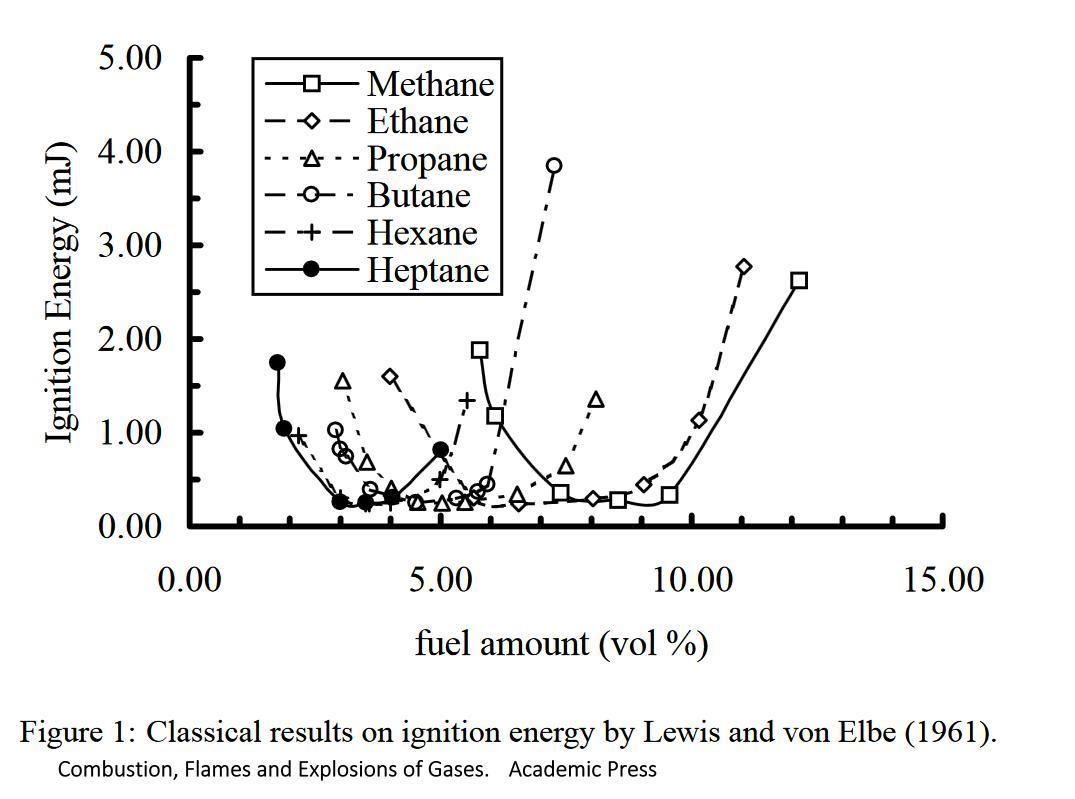

The diagram here illustrates the effect of the fuel/air ration on the ease of ignition.

Too little fuel or too much fuel and the energy required goes right up. I do have a simpler diagram, but I cannot find it right now.

”The chemistry of a flame is fascinating . . .”

Cheers

Aug 25, 2021 at 7:47 pm #3725825Found!

Same results though.

Cheers

Aug 27, 2021 at 8:41 am #3725946When I first started using my Ractor I used the small canisters of 70% Propane 30% butane. Maybe that’s why I had a good experience with flame adjustment and lack of odor of unburned gas.

Aug 27, 2021 at 3:41 pm #3725987

Aug 27, 2021 at 3:41 pm #3725987High heat:

Simmer:

Aug 27, 2021 at 4:24 pm #3725997

Aug 27, 2021 at 4:24 pm #3725997At the simmer temperature there will be a lot of CO emitted. The flames are just not hot enough for complete combustion of the CO. It’s a design problem.

My 2c.

CheersAug 27, 2021 at 5:22 pm #3726007Do you think the 70% propane fuel will combust at simmer mode?

Aug 27, 2021 at 6:02 pm #3726015I don’t think it has anything to do with the source gas, be it propane, butane or whatever. It has to do with the temperature needed for CO molecules to combine with O atoms, and that happens in the upper reaches of the flame at a high temperature , long after the source gas has broken down.

There is a sort of energy or temperature hump the molecules/atoms need to overcome before they can merge. This hump is due to the electrostatic repulsion between the clouds of electrons around the nuclei. To be sure, once they do merge there is more energy given off.

Sorry about that.

CheersAug 27, 2021 at 6:14 pm #3726016The reason I’m interested in CO is the amount of holes I had to put in the adaptor plate to get it to operate at full throttle. The plate made by Gardner looks like it has too few holes, that’s why I posed the question to him how it was operating.

https://backpackinglight.com/forums/topic/sterno-inferno-olicamp-stove-adaptor-plate/#post-3725819

Gardner Plate for inferno:

Aug 27, 2021 at 6:54 pm #3726022

Aug 27, 2021 at 6:54 pm #3726022Yeah, I agree.

Let a hole of diameter 1 have an area of 1 square things. Then a hole of diameter 2 will have an area of 4: diameter squared. Thus far, very simple.

BUT, this does not mean that 4 holes of diameter 1 will let through as much air as one hole of diameter 2, despite the equivalent areas. Aerodynamics does not work that way. Why not?

Because there is always a boundary layer at the edge of the hole. This is similar to the way down insulation works. Depending on ‘things’, a hole of diameter 2 might be equivalent to 5 or 6 holes of diameter 1 as far as air resistance is concerned: the boundary edge layer is a smaller fraction of the diameter. of course, the bigger the holes, the less the effect, as the boundary layer stays approx the same.

I ran into just this while working out the air flow for my Vortex stoves. Four small holes around the jet did not let as much air through as 2 larger holes, even though the larger holes were less than double the area of the small holes. (And that was without allowing for reduced air pressure at altitude.) Simple scaling does not work at these small dimensions.

When you get down to the size of the fuel jets in canister stoves, all bets are off. You need to consider both the diameter of the hole and the length of the ‘pipe’ the hole makes through the top of the jet. I searched, but I could not find any published research on this, just a few casual comments that such calculations are useless.

Lots of air!

CheersAug 27, 2021 at 7:40 pm #3726023This amount of holes works good:

This amount is best. Full throttle pushes flames out beyond the side of the pot, roars like a lion :-)

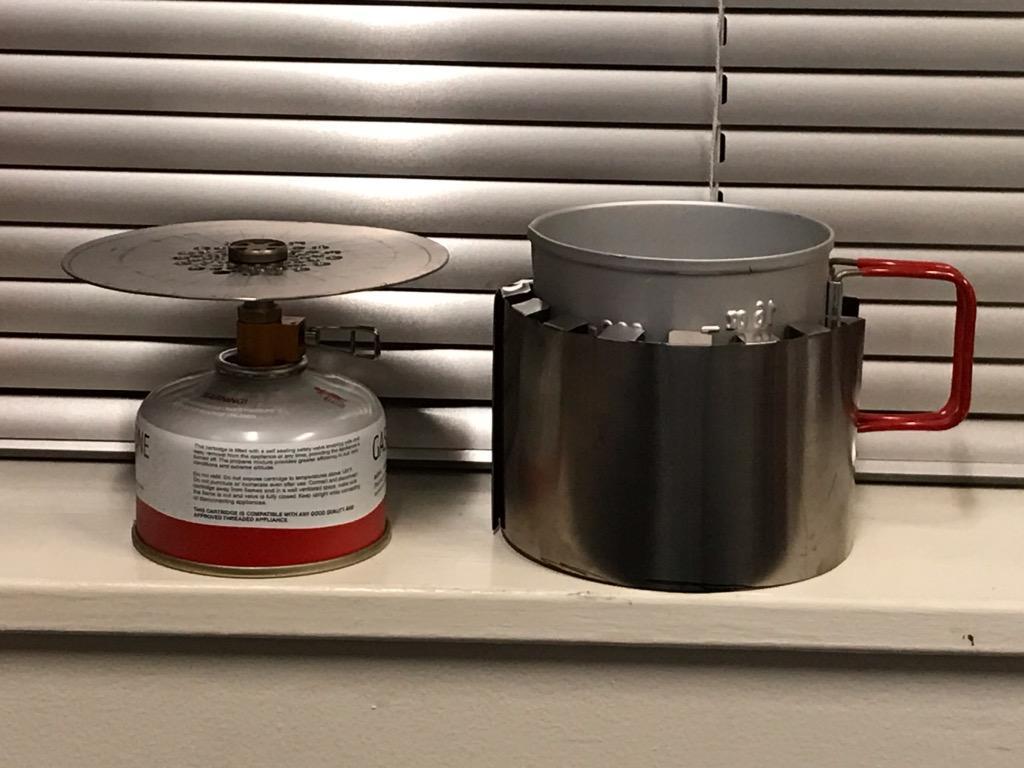

Plate and stove easily fit inside the Inferno Pot.

Aug 27, 2021 at 7:46 pm #3726024

Aug 27, 2021 at 7:46 pm #3726024Holes look good, and roars like a lion sounds good as well, to me.

Cheers

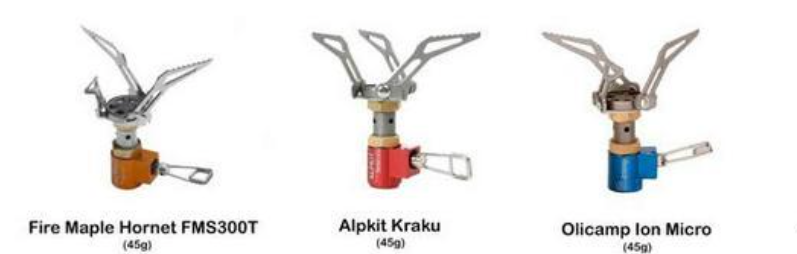

Aug 28, 2021 at 7:18 pm #3726146The adaptor plate should be able to fit all these stoves:

Aug 29, 2021 at 3:30 pm #3726205

Aug 29, 2021 at 3:30 pm #3726205Made an adaptor plate for the BRS3000T

Aug 29, 2021 at 3:57 pm #3726210

Aug 29, 2021 at 3:57 pm #3726210OK, so how did you get the pot supports off? Enquiring minds want to know!

Cheers

Aug 29, 2021 at 4:22 pm #3726214I carefully took the head portion appart as seen in this video:

And then machined the center portion and then inserted a thin wall titanium tube into the center.

Aug 29, 2021 at 5:58 pm #3726226Ah yes, but the pot supports? Did they just press off?

I would expect so: at the price of the BRS-3000T there is not going to be complex engineering. But very good design-for-manufacturing, oh yes indeed. A very smart design.

Btw: I do remove that little ‘safety’ pin on all my commercial stoves. You can’t get the needle valve out for cleaning unless the pin is gone. It represents a little too much of the nanny state imho. After all, only a complete idiot would try to remove the needle vale completely while the stove was still on the canister. And such complete idiots are just contaminating the gene pool.

Then, when reinserting the needle valve, I always make sure I have regreased the O-rings.

Cheers

Aug 30, 2021 at 7:01 am #3726252Ah yes, but the pot supports? Did they just press off?

No, not that easy. When you get to the point as seen in this screen shot it has to be put into a milling machine and the peened over metal removed:

Aug 30, 2021 at 5:01 pm #3726312

Aug 30, 2021 at 5:01 pm #3726312So what sort of mill do you have?

Cheers

Aug 30, 2021 at 7:01 pm #3726325Poor man’s endmill made of heavy duty cast iron Craftsman drill press fitted with 1/2″ chuck. It has a Mech Speed Selector that reduces speed down to low rpm’s for using end mill cutters.

Aug 30, 2021 at 7:10 pm #3726327Got an XY slide for it? You can get them in cast iron with ACME thread and dovetails with gibbs.

Btw: using a chuck to hold an end mill is OK for plastic but not recommended for steel. The chuck is not rated for sideways vibration. A nice ER25 fitting would be lovely, but NOT on a Morse taper without a drawscrew.

Cheers

Aug 30, 2021 at 7:53 pm #3726335Most of my machining has been in wood and plastic. Served a 4 year apprenticeship in pattern making for foundries. Wood patterns and core boxes. My machining has come to an end. All my tools and machines are being packed up and will be taken to my sons workshop. Time to really retire ;) Getting ready to head south for the winter months where it’s warmer.Got an XY slide for it? You can get them in cast iron with ACME thread and dovetails with gibbs.

Got an XY slide for it? You can get them in cast iron with ACME thread and dovetails with gibbs.

No, it’s a poormans set-up :-)))

Aug 30, 2021 at 8:59 pm #3726341How sad. Me, I could not imagine living without my workshop. “Men’s Shed” for sure!

Oh well, enjoy.

CheersSep 1, 2021 at 6:34 pm #3726493I made a few extra just in case someone would be interested in one along with a free lid that fits the Inferno pot. I’ll make a listing in Gear Deals tomorrow.

Sep 1, 2021 at 7:20 pm #3726496

Sep 1, 2021 at 7:20 pm #3726496Atta boy Dan!

Sep 15, 2021 at 9:15 am #3727415I have a few left if anyone would like to update their Inferno Kits to use canisters.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

HAPPENING RIGHT NOW (February 11-21, 2025) - Shop Hyperlite Mountain Gear's Biggest Sale of the Year:

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.