Topic

MLD in sil-poly .. gamechanger?

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › MLD in sil-poly .. gamechanger?

- This topic has 75 replies, 23 voices, and was last updated 1 day, 7 hours ago by

Sam Farrington.

Sam Farrington.

-

AuthorPosts

-

Mar 30, 2023 at 9:30 am #3777610

Saw on another site that there’s an MLD Trailstar being sewn in sil-poly on their official instagram (so not exactly a secret).

https://www.instagram.com/p/CqYkinvpEgR/

The reason I say game changer is how long before other U.S. companies making somewhat similar designs follow? (though MLD would likely use materials that could take the conditions the designs call for):

The picture is of a cute doggo at the sewing station, earning that extra bacon.

Also this would solve the DCF/Sil-nylon conundrum for a lot of folks.

Mar 30, 2023 at 9:45 am #3777612The cutest sewer ever.

Mar 30, 2023 at 9:56 am #3777614I’m interested to note that MLD is building the Trailstar with silpoly. My perception is that the Trailstar is intended to be a solution to very high winds in exposed locations. I would have expected the silpoly to debut in lighter duty applications like the Grace tarp.

Mar 30, 2023 at 10:43 am #3777616I would be down with Silpoly Solomid XL..

Mar 30, 2023 at 11:13 am #3777617I’d guess that the trail star was chosen as to prototype the new fabric in order test the limitations of silpoly

Mar 30, 2023 at 11:13 am #3777618The Trailstar has lower gentler slopes and therefore doesn’t create as much resistance as the Solomid XL or Duomid.

But Ron might have chosen the Trailstar as a first go on the silpoly for the heck of it without any concern about design. I’m sure the material will go through all the rigorous MLD testing you’d expect before it’s sold to the consumer.

Mar 30, 2023 at 12:18 pm #3777620From comments that Ron has made here and there — and this is purely my own subjective interpretation — I’d say that the choice to move to silpoly is market driven not performance driven. At least as far as MLD shelters are concerned, smaller mids supported by a central pole just aren’t that affected by fabric stretch when subjected to moisture. And when sag does become a problem, it’s so simple and easy to fix that it’s really just a non-problem.

Nevertheless, “silnylon is outdated” is by now a well established meme. Ironically, the meme was largely created on the basis of silpolys that contain PU in the coatings (by manufacturers who needed to privilege seam taping over performance), thereby reducing some of silicon’s best advantages. Yet here we are. Any cottage manufacturer that doesn’t use silpoly in their shelters today is probably faced with declining market share. Ron is probably testing to make sure that it meets the minimum performance requirements in the field. After that point, it doesn’t matter which is better because the meme and influencer driven market has already decided.

To be honest, when I saw Ron’s post on IG, the first thing that came into my mind was, “Quick! Better grab a Trailstar or Duomid in MLD’s high performance 20D silnylon while still available!”

Mar 30, 2023 at 1:03 pm #3777626I didn’t know MLD used any Silpoly. I’m interested to hear Ron’s thoughts as there are some things I really like about the Silpoly on my X-Mid though I will admit I don’t have the confidence I have with Silnylon when it comes to tear strength.

Mar 30, 2023 at 2:55 pm #3777634I think a high quality sil/sil poly that I imagine mld would only work with would be more than just meme marketing. mld has integrity and a reputation for quality that I doubt they’d want to risk for extra sales. I seem to recall ron saying he had found a poly fabric that met his standards and was worthy of testing out. I assume this means sil/sil not sil/pu

Mar 30, 2023 at 4:08 pm #3777639I think a high quality sil/sil poly that I imagine mld would only work with would be more than just meme marketing. mld has integrity and a reputation for quality that I doubt they’d want to risk for extra sales. I seem to recall ron saying he had found a poly fabric that met his standards and was worthy of testing out. I assume this means sil/sil not sil/pu

I did not suggest that this potential switch was for extra sales. What I said was that MLD has probably (almost certainly) been losing sales that otherwise would have gone their way because of the indiscriminate preference for “silpoly” (which is a category so large and irregular that it’s close to meaningless) that has taken hold, despite using a 20D silnylon fabric that is of superior quality and well suited to center pole mids.

I have no doubt that MLD would not switch fabrics if it didn’t meet certain standards. After all, MLD has refused in the past to go below 20D silnylon and stopped making shelters in CTE1.08 DCF for that very reason.

If the new silpoly offers other advantages over the current 20D silnylon besides the “won’t stretch when wet” meme which is practically meaningless for single pole mid designs then that would be interesting but “silpoly” in itself isn’t necessarily something to get excited about. Lower weight at greater strength, reduced cost, lower environmental impact, higher UV resistance, etc. — now those are the kinds of things that I would find really exciting.

Mar 30, 2023 at 4:11 pm #3777641“At least as far as MLD shelters are concerned, smaller mids supported by a central pole just aren’t that affected by fabric stretch when subjected to moisture.”

I have Ron’s Solomid XL in sil-nylon and am VERY happy with it. It’s my go to shelter. On initial set up in camp, I check and tighten the tension at the 4 corner stakes after about a half hour and that’s usually the only adjustment I have to make. If it DOES rain in the night and I get a little sag, it’s easy to lengthen the pole from the inside. EASY PEASY!

I’ve gone through high wind hail storms in this shelter without concern. Sil-poly should make an excellent shelter even better.

Mar 30, 2023 at 6:01 pm #3777649“silnylon is outdated…. was largely created on the basis of silpolys that contain PU in the coatings (by manufacturers who needed to privilege seam taping over performance), thereby reducing some of silicon’s best advantages.”

It sounds like this may be referring to my tents, but I use PE (not PU) on the inside because it lasts longer than PU and can be seam taped. It is true that I think it’s worthwhile to seam tape or otherwise seal a shelter but that doesn’t mean our poly is substantially weaker.

Most cottage companies that have switched to 20D poly with sil/sil coatings are getting that from a certain fabric mill in Korea. They are a good mill and have some very nice fabrics so companies are making very nice tents with it, but their sil/sil 20D polyester is not meaningfully stronger than what we use. They approached me (and most cottage companies) about using their sil/sil 20D so we sent some for 3rd party testing and the tear strength was good but roughly similar to the sil/PE 20D poly we use. I even sent our fabric to them to let them test it and they agreed our poly was ‘very good’ and stopped trying to sell us theirs.

All that is to say, most of the 20D sil/sil poly is coming from the same source and speculation about this sil/sil material being substantially stronger is generally not the case. It’s good fabric, but quite similar. I expect it is possible to make a sil/sil polyester than is stronger than what we use, but the sil/sil ones I’ve seen have thus far tested similarly.

Mar 30, 2023 at 7:57 pm #3777673I would be down with Silpoly Solomid XL

Could be what I’ve waited for too. DCF in 0.75 just doesn’t pack down nicely in these lower volume packs. Hope it would be offered in a light-grey, silver-grey, for those low mileage days.

Apr 1, 2023 at 9:59 am #3777797I use PE (not PU) on the inside because it lasts longer than PU and can be seam taped. It is true that I think it’s worthwhile to seam tape or otherwise seal a shelter but that doesn’t mean our poly is substantially weaker.

Both polyester and polyether are types of polyurethane. The advantage of PE as a coating compared to PU is that it is much more resistant to hydrolyzation.

Compared to silicone coatings, which can strengthen a fabric, PU coatings weaken it in terms of tear strength. Obviously, you’re not claiming that PE coating performs like silicone to strengthen a fabric’s tear strength. You’re just saying that the coated polyester you’re using (one side coated in silicone the other in PE) is not substantially weaker compared to other fabrics, not compared to what that same fabric substrate would be like if it were coated exclusively with silicone on both sides. Please correct me if I am wrong. _/\_

Apr 1, 2023 at 2:48 pm #3777823I generally agree with that characterization….with a few notes to add.

Ron had a poetic post a few months ago talking about how complicated fabrics are where he cautioned against thinking about things too simply (e.g. some nylons are much stronger than some polys, but some polys are much stronger than some nylons…etc). Similarly, SlingFin had released some content on how complicated fabrics are to show their 10D sil/sil nylon is stronger than a lot of 20 sil/sil nylon. I’m finding the same thing where it’s really hard to predict the performance of a fabric just from the headline info. There are a huge number of factors that go into a fabric including fiber type, different chemical formulations of the fiber types, denier, threadcount, coating types, coating thicknesses, weave, heat applied, calendaring, effects of dye, UV additives, FR additives, ripstop….etc. As such, it is risky to assume higher performance from an on paper edge in one or two factors. With strength tests, we can tell which fabric is stronger but we still can’t really say why that is because of all the variables.

Anyways, yes if everything else is equal then sil/sil will be stronger than sil/PE but when the sil/PE is dominantly sil and the PE coating is just a thinner coating (so that it can be seam taped) then the difference is relatively modest such that a sil/PE could easily outperform another sil/sil poly if it has advantages in some of the many other variables. So I wouldn’t immediately expect a substantial edge for either. Right now the sil/sil poly 20D that many shops are switching too is roughly similar in tear strength to the sil/PE 20D poly that we use. I think both of these are good fabrics that work well but with continued technical advancement we’ll see better materials than both in the next few years. This continued advancement might be hardly noticeable to customers since the current polys are pretty good already.

I do know one of the major cottage companies currently offering 20D sil/sil poly is doing serious testing on a sil/PE poly for a possible switch next year. I’m not sure if that is driven by a desire to start seam taping or because this sil/PE has higher strength (again not because of the sil/PE but because of other factors that might outweigh the effects of sil/PE) but regardless they – like everyone – are working hard to source increasingly good materials that will work well for the priorities they have.

Apr 1, 2023 at 6:35 pm #3777841Ron had a poetic post a few months ago talking about how complicated fabrics are where he cautioned against thinking about things too simply

Perhaps this post?

My observations about UL tent fabrics I’ve learned over the last 20yrs.

1: Some equal weight Silnylons and SilPolys are way better than others.

2: Some 20d silnylons are way better than some 30d Silnylons.

3: Some 20d silpolys are stronger than some 20d and even 30d silnylons.

4: Some 20d silnylon stretches way less than some 20d silpoly, even when wet.

5: Some/Most of the 20d silpoly and 20d silnylon availble to DYI’ers though resellers are not as good as the ones used by some tent manufacturers.

6: No one on any forum hardly ever talks about dry stretch on the bias. That is very important to making curved or large panels function well. Some equal specs fabrics ( 20/30/poly/sil/pu/nylon/etc) stretch on the bias very much different. Some as much as 400% more than others. I think that the dry stretch is far more important than wet stretch, at least for MLD shelter. It’s not part of marketing lit so no one talks about it. I’ve seen some dry stretch (nylon and poly/ ripstop and non ripstop) that is bad and only get worse when wet. Could this be part of the over generalized myth of wet stretch Silnylon vs SilPoly? Is there even a lab test standard for this? I don’t know. I only know how I measure.

7: Some Silnylons wet stretch less than other Silpolys. Some silpolys stretch a LOT less than other silpolys. Same goes for Silnylons.

8: Some runs of the exact same fabric from the same factory perform different. What vintage year was your 20dSilwhatever? Ohhhh- 2017 was a great year!

9: All discussion of tech fabrics exist in a tiny time compressed bubble, but get repeated as current fact for many years.

10: Labs tests on any tent fabric is only a starting point to understand the end shelter. Design, construction and sealing often is more important to any end function vs the raw material.

11: A DYIer tent fabric choice is almost always great, no matter what happens. Same fabric in a mfgrs tent is not always that great.

12: A higher HH coating can make a fabric weaker due to the higher+longer heat drying process of curing the coating. Do you really want a super high HH…maybe not?

13: Some 10/15d silnylons are stronger with less coating. How little can your marketing shaped perception accept?

14: I finally saw a 20d SilPoly that, on balance for 10+ factors, I think is sort of pretty good. Nope, I can’t say what it is except that it’s nothing on any list or post from any place anyone here has ever noted.

15. Be careful making generalizations. They can often be generally wrong. I’ve been wrong so many times I now understand the massive amount of what I do not know, maybe. Probably Ok to disregard all I’ve said above, except #14 and #15.

Apr 1, 2023 at 7:40 pm #3777844John Muir has some “poetic’ texts about the Sierra too. These give a far more accurate account of the Sierra and elsewhere than most scientific texts from the day. And in fact, Muir’s musings on the geology of the Sierra proved more accurate than those of the leading academic scientists of the day.

this isn’t a critique of Dan’s throw away phrase. It’s just a push back against the modern tendency to dismiss poetry as second class information. poetry isn’t “information”. One doesn’t order information from the menu of a good restaurant. One orders poetry. Muir was trained as a scientist, but he appreciated the distinction.

I know some scientists who work in the Sierra doing research. they love their work, but they love being there even more for the poetry of their surroundings.

edit: sorry for the hobbyhorse. i also hang out with scientists ( I live in berkeley Ca. and scientists are everywhere) for whom “poetry” is bandied about as the new N word, in that it’s meant dismissively or worse. gotta push back!!

Apr 2, 2023 at 2:35 am #3777849Talk about poetic justice. Look at where this thread has wound up.

So “silpoly” isn’t necessarily a “gamechanger” after all — especially not in a monopole mid construction made with a superior silnylon (which was the original topic of this thread).

Maybe it’s time for the poets and the scientists to join hands in debunking the myth of generic superiority (i.e., the idea that whatever silpoly is generically superior to whatever silnylon, or vice versa).

I certainly fell for the myth a few years ago and purchased mids made with 20D silpolys that were certainly lightweight but “meh” at best performance-wise in demanding situations. By contrast, a mid more recently made in a wonderful sil/sil 30D silpoly really impressed me, but the fabric was ever so slightly on the heavy side.

Fast forward to today, the myth of generic superiority has become a central part of product lines, guerilla marketing techniques, backpacking magazine reports, and online forums.

Maybe those of us who are true poets (or scientists) — those who would “prefer not to” — will just have to keep their heads down and their eyes sharp against the herd.

Perhaps the most poetic remark in the industry comes from Scandinavia (where else?), Silnylon. It’s Alive!

I’ve often wondered why superlative 10D silnylons, such as those used by some Scandinavian manufacturers (and others), are not more widely available, especially for the market niche devoted to trekking pole supported minimalist shelters? Even among those 7D and 10D fabrics that are available, not all are equal. Some are manifestly superior to others in terms of performance (*where seam-taping is not a metric of “performance”, lol).

In the end, end-users have to rely on manufacturers like Dan and Ron for information and innovation. Unfortunately, the idea of market driven innovation is as much of a myth in some respects as the idea that generic silpoly is better than generic silnylon.

If MLD were losing market share simply because the herd has been trained by certain parts of the industry to think that generic silpoly is better than generic silnylon, then the switch to silpoly might not be innovation so much as survival.

Ideally, third parties without a monetary interest in the game but with crucial access to industry insiders would defend both innovation and consumer education against the herd-trainers. Now that would be a game changer.

Apr 2, 2023 at 12:16 pm #3777868All genuine and intuitively thorough conversations here. Enjoyed it. However, has anyone given any thought to the timely matter of the date around this thread?? Happy April fools day!

Apr 2, 2023 at 1:22 pm #3777875Initial post on the MLD IG page was 3/30 but 🤔

Apr 3, 2023 at 12:47 am #3777940An April fool would not be so tedious.

I don’t expect merchants to disclose private info. Also, don’t expect musings to help with choice of materials.

But I did continue with tests of silpoly tarps, despite having no clue whether the sil/PE is a blend or two different coatings on opposite sides of tent fabrics. Or for that matter the ratio of the different coatings if blended. I may never know; but intend to continue obtaining information to make choices about fabrics. One sure way to do that is to assess water resistance of the fabric, and another way is to assess the ability of a fabric to hold its shape. And both ways are feasible without great expense.

As readers of BPL may know, I’ve been testing tent fabrics for waterproofness and elasticity for a number of years using prototype canopies and plastic embroidery loops to expose tent and tarp fabrics to stormy weather.

In doing so, I discovered that all the polyesters held their shape when exposed to moisture in the air, and that all the nylons did not, although most nylons were water resistant when exposed to high water pressure. But the polyesters varied greatly with respect to waterproofness. The logical deduction suggested choice of the waterproof polyesters.

The reason for this choice is that I design or remodel tents that are supported by flexible tube frameworks that are self-supporting, or free standing, to use the popular term. For such designs, it takes BOTH the tent fabric and the flexible pole framework, working together, to keep the tent taut (unflappable) and even more important, able to hold its shape in high winds accompanied by all the forms of precipitation experienced by backpackers; from ice storms to drizzles. Otherwise, the tent will eventually fail, possibly causing death or serious harm to occupants, and almost surely to soak them. Roger Caffin has some great photos of free-standing tents blown flat that illustrate this.

I was trained to base decisions on evidence, not mere speculation, and will continue to do so.

Apr 7, 2023 at 6:55 am #3778285Yeah, I suppose you’re right. A dog sewing the new prototype from a company that seems to be adamantly not pro sil-poly, does sound like a legitimate venture. Good point.

Apr 8, 2023 at 2:12 pm #3778420As readers of BPL may know, I’ve been testing tent fabrics for waterproofness and elasticity for a number of years using prototype canopies and plastic embroidery loops to expose tent and tarp fabrics to stormy weather.

Sam, obviously I’ve been around here a while but I’m really unaware in what capacity you’re testing fabrics. Are you a curious amateur interested in experimentation and MYOG, or are your tests in a professional capacity for a company that sells tents? Or something in between?

Thanks!

Apr 9, 2023 at 11:17 pm #3778515bradmacmt: Not even something in between. But do not consider myself an amateur because I’ve been doing MYOG and backpacking for a long time, and am totally unimpressed with the tents on the market; (but will save you the pain of a rant). That’s why I got into MYOG, then called DIY, a long time ago, and have never looked back. I test fabrics with simple tests just because I don’t want to put extensive time into an inferior fabric. If you’ve been on BPL a while, you may have seen tests by Stephen Seeber and Richard Nisley citing me as the source of samples. Also, I don’t want to take up their time when simple tests tell me more actually than expensive HH testing rigs. And, one man’s “professional” can be another’s nightmare, whatever the profession may be. That is why I try to outline the evidence, reasons and experiences behind my opinions. Most experienced members do on BPL, which is why I enjoy the forums and appreciate their contributions so much.

Apr 10, 2023 at 3:27 am #3778517I saw this on trek-lite a couple days ago but was too busy to look at MLD’s own site. Guess it’s official.

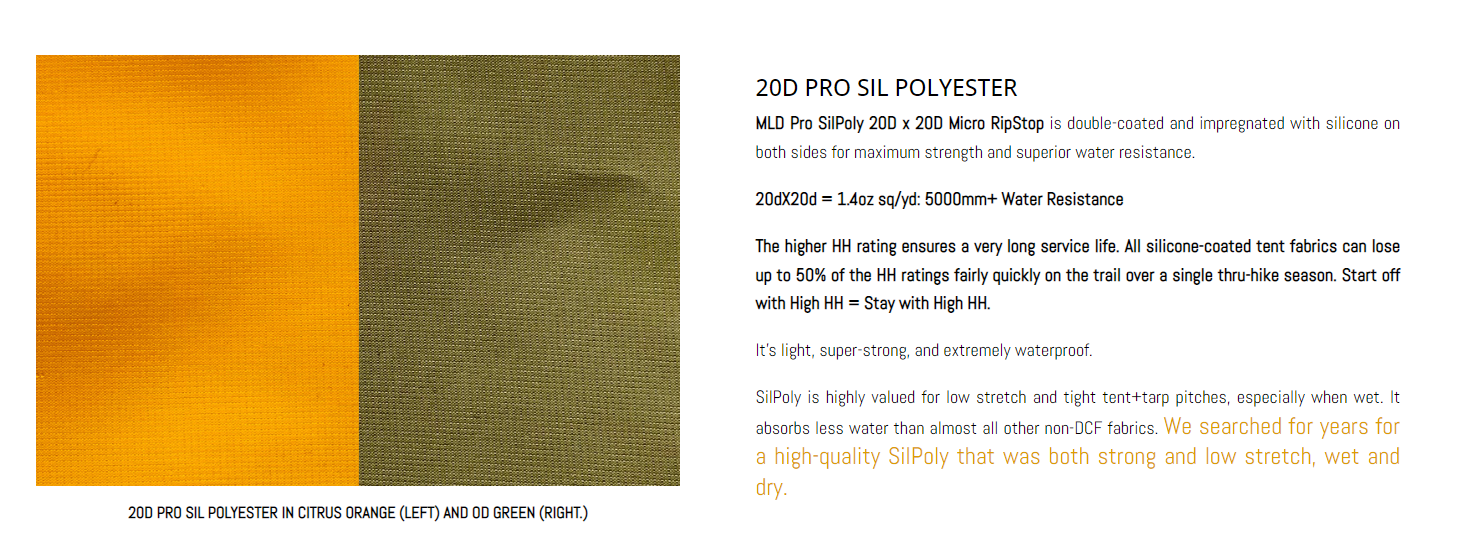

It’s not available as an option on the individual product pages (only listed on the Fabric Mojo page so far) but it is already being used in production. The HH (5000) is very high for a sil/sil fabric. Hilleberg achieves their claimed 5000HH by using three coatings sil/sil on each side. The claimed HH of their fabrics today is higher than it was a decade ago (when the 30D was rated at 3000mm). Presumably coatings have improved. This new 20D silpoly weighs 1.4osy, exactly what the old 20D silnylon weighed. A substantial chunk of that (maybe 0.2 osy) must be in the coatings, new and improved as they may be. Would be interesting to know the tear strength but 1) it is polyester and presumably sil/sil so I think we could guess that while it’s probably only 1/2 to 1/3 of silnylon at comparable weight (*using Hillberg’s claimed stats as the gold standard), 2) it’s certainly high enough.

Note that the former 20D silnylon is no longer listed at all on the Fabric Mojo page. Given the way the market is at the moment, I’m not going to hold my breath for Ron to explain publicly the differences between the two fabrics. Too bad neither are available to the DIYer for “off trail” projects like Sam’s tent or my octagonal mid.

I was going to say that the disappearance of the 20D silnylon leaves me feeling misty-eyed, but that word “mist(ing)” rings alarm bells in relation to “silnylon” (blast from the past), so maybe I’ll just keep my nostalgia to myself.

Good luck to Ron and MLD with the new fabric! Hope those gamechanger folks like the OP have a field day with it!

The park of manufacturers offering mids in silnylon has shrunk quite a bit. Locus Gear, Tipik (as an option next to silpoly), and 3F UL are some of the remaining names that come to mind for silnylon mids these days.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

HAPPENING RIGHT NOW (February 11-21, 2025) - Shop Hyperlite Mountain Gear's Biggest Sale of the Year:

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.