Topic

Smallest possible butane-stove set-up?

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › General Forums › SuperUltraLight (SUL) Backpacking Discussion › Smallest possible butane-stove set-up?

- This topic has 77 replies, 17 voices, and was last updated 1 month, 2 weeks ago by

Philip Tschersich.

Philip Tschersich.

-

AuthorPosts

-

Mar 26, 2022 at 11:15 am #3744307

Hi Piney! Cool seeing you here too ;)

So i’m not entirely sure what I’m doing differently, but my Falcon Air horn canister accepts 24 grams easily at room temperature without the need to do it in increments of 4-5 grams at a time as mentioned by others. If I put the receiver can in the freezer and keep the donor at room temperature, I have no problems getting to 28 grams either (I often go higher on accident and have to vent). I have only used butane in it though, haven’t tried the usual camp gas mix.

Here is my process, maybe someone could try it and confirm if it is indeed just a difference in practice or a variance in the canister itself.

- I screw the adapter set onto the receiving can (this is the adapter i’m using)

- I put the receiving can with the adapter on it in the freezer for 20 minutes (the adapter has a lot of thermal mass so I figured its best it goes in with the can)

- I then put an insulated glove on my dominant hand (idea is to reduce conduction of body heat to receiving canister)

- I grab the donor can with my ungloved hand and get ready to take the receiving canister out of the fridge.

- I grab the receiving canister out of the fridge from the top of the adapter, careful not to touch the aluminum receiving canister itself.

- I then connect the two and start the transfer process

- during the transfer process I do not put the canisters down, and I keep my hands off the receiving canister, only supporting the unit via the donor canister and using my free hand to adjust the valve.

- Next is to take the donor canister off and see how much fuel I got into my receiving can. This method usually gets me 30-32 grams of fuel in the canister each time, so I immediately vent it till I get down to 28 grams.

I recently used the Falcon Signal Horn canister on a boomerang of the Trans Catalina Trail last weekend. Me and my dad took just the one canister with 28 grams of fuel and my personal Joule Thief pot between the two of us. It lasted us the entire 3 days and we boiled 16 cups of water in total with it during the trip.

The exciting thing about this trip for me was I used my fuel consumption calculator to figure out how many grams of fuel I should bring. Based on the conditions I entered and the efficiency of the stove system I entered, the calculator told me I needed 27.4 grams of fuel for the trip. It ended up being nearly exactly right! We ran out of fuel on the last boil for coffee on the last day, it didn’t reach boil before running out but it was darn close. Super neat for this nerdy fellow to see!

Mar 26, 2022 at 11:45 am #3744310Love it when the numbers work out. :)

Apr 2, 2022 at 2:31 pm #3745104Update: A potential Solution, though there exist a Question of Safety.

I think I now know why my canister accepted a full load of fuel on one go without needing to fill in increments. And also why it plays nice with more stoves than others have mentioned.

@Piney mentioned to me in a private conversation that perhaps my lindal valve was protruding higher than his canister because trying the method I outlined above did not change the need for him to fill in 5 gram increments.

Well it looks like Piney was right. I recently purchased a second cannister to forward to an internet friend who can’t get ahold of them in his country.

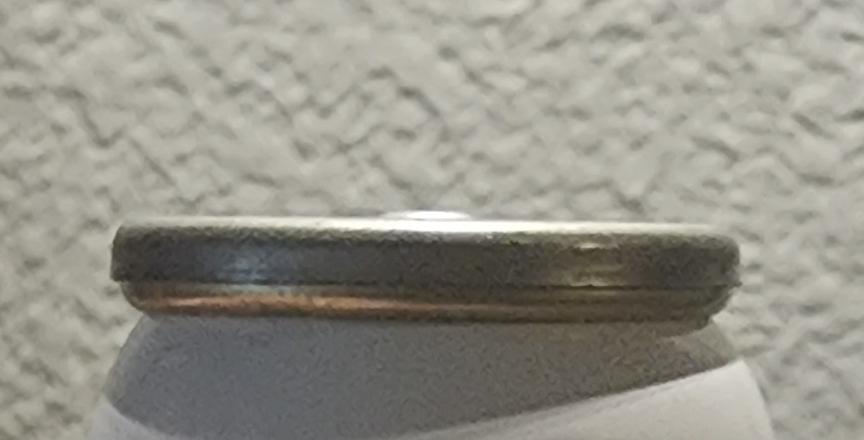

Comparing the new canister to my canister… sure enough! Mine (right hand side) has a lindal valve slightly higher than the new one on the left.

It’s a small difference, calipers measure a .37 MM difference in height. But it appears to be the cause because filling the new canister on the left has to be done in increments as described in this thread earlier.

The Solution:

This is where things get iffy and safety concerns that weren’t already there start to pop up. I found that you can raise the height of the lindal valve by screwing on the adapter till it becomes snuggly seated onto the canister rim… than proceed to turn 1/4 of a revolution to pull the valve up by .37 mm.

I must of done this to my first canister without realizing it, because after doing it to the second canister, it now works perfectly as the first does.

The Question of Safety:

The threads look great and show no damage that I can notice, but does anyone know about the safety concerns over doing this?

Apr 2, 2022 at 3:32 pm #3745111Trying to modify the Lindal valve can be inherently dangerous: there is a lot of volatile, flammable and explosive fuel inside the canister, under very high pressure.

That said, small variations in the exact contours of the Lindal valve do happen, usually due to a faulty crimping machine. ‘Faulty’ often means ‘worn’ and not adequately maintained. It happens, all the time. Yes, I have known of and documented specific cases.

However, changing the profile of the valve by 0.37 mm is not what I would call all that serious, in my own experience. NO responsibility accepted for this comment: NONE at all, just my opinion.

What I should point out is that putting a high torque on the adapter means that the poorly formed steel thread on the canister will start to strip the brass thread off the adapter. This is a known and documented risk. Fortunately, it does not create a hazard as the loss of the thread on the adapter simply means you can’t screw it down solidly enough to open the Lindal valve. This has happened to me with a stove.

Cheers

Apr 2, 2022 at 3:40 pm #3745113Has anyone experienced the Lindel value sticking open ever so slightly on one of the air horn canisters.

I did have such a problem on a hike. The leak of course resulted in all the fuel escaping. I was using a 1.5oz ( 40g) canister at the time.

Apr 2, 2022 at 3:55 pm #3745114The idea of Soto Hinoto fuel canister combined with an ultralight stove seemed very interesting until I found out the canister weighs 128g (4.50z) empty. It is however compact @ 2 x 1 3/4 inches

Apr 2, 2022 at 4:45 pm #3745118Wanted to add some thoughts to Tyler’s excellent post. I think the quirks of the Falcon canisters have a common cause. If you look at the horn that comes with them, it has an extremely long pin. My theory is that the pin on the BRS is just barely long enough to engage the average Falcon valve, and the pin on the adapter is a little short. So you get fill problems with the adapter, but the BRS will run fine.

I tried the same Falcon canister with three different stoves – my Caffin V1, a Soto Windmaster, and the BRS. With the V1 it would run for maybe 10 seconds or so before the pressure dropped and it flamed out. The Windmaster did not vent gas at all. The BRS runs normally at around 60-65 degrees ambient, with no pressure drop issues. I was discussing horn canisters with a user on Reddit, who reported that he had the pressure drop problem with the BRS as well (different brand of horn canister though.) Unless I am missing something, the problems with fill and with pressure drop in use both seem to be arising from a combination of short pin length (for the particular valve on these canisters) and low valve height.

Apr 2, 2022 at 4:51 pm #3745119The idea of Soto Hinoto fuel canister combined with an ultralight stove seemed very interesting until I found out the canister weighs 128g (4.50z) empty. It is however compact @ 2 x 1 3/4 inches

Oof!! It is a wonder there is any room in that thing for fuel, given the thickness of the material required for it to hit 4.5oz.

Apr 2, 2022 at 5:00 pm #3745122Trying to be helpful here and to clarify some details.

The actual height of the central nipple in a canister does not matter at all UNLESS the thing being attached hits the surrounding rim. All that should matter is the distance from the top of the nipple down into the interior of the Lindal valve and the plug which seals the valve. The length of the central pin and the thickness of the O-ring are what matters – for a properly designed attachment.

If the thing being attached has been designed to rest on the rim of the valve, then of course that is going to affect the operation. However, as far as I know, the distance between the top of the nipple and the rim is not part of the specification. That means the defect (if any) lies with the design of the thing being attached.

Yes, some stoves do have a flange which can rest on the rim. Bad choice by the designer. In some cases the flange even has a rubber gasket on it to act as a secondary seal. Very bad choice. Sadly, the otherwise brilliant Snow Peak GST-100 stove did this, but that gasket rarely touched the rim anyhow. The stove is wonderful.

The standard O-ring is the BS-011, although I have seen differences. If the pin is too short, that is a design fault and you can only try to replace the device. A skilled artificer could perhaps ‘fix’ the problem, but it ain’t easy.

HTH

CheersApr 2, 2022 at 6:23 pm #3745125Thanks Roger! I definitely am not laying any blame on the design of the horn canister, especially considering that it is meant to interface with their horn and not a stove or refill adapter. Hopefully we can get to the bottom of this.

Some additional data points:

Valve height of my Falcon canister

Pin length of horn vs. BRS. There is also a difference in pin diameter. Horn pin is 1.25mm, BRS pin is 2mm.

Shoulder height for the two different adapter types. G-Works is appx. 4.25mm, cheaper version is appx. 6mm.

Cheaper adapter tightened all the way down on the Falcon canister. It stops just short of contacting the rim. I am able to fill with this adapter, but only in small increments. The shorter and more expensive G-Works adapter will not vent or accept gas from my canister.

Apr 2, 2022 at 6:50 pm #3745127

Apr 2, 2022 at 6:50 pm #3745127Ughh, just realized my referencing the pin length on the horn is not relevant. The pin is attached to a button and free floats to whatever height is required. I still am inclined to think pin length is important, but the horn attachment is not helpful as a data point.

Apr 2, 2022 at 6:58 pm #3745128Hi Piney

Happy to help.

Pic 1: I can’t see any problem here.

Pic 2:

Threads: I am yet to be convinced that the threads on the two units are exactly the same. This may be an artifact of the lighting, but to me they look slightly different.

Pin diameters: not really a problem if they are different, as long as they are rigid and can poke the valve in.

Pin length: yeah, wildly different! That would certainly make me look very closely at what is going on.

O-rings: I can see the O-ring on the BRS at the left, but I can’t claim to be able to see one in the horn unit on the right. Is there an orange O-ring in there? It would be astonishing if there was no O-ring, but Asia . . .Pic 3: The G-works adapter is, as far as I know, well made with a good thread. I have not met the cheap one on the right. If the G-works will not vent gas out of the horn canister, then I really do wonder whether the threads are the same. Maybe it is jamming when only partly screwed on? That would prevent the pin from opening the valve. If the cheap adapter has a more sloppy thread, then it may be able to screw on far enough – maybe?

EDIT: Actually, there is no hard reason why the thread on the horn and the thread on a stove canister should be the same. If they want to be different, they can.

Frankly, something does not look right here.

Does the horn or the canister or their packaging have any country of origin on them?

Note that while the Lindal patents may cover the western world, they probably do not cover China. By now, anything goes.Cheers

Apr 2, 2022 at 8:03 pm #3745133Threads: I am yet to be convinced that the threads on the two units are exactly the same. This may be an artifact of the lighting, but to me they look slightly different.

To me as well. The horn attachment threads look a bit finer and are cut deeper.

Pin length: yeah, wildly different! That would certainly make me look very closely at what is going on.

That was a red herring on my part unfortunately. The pin on the horn attachment free-floats.

O-rings: I can see the O-ring on the BRS at the left, but I can’t claim to be able to see one in the horn unit on the right. Is there an orange O-ring in there? It would be astonishing if there was no O-ring, but Asia . . .

No O-ring, but once I took a better look at the horn attachment I realized why. It is designed to vent gas quickly into the open air. 10 blasts and the canister is empty. So no back pressure.

Pic 3: The G-works adapter is, as far as I know, well made with a good thread. I have not met the cheap one on the right. If the G-works will not vent gas out of the horn canister, then I really do wonder whether the threads are the same. Maybe it is jamming when only partly screwed on? That would prevent the pin from opening the valve. If the cheap adapter has a more sloppy thread, then it may be able to screw on far enough – maybe?

The G-works pin is recessed further (into the body of the adapter.) It bottoms out on the canister rim, presumably before it can activate the valve on my Falcon canister. The G-Works does a great job with my Snow Peak canisters, but the valve on those projects well above the rim:

Does the horn or the canister or their packaging have any country of origin on them?

The canister has “Made in the USA” on it. Nothing is marked on the horn attachment.

Apr 2, 2022 at 10:13 pm #3745139I would really need to put a vernier caliper and a thread gauge on both the canister and the horn to be able to say what is going on.

Is there any sort of engineering place nearby which could do that for you? Even a good hardware shop?No O-ring.

Incantations to about half a dozen different divinities follow. Unreal.Cheers

Feb 23, 2023 at 12:22 am #3773939I have a chemistry question that I hope will be answered with a reasonable and justified “nothing to worry about” type of answer.

Fluoroethanes are ingredients in some of these off the shelf air horns.

So we empty the canister by blowing the horn until the canister is empty because we don’t want to actually burn the fuel in the off the shelf canister. Burning fluoroethanes creates hydrofluoric acid which is bad to breathe – like, really, really bad.

And then we fill the canister with our hydrocarbon stove fuel of choice, like isobutane.

And then we cook and burn what’s in the canister.

Here’s my question:

Could there be enough residual fluoroethane left in the canister from the original liquid, that when it’s now being burned with our new fuel, that there is any risk of inhaling a meaningful amount of hydrofluoric acid gas?

Feb 23, 2023 at 12:33 am #3773940Fluoroethane has a boiling point of about -37 C (slight variations of about 1 C depending on data source).

I think it is very unlikely that there will be more than tiny traces of the liquid left in the can after you have emptied it, but you do need to flush the remaining GAS out Do this with either dry nitrogen, CO2, or butane. Insert a gram or so, shake, expel (outside).Photos?

Cheers

PS: it is also highly inflammable.Feb 23, 2023 at 11:11 am #3773972Ryan: I wouldn’t fret about it (even though I know about bad HF is – it etches glass!). If you’ve purged the canister of gas (down to atmospheric pressure) and then refilled it, mostly, with liquid butane, the concentration of fluoroethane will be about 1/500 of the butane. You certainly could vent the first butane fill and not burn anything until after the second filling when it would be down to 1/250,000.

Feb 23, 2023 at 11:18 am #3773973Good to know, David – how did you arrive at the 1/500 fraction? Thanks!

Feb 23, 2023 at 2:20 pm #3773990Typical gas (at atmospheric pressure) to liquid volume ratios are around 600-800 which I reduced a bit since the there’d be some unused head space without liquid in it.

Checking now, specifically for butane now, I was a little off from the methane and water vapor I’m usually dealing with, due to butane’s higher molecular weight. Butane liquid is 0.6 grams/ml while its vapor at STP is 0.00248 g/cm³ so a multiplier of 242.

Feb 23, 2023 at 5:10 pm #3774013I have always used a (rough) figure of 250:1 for that.

I suggest that putting 1 g of liquid butane into the container would be enough. I don’t think one needs to fill it.

Cheers

Nov 16, 2023 at 11:11 am #3793245OK, I purchased one of these little canister to try out: I got the Shoreline Marine/Sport horn. Turns out that the following stoves do not fit: Soto Amicus, Soto WindMaster and the Original Pocket Rocket stove. They will start to thread but cannot make it past the uppe lip of the crimp.

Nov 16, 2023 at 5:29 pm #3793269

Nov 16, 2023 at 5:29 pm #3793269Hi Jon

I do not understand the complaint. Is it that the metal surround with little outward lugs or loops (one is visible at the front) will not fit inside the Lindal valve rim? It is not meant to, after all.

Is there an O-ring inside the stove female thread? There SHOULD be one to provide the seal.Cheers

Nov 17, 2023 at 8:10 am #3793283Roger, when screwed down all the way, no gas will flow. The valve does not engage because the body of the stove prevents the full engagement. Does that make sense?

In reviewing the entire thread, I see that this is a problem with other small canisters. The Lindal valve is flush with the top of the rim where as my MSR canister the valve sits up about 1 mm higher. Just suprised that it would not work on three different stove types.

Nov 17, 2023 at 12:52 pm #3793300Hi Jon

Have a look at postings

3745125

3745133

and note the lengths of the pins: they vary.

I am not too sure that the RH unit in the 1st posting is even compatible with the B188 screw-thread canister, as the thread looks wrong.

In the 2nd posting, the height of the pins with respect to the O-ring are also different.If the pin is a bit short it may not reach the plug in the Lindal valve, and I suspect that this is the problem here. Of course, it the metal rim was not there, getting in the way, you might be able to screw the stove down a bit more.

However, if the Lindal valve has been crimped in place with a machine which is out of alignment, the central nipple may be depressed wrt the rim, so that the pin cannot reach the plug inside. I have seen this several times.

Against this is the probability that all 3 stoves do work on standard screw-thread gas canisters, so they can’t be too wrong. Focus instead on the canister.

So yes, the stove design may be preventing the assembly from working, but that may be a combination of the length of the pin, the presence of the metal rim, and how far the valve nipple is sticking up. I strongly suspect that the crimping machine used was poorly adjusted. You could try to pull the nipple up a millimetre or so with a carefully machined steel socket, as I think someone else has already done in this thread, but it might be easier to try a different stove – a BRS-3000T maybe.

Cheers

Jan 11, 2025 at 2:52 pm #3826270I scanned through this thread (aside from the parts about safety, lol) and here is my first crack at it.

I took an empty 1.4 oz Ozark Trails airhorn canister from Walmart ($8), put it in a 16 ounce deli container, filled that about 3/4 full of water, snapped the lid on, and popped it in the freezer. Once it was frozen I attached the transfer valve and put it back in the freezer. Later I attached a room temperature, large, partially-filled MSR fuel canister to it, opened the valve and waited for the sound of fuel transfer to stop. I estimate the airhorn canister accepted 18 g of fuel on the first transfer. I put it back in the freezer in its block of ice and after a while did a second transfer resulting in an estimated total of 33 g of fuel transferred.

Both my BRS 3000 stove and my fuel transfer valve experienced some bottoming out on the rim of the canister prior to seating as fully as I liked, so I used a Dremel to remove about a millimeter of offending material from the stove and valve prior to the transfer. Bob’s yer uncle.

I made a resistance-fit stove base out of the bottom of a 12 oz epoxy mixing tub.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Trail Days Online! 2025 is this week:

Thursday, February 27 through Saturday, March 1 - Registration is Free.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.