Topic

Stainless Steel Heat Diffusers for Dry Baking

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Commerce › Gear Deals › Stainless Steel Heat Diffusers for Dry Baking

- This topic has 9 replies, 3 voices, and was last updated 8 years, 8 months ago by

DAN-Y.

DAN-Y.

-

AuthorPosts

-

May 16, 2016 at 6:15 pm #3402845

(I have a vested interest in this product listing)

Exclusive Offer for BPL Members and Viewers ONLY

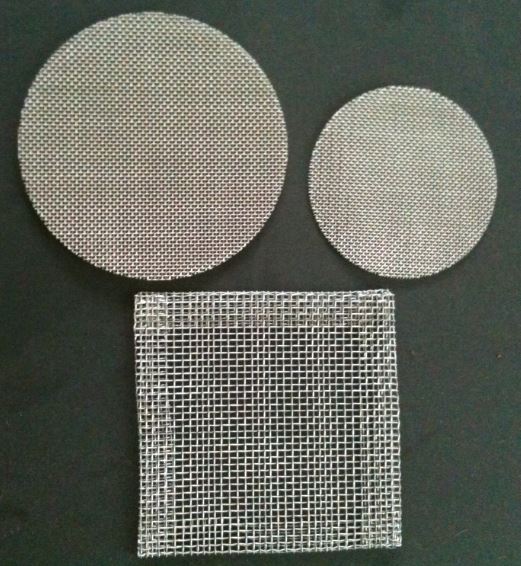

Stainless Steel Heat Diffusers for Dry Baking

3″ diameter

4″ diameter

4″x4″ square

Cost: $2.75 each

Shipping: $3.25

Stainless Steel Heat Diffusers for Dry Baking

May 16, 2016 at 7:19 pm #3402874

May 16, 2016 at 7:19 pm #3402874Dan, do you have a link detailing how these are used?

May 16, 2016 at 10:43 pm #3402916Dan, could you please confirm the SS mesh type is the same for the discs and the square piece?. Looks a bit different on the picture.

May 17, 2016 at 10:40 am #3402998The square is made of nichrome wire.

Nichrome is used in a very wide variety of devices where electric heating is required.

Almost any conductive wire can be used for heating, but most metals will be rapidly oxidized when heated in air. When heated to red hot temperatures, nichrome wire develops an outer layer of <span style=”color: #0066cc;”>chromium oxide</span>,<sup id=”cite_ref-1″ class=”reference”><span style=”color: #0066cc; font-size: small;”>[1]</span></sup> thermodynamically stable in air, mostly impervious to oxygen, and protects the heating element from further oxidation.

Nichrome is used in the <span style=”color: #0066cc;”>explosives</span> and <span style=”color: #0066cc;”>fireworks</span> industry as a <span style=”color: #0066cc;”>bridgewire</span> in electric ignition systems, such as <span style=”color: #0066cc;”>electric matches</span> and <span style=”color: #0066cc;”>model rocket</span> igniters.

Industrial and hobby <span style=”color: #0066cc;”>hot-wire foam cutters</span> use nichrome wire.

Nichrome wire is commonly used in <span style=”color: #0066cc;”>ceramic</span> as an internal support structure to help some elements of <span style=”color: #0066cc;”>clay</span> sculptures hold their shape while they are still soft. Nichrome wire is used for its ability to withstand the high temperatures that occur when clay work is fired in a <span style=”color: #0066cc;”>kiln</span>.

Nichrome wire can be used as an alternative to <span style=”color: #0066cc;”>platinum</span> wire for <span style=”color: #0066cc;”>flame testing</span> by colouring the non-luminous part of a flame to detect <span style=”color: #0066cc;”>cations</span> such as sodium, potassium, copper, calcium etc.

Other areas of usage include motorcycle <span style=”color: #0066cc;”>mufflers</span>, in certain areas in the microbiological lab apparatus, as the heating element of plastic extruders by the <span style=”color: #0066cc;”>RepRap</span> 3D printing community, in the solar panel deployment mechanism of spacecraft <span style=”color: #0066cc;”>LightSail-A</span>, as the heating coils of <span style=”color: #0066cc;”>electronic cigarettes</span>.

dk, I don’t have any links for you. Maybe later.

May 21, 2016 at 3:30 pm #3403882A video of some tests:

May 21, 2016 at 3:55 pm #3403885

May 21, 2016 at 3:55 pm #3403885Interesting. Any idea on how much is the “thermal feedback” in each of those options? if you had a kitchen thermometer and put the probe on top of the gas canister I wonder if you could measure the thermal feedback objectively.

May 21, 2016 at 4:02 pm #3403887The top of canister is definitely getting warm during the tests.

I’ll see what kind of thermal tester I can come up with. I know I have an infra red gun around somewhere. It’s easy to lose kitchen thermometers in my workshop :)

May 21, 2016 at 5:36 pm #3403898The kitchen thermometer works well to assess “thermal feedback”. I just tried it using a MSR pocket rocket stove and a evernew UL 0.9L pot. When you set the pot on the stove it raises the temp on top of the gas canister to 78F and 2 cups of water reached a rolling boil in about 2 minutes.

Then I tried a DIY diffuser I made from a can lid with some holes on it. The diameter of the lid is slightly smaller than the diameter of the imaginary circle where the pot sit on the stove so it the difusser does not touch the pot (there was about 0.25” gap between the bottom of the pot bottom and the diffuser)

I took measurements again and this time, using the diffuser, the temp on top of gas canister got much warmer (raised to 107F) and 2 cups of water reached rolling boil in 4 minutes.

I would imagine all your diffusers would provide better results?. Your corrugated disk should channel some of the heat to the sides not back down (and if you are using a cone type of windshield, on an alcohol stove, up to the sides of the pot) and your mesh diffuser should let more of the heat to go thru and not back down. Looks they do also a nice job spreading the flame wider too so this may be beneficial in wider pots?

Looking forward to what numbers you come up with.

Cheers

May 21, 2016 at 5:42 pm #3403899I like the 2 layer mesh disc so I did the test with it first. Temps at the canister radius rim gets warm and stays pretty constant. The base of the canister stays pretty cool. I had to move the infra red temp tester back away from the canister to get an accurate reading.

May 21, 2016 at 9:36 pm #3403923

May 21, 2016 at 9:36 pm #3403923testing a new design

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.