Topic

MYOG Tent Planning

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › MYOG Tent Planning

- This topic has 34 replies, 9 voices, and was last updated 8 years, 6 months ago by

Hoosier T.

Hoosier T.

-

AuthorPosts

-

Jun 12, 2016 at 9:18 pm #3408511

Now that my quilt is complete, it’s time to move on to the tent. :)

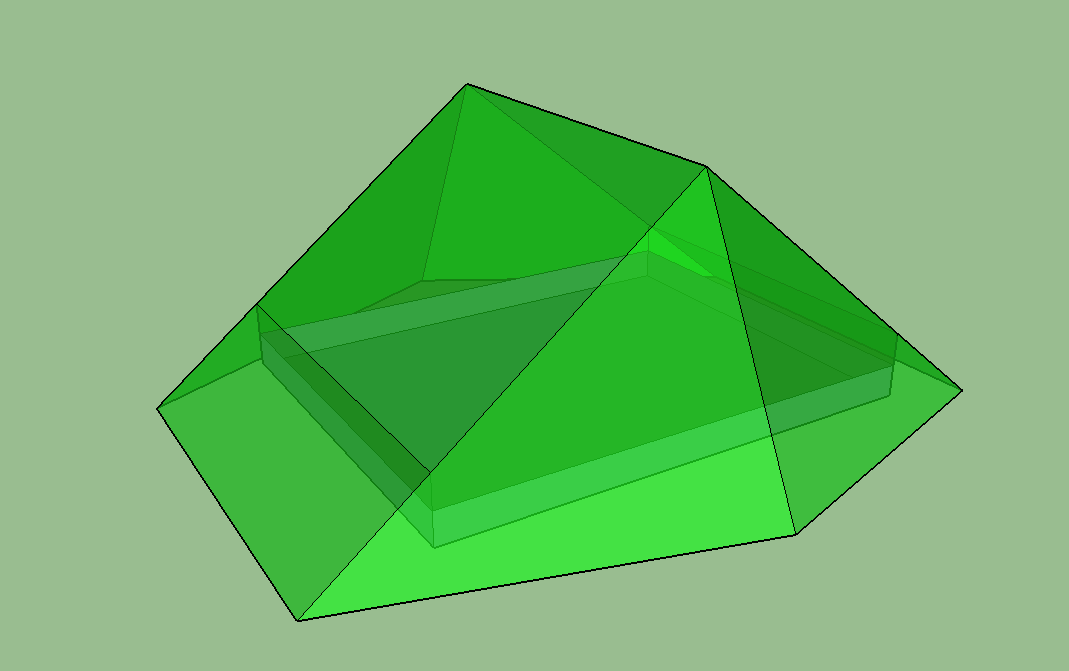

I was originally planning to build a pyramid, but after using sketchup to compare design options and the resulting usable floor space, total required material (and the resulting weight), and head room, I’ve decided to build an A-frame style tent, with doors and vestibules on each side. (Basically the same thing Hoosier T is planning, but a little smaller.)

Fabric selection questions:

Canopy: I’m heavily leaning towards the RBTR Membrane Silpoly. My reasoning is: It’s light, and it has higher tear strength and puncture resistance than Membrane Silpoly PU4000. However… will the lower hydrostatic head be a problem? Is the low tear strength and puncture resistance of the Silpoly PU4000 a big issue for a canopy?

Floor: I was thinking of using 1.1oz Silpoly. Will this be sufficient?

Netting: 0.5 oz noseeum. I’ve read it’s more difficult to work with, but I’m hoping I won’t struggle too much! I used it for my quilt baffles, and it is a bit floppy, but not terrible. Is there a “rule” for which direction it should be oriented based on it’s stretch?

Design Questions:

My plan is 6′ wide x 12′ long pitched with ~48″ tall trekking poles, resulting in a length of 10′ 10.5″, and extending the vestibules 2′ from the floor. No that I type that, it sounds excessive… I could probably tighten that up. For the floor, I was thinking 7.5′ long x 6′ wide. 6″ tall bathtub floor with 6″ of netting on the foot and head end.

However, from looking at the Zpacks design, it seems their floor extends pretty much to the edge, and the mesh connects horizontally, or is sloped downward to the edge of the canopy, allowing any condensation to run down through the mesh. So I’m wondering if I should take the mesh and floor out closer to the edge.

Another consideration is that the fabric will only have a usable width of ~58″, which is not wide enough to make a 6×12 canopy in one piece. So I was thinking perhaps I would make a horizontal seam where the mesh will connect, and attach a tie-out to the center of the seam, which could have a line run over a stick or trekking pole, increasing the interior tent space.

Here’s my very basic initial sketch of the design.

Jun 12, 2016 at 11:05 pm #3408530

Jun 12, 2016 at 11:05 pm #3408530Fabric: I would prefer a HH over 1,500 mm for the fly, and this should be available. But for the floor you really want something over 2,500 mm HH, as you will be kneeling on it. 3,000 mm is not at all unreasonable.

Floor size: the ‘standard’ groundsheet for a 2-man tunnel tent, and for many others as well, is 2,200 mm long x 1,100 mm or 1,200 mm wide. This is the inside sleeping area and does NOT include any vestibule space. Extra space is required, outside the groundsheet area.

Bucket groundsheet with the edges held up by mesh works very well. I have even used tulle for the mesh. It sounds weak, but it is actually made from quite strong monofilament.

Cheers

Jun 12, 2016 at 11:23 pm #3408533Thanks Roger. Do you think the Membrane Silpoly PU4000 would be the better choice? I really like that its aged HH is just as good as the new HH. The only thing that concerns me is the low puncture and tear resistance. But maybe that is fine, because I most likely won’t be using it in very severe weather.

I’ve read the most about RBTR materials, are there others I should consider?

Jun 13, 2016 at 5:55 am #3408543Hi Lydia

I am sorry, but I have not been keeping up with the latest fabrics from RBTR. I have been developing my new stove instead. Have you asked Kyle (the owner of RBTR) for suggestions? He does post at BPL.

However, I think it unlikely that a silnylon tent with carefully made seams and hems and adequate guy ropes would prove too fragile. Silicone-coated nylon fabric is quite strong. My silnylon tunnel, made with ‘1.1 oz’ nylon, took a 100 kph storm all night without problems.

On the other hand, if the fabric has a low puncture resistance, then I doubt its suitability for a groundsheet. You want something a shade better there.

Cheers

Jun 13, 2016 at 6:08 am #3408545Lydia, FWIW I’ve really been struggling with floor material as well. I would much rather use at least a 30d silnylon but can’t find one with a higher HH so that points to the 1.1 PU4000. I’m guessing you will see some folks start chiming in saying to just get a standard 30d Silnylon (DIY Gear Supply has it RSBTR only has 20D) and coat it with a silicon slurry to raise the HH. This also has the benefit of a less slippery floor. However, I’m not sure I’m comfortable to dive into that myself just yet.

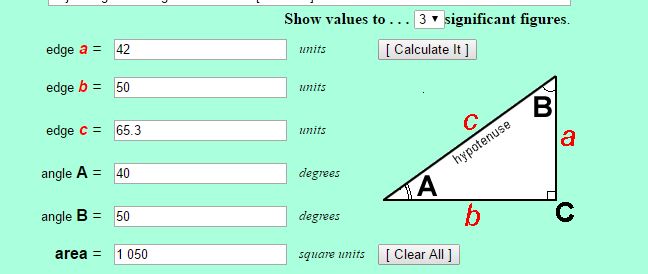

For your design, a big part I forgot while designing mine in sketchup is that the canopy will not be on the ground so you can decrease the needed width of your tarp. So here’s how I started calculating it. Use a right triangle calculator and input HALF of your desired sleeping length (head to toe) into edge B. Then take your desired peak height (sounds like 48″ per your original post) and subtract the distance the tarp will be off the ground. I decided I wanted it to be 6″ off the ground for decent ventilation so using your peak height of 48″ the height of the triangle would be 42″ so put that into Edge A on the calculator. Remember you’re just using this to determine the canopy’s dimensions so you need to leave off the ground clearance. This will reveal the hypotenuse and that is the width you would want each tarp panel to be. Since you want a 7.5′ floor you would put 45″ into the edge B field. If you want some tarp overhang just add it here. Per Zpacks, their Duplex canopy overhangs by ~5″ so I wanted to copy that design. Add 5″ to your 45″ measurement for half your sleeping length and this leaves you with 50″ for edge B. So here’s what you come out with:

This means that each side of your tarp (canopy) need to be roughly 65.3″ wide. Given that there aren’t any coated fabrics available in this width you will need to have your seam opposite the ridgeline like Zpacks has on their Triplex since this is how they build it. This is why the Duplex has the finished width that it does. They basically use the fabric width to make up the ridgeline length ad why you don’t see a seam down the ridgeline on theirs. The width of the canopy actually comes from the LENGTH of the fabric. Triplex example below. And sorry for the long writeup. You may have already done all of this but I figured I would share what I have come up with since they’re similar designs. Have fun!

Jun 13, 2016 at 7:16 am #3408552

Jun 13, 2016 at 7:16 am #3408552I’m currently sewing a bivy using the RBTR 20D 1.1 silpoly PU4000 for the floor. It seems pretty strong to me, perhaps even a little stiffer than my the 30D silnylon used on my Gatewood Cape. I haven’t felt the 0.9 membrane silpoly PU4000.

Jun 13, 2016 at 7:32 am #3408553The 1.1oz Silpoly PU4000 is pretty ideal for a floor fabric. Yes, compared to Silnylon and normal Silpoly, the PU4000 has lower tear strength; however, it is much harder to puncture – try pushing a needle through it and you’ll see. For a tent floor, I am not much concerned about the lower tear strength because my tent floor is never in significant tension (like the fly/tarp is).

So for a floor fabric, the PU4000 has high HH, high puncture resistance, and the PU-coating makes it less slippery than silnylon. The PU4000 floor on my MYOG tent has worked great so far, for around a couple dozen nights.

For a tent fly, I would not use PU4000. Maybe one of the normal Silpoly fabrics would work. For my latest tent, I calculated that going with 30D silnylon from Thru-Hiker would only add 2 oz, so I went with that fabric. 2 oz seemed worth it for a proven fabric with good strength and tear resistance

Jun 13, 2016 at 12:00 pm #3408594For your design, a big part I forgot while designing mine in sketchup is that the canopy will not be on the ground so you can decrease the needed width of your tarp.

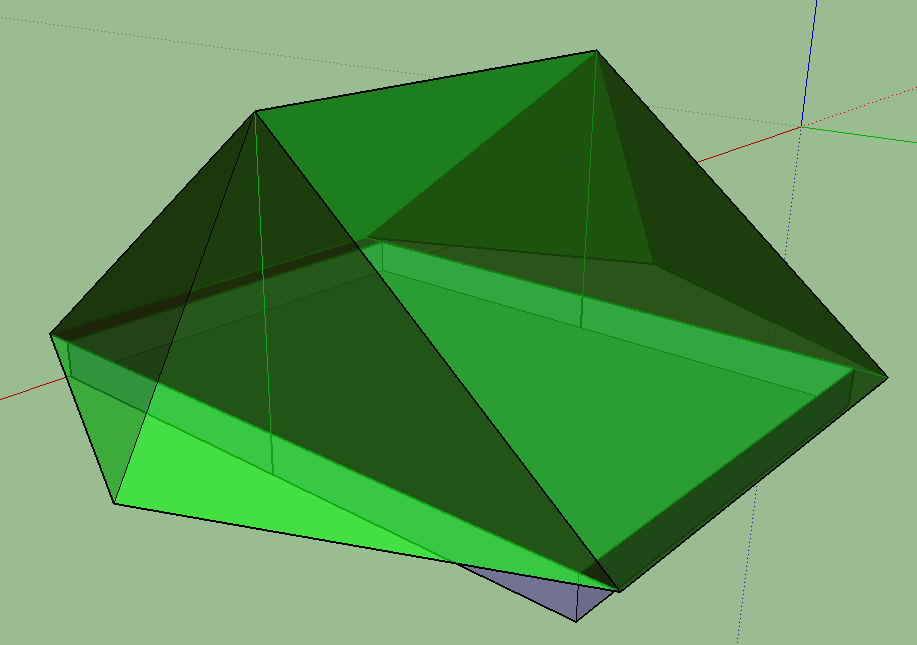

I’d use the cunning tools in SketchUp. If you draw the groundsheet bathtub and hanging mesh first, and make it a component, you can then draw raised ground clearance plane for the fly. Draw lines from the ridge corners to the four corners of the mesh panels (if you have created a groundsheet component, but aren’t editing that component, the points will still be useable as guides, but the lines drawn won’t ‘stick’ to them, so you end up with separate, but mating groundsheet and fly components). Then use SketchUp’s line editor to extend the line along its length (select pencil, then draw from the end of one line; the extension will be magenta), until it intersects with the ground clearance plane. Then link the intersect points to give you the elevated fly outline.

Or simply take the existing design, and draw in a ground clearance plane, and then delete the fly below this plane, then delete the plane itself. But it’s a very good idea to make the groundsheet a component first.

Since your ground clearance plane can be complex, you can have different ground clearances at different points around the fly.

SketchUp is cunning. Learn to use that cunning…

Jun 13, 2016 at 1:30 pm #3408612Thank you Roger, Hoosier, Ryan, John, and Kevin!

I chatted with Justin from RBTR, he prefers the 0.9 MEMBRANE Silpoly for his canopy, and said they haven’t had any complaints of misting. So I’ll go ahead and use this for the canopy. I would like a higher HH, but it seems like there aren’t any options that offer this without getting significantly heavier and a lot more costly, other than the MEMBRANE Silpoly PU4000, but its reduced puncture and tear resistance is a deterrent. Justin also said the 0.9 MEMBRANE Silpoly packs smaller – another plus. For the floor he recommended the 1.1 oz Silpoly PU4000. He said it was the only material they have which is specifically designed for floors. A little heavier than I was hoping for, but for a floor, I suppose I’d better not be too stingy on the weight allowance.

Hoosier thank you for pointing out the elevated canopy, and reduced length requirement – this is VERY helpful! As were your other design pointers.

Kevin – thanks for the pointers on modeling this in Sketchup, I just did this, and am pretty pleased with the results.

I’ve also decided to make the floor 8′ long by 6′ wide, instead of 7.5′ long. My brother is pretty tall, and I just don’t want it to feel cramped. My husband is also very tall, so if we ever used this tent, I think the extra length would be good.

For the canopy ridge line, I was thinking I should cut the fabric there and make a sewn ridge line, for added strength. Is this correct? Should this be a cat curve? It looks like the Zpacks design uses a cat curve. Should the edges from corner to peak also be cat curves? Not sure if that would be necessary for a taught pitch.

Jun 13, 2016 at 1:32 pm #3408613

Jun 13, 2016 at 1:32 pm #3408613I will agree on the Membrane Silpoly. I have a flat tarp I made using it and have experienced NO misting with it. Great stuff and packs down so tiny.

Jun 13, 2016 at 3:41 pm #3408635Ridge line cat curve – optional, but could be a good move. See our article on Cat curves for tech details.

Length – surprising just how nice the extra 6″ can be inside. Takes more ground space, weighs a tiny bit more, and is a shade less robust in the wind though. Trade-off.

Cheers

Jun 13, 2016 at 4:47 pm #3408648“For the canopy ridge line, I was thinking I should cut the fabric there and make a sewn ridge line, for added strength. Is this correct? Should this be a cat curve? It looks like the Zpacks design uses a cat curve. Should the edges from corner to peak also be cat curves? Not sure if that would be necessary for a taught pitch.”

Cat cut the ridge line. I like 1/3″ for every foot both for function and aesthetics. Corner to peak – I doubt you will need it. I’ve been thinking about what direction all of the forces would be pulling and I think the ridge line’s cat cut will suffice for making a taut pitch. Maybe some others will weigh in.

Thought about how you’re going to reinforce the tie outs? RBTR is advocating using adhesives for the reinforcement patches on .93oz silpoly, but admittedly I’m stubborn and would probably sew them in just because that’s how I’ve always done it.

Ryan

Jun 15, 2016 at 12:01 am #3408948Hoosier – Thanks for the confirmation regarding the Membrane Silpoly, I went ahead and placed my order, it shipped today so hopefully I can get started on the tent this weekend. :)

Roger – Thank you for the link, excellent article, I have not seen it before. Being relatively new here I’m afraid I’m quite behind on my reading! Regarding length, yes, I think that extra 6″ will be great to have. If I were building a solo shelter I’d be comfortable going shorter, but knowing I’ll be sharing with much taller folks, having those extra 6″ seemed worthwhile.

Ryan – Cool, I’ll just cat curve the top, and not worry about the corner ridges. Less work is always nice. :) I do plan to “glue” the reinforcement patches, instead of sewing them on. The testing RBTR did, and the pictures Hoosier shared of his tarp have me convinced it’s the best method, and if I’m going to do all this work, I’d like to make sure it lasts. It will be a bit more time consuming than just sewing them on though, but that should be OK.

Question regarding attaching the noseeum netting: Should I sew the canopy, and bathtub floor, then sew the noseeum onto the existing seams? This was my plan… but then I started wondering if people get fancy and actually insert the noseeum edges into the canopy and floor seams. Not sure how I’d even do that accurately, but wanted to make sure my plan is OK. Or perhaps there’s another option I haven’t even considered?

Jun 15, 2016 at 4:59 am #3408964Should I sew the canopy, and bathtub floor, then sew the noseeum onto the existing seams?

More or less what I do.

Cheers

Jun 15, 2016 at 5:04 am #3408967Lydia, I’m glad you posed that question because I have been wondering the exact same thing. It would be so challenging to calculate the cuts well enough to roll then into the hems of the canopy and bathtub. I was hoping people would say they just slap it on after the fact. Can I ask, since we’re both trying to build something similar, do you plan to double roll the netting before sewing it? This will be my first exposure to noseeum so I’m clueless on proper techniques. Also, how do you plan to attach the Vestibules? Are you rolling those into the hem of the canopy “body” or doing a rolled hem on each then sewing them together?

Jun 15, 2016 at 9:45 am #3408998I sewed my netting onto the seam allowances after the fact; since I used tulle rather than noseeum, I wanted to be able to replace it easily if it gets damaged. On the end panels, I sewed strips of 1″wide silnylon several inches above the bottom, and attached the tulle to that; but for noseeum you can just sew it directly to the outer wall, I think.

Jun 16, 2016 at 5:52 am #3409144I would Silnet the pull outs on the .93 Membrane that will be under the highest tension. The tests take all doubt away from the possibility of a rip.

That’s great layout of a tent you have. I’ve drawn up an exact floorless plan but with just the 58″ fabric width on top.

I’ve had zero issues so far using .93 Membrane.

Jun 16, 2016 at 10:47 am #3409195Hi Hoosier, I took a look at my Tarptent Contrail to see how it was constructed. The netting for the sides is actually sewn into the bathtub floor and canopy hem. The door at the front is actually sewn into the canopy wall, as it is set back from the vestibule seam.

For that front seam which isn’t rolled into the hem, it is folded over once and sewn through a double-thickness. I’m actually leaning torwards not doing this, as I tested the strength of the NS50 and am very impressed. I did not fold it over when sewing my quilt baffles, did not feel the need. The irregular structure of the noseeum net does not fray, and considering it’s strength, I don’t feel folding it over is necessary. I might do another test and really yank on the seam before I start.

Now that I know Tarptent actually rolls it into their seams, I’m considering doing that. It would certainly give a nicer looking finish for the head and foot ends. For the front side, I will not attempt this.

Good question about attaching the vestibules, I’ve been thinking about this, and here’s what I currently have in mind for a construction process (but I’m definitely open to suggestions!)

- Sew the cat cut top ridgeline.

- Use seam sealer to glue on reinforcement patches to the edge of the tarp, and peak/ridgeline area (Trying to decide the best time to add the peak reinforcements… after it’s all built, or pre-sewing?)

- Hem the front vertical edges of the vestibule (where it opens).

- Sew the vestibules to the sides of the main tarp, making just one felled seam to connect all that and finish the edges. I *think* the angle will be wide enough at the peak I should be able to get that through the machine without getting into trouble.

- Sew the bathtub floor

- Sew the head and foot end netting into the end seams of the floor.

- Sew the netting into the canopy hems.

- Sew the door netting & zippers in (perhaps behind the vestibule seam)

- Add tie-outs to the reinforced areas

- Seam seal

In your experience, how long does it take for the reinforcement patches to dry/cure before proceeding with the sewing? Is it necessary to weight them while they cure?

For the vestibule doors, I’m planning to do overlapping doors like Zpacks does, rather than putting a zipper in the vestibule, or using hook and loop like Tarptent.

DK – You present an interesting option of sewing a narrow strip of the canopy fabric into the vestibule attachment seam, to which the noseeum net could be attached. Not sure I’ll go this route, but I’m definitely considering it.

Aaron – glad to hear you’ve had no issues with this fabric! If all goes well with this tent build (honestly, probably even if it doesn’t…) I will most likely want to build a smaller shelter for when I’m solo, or just with my dog. And yes, based on the tie-out tests, I will definitely use the recommended reinforcement method.

Jun 16, 2016 at 11:01 am #3409201The more I think of it, the more it seems like a good idea to offset the attachment of the netting to the canopy by a couple of inches or so, so the peak is completely clear of netting and open for a reinforcement patch, and has plenty of space for the trekking pole to sit, without interfering with the net door.

Jun 16, 2016 at 11:12 am #3409206Thanks for all the details! I know this somewhat in response to the question in my thread but I’m really glad we’re both asking the same things. Wow, I’m glad you mentioned setting the netting back to leave room for the poles/reinforcements. I might have thought of that while actually constructing but otherwise I would have ended with a crappy build.

For the peak reinforcements, I was thinking of just cutting circles and gluing them on after sewing everything so they’re tucked nicely and help to meld the doors and canopy into one connected joint for your poles. Not sure if that’s the best way since none of my ideas come from experience but simply logic.

Jun 16, 2016 at 11:58 am #3409216That’s part of the reason I sewed a separate triangular Cordura pocket in the peak to hold the poles – so that the netting wouldn’t be part of it; the other reason was to add some structural reinforcing, since I made a peak vent at the top of each door, a la SMD Haven.

Jun 22, 2016 at 6:13 am #3410116Lydia,

Did you work on your shelter over the weekend? Just curious to see how it’s coming along.

Jun 22, 2016 at 10:26 am #3410149Hi Hoosier, Yes, I got started this past weekend. :) I have everything cut out, the canopy is sewn together, and the two floor pieces are sewn together. Last night I “glued” on the reinforcement patches for the perimeter of the tent with silicone, and weighted them overnight. They’re airing out now with the weights removed, and I hope to hem later today.

The biggest lesson I’ve learned so far is that when sewing on the vestibule panels I initially made the mistake of overlapping the vestibule section instead of the main canopy section for the felled seam. The vestibule section is cut on a diagonal, so it has bias stretch, which makes for a much messier looking seam. Overlapping the straight cut canopy panel and folding it over the bias cut vestibule panel works MUCH better. unfortunately I have a couple of ugly seams because I was slow to pick up on this, which was silly of me, because I know how fabric behaves and should have thought of it to begin with.

Sewing the two floor pieces together was a breeze, the stiffness of the 1.1 oz Silpoly PU4000 makes it SO easy to work with, great stuff. I used some scraps to do a practice hem with the NS50 rolled into the seam, and it worked really well, so I’m leaning towards doing this for the perimeter, it’ll be a lot more tidy than sewing it on after the fact.

The biggest decision left is the configuration of the zipper in the netting. I was considering one big arc, like Zpacks, but really like the idea of being able to open either side of the net door instead of unzipping the whole thing. So, I’m considering doing a “T” design. This would have a small gap where the 3 zipper sections meet, but I was thinking a flap could be added to one of the doors to cover it. Have you thought about this part yet?

Jun 22, 2016 at 10:33 am #3410153I plan to use a rainbow zipper config. So did you roll the vestibule and canopy seam together or just roll hem them both then double stitch them together?

Jun 22, 2016 at 10:37 am #3410159I rolled them together, using a flat felled seam, the same as I did for sewing the ridgeline.

Wish I could re-do those ugly seams, but I didn’t want to weaken the fabric by ripping out and re-sewing.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

HAPPENING RIGHT NOW (February 11-21, 2025) - Shop Hyperlite Mountain Gear's Biggest Sale of the Year:

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.