Topic

Need old Nalgenes

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › Need old Nalgenes

- This topic has 38 replies, 14 voices, and was last updated 7 years, 3 months ago by

Mike B.

Mike B.

-

AuthorPosts

-

Oct 31, 2017 at 9:36 pm #3499555

Hi Diane

I am happy to send you my one bottle (PM me), but really your problem would be far better solved in another way. The two brass fittings look like ordinary couplings, possibly sealed with a drop or two of silicone where they go through the lid. There may also be a disk of reinforcing material on the underside of the lid.

What you would be much better off doing is finding someone with a little engineering skill and a drill press. Buy some new-format bottles and transfer the brass fittings over. I would do this for you except that you would be without your machine for maybe 4 weeks at the least. A BPL member in your city with a workshop would be ideal.

Cheers

RogerNov 1, 2017 at 2:25 am #3499584Thanks, Roger. The crux of the matter is the grey disc on the underside of the lid, helping to form the seal. I have no idea if it is secured with just the metal fittings, or if it has some sort of adhesive. I am afraid to tear it apart, for fear of not being able to seal the unit again. I agree that transferring everything to a modern bottle would be better. You and David live too far away for me to be able to utilize your excellent engineering skills. The company that makes the machine no longer exists, so no repair personnel, although I do have access to a machinist. He might have a drill press.

Nov 1, 2017 at 2:41 am #3499586Hum ….

Can you measure the tubing internal and external diameters – preferably to 0.1 mm but as good as you can? or the diameter of the bit of the brass fitting which goes inside the black tubing?

If the tubing is of a standard size, then the best solution might simply be to build a new bottle system to be attached to the existing black plumbing.

My gut feeling is that the brass fittings are probably fairly stock items bought off the shelf, and that the disk inside the bottle cap is just ‘some material’ stuck in place with silicone sealant.Cheers

Nov 1, 2017 at 8:13 am #3499602Agree 100% with Roger

100psi is a LOT of pressure for a plastic container

My advice would be to search for a local company that sells compressors, for certain they will have something more suitable, the only possible spanner in the works is that it seems you need a food grade container.

On the plus side the tubing looks to be industrial standard push fit type, so any food grade container that’s built to take the pressure should be easily adapted to fit.

If you don’t get a solution at a compressure store then try searching for a store that sells components used for reverse osmosis, these will use food grade pressure containers that will see pressures far higher than you are needing.

Nov 1, 2017 at 8:21 am #3499603I agree with Mark. I am surprised that the mfr got away with it, unless the 100 psi is a seriously exaggerated estimate.

If you are running a compressor into this bottle, can you check what the compressor is set for? I would have thought 10 – 20 psi would have been tons.

Cheers

Nov 1, 2017 at 2:26 pm #3499620100 PSI seems a little on the high side. I’m wondering if the original bottle was designed for high pressure, but failed, and someone replaced it with a standard nalgene bottle because the treads fit, not realizing the pressures involved. This may explain the previously failed bottles. The OP made it appear that standard nalgene bottles is what the machine required, but that may not be the case. I’d be very careful on replacement bottles until the actual working pressures are determined. Once determined, find a replacement that is designed for those pressures.

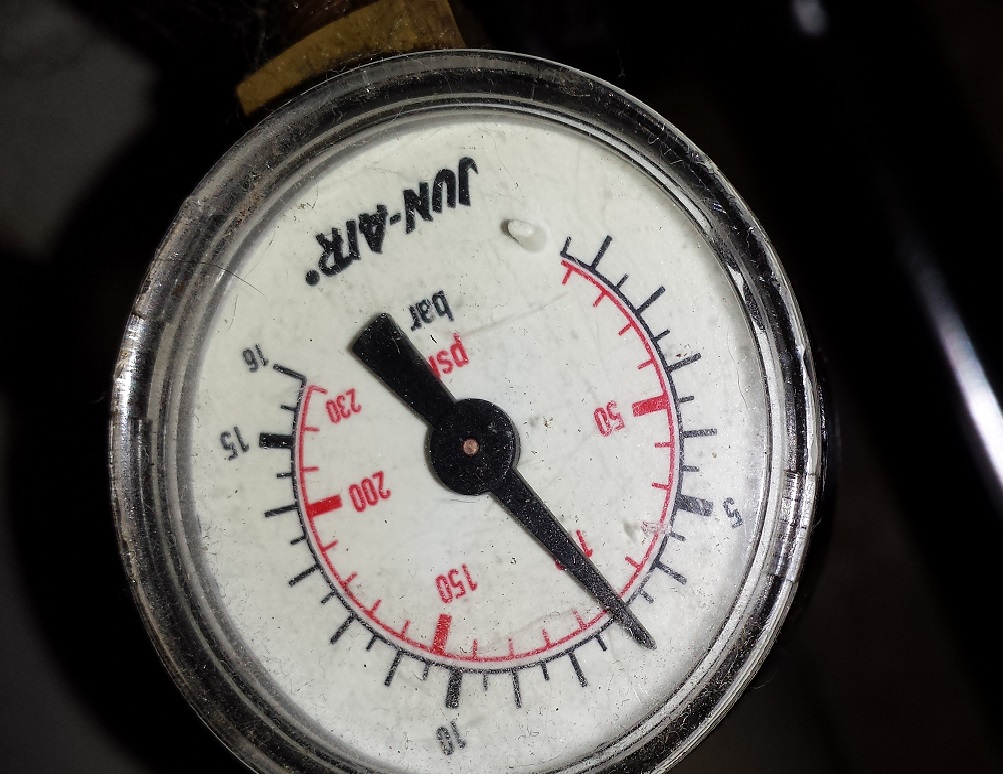

Nov 1, 2017 at 4:32 pm #3499644Well, I’m not an engineer, I could be reading the gauge incorrectly. One side has bars, the other PSI, and I thought I was reading it properly. We aren’t using the machine today, but tomorrow when it is pressurized and in use, I’ll snap a photo of the gauge, and let the rest of you take a look.

As for replacement of an original vessel, it wouldn’t surprise me what my previous boss might have jury-rigged. We got along fantastically for years on one bottle, though, it is only recently we’ve had failures, which I attribute to the aging of the material, so it is clear to me that whatever the pressures really are, the Nalgene can handle it as long as the integrity of the plastic isn’t challenged.

Nov 1, 2017 at 7:55 pm #3499683Diane, that’s what I was thinking too: the system worked, barely, but it worked when the old-style Nalgenes were new. Now that they’ve all aged for a few decades, they’re all weakened.

A CBB (carbonated beverage bottle) like a 1.25-liter PETE Coke bottle has a burst strength of around 185 psi – they are wicked loud when they do explode and can do some damage empty and a fair bit more damage if there’s liquid in them when they blow (if it splits below the liquid level, the liquid serves as a propellent as it exits). Some smaller CBBs have been tested to 250 psi. The narrower cap would require a different style of adaptor, but it seems doable.

I too am surprised that the system gets anywhere near 100 psi. Perhaps that is the maximum reading on the gauge, not the operating pressure?

Nov 1, 2017 at 10:34 pm #3499707Nalgene bottles are not designed to hold pressure and a wide mouth bottle in particular is not good for holding pressure. Plastic can handle quite a bit of pressure, so it is not surprising it works, but I think you are playing with a bomb. Soda bottles can handle quite a bit because they are highly engineered to do that (they have significantly narrower opening). I’ll try to think up a better easy solution.

Nov 1, 2017 at 10:55 pm #3499710I just did a quick calculation. The cap is about 10 in^2 That means at 100 psi, the cap is withstanding 1000 lbs of force!

As an example here is the only bottle I could find design to hold pressure and its only rated to 22 psi:

https://www.mcmaster.com/#general-purpose-bottles/=1a2l5k8

This is the kind of thing I suspect you need, but they look too big for your application:

https://www.mcmaster.com/#pressure-dispensing-containers/=1a2l7cw

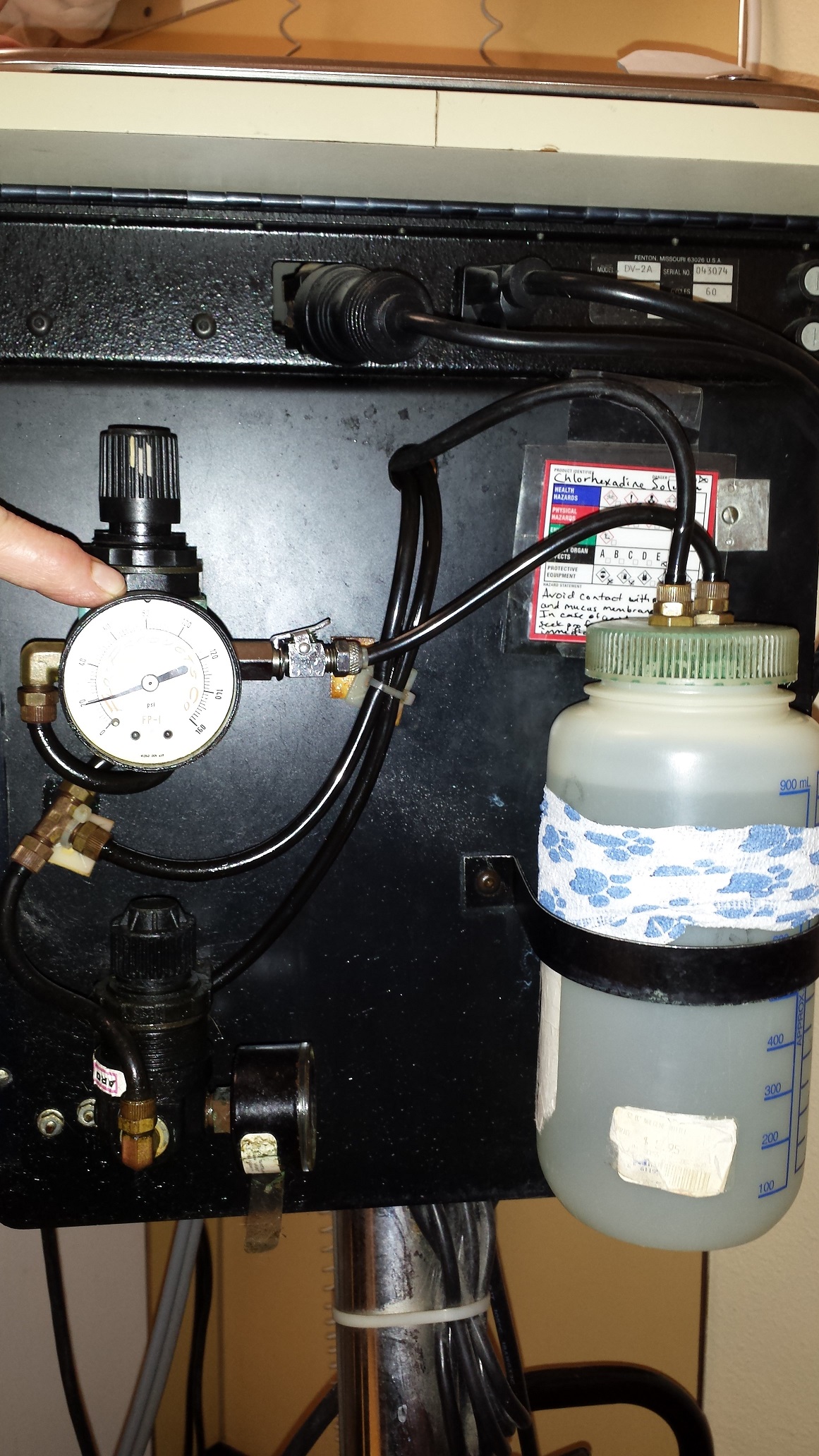

Nov 2, 2017 at 12:38 am #3499739Ok, so I took a few photos. The gauge showing 100 psi is on the compressor end of things. There is another gauge near to the bottle, that is showing more like 20 psi. That is probably what the bottle is actually expected to hold.

at the compressor: this is the gauge we have to wait for to be able to run the machine, so this is the one we pay attention to the most.

Hope this makes better sense. I confirmed with my technician that the Nalgene that was original was the original vessel. This machine was purchased used, and is at least 30 years old. Not many medical machines are still in use after this long, what with technology and all.

Nov 2, 2017 at 12:56 am #3499746I’ll be off the air for a bit.

CheersNov 2, 2017 at 3:39 pm #3499839OK, I am glad these bottles are not at 100 psi. At 20 psi, the force on the lid is around 200 lbs. That is still quite a bit for a plastic bottle, but perhaps not beyond the range of a heavy duty Nalgene. I am still concerned you are using old off-shelf replacements that are not rated to withstand pressure. And… if I understand correctly, that cap is 30 year old plastic which is well beyond its useful life.

I am fairly certain the grey disc inside the cap is there just to give some thickness for the brass fitting to grab onto. It may give some rigidity to the cap which is why it has lasted as long as it has. There is probably some sealing compound around the threads of the fitting to provide sealing.

If you have already “popped” a few of these bottles, I think it is time to re-work. At the very least look for bottles that have IP2 certification. Which, if I understand correctly, means they are certified to 15 psi:

Nov 14, 2017 at 5:20 am #3502037Diane,

A couple of thoughts.

Does the machine require a Nalgene bottle? There are other bottles with similar thread patterns like the camel back eddy style bottle. Also does it require the full 20psi shown on the gauge after the pressure regulator? If you could reduce the pressure and maintain functionality it might make the bottles last longer between changes. Even 2 psi would reduce the pressures by 10%. Also I have 2 older Nalgenes with the number 7 on them if you still need bottles you are more than welcome to them. One of them I just bought a month or 2 ago from a thrift store (it is an ugly mettalic purple) I mention it because I see them occasionally in thrift stores so that might be a supply of them once we send you all of ours.

Mike

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

HAPPENING RIGHT NOW (February 11-21, 2025) - Shop Hyperlite Mountain Gear's Biggest Sale of the Year:

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.