Topic

MYOG – Modular Bear Canister?

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › MYOG – Modular Bear Canister?

- This topic has 20 replies, 13 voices, and was last updated 8 years, 8 months ago by

Jon Fong / Flat Cat Gear.

Jon Fong / Flat Cat Gear.

-

AuthorPosts

-

Jun 15, 2016 at 11:23 pm #3409125

Hello fellow BPL’ers,

This post is partially inspired by Caffins Vortex MYOG design in that its time to poll BPL’ers more about gear ideas.

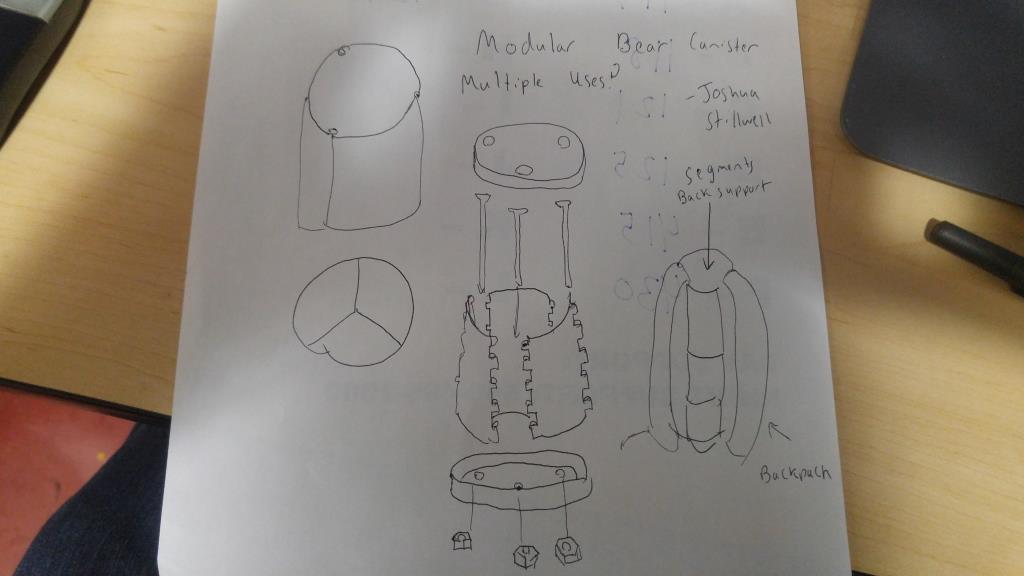

My idea is for a modular bear canister that breaks down into 3 segments that can be used as backpack supports in a MYOG backpack.

I imagine the canister being made of Titanium or some some strong lightweight material being about the size of a Bearikade Weekender. The motivation for the new bear canister, is to take a 1 purpose device and make it 2 (maybe more) purposes. In general I hate packing bear canisters in my lightweight backpacks. They take up the entire backpack it seems, and I feel like I never even bring that much food. I would love it if I could pack my backpack without worrying about a bear canister, and then voila having one at camp overnight. Also a lot of ultralight backpacks could use more spine support, and if a custom made backpack could fit the segments perfectly you would have a built in frame for the backpack. Lastly if metal is used, the end caps could theoretically turn into a fish fry pan if needed.

I’ve attached a “back of the napkin” drawing, and would love some critique and thoughts about my idea. Thanks!

Jun 16, 2016 at 12:32 am #3409129

Jun 16, 2016 at 12:32 am #3409129If it were a simi-rigid frame sheet wouldn’t you want the circumference of the bear can be the length of the packs back support?

The semi-rigid piece can just wrap around the outside of your 4 supporters.

I would also use 4 of the rigid support pieces for body that are half the length as your torso.

They would need to screw together to be used as the support pieces for the pack, but that would be easy.

Then your lid would just need a lip to hold the frame sheet in. The 4 solid pieces could screw into the lid or have a locking system that holds everything into place.

Jun 16, 2016 at 12:41 am #3409130Yeah maybe 4 pieces to make the cylinder is better then 3. Thats a good point, thanks!

To me the circumference of the bear can doesn’t need to be the length of the frame sheet. I was thinking taking the segments apart all together once inserted into the backpack to take advantage of the curvature of the segments to align with your spine. If you have Titanium thats strong enough to withstand a bear bite I don’t think its going to able to flex much.

I imagine the pins that hold it all together as a bear canister could be used to hold it togther as a frame sheet?

Also just thought these segments could work great as a windscreen for a stove as well.

Jun 16, 2016 at 3:36 am #3409137But to be able to use it, you would need to get it approved by the Working Group on bear canisters. Without that, the Rangers will not accept it, and you will be ticketed.

Cheers

Jun 16, 2016 at 4:09 am #3409139Right totally understood, it has to be approved by SIBBG. But obviously in order to get it approved it has to be built, and in order to be built it should hopefully be a decent or maybe even a good idea. And in order to make sure I’m not insane I wanted to hear what you guys have to say. You are over there spinning metal, and machining titanium Roger, what do you think about it? I’m not sure if my “napkin” visualized it well. Is the general idea coming across? I have some access to CAD and could have it built up in CAD.

Jun 16, 2016 at 4:26 am #3409140If you are doing it as a bit of a challenge but without really intending to get it approved it could be a fun project.

On the other hand, as Roger hinted at, if indeed you want to use it where bear canisters are a requirement, you will find that it might be a lot more difficult and expensive than one would think.

Jun 16, 2016 at 4:36 am #3409141Going to be tough to make it light, rigid and durable enough with metal to match polycarbonate and carbon fiber.

Also, there are lots of bits to it… easy to lose a critical part, and they’re all critical.

Jun 16, 2016 at 8:02 am #3409160I know absolutely nothing about bear canisters but is there any reason a bear canister has to be round? Full dyneema cloth metal etc wrapped around the four supports with solid ends …

Jun 16, 2016 at 8:24 am #3409165Titanium is going to bend and fatigue. I don’t see this as a viable design.

Jun 16, 2016 at 9:11 am #3409178Somebody correct me if I’m wrong, but isn’t one of the key design elements that make a bear canister effective the fact that it is too large for a bear to put it’s mouth around and the lack of any edges/corners/etc that would allow it to get a good grip?

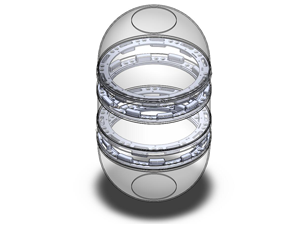

Jun 16, 2016 at 9:19 am #3409180There was a modular design in the works, they were attempting to get approval, and then the website vanished and it all went away…

It was a ball that opened in halves, with one or two collars you could latch together with the halves on the ends.

Generally, as I learned while learning ropes for SAR, the more joins something has, the weaker it is. This is true of trekking poles, umbrellas, and all manner of things. I would be surprised if a modular bear canister worked — if it sags at all when pressure is put on it, the bears will figure it out pretty quick. Just like the one in Kings Canyon that figured out pushing on a Bear Vault pops off the lid.

Jun 16, 2016 at 12:51 pm #3409227JCH: Yes, a large diameter prevents the bear from getting it in their mouth and exerting tremendous force and (at the tip of their teeth) great pressure on the container. OTOH, making it larger than needed and you’ll need even thicker walls just like you do for any pipe or pressure vessel to resist bursting or, in this application, being crushed.

I’ve pondered using a custom bear canister as the pack bag / pack frame by attaching some struts to it and attaching pack straps and back padding to those struts. Depending on the canister construction, it might also be reasonably waterproof, and certainly more brush-proof than our UL packs are. If you’re going to carry a bear canister anyway, could it multi-task as something beyond just a camp chair?

Jun 16, 2016 at 3:59 pm #3409257Yeah apparently there is a bear canister backpack called the “Wise Backpack” I can’t find much info beyond that its approved, no weight or material or anything. http://wisebackpack.weebly.com/ and https://www.nps.gov/yose/planyourvisit/containers.htm

Anyone know anything more about the Wise backpack?

Clue, I don’t think Titanium is prone to bending and fatigue anymore then aluminum which the bearikade uses right?

Cool idea about the spherical bear canister, I had never heard about it.

Very true Lori about more points of failure and risk of losing essential pieces. How many times have we lost important things like stakes, etc. Very good point.

Jun 16, 2016 at 4:11 pm #3409260“Cool idea about the spherical bear canister,”

Just don’t put it down on a slope! There is a spherical ice-cream maker. You fill the inner part with cream and sugar and put salt and ice in the outer part. Then you roll it around until it has set up. Makes me wonder how tough that plastic is on the ice cream maker. A sphere certainly would be hardest shape for a bear to bite or jump on. It also has the minimum possible surface area to volume (lower weight) and no weaker areas.

Ah, alas, the ice cream makers have lots of ridges and seams on the outside, so it would be fairly easy for a bear to get a good bite on it.

A slightly “egg”-shaped container wouldn’t roll so far as a sphere.

Jun 16, 2016 at 4:16 pm #3409262Hi Joshua

You could make the sides out of stock 6Al-4V alloy by rolling. You would need a very strong rolling mill, but I think that alloy could take that. The end caps would need to be made of a different alloy, or even CP (Commercial Purity, ~100% Ti), as you could not get the corners.

Spinning Ti, even the relatively ‘soft’ CP, would require a VERY robust hydraulic spinning machine, up in the $50k+ region. I tried spinning Ti … sigh.

I would suggest domed end caps rather than flat ones anyhow. You might get those pressed (using CP) using a large (100 ton) hydraulic press. The die would not be cheap. My press only goes to 10 ton.

Cheers

Jun 16, 2016 at 4:41 pm #3409267Another drawback that hasn’t been mentioned — the inconvenience factor! Maybe I’m too oriented towards long trips, but I can’t imagine finishing up a 20 mile tough day in the mountains, cooking dinner, setting up shelter, and then having to disassemble my backpack and assemble my bear canister. And then having to do it all in reverse every morning, in rain, bug swarms, high winds, cold temperatures, hot temperatures, etc. Whew!

Now, the idea of a backpack that is a bear canister — that’s appealing!

Jun 16, 2016 at 4:45 pm #3409269This is the modular Bear Canister, still not approved :

http://camp4outdoors.com/products.html

From a Jan 2011 review :

Rubenson, along with J.J Ganjei and Max Vanderwyst at Camp 4 Outdoors, hope to have the Bearier 700 on the market by May 2011, pending bear canister approval.Jun 16, 2016 at 4:54 pm #3409271Form Follows Function

The first proof of concept is: will a titanium bear canister work? If it were a straight cylinder, it would probably have the same issues as a beer can: easy to crush (and then it would be easy to get a jaw/paw on it and create further damage). If you had Dan put ridges in it, it would be a lot sturdier. OK, so now you have modified a cylinder to look more like a beer keg; how would the walls hold up to impacts from say claws or rocks? Well, an easy way to test this is to buy a couple (hopefully used) larger say 2 to 4 liter titanium pots and bolt them together. You probably can’t give it to a bear to test, but you could probably play soccer with it (with lots of test rocks / boulders around). If that seems to work, then you can probably pass GO, collect $200 and move to the next phase: a segmented cylinder. My 2 cents and Good Luck.

Jun 16, 2016 at 5:26 pm #3409276Wow that Bearier looks awesome. If that can’t get approved, then it truly is a roadsign of beware of making bear canisters.

Jon and Roger, if a modular design is even feasible, do you think that Polycarbonate would be better then Ti or AL? I guess I inherently I dislike plastics, but maybe I need to adjust my bias against them.

I guess my inherent desire was to not have to figure out how to fit these massively awkward bear canisters into my backpack. So I thought about breaking it into pieces. Is there another way to better breakdown the bear canister? Some kind of origami bear canister with less moving parts?

Jun 16, 2016 at 5:37 pm #3409280Approved not quite everywhere.

Jun 16, 2016 at 5:41 pm #3409281Joshua,

My vote would be Polycarbonate as it has good impact resistance. The first Proof of Concept is already established: the Garcia and Bear Vault are both engineered plastics. The second phase Proof of Concept might be “can I take these shapes and make an effective, segmented bear canister?”. I would recommend that you buy a couple of used bear cans segment them into the shapes that you want. You would have to build in the hinges/locking mechanisms to re-assemble the parts but the bodies already exist. You could also investigate if these segments add value to one of your main objectives: multiple uses. Will the segment add value as a pack support? Chair? whatever. If so, Pass GO and collect $200 and move to the next round. Again, my 2 cents.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Trail Days Online! 2025 is this week:

Thursday, February 27 through Saturday, March 1 - Registration is Free.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.