Topic

PROPOSED CLAMSHELL HEX-TENT – SOLO WITH SIDE ENTRIES

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › PROPOSED CLAMSHELL HEX-TENT – SOLO WITH SIDE ENTRIES

- This topic has 13 replies, 6 voices, and was last updated 6 years ago by

Sam Farrington.

Sam Farrington.

-

AuthorPosts

-

Dec 26, 2018 at 2:30 am #3570083

This design arose from discussion in a thread begun by Rene Ravenel in the MYOG forum:

https://backpackinglight.com/forums/topic/lateral-tunnel-tent/

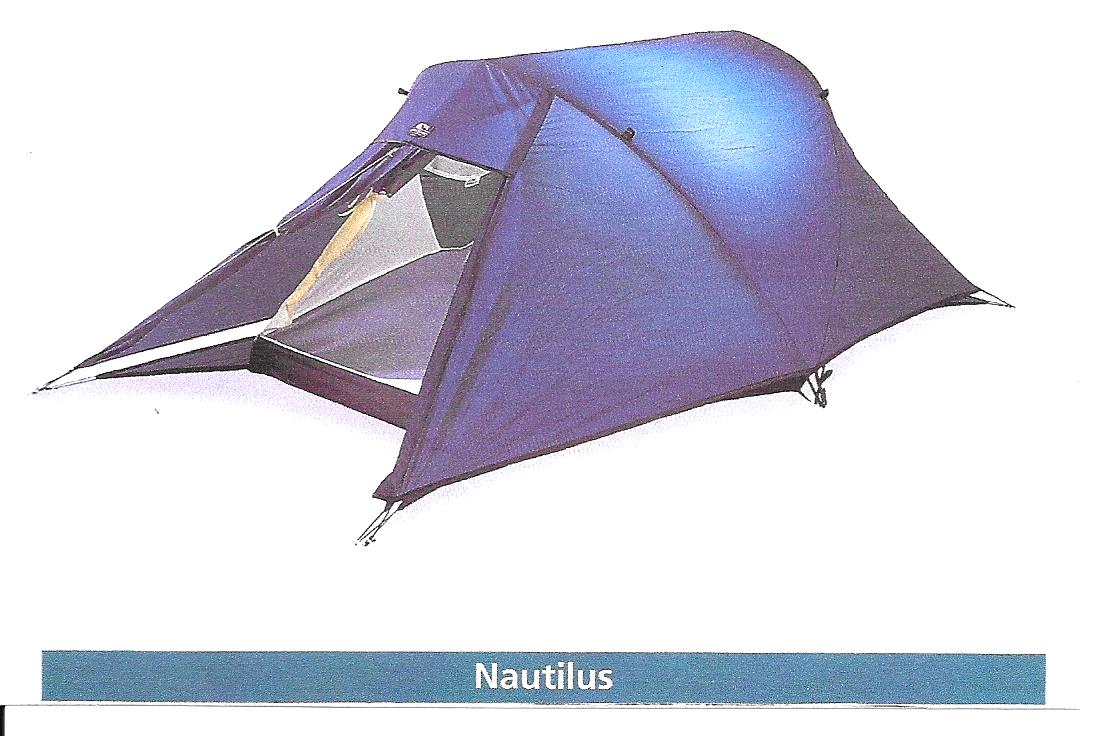

This illustration from Macpac shows the pole arrangement and how the floor is tensioned in a basic clamshell design:

Dec 26, 2018 at 3:36 am #3570086

Dec 26, 2018 at 3:36 am #3570086This proposed clamshell design, solo with side entries and a hexagonal footprint, orients the sleeper parallel with the poles, and is illustrated without catenary cuts on the vestibules by the scale model (1”=1’) below:

Here is the scale model shown without one of the two identical vestibule covers, and a scale 2’W x 6’L x 1’H foam block placed within the floor area:

This design is intended to address some fundamental goals of a 3-season mountain tent:

- High strength, durability and wind resistance

- High rain resistance and protection

- Comfort and efficiency

- Lightest weight without sacrificing the above

- Simplest construction without sacrificing the above

In order to achieve these goals, a change was made from two more conventional tent constructions: 1) a waterproof tent with a breathable inner strung inside; or 2) a breathable tent with a waterproof full coverage fly attached outside.

Instead, the main tent structure consists of a breathable ceiling between the poles that is connected to two waterproof sections covering the vestibule areas on each side of the tent. A narrow fly rests on the sleeved poles supporting the breathable ceiling, and protective netting with doors is hung on each side of the sleeper from the pole sleeve seam down to join the tent floor. The result provides double walls covering the entire sleeping area, but not the vestibule areas that are used for storage and cooking in severe weather. The proposed dimensions are shown in the scale diagrams below:

The design helps to address the above mentioned goals by:

- Allowing the fly to be narrow (3’) and mostly flat; thus more readily attachable in severe weather.

- Keeping the breathable inner ceiling tautly arched, as it is part of the main tent structure. The breathable inner ceiling is highly water repellent, and will deflect rain for a few minutes during pitching.

The above goals are further addressed in the following ways:

High strength, durability and wind resistance:

- The tent fabrics are nylon throughout for both high strength and high durability for weight..

- The tent is designed to present the wind with aerodynamic surfaces that are as far as feasible from horizontal or vertical orientation.

- To limit stress on the stakes, the arched poles join at the tips on the ground, and the peaks are canted outward in order to increase leverage against the wind. To disperse the stress, the tent is tensioned by two stakes placed on each vestibule. And cords from the fly that normally attach just above the vestibule stake points can be reattached to a fifth and sixth additional stake on the windward side of the tent.

- Two stakes on each vestibule also allow the doors to open fully without affecting the rigidity of the tent.

- Five-layer carbon poles are sleeved to the breathable main canopy, and attach at the peaks to elbows that are flexible to deter breakage. The poles have shown maximum strength for weight in break tests.

- The vent awnings are held aloft by insertion of short fiberglass rods flexed to a partial hoop shape.

- Use of only one vertical zipper on each door adds to zipper life, and simplifies replacement if needed.

High rain resistance and protection:

- The coated fabrics have been tested by Richard Nisley with favorable results reported on BPL.

- The walls are sloped at all points to deflect rain and allow it to run off and not collect on the tent.

- The vent covers also serve as awnings over the entrances to help prevent rain from blowing through the inner netting onto the tent floor when the doors are opened.

Comfort and efficiency:

- Interior space is maximized where needed, but minimized where not essential. Hence, the floor is 3 feet wide, but narrows to a point at head and foot ends. The interior is 46 inches high under the peaks, but reduces to 18” high at the head and foot ends of the scale 6 foot foam block pictured above; thus allowing adequate space to sit up from a sleeping position.

- The arched poles increase interior space compared to flat A-frame walls made even more cramped with catenary cuts. There are no upright supporting poles to slip or obstruct movement.

- Condensation is reduced by the vents just below the peaks at the top of each vestibule. Protection from condensation is afforded by the breathable fabric ceiling and inner net walls. Also, the single vertical zippers on each vestibule door can be slightly opened for low ventilation with only a small portion of the door flaps pulled back and secured; or can be almost fully opened to serve as awnings over the entry.

- Fabric sagging is reduced by Sil/PU coatings, ripstop threads, and shock corded stake loops that maintain tension on the fabric panels. The fabrics have been tested with minimal sagging in cold and rain.

- The poles can be arched and fully mounted in their sleeves and hardware while the tent remains flat on the ground. Then, with two stakes planted on the windward side of the canopy, the tent can be raised like an accordion to its full shape with one motion.

- Double vestibules allow storage on one side, and unobstructed access and cooking on the other side of the tent. Door zips run behind the vent awnings up to the peaks, allowing wider door openings for access.

- The fly can be quickly removed for shaking out or drying, and can be easily replaced if needed.

Lightest weight without sacrificing the above goals. The amount and weight of fabric is minimized by eliminating unnecessary space as outlined above:

- All fabrics used range from 0.7 to less than 1.1 oz/sq/yd, total weight with coatings and treatments.

- The Gold Tip carbon pole shafts weigh 0.247 oz per running foot, plus weight of carbon ferrules and tips. (Note: Easton ‘6.3’ carbon poles sold by Quest and Tent Pole Tech. are about 25% heavier on my scale, but also slightly stiffer, and might be used if the tent does not turn out to be as rigidly upright as expected in high winds. The elbows could then be fashioned from Easton alloy hubs that fit the poles.)

Simplest construction without sacrificing the above goals:

– The vestibules and awnings on each side of the tent are identical.

– A frame will be needed for construction, in order to define the shapes of fabric panels, and locate catenary cut lines on the vestibule panels. To make the frame, two rigid gothic arch-shaped fiber board panels will be braced at the correct angle of spread, and must be able to accept pinning of the fabrics.Materials (tentative):

– The fly will initially be Rockywoods gray 7D, 0.7 oz/sq/yd, mini-ripstop nylon

with sil/PU coating.

– Floor and vestibules will be Sea to Summit pale green 15D,1.05 oz/sq/yd, ripstop

nylon with sil/PU coating, and taken from Escapist tarps.

– The inner ceiling will be DWR Extrem Textil yellow ripstop “Impregnated inner

tent,” 20D, 0.77 oz/sq/yd (now sold out, but good alternatives are available).

– Poles will be cut from Gold Tip XT Hunter 75/95 carbon shafts, 0.247 oz per

running foot. Ferrules will be cut from Easton Injexion 330 carbon shafts.

Pole tips that hold the shock cord and protect the ends of the carbon tubes are

made by modifying the arrowhead mounting inserts that come with the shafts.

– Flexible peak elbows are cut from US Plastics equal angle Wyes (120 degrees).

– Cord tensioners for floor and fly corners will be small tension lock hooks from

RBTR, weight 0.05 oz each.

– Cord will be Spectra cord, as light as will work double wrapped on the RBTR

small tension lock hooks.

– Netting will be the lightest durable nylon available, except stronger Sierra

Designs netting at peak vents.

– The six stakes will be medium weight titanium shepherd hooks.

– The pole end receptors are made by removing the hooks from acetal swivel hooks

from Jontay. (Mounts on the ‘generic’ swivel hooks from Quest do not hold the

carbon shafts firmly.)

– Stake loops will be medium-lightweight shock cord – to be selected by strength

for weight.

– Outer vestibule zips will be Warmlite YKK # 3, 0.12 oz per running foot – Inner

netting zips will be YKK # 3 from Quest, 0.1 oz per running foot. For smooth

operation, outer zips will be flapped, not waterproofed.

– Support rods for the vents are 1/8” dia. fiberglass, 0.17 oz per running foot

& more flexible than carbon.Thanks to everyone, especially editor Roger Caffin, for their insights. The tent is not intended for raging winter blizzards, but should be rain and wind worthy, and very light. All responses will be welcomed.

Happy Trails.

Dec 26, 2018 at 6:34 am #3570094First thought is that the scale model shows minimal clearance over the mat and being an old feller who needs a thicker mat I’m wondering if the design could be tweaked to increase height there?

Is it possible to use the clamshell pole design with a short triangular strut at the base using aluminium sections there?

Dec 26, 2018 at 6:52 am #3570096I estimated the poles to be around 150″ , so already rather long.

The other way to increase headroom (laying down) would be to keep the poles as they are but lower the shelter height by a 5″ or so.

Anyway, I am under the impression that Sam is building a tent for himself so as long as he is not taller than 6′ I don’t see why he should change the design.

Dec 26, 2018 at 3:19 pm #3570104Re: First thought is that the scale model shows minimal clearance over the mat and being an old feller who needs a thicker mat I’m wondering if the design could be tweaked to increase height there?

Edward: Unfortunately, the perspective in the picture makes the clearance seem less than the 18″ that it actually is at the six foot points. Compare 18″ to the ceiling on a TT Moment at those points. And note that the ceiling is 18″ wide directly over the top of the head. Since I still use self-inflating mats no more than an inch thick, am not familiar with how much the thicker mats raise the sleeper off the ground. Could you fill me in on that? But the answer to your question is yes, the design could be modified by using elbows at the peaks with an angle larger than the 120 degrees. This would increase the radius of the arch, and raise the ceiling. In an earlier project, I used Ti stakes to make elbows the exact angle desired, which also happened to be 120 degrees, and boring the ends of the pole tip inserts to accept the diameter of the Ti rod used in the elbows. But I also thought about using Fibraplex 145 degree elbows (the Easton 145 degree elbows are quite strong, but also quite heavy, but might make sense if using the heavier Easton ‘6.3’ poles mentioned in the post.) One note of caution – the Fibraplex alloy elbows are not highly tempered, and their angle can be changed just by hand pressure. After a few windy storms, there might be metal fatigue issues. Not good. The poles would have to be slightly longer to keep the same peak height with the increased radius of the arch.

Re: Is it possible to use the clamshell pole design with a short triangular strut at the base using aluminium sections there?

Am not sure I understand. Can you clarify a bit for me? Thanks.

Re: I estimated the poles to be around 150′ , so already rather long.

Franco, the length of each of the two poles would be 12′, for a total of 24 feet of pole length, Tested this with a larger scale model. The receptors that substitute for grommets where the poles meet the ground add about 3/4″ to the length, and the elbows add around another 1/2 “. Since I would find it easier to insert the poles into the sleeves at the peaks, I’d use 4 poles, each one being 6′ in length, and made of 5 pole sections. Used feet as a measure, since the pole weight given was in ounces per running foot.

Re: The other way to increase headroom (laying down) would be to keep the poles as they are but lower the shelter height by a 5″ or so.

Yes, as mentioned to Edward, this would be done by increasing the angle of the elbows. Since 18″ over my noggin lying down is plenty for me, I saw no reason to do this, and preferred to keep the advantages of having more overhead space when sitting up, to cook or whatever, to limit the fabric weight, and also to present a more slanted surface to wind striking the tent from the head and foot directions. And as you suggest, if I were designing this tent for market, the elbow angle would be increased to insure that 6 1/2 footers would have more clearance over their heads and feet when lying down. FYI, I used to be 5′ 11.5″ tall, but have shrunk to 5′ 10″ after a back fracture and perhaps general wear and tear as well. Switching to a pack in 2007 that took less weight off the back turned out to be a bad idea over the long run. So am working on a frame that will take more pack weight off the back and place it directly over to the legs. You may have noticed my mutterings about Jackpacks and such on BPL.

P.S. – Here’s another photo of the 12” thick foam block in the scale model:

Dec 26, 2018 at 8:39 pm #3570153

Dec 26, 2018 at 8:39 pm #3570153That 150′ was meant to be 150″. So I was 6″ off but I included some curvature , maybe more than you have.

Dec 26, 2018 at 9:00 pm #3570156It was an idle thought Re the aluminium sections. I was thinking of the ring hub used by tents such as the MSR Hubba-hubba oriented vertically

Dec 27, 2018 at 1:32 am #3570189Why not use one large arched pole with an orthogonal strut to support the center section, like the Tarptent Rainbow?

Either way you could use trekking poles/extra poles to support the peak ridge during storms.

Dec 27, 2018 at 4:28 am #3570207Franco,

The supporting poles for that scale model are flexed music wire as close to 12′ per pole as I could get it. So the curvature is taken into account. The peak elbows are sewn into webbing attached to the tent, so four 6′ poles does it. More pole length would be needed only if the curvature is increased without lowering the peaks, which has been suggested and worth pondering I think. I like the 120 degree elbows made from plastic hubs, because they will absorb shocks, like wind blasts, and then return to shape. But am still pondering.Edward.

It sounds like you may be thinking of a metal hub (or elbow?) to hold the poles where they meet on the ground – maybe also something like the triangle arrangement TT uses on several of its tents, which is very simple and effective. But the clamshell just needs something to hold the poles together at their base, so what I meant by ‘receptor’ is in the lower right of the parts pictured here:

It is just the base of a swivel hook, disassembled, and two of these, one sewn to each side of a webbing tab that is sewn to the tent will hold the poles fast, and allow them to cant outward until they reach their limit by pulling the breathable ceiling taut. The tab would be sewn to the base of the floor where the poles meet, and would also need a separating buckle at its outer end to attach the fly. So everything would come to a point at each end of the tent. The biggest challenge might be getting the right webbing that the sewing machine can handle.

Jacob,

Not being an engineer, can’t give you a technical argument. It is just my sense that the clamshell two arch pole design will be more stable than the Rainbow one hoop pole design. As has been pointed out on BPL, that design is very much like the Pheonix Phreeranger used by Chris Townsend, and on reflection is similar to the MSR Hubba designs. TT’s use of trekking poles to hold the stake points apart on the left and right sides is a great idea, and using the poles to support the peak of a hoop could also work.However, my intention was to design a tent that would stand alone without the use of trekking poles, and work for those who want the inside of the tent to be free from obstructions. The two arches should also create more headroom than one hoop with a transverse strut on the top; but the primary reason for two arches was strength and stability. Without a highly trained engineer, experienced with tent design, I guess we will each have to draw our own conclusions about that, but in the OP, I’ve tried to enumerate the advantages of the clamshell design.

Jan 11, 2019 at 7:54 pm #3572720Sam

Nothing much to add except to congratulate you on what looks like a really smart design – I’m surprised there hasn’t been more interest.

I particularly like the way that wind load would be spread between the panels. Looks very stormworthy for such a liveable design.

The Phreeranger still has a following in the UK, to the point that It’s been revived by TrekkerTent. But your design looks much more wind-worthy.

http://www.trekkertent.com/home/home/25-phoenix-phreeranger-replica-complete-tent.html

Looks like a daunting build though – please write it up and let us know how it goes.

No idea if this would interest you, but I’ve been keeping an eye on Dan Durston’s collaboration with MassDrop on his X-Mid shelter. Judging by the numbers it’s been a roaring success. Seems to me that if this design works as well as you hope there’s enough about it to make it a candidate for a drop, provided you tweaked it a bit to accommodate taller users.

Jan 12, 2019 at 1:42 am #3572783Geoff,

Thanks for the kind words. But we’ll see what the prototype looks like and how it performs before thinking about moving from the amateur to the professional realm. I also was quite inspired by Dan’s success with his current venture.As for the clamshell tent, I trust that anyone should be able to pursue it should they wish. A lot of work there, though.

As for taller users, I really screwed up the photos of the foam block. They should have been straight on, and the headroom at six feet would have been much more visible. And although the floor tapers beyond six feet, there is still the addition of a total of three feet to the length. For most folks, that could be used for storage of slippers and such – the kinds of things that are too big to fit into a net pocket, but are among the first things reached for when getting up in the night. But that added space could also be used to accommodate a 6 1/2 footer I think.

Jan 12, 2019 at 1:57 am #3572785It is rather difficult to give the right impression of available space even using a real tent with a real person inside.

Perspective stuffs that up.

Apart from a recent example that many commented on (TT Aeon) , I remember doing a mock up to show the available space with a tent design. In reality I had about a foot free at both ends, in the photos it looked like my head and feet were almost touching the walls.

Jan 12, 2019 at 6:21 am #3572805Hey Sam,

Your thread arrived while I was roasting on a beach – provided some good day dream fodder :)

Your fly is interesting. Still haven’t been able to make up my mind on pro’s vs. con’s for it. But I do think you’ll need to do something to keep the mid-points along the edges lined up with the pole elbows – otherwise I think it’ll slip off towards the middle of the roof, exposing the ceiling panel to rain.

I’m curious – why are you going with more of an A-frame pole structure than a hoop? Seems such a flat arc could invert under a gust of wind and collapse – especially if you go with flexible elbows. A hoop will resist that and provide more interior volume. A hoop also goes vertical at the ground, so you could reduce the width of the tent with out loosing head/foot clearance when laying down. A smaller foot print is easier to find sites to pitch.

Moving the feet of the poles apart (while keeping the elbows in the same position) will also reduce their length (stiffer and lighter). I understand the mechanical advantage of leaning a pole towards the anchor, but you said this isn’t for winter storms, and I think you’ve got more lean than Caffin’s winter tent. Hilleberg has plenty of models with no lean at all.

Taken together, the above two changes produce a structure closer to a hemisphere, which improves the surface area to volume ratio, and thus reduces weight.

Mind you, given that my exploration in to the lateral tunnel paradigm arrived at parallel hoops, the above opinions shouldn’t be terribly surprising coming from me :)

Jan 13, 2019 at 4:11 am #3572943Franco, glad to hear that I’m not the only one. Will look for a six inch tall Barbie (or Ken) doll in the toy stores (6″ = 6′ on the scale of the model), cut out a 2 by 6 piece of thin foam to represent a pad, then take and post another picture with the camera at simulated ground level. Am pretty sure that will look better for taller folks.

Rene, it is below zero degrees F. here at the base of Mount Chocorua, and will get colder before the sun returns tomorrow, which is the prediction thank goodness.

Not wanting to get too deep into the weeds, did not mention that there will be a small triangle-shaped gusset sewn into the fly at each peak, to overlap the elbows and stabilize the fly with Velcro tabs, and also keep blowing rain from coming in between the fly and the poles at the break in the pole sleeves near the peaks. The break is to allow the poles to be loaded into the sleeves and inserted into the elbows from the peaks, and the theory is that 4 6′ poles will be easier to handle and load than two long 12′ ones. The gussets will keep the fly from lying completely flat on the ground, unless the fly is folded in half at the peaks, which should not be an issue I think.

Also, as hopefully shown on the front/back and side view diagrams in the OP, the fly will be secured over the sleeved poles by large triangle shaped projections whose points will be corded to the reinforcement patches at the four stake points. And of course, the fly will be buckled down where it meets the ground at the head and foot ends. I think this will keep it taut over the sleeved poles. It will also allow detaching the fly at the stake points on the windward side, and reattaching it to two additional stakes, to double the number of stakes resisting the wind. The shape of the fly will look a bit like the floor, a long rectangle with a triangle at each end, but longer since it has to go over the arches. I thought about putting a separate scale diagram of the fly on the diagram sheet, and probably should have.

Re: Gothic arches vs hoops, which are parabolas, unless you consider Roger Caffin’s

3-elbow poles as hoops. I like the one-elbow gothic arches vs hoops because arches present less vertical walls to the wind. They also require less fabric – so less weight. But true enough, they also provide less space at the head and foot ends of this tent. As mentioned, a marketable tent would have to increase the angle of the the elbows to provide more overhead space at head and foot; but compared with all the basically A-frame designs out there, I think the shallow arches will actually increase the ceiling height at toes and noggin, and even moreso nearer the peaks.Agree that especially with the shallow gothic arch, the threat of the poles rotating and inverting in wind gusts must be considered. You’ve probably noted the video of the Warmlite tent pole rotating on its ferrule connections and inverting, with severe distortion of the tent. That was another reason for canting the poles forward and backward, to deter their being blown towards each other by wind pressure. So I’ve experimented with sectioned poles in shallow gothic arches. A tight connection at the elbows is a must, and is the case with plastic Wyes that taper to a very tight fit at their base, while being a little looser at their ends to allow the carbon poles a little give in extreme winds. I’ve found that once the pole sections in even the shallow arch are flexed, the sections do not rotate at the ferrules. Which makes the video of the rotation of the pole sections in the Warmlite video all the more mysterious. Possibly the poles were not fully inserted over the ferrules, or the pole bent. I picked up some pole sections for the lower hoop of a Warmlite, and discovered that the alloy is quite malleable. It may also help to be using carbon on carbon, or on plastic, with no metal ferrules or elbows that can turn into bearing surfaces. In any case, I’m comfortable enough with the sectioned shallow arches to proceed with the shallow arches without fear of a redo, but of course, nothing is certain. For anyone uncomfortable with the shallow arches, I would recommend redesigning with larger angled arches, creating an arch closer to a hoop shape, and as you note, more vertical room over the head and feet. In the final analysis, this is a tent supported by tension, not a free-standing frame, and its stability will depend a great deal on the reliability of the staking.

I appreciate the popularity of hooped tents vs the few with angled arches, but I’ve also read many reports, including here on BPL, of hooped tents blowing almost flat in strong winds. I suppose added guylines and stakes will hold up almost anything, but I’m trying for something less vulnerable to the wind – win or lose. I know my Goondie, basically a cross pole dome, would be a disaster without the built-in guylines angling from the poles. It turned out that the guylines put so much pressure holding the corners of the tent in place that I stopped staking the corners most of the time.

I don’t think you can go wrong with hooped tunnel tents – better space to weight, as you say, than most types. The problem is that most on the market are quite heavy, as Roger found in his article; but that is all the more reason for going MYOG using very lightweight fabrics and components that are now available.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.