Topic

MYOG CF Tent Poles

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › MYOG CF Tent Poles

- This topic has 40 replies, 6 voices, and was last updated 3 years ago by

Sam Farrington.

Sam Farrington.

-

AuthorPosts

-

Aug 18, 2016 at 5:26 pm #3421082

I have been hesitant to post about this project as it is very simple, employes well known\n techniques and is quite honestly, rather obvious. I use trekking poles as support for my Duplex, and have relied on found sticks to serve as poles for the side panel pull outs. Recently I was lucky enough to receive a pair of custom trekking poles from Bob Moulder and was so impressed by the quality of the materials and construction that I was emboldened to try making my own tent poles,

I take many trips with little to no elevation change and for which trekking poles really aren’t needed. It seemed silly to carry 10 oz of poles just to support the tent. In addition, finding new sticks for the panel pullouts at each campsite quickly starts to suck, especially in the rain when you just want to setup your shelter and get inside. So I decided to make a pair of main support poles and a pair of side panel pull out poles.

The material I used is from the same vendor that Bob used for the trekking poles…an eBay vendor named HaoZhong (http://stores.ebay.com/HaoZhong-Carbon-Fiber-Tube). Obviously there are many sources for CF tubing, but I consider these to be of high, and proven, quality.

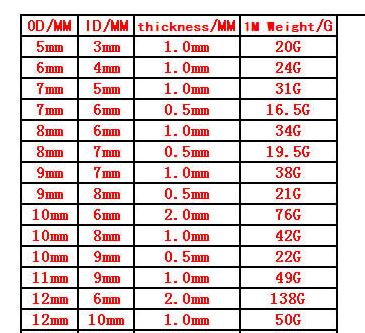

The main support poles are 45” long and made from 3 – 12mm x 10mm main sections with 10mm x 8mm sections for the ferrules. The panel support poles are 26” and made from 3 – 8mm x 7mm x sections with 7mm x 6mm sections for ferrules. This vendor offers a couple of length options, up to 1000mm sections, but charges shipping for lengths longer than 500mm…the 500mm lengths are free shipping. The specifics of your project will determine which length options result is the lowest price.

Construction is trivial…determine your section and ferrule lengths, cut the tubing with a Dremel (I’ve been told a hacksaw works), and use epoxy to glue the ferrules. I used 1/16” shock cord from the local fabric store (also available from several sources such as ZPacks, etc.) and vinyl bolt thread caps from Lowes. That’s it!

The pair of main support poles came out at 145g (5.11oz) and are as sturdy as the trekking poles. The pair of side panel pullout poles are only 40g (1.41 oz !) and are very sturdy. I’m really excited at how well this project turned out, how easy it was, and by being able to cut my carry weight in half for the trips where trekking poles are not needed.

Aug 18, 2016 at 7:42 pm #3421101

Aug 18, 2016 at 7:42 pm #3421101Can you confirm these weights are correct (for the size poles you ordered)?

Aug 19, 2016 at 4:47 am #3421135

Aug 19, 2016 at 4:47 am #3421135I did not weigh the pieces I received prior to constructing the poles, but just looking at the listed weight of 19.5g for 1 meter of 8×7 and comparing to my finished side panel pull out poles, they seem about right. I suspect like any other product there will be small variations.

I do have some leftover scraps so it may be possible to extrapolate full section weights.

Aug 19, 2016 at 5:09 am #3421136JCH, those came out very well and will be plenty strong enough for the job!

Brian, I just measured a brand new piece of 11x9mm (1 meter length) and it weighs 47.9g, which gives us some reassurance that the rest of the published weights are reliable. When they ‘fudge’ on the conservative side it demonstrates they’re somewhat sensitive to customers’ concerns about specs. :^) I’ve also measured ID and OD with a fairly decent micrometer and those are accurate as well.

Aug 19, 2016 at 8:45 am #3421152Appreciate it Bob!

Aug 19, 2016 at 9:00 am #3421155re: ID and OD specs – I found the 10×8 sections to slip freely into the 12×10 sections. If I *had* to complain about anything, they could have been a just a skosh tighter. I found the 7×6 sections would not fit more than 1/4″ into the 8×7 sections without a great deal of force (which I never applied) and required some judicious sanding with 220 grit to reduce the OD.

I would imagine the manufacturing tolerances are such that you might reasonably expect either of these situations with any random pairing of tubing samples. Either way, the tolerances were close enough to not cause any problems in the final project, and simply required fine tuning.

Aug 19, 2016 at 3:45 pm #3421225The IDs are going to be highly reliable, as the tubing is made on polished steel mandrels. The OD will depend slightly on wrapping forces and process variations. For archery use, the higher quality tubes are actually ground to diameter.

Powerful stuff, CF tubing. Just do NOT buy the pultruded stuff! It splits easily.

Vinyl bolt caps for the ends – very clever!

Cheers

Aug 19, 2016 at 6:20 pm #3421238I particularly liked how the bolt caps captured the shock cord with a simple stopper knot. Easily field serviceable.

Oct 12, 2021 at 7:53 am #3729456I bought some 10×8 tubing from the eBay vendor mentioned in this thread. Quality does indeed seem very good. Thanks for the recommendation, fellas.

Unfortunately, I meant to also get some 8×6 tubing from the same vendor to make ferrules with, but somehow bungled it and didn’t get it into the order. There are several vendors on Amazon that can ship roll-wrapped tubing from domestic locations, so I got some 8×6 tubing from the highest rated of them, rather than waiting another 2-3 weeks to get some 8×6 from the China-based eBay vendor.

This 8×6 tubing from Amazone seems to be of comparable quality, but does not slide into the 10×8 stuff I’d got from the eBay vendor. From JCH’s, and others, accounts, some minimal sanding might be required to get a good fit, but with the stuff I have I think some more extensive sanding might be required to slip the 8×6 inside the 10×8.

Anyone have any advice on whether I should go ahead and sand away to get the 8×6 to fit inside the 10×8, or if I should instead try another vendor and see if some different 8×6 is more compatible.

The labor/time of sanding doesn’t concern me greatly, but I’d rather not have to sand so much that I get though the the clear coat (matte in this case) and deep into the carbon. Just don’t want a lot of fine carbon dust floating around (although I’ll be wearing a respirator so maybe not a big deal). Any advice welcome. Thanks.

Oct 12, 2021 at 3:20 pm #3729478Easton aluminium arrow shafts come in a big range of sizes with fine steps in size, and I use some of them for my tents. They are very high performance. But I don’t think they come that big.

Cheers

Oct 17, 2021 at 9:30 pm #3729913Sanding the inner or outer of either alloy or carbon tube (probably laid up with fabric wraps – filament wound carbon is very expensive, so it is probably not that unless you the vendor can verify) can weaken the material considerably.

When seeking to make tubes telescope, and the exact sizes can’t be found, you can look for tubes where one of them is a bit larger. Then shorter tubular shims can be used between the inner and outer tube. The shims can be made from less sturdy material as they are less weight bearing.

In looking for tubing that is a good fit for telescoping or shimming, agree with Roger’s above note about the Easton arrow shafts that come in numerous sizes. The diameters are contained in the code for the alloy shafts that they sell, as Roger has often noted: For example, “The 2413 number is actually a coded value for the diameter. The first two digits (24) gives the OD of the shaft in 1/64 increments. The second two digits give the wall thickness in 1/1000 inch increments.”

Or you can maintain a basement full of construction materials and look around for a match. Having done that, would not recommend it, as the shop becomes jam packed with junk everywhere that I’d not wish on anybody.

Oct 17, 2021 at 9:56 pm #3729915as the shop becomes jam packed with junk everywhere

It expanded into the house ages ago.

:)Cheers

Oct 18, 2021 at 10:49 am #3729946Thanks, gents. I ended up ordering another pair of short tubes to use as ferrules from a different Amazon vendor. These are a little narrower in OD and will fit with just a little sanding. There is the outer cosmetic coating and then outermost woven carbon wrap that is there to allow a little sanding without great loss of strength. So all well there.

But I have to report that the 500 mm tubes I got from the eBay vendor recommended in this thread have end cuts that are not at 90 degrees.

Apart from this, these tubes appear excellent, but just wanted to alert other forum members that there may be a quality control problem, at least with this batch of 10x8mm, matte-finish, 500 mm roll-wrapped tubes. I’m not sure how they cut these down into lengths, but I was pretty surprised this morning to find the ends cut askew – about 5-10 deg off square. Hopefully, they were all cut at the same skewed angle so it will be possible to rotate each section just so, and thereby end up with a straight 3-section pole. Of course, I could cut a little off each end, but that’s a lot more cutting than I planned on, and I also need 1500mm poles, so any cutting will result in poles too short.

EDIT: Yep, they are all cut on the same end-angle, so can be rotated into a straight pole when joined end to end. I think I’ll just put little silver marks at each junction to make it easy to line them up. Would be better if they were cut true, but not a big deal in the end.

Oct 19, 2021 at 9:25 pm #3730062Roger, Tell me about it! Priority two after maintenance and repairs this winter is clean-up.

JCH et al: Am curious as to the flex of the 10mm & 12mm dia. tubes you are using. This can be measured roughly by the amount of deflection over a 3′ span when a common solid brick is rested at the center. The reason I ask is because the larger of the two Easton carbon poles sold by Quest Outfitters is just shy of 4mm in diameter and competitive in weight and price. They are flexible poles, intended for dome and tunnel tents; but quite stiff, and wonder how they compare with the stiffness of the 10 and 12mm poles you are using. If the Eastons are as stiff, they are of excellent quality, and might be a good choice. Quest also offers connecting ferrules and tips, so no issues with fit.

Oct 20, 2021 at 5:34 am #3730074The larger of the poles I made do not flex…at least not that I can see…under anything like normal usage (Duplex main support poles). They are stiffer than AL hiking poles of a similar size. I am unable to see any flex attempting to bend them by hand. If I were trying to apply enough force to bend them, I would expect them to fail long before they flexed to any real noticeable degree.

The smaller ones are slightly bendy in the hand, but they carry very little load and so do not flex under my usage conditions (Duplex panel tie-outs).

My take is that the tubes I used are designed NOT to flex.

Oct 20, 2021 at 7:59 am #3730080Sam, the 10x8mm poles I have are fairly flexible at 1m in length. Are you talking about common masonry brick, like to build the brick facade on a house? I can try to carry out that test in the next couple days.

I agree with JCH that these poles are meant not to bend. I’m trying to push it, weight-wise, with thee 10 mm poles and am only trying them because I’m using them in a mid, in inverted-V configuration with apex guylines going in both directions perpendicular to the plane of the poles. So I’m hoping the apex is stable enough in space that the poles won’t twist, as that is where they are vulnerable to bending. With force straight down (in compression), they will not flex unless the force gets very high. But I may find that they are too flexible and have to move up to the 12mm poles that JCH refers to.

High Modulus carbon tubes would actually be better for vertical support poles in trekking pole and mid tents. Those tubes are often referred to as having equivalent strength to standard modulus poles but having much higher stiffness (I’ve forgotten how much higher). But these poles are sold at 2-5x the price of standard modulus ones, and all of those I’ve found for sale on line that are in the OD/ID range of what we might want for this purpose are sold at the more exhorbitant end of that range.

Oct 20, 2021 at 2:47 pm #3730115Stumphges – My 12mm poles are 45” long, 3 section. I bet adding another section for a 60” length would still be very stiff. Personally, I’d opt for the strength of the 12mm over the sub 1 ounce (8gm/m) total weight saved using the 10mm. I like my shelters to remain erect :)

Oct 20, 2021 at 3:37 pm #3730129I have to say that 12 mm strikes me as being immensely stiff. The CF poles on my winter tent are 7.5 mm OD, and that tent took a 100 kph storm all night.

Iirc, the stiffness of a tube is proportional to the 4th power of the diameter. So a 12 mm tube will be about (12/7.5)^4 times as stiff as my CF poles, or 9.18 times higher. Interestingly, there is little difference between hollow tubes and solid rods as just about all the stress is at the outer surface (so to speak).

Cheers

Oct 20, 2021 at 4:15 pm #3730132Roger – I agree…they are very stiff. Do you think that the full length sleeves in which your poles fit might lend some strength? The poles being discussed are straight, loaded primarily in compression and have nothing to “help them”.

Oct 20, 2021 at 4:36 pm #3730133Do you think that the full length sleeves in which your poles fit might lend some strength?

A slightly tricky answer here. No, the sleeves make no contribution to the strength of the poles per se, BUT they do seriously prevent any buckling from occurring.Poles in lengthwise compression are very strong, up to the point where sideways buckling happens. Buckling is a catastrophic failure with a sudden onset. For more info on that, search for ‘column buckling’ on the web.

Obviously my tent poles could buckle sideways, along the length of the tent, despite their curvature. That would be ‘unsettling’ to say the least. (Department of Massive Understatement.) The fabric walls and the sleeves prevent this from happening. The high lengthways tension in the fabric walls helps a lot here.

So what would happen if the sleeves were very large? The odds of sideways buckling would be significantly increased. My sleeves are wide enough that I can thread the poles through them easily enough (in a storm), but no wider than that.

Cheers

Oct 20, 2021 at 9:02 pm #3730154I thought tube bending stiffness was a function of diameter squared; Roger says diameter to the 4th power. This is not my area, but did a bit of reading and found this article which says “If the diameter is multiplied by k but the wall thickness is not changed, the rigidity increases by a factor of approximately k^3 and the strength by a factor of approximately k^2. (Weight increases by a factor of approximately k.)” If this is correct, then 12x10mm poles will be about 73% stiffer and 44% stronger than 10x8mm poles. JCH points out that for two 150 cm poles, the difference will be about 1 ounce, which might be the best ounce ever carried, depending on conditions. If this article is accurate, a 2mm increase in tube diameter gets you 73% greater stiffness and 44% greater strength at the meager cost of 20% more weight.

A couple lessons learned from putting these poles together in very much the manner JCH describes in the OP: 1. Ferrule thickness is a bit tricky. As Roger points out, the ID of these poles will be very consistent, but the OD varies a lot, even from the same vendor, same model. I bought 8x6mm tubes from two different vendors. One batch would not fit into the 10x8mm tubes I bought from a third vendor, while from the other batch, one of two slipped in nicely and the other required sanding. 2. The finish on these tubes is very thin. I thought I could get away with a bit of sanding before hitting carbon, but no, my wet sandpaper got black very soon after starting. 3. If the OD of the ferrule tube is just a tad small you’ll get rattle in the poles. This makes me think that having an OD just a little big at the start is what’s wanted. Relatively easy to carefully sand to a snug fit, but the one 8×6 tube that fit into the 10×8 out of the box ended up being too loose and rattles. I don’t know yet if this rattle will occur in use. 4. I can’t really tell any difference between the stuff I bought from the eBay seller in China linked above and the tubes I got off Amazon. They may have all come from the same factory. That said, I have another and possibly two more sets to make and I will continue to buy from the eBay guy; carbon tubes might be like surgeons – there is no way to evaluate them apart from word of mouth. JCH and Bob Moulder like the eBay poles; some random people on the internet have mostly meaningless things to say about the poles I got off Amazon.

BTW, does anyone know how MLD have the shockcord in their poles so that an extension can be added to them?

Oct 21, 2021 at 5:21 am #3730162Bob Moulder made quite a few pair of trekking poles, one of which I am lucky enough to own. In all of them, Bob told me the quality of the tubes from HaoZhong eBay vendor was very consistent. The tubes I got from HaoZhong for my tent poles look identical to those Bob used to make my trekking poles. Obviously appearance is no guarantee of quality, but I have been happy with the HaoZhong product. Of course, as with everything sourced from China, it is certainly possible that the product could change/vary without notice.

re: OD – I wonder if the thickness of the outer coating varies between the glossy and matte tubes? It might be possible that the glossy tubes have a thicker outer coating.

re:MLD’s extension – my guess, and it is simply a guess, is that the only way to allow the pole extension to function as the photo on the MLD site suggests, is to anchor the shock-cord through a “bung” glued into the body of the pole at a depth a bit deeper than the length of the ferrule.

Oct 21, 2021 at 6:43 am #3730165

Oct 21, 2021 at 6:43 am #3730165Thanks JCF, I think you’re right. And I think I saw some of those “bungs,” …but where was that?

I would not be surprised if glossy coat is thicker than matte. I may try glossy ferrule stock next time. All in all the poles turned out fine. The 150cm inverted V setup with shockcord, vinyl bolt caps and a bit of vinyl tubing as a connector came out to 6.5 ounces wiht 10×8 poles. I plan to setup the tent next time there gusting winds and see how the poles fare. I think I’ll try to use the super-slow camera function to document pole flexure, just for kicks.

Oct 21, 2021 at 3:04 pm #3730211use the super-slow camera function to document pole flexure,

I want to see the photos!

I imagine many others would too.cheers

Oct 21, 2021 at 6:21 pm #3730223Roger, I’ll do my best. Using 10x8mm poles at 1.5 m length is a bit of an expiment in pushing the envelope. Stability of the poles, I think, will depend on the spatial stability of the apex. This tent has apex guylines going in the two directions orthagonal to the inverted-V pole set, so I’m hoping the apex will stay stable in space. But if the windward panels deflect enough, pulling the apex in the direction of the windward side, I think the pole on that side will bend. But that’s if the tent is oriented broadside to the wind. I would not pitch it that way in real life, but will for testing, for the wind could always shift. There is a high prairie near me that gets wind blasted from time to time. I’ll try to time it right and get the super slow camera going on the inside. I think the frame rate will be high enough to catch deflection of the poles from gusting.

I’ve got an anemometer of questionable accuracy. One thing I learned recently is that the weather man’s wind speed is taken from 10m height. The windspeed at tent-height will be about 0.7 of that value, according to theory. I wonder how many windspeed estimations are pegged to the weathermen’s value rather than tent-height. A decent anemometer appears to cost about $100 (e.g. Kestral 1000). Anyone know of an accurate cheaper one?

I’ve been sticking my windshirt-clad arm out the car window and think it possible to make a windshirt-flapping frequency version of the Beaufort Scale:) It would be windshirt model-specific, unfortunately.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.