Topic

Quilt idea- Partial height cross baffles to avoid down shifting

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Quilt idea- Partial height cross baffles to avoid down shifting

- This topic has 9 replies, 6 voices, and was last updated 4 years, 5 months ago by

Jerry Adams.

Jerry Adams.

-

AuthorPosts

-

Sep 6, 2020 at 5:53 am #3674903

I am making a down quilt as a covid lockdown project.

I am attracted to the flexibility of horizontal baffles, and the possibility of moving the down for different temperatures.

The “downside!” is the undesired shifting of the down during sleep to leave a cold spot.

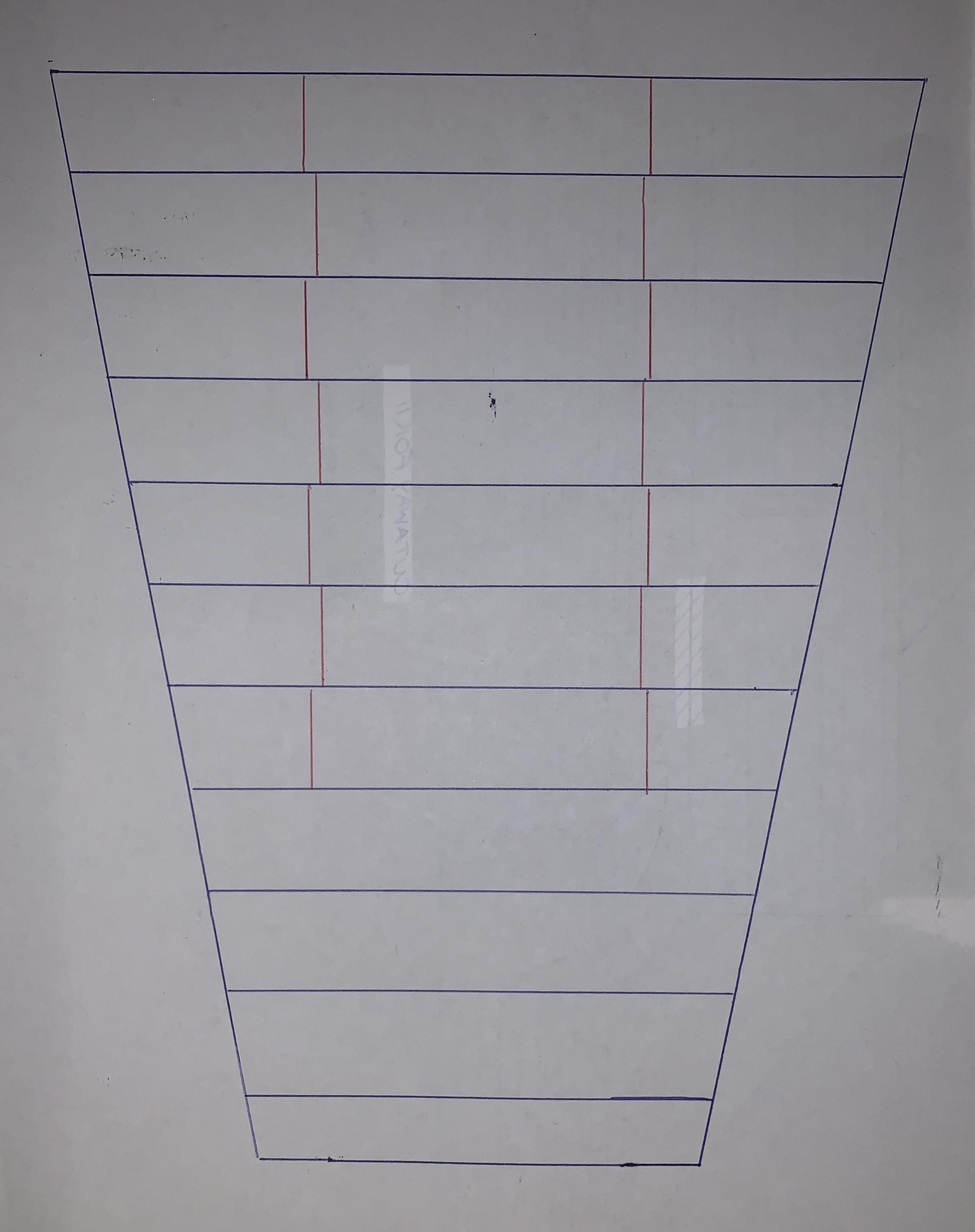

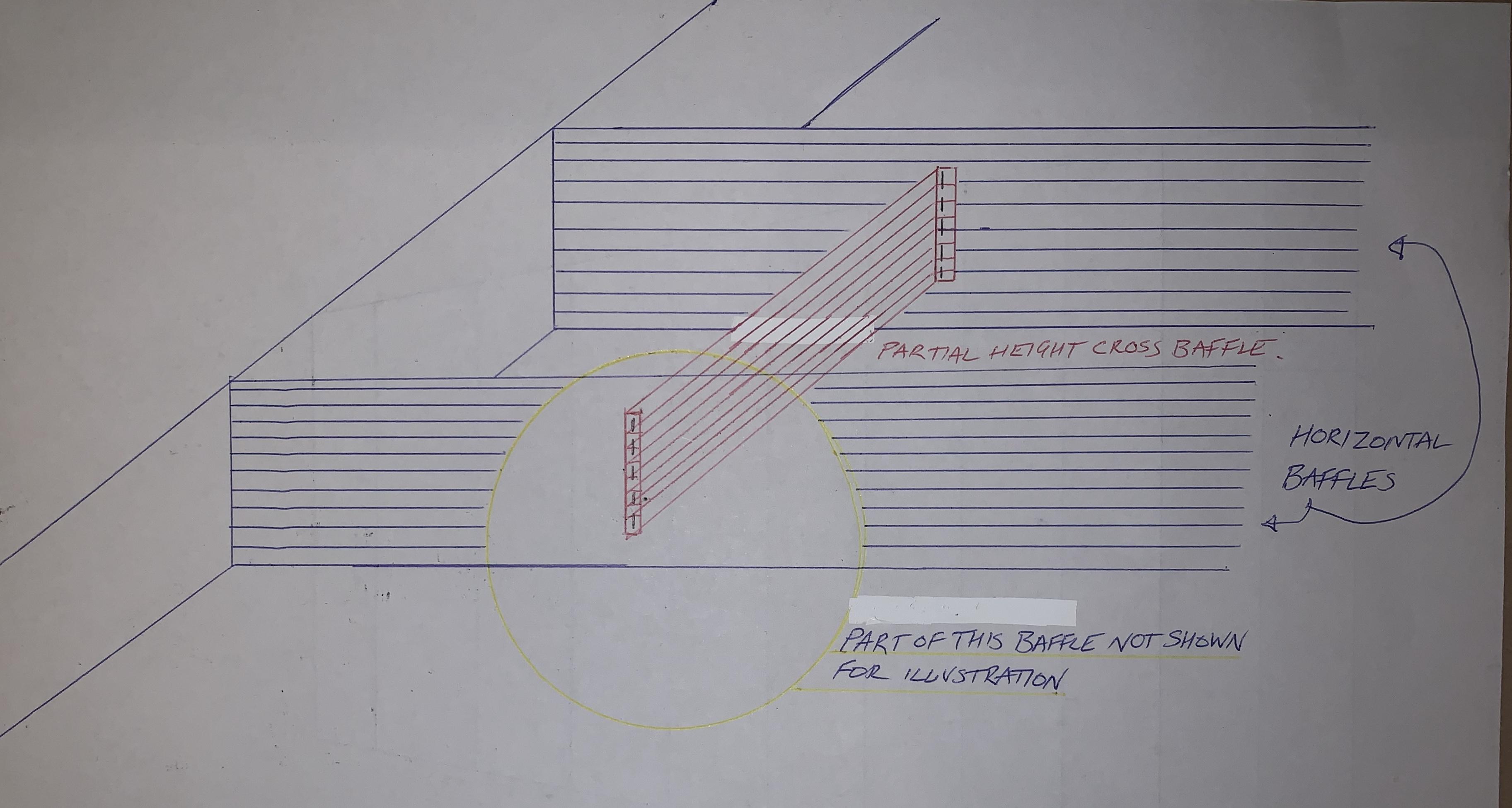

I wonder if it would be helpful to sew a run of baffles perpendicular to the horizontal baffles, along a line approximately half way down the body position. Illustrated on a full taper quilt for simplicity.

The cross-baffles would not be attached to the shell, and only be approximately half the height of the main baffles.

This is my representation.

The cross baffles could be central – or alternatively closer to either inner or outer shells. Central would be easier for sewing the main baffles.

One end of each cross baffle could be attached to all the horizontal baffles first. They are then folded back while the horizontal baffle is attached to the first shell. Then the far end of the cross baffle could be attached prior to the next horizontal baffle being sewn on. The entire matrix will fold back with the outer shell as the baffles are progressively attached to the inner shell.

While lax, it should be easy enough to fill- even poking a tube of down past the first cross-baffle.

I am likely to chicken out and use the well-thought-out pattern based on experience from Aaron Sorensen.

I am interested in the thoughts of the experts here!!

In addition,a simple question .

How much “shrinkage” can one expect after filling with down – or really, how much extra length over the final desired length and width does the shell need to be cut?

Sep 6, 2020 at 7:10 pm #3675009I’ve thought of something similar in the past but never executed it. Basically sew the ends, and base of the baffle, but not the top except for perhaps a small “loop” in the middle to try and maintain some height and ensure the baffle doesnt flop over. Main advantages I saw of this being that the outer shell had less perforations…less water ingress at seams, slightly more wind resistance, slightly better heat retention. I think this is more useful on baffles in the centre of the quilt. Those towards the outer edge you want more stitching (to prevent migration). Also the outer baffles I was thinking of slowly reducing fill/baffle height a little, with the outermost baffle being completely sewn-through (this is often compressed/under you anyway).

I think Aaron’s baffle design is a good one.

Sep 6, 2020 at 10:01 pm #3675023Thanks Adam,

Yours is another vote for the tried and true pattern. I’ll head that way

Hopefully someone, maybe me, will try the new technique one day

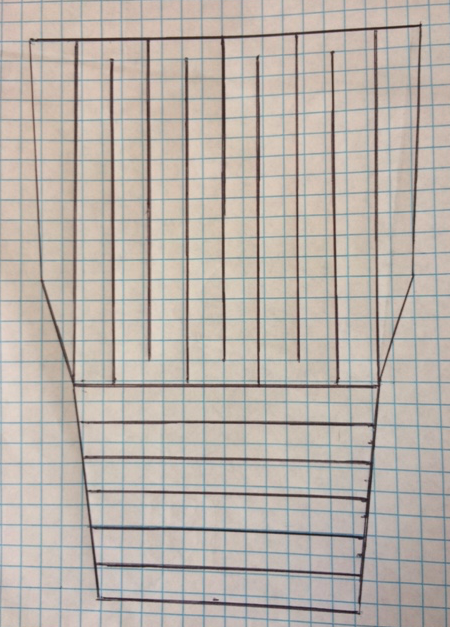

Sep 7, 2020 at 8:12 am #3675065Here are two different quilt designs. The first one works well, though sewing the baffles was more of a challenge.

For this quilt I used 0.5 noseeum mesh for the baffles. Too stretchy and flimsy. And it was too difficult to peel the tape off. For the second quilt I used dutchwaregear.com .67 noseeum precut baffles. Way better.

In the second one, I find the down sometimes tends to migrate away from the middle channels and requires some shaking to redistribute it.

Shrinkage? For both, I listed starting fabric sizes and finished dimensions.

The length of the gaps at the top end of the vertical baffles in Aaron’s design would take some thought. The edge at the top end would restrict the size of the openings.

Sep 8, 2020 at 3:08 pm #3675256Thanks Bob,

I had previously seen your excellent quilts and write-up. I missed those details – there are so many aspects to research.

The before & after dimensions are really helpful.THANK YOU

Incidentally, I was watching a video from unlighted equipment about redistributing down. It appears they previously had a small section in their quilts which was similar -a “stuff gap”- a section of baffle present, but not sewn to the lining. It has now been changed.

It sounds like the unseen baffle works well in the field but is an problem after washing the quilt.

That wouldn’t be so much of an issue when the cross baffles were in addition.

Sep 10, 2020 at 3:45 pm #3675580Isn’t that how the Insotect Flow system works?

I had a Brooks Range half bag with the system in and I saw no benefit to the extra complexity, simply using enough down would be a lot easier and cheaper. I can see it being a huge burden if down shifted while washing and re-fluffed in the wrong sections

Sep 10, 2020 at 3:57 pm #3675581I agree with Edward John M.

Sep 10, 2020 at 4:38 pm #3675589I found full height horizontal baffles are good to keep down from shifting. Like the first picture.

The argument that you can shift down to the sides if it’s too warm never seemed reasonable to me. More of a justification for not having enough down. Or something to say to a customer that’s complaining.

Sep 11, 2020 at 8:28 pm #3675775Thanks Edward and Dan,

I had not seen the Insotect Flow system. It is similar, though they then use a wider baffle spacing to reduce material.

The video from enlightened equipment certainly showed it was quite tricky re-lofting the down if it shifts after washing.

I am reassured,thanks, Jerry – I am a side sleeper and thought down shifting will be more of an issue for me.

The idea of “tuning” the quilt sounds good in theory, but each and every night sees a variety of temperatures anyway, when out in the field!

Sep 11, 2020 at 8:43 pm #3675780I found that the problem is just that sometimes I’ll notice I’m cold and then notice that most of the down has shifted from the very top

Not that big a deal, just fluff the down up so it fills baffles completely. Best done by grabbing edges of quilt and shaking. Which is best done after I remove quilt from it’s bag, before I put on ground.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

LAST CALL (Sale Ends Feb 24) - Hyperlite Mountain Gear's Biggest Sale of the Year.

All DCF shelters, packs, premium quilts, and accessories are on sale.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.