Topic

Pyramid Tent: Seam Order of Operations

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Pyramid Tent: Seam Order of Operations

- This topic has 15 replies, 3 voices, and was last updated 4 years, 6 months ago by

Michael B.

Michael B.

-

AuthorPosts

-

Jul 29, 2020 at 1:37 pm #3667211

First time poster – however, I have been lurking a long time, and read about first post of a thread not being editable. See next post for details. -Michael

Jul 29, 2020 at 1:43 pm #3667212Ok, so here goes- I’ve been reading a while on here, Reddit, various other myog websites and watched lots of videos, but have not really gotten my questions answered by my observations so far.

I’ve managed flat tarps, apex quilts, stuff sacks, ZPP bags, and a few other little things without much difficulty. I’ve tried to make a couple pyramid style prototypes, but have not done a good job with making the felled seams work well at the pyramid apex. I don’t own any manufactured pyramids, since I am a bit miserly, and frankly, I like to make my own stuff. If any of you have tips on the correct order to sew the panels to each other to make the best looking, most robust seams with minimal fuss, I would appreciate it!

Jul 29, 2020 at 2:33 pm #3667215“since I am a bit miserly, and frankly, I like to make my own stuff.”

same here : )

if I have 8 panels, I sew pairs together to get 4 assemblies. sew pairs together to get 2 bigger assemblies. Sew them together.

I don’t think that answers your question : )

Can you sew together two panels and keep them aligned? I tend to start at one end, but the top piece of fabric sticks to the pressure foot a little so it slides relative to the bottom piece of fabric so by the end of the seam they’re no longer aligned

Jul 29, 2020 at 2:58 pm #3667220Hi Jerry, I have appreciated your MANY posts on this forum over the past couple years, so thanks for the reply!

What is the last seam you typically do, besides hemming the bottom? I have done what you proposed on my prototypes, but it has been a pain to cross over the apex while felling the last seam due to the geometry, so that was mostly my question. It seems like MLD, from what I can tell, sews its little vent flap piece on last to minimize the impact on the other seams; I was thinking that might be the best way, but was interested in how other MYOG guys might do it.

Jul 29, 2020 at 3:27 pm #3667222I have a six sided pyramid by the way

peak, inside out:

You can see the flat felled seams overlap as they reach the peak. the last 1/2 inch or so get’s funky, it’s hard to get the presser foot in there

outside out:

After I sew the 6 panels together, and I have a pyramid, I finish the bottom including tent stake loops. Then I erect tent, but don’t put so much pressure on it that the tent pole will poke through.

Then, take a 6 inch diameter circle of the same fabric as the tent. fold over edges one time and hem (don’t need to hide the unfinished fabric edge) so now it’s a 5 inch diameter circle. Put that over the peak of the erect tent and sew one hand stitch, reinforcing circle to tent, at each of the 6 flat felled seams. You have to make folds in the reinforcing circle to make it into a cone, rather than a circle.

Repeat with a 5 inch diameter circle of heavier fabric.

Then, with sewing machine, sew all the way around the edge of the reinforcing circles. I just leave the hand stitches.

The reinforcing circles cover the top of the zipper. The zipper goes all the way from top to bottom.

I add a grosgrain loop to hang it to dry.

This is so much better than working for a living :)

Jul 29, 2020 at 3:33 pm #3667224I am glad to know that others have encountered the “funky” sections :) Thank you for sharing your methodology, and for the tip about the reinforcement.

Jul 29, 2020 at 3:49 pm #3667232then, the last thing, is to take a 3 inch strip of fabric along the grain. Fold over 3 times to make 6 layers, 1/2 inch wide. Sew a couple rows of stitches along it to keep it together.

Then sew that to the ridge seam. So the strip goes from the peak to the bottom of the tent. Repeat for all 4 ridge seams.

I claim this makes the side panels flap less in the wind. Normally, the ridge seams are along the bias so they stretch more. Then the side panels will be loose perpendicular to the seam.

Haven’t heard of anyone else trying this so it may not work for other people. It may make it flap less, but not affect the point where the fabric rips. It could actually make that worse.

Or you could use a 1/2 inch wide non stretchy strip, grosgrain maybe.

Jul 29, 2020 at 4:06 pm #3667234Interesting. So the strips, you posit, are just making the structure stiffer?

Jul 29, 2020 at 4:50 pm #3667243yes

I’ve noticed that they put poles in the ridges for antarctic trips

putting non stretchy strips, and then pulling out with tent stake, you get sort of the same effect

I did it on one ridge, but not another, took it on a windy trip, the ridge with the strip was much better, so I did it to all ridges

There’s a thread a couple months ago with some pictures, but it doesn’t say much more than I just said

Jul 29, 2020 at 6:27 pm #3667275Interesting. I plan to use a French/felled seam for my ridge lines, and my camping destinations have been far milder than you describe. Thank you for the idea.

Jul 30, 2020 at 12:58 am #3667585I’ve done that differently, adding the reinforcement before I sewed the last seam. Here are the steps for a four-sided pyramid:

- Make the four panels

- Join each pair of them. For the pair containing the vent, you may insert the vent hood into the seam

- Join these two pieces so that the other side of the vent is at the unfinished edge

- Now you have one flat piece

- Add the reinforcement – on my silnylon mid, I’ve glued on extra layers of the same material, but you can sew it on too. If you already sewed in the vent hood, you have to stop at that seam, fold it out of way, and continue from there

- Alternatively, you can now sew the vent hood over the seam

- Finally, there’s only one last seam to finish. The other side of the vent hood is inserted into this seam. It can’t be felled all the way to the peak, but the last piece is hidden inside the peak

Jul 30, 2020 at 10:28 am #3667615Thanks Jan, do you have any pictures to show what your finished product looks like?

Jul 30, 2020 at 10:32 pm #3667684

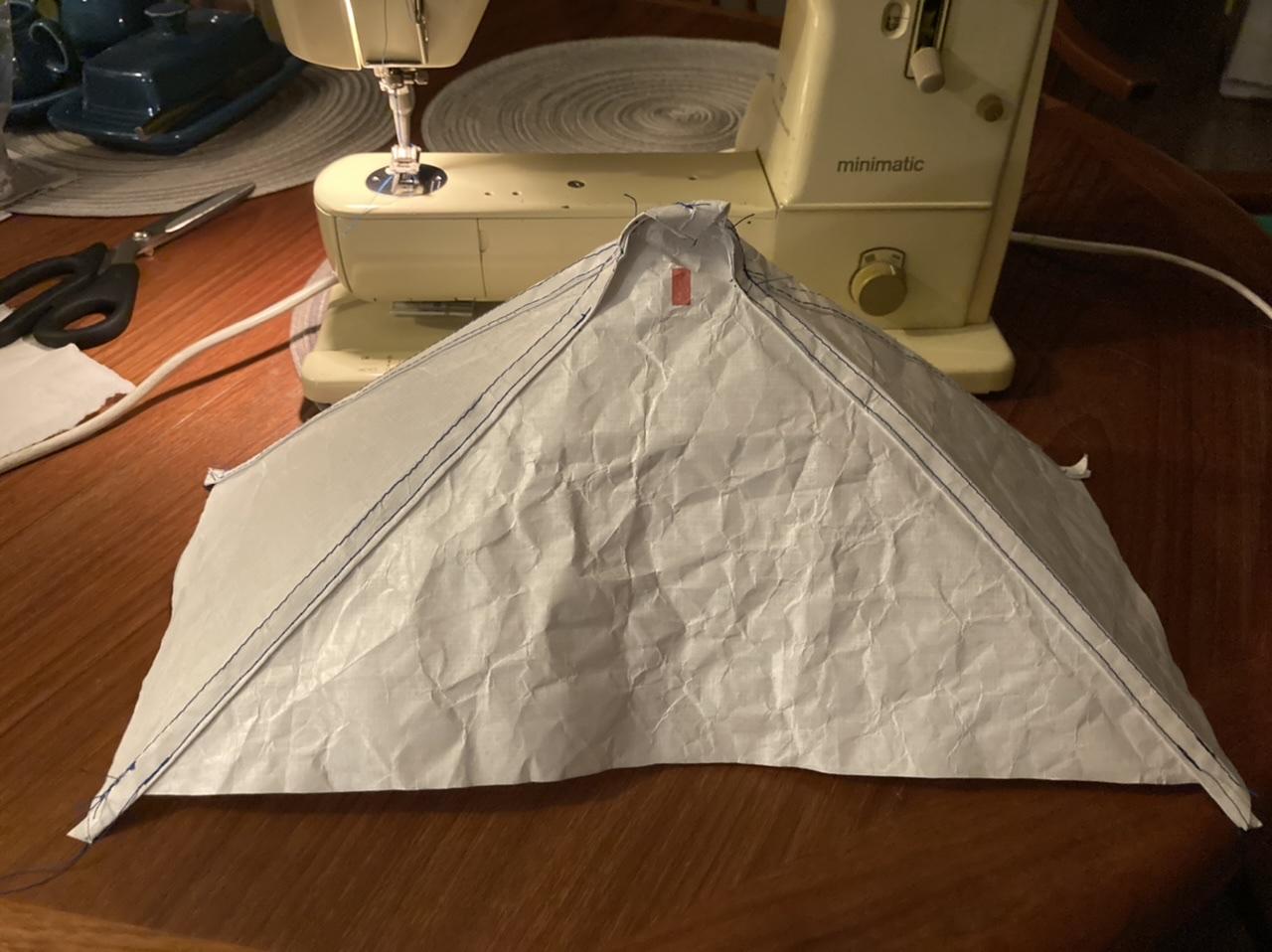

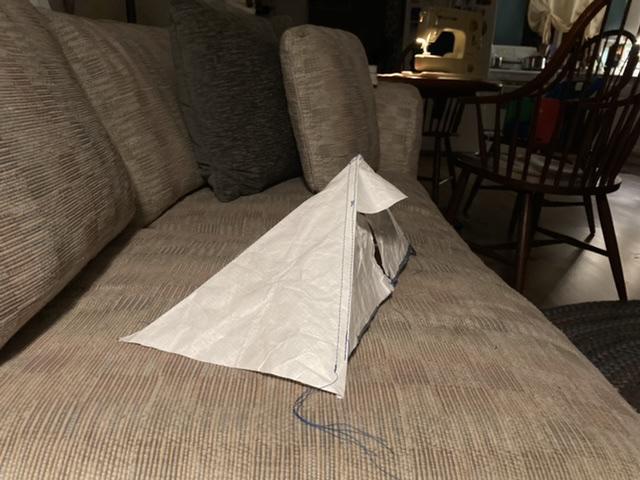

first mockup attempt with tyvek.

I think I need to split the sides up into two panels, then sew up a front and a back section, each consisting of the front/back and left and right half panels. Then I should be able to deal with the peak a little easier. The mockup is just about 8” of the top of a solomid-style tent I am thinking will be a good fit for my first effort at a tent.Aug 1, 2020 at 11:53 pm #3668087

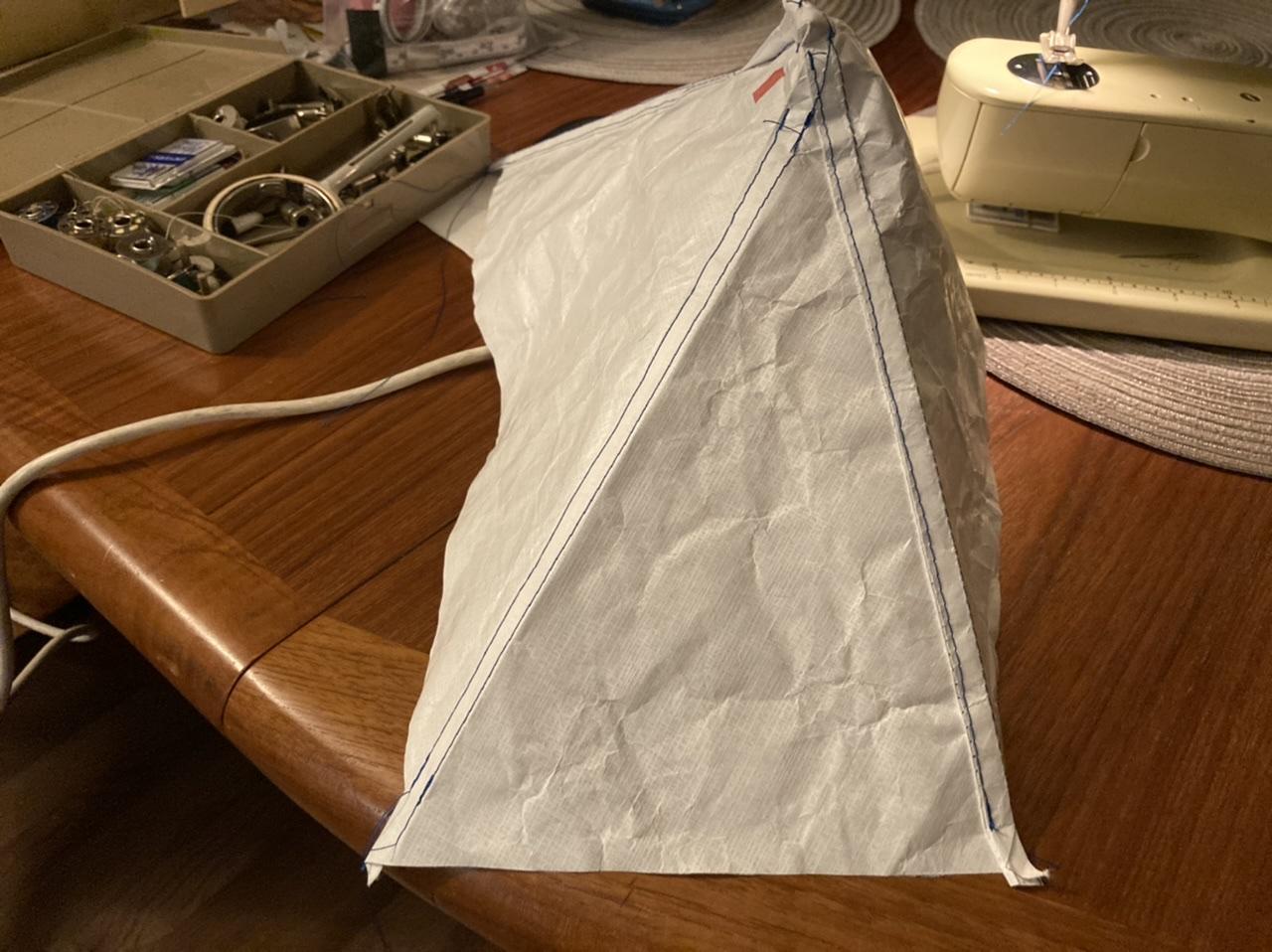

After a few more efforts, I am approaching something workable. A couple more and I think I may try on some real fabric. I need to work on the lay of the fell so it doesn’t get too thick at the top. Thinking to tell the seams away from the center, rather than toward the center as I did in this try.Aug 2, 2020 at 7:56 am #3668103

After a few more efforts, I am approaching something workable. A couple more and I think I may try on some real fabric. I need to work on the lay of the fell so it doesn’t get too thick at the top. Thinking to tell the seams away from the center, rather than toward the center as I did in this try.Aug 2, 2020 at 7:56 am #3668103have the fell of the seam go the same direction on all seams, for example clockwise wround the tent

Aug 2, 2020 at 9:41 am #3668124I will have to try that.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

HAPPENING RIGHT NOW (February 11-21, 2025) - Shop Hyperlite Mountain Gear's Biggest Sale of the Year:

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.

After a few more efforts, I am approaching something workable. A couple more and I think I may try on some real fabric. I need to work on the lay of the fell so it doesn’t get too thick at the top. Thinking to tell the seams away from the center, rather than toward the center as I did in this try.

After a few more efforts, I am approaching something workable. A couple more and I think I may try on some real fabric. I need to work on the lay of the fell so it doesn’t get too thick at the top. Thinking to tell the seams away from the center, rather than toward the center as I did in this try.