Topic

Help chosing my "last" sewing machine

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Help chosing my "last" sewing machine

- This topic has 13 replies, 2 voices, and was last updated 4 years, 12 months ago by

Geoff Caplan.

Geoff Caplan.

-

AuthorPosts

-

Sep 25, 2019 at 4:57 pm #3611694

Hello –

I’ve been getting into MYOG over the last couple years, making a few tarps and hammocks (UL fabrics, siliconized for the tarps) as well as some heavier hear (bikpacking bags; I’ll attach a pic below; I’m OK with design, stitch quality leaves a ton to be desired. To be clear; i know skill is a limiting factor :) )

I’d like to upgrade from my home machine. I don’t have a fixed budget, and want to have something that I will be happy with (and ideally continue to have use for, even if i buy more equipment) for “ever”. Obviously many threads on this, but most seem to focus more on price than I’d like to. I’m not rich, just very busy, and want to buy a long-term keeper. I have nothing against used machines, and would buy if the right one popped up, but I the easy availability of new is a huge plus, as is the warranty and lesser risk of problems).

I have looked into a wide range, from:

- Industrial machines or high end consumer mechanical machines, often straight stitch only, with talking foot & likely compound feed: from Juki, babylock, Consew, etc

- “pro-sumer” such as Janome 6700p or new M7* (The M7 is likely the upper end of what I would spend; i love the deep table (13″) for some very large projects I’d like to tackle; but I’d be paying A LOT for features that are really geared to quilters/crafters)

- nice home machines: Brother bq950 and others

The options are … a bit overwhelming. The following stand out as features I care about:

- Stitches: 90+% straight stitch; but if i go straight-only i would need to retain or buy a second machine for at least diagonal stitch (bias or stretch work). I could probably make due with my current machine for that for now.

- Threads: primarily “medium”, TEX 30~70 (Mostly use Gutermann Tera 80 ~ Mara 70 and 50); I do have some heavy canvas and cordura work i want to do -BUT recognize that my UL fabric machine, even if industrial, may not be a great fit ??)

- Throat depth: Larger the better. ~8.5″ seems to be the current ~min, but 10+” would be a big benefit

- Feed: it seems that build-in walking foot would be a plus, and that true compound feed would be a HUGE plus (needle moves, while Down, in conjunction with 1/2 of the presser foot)

Many thanks for your input!

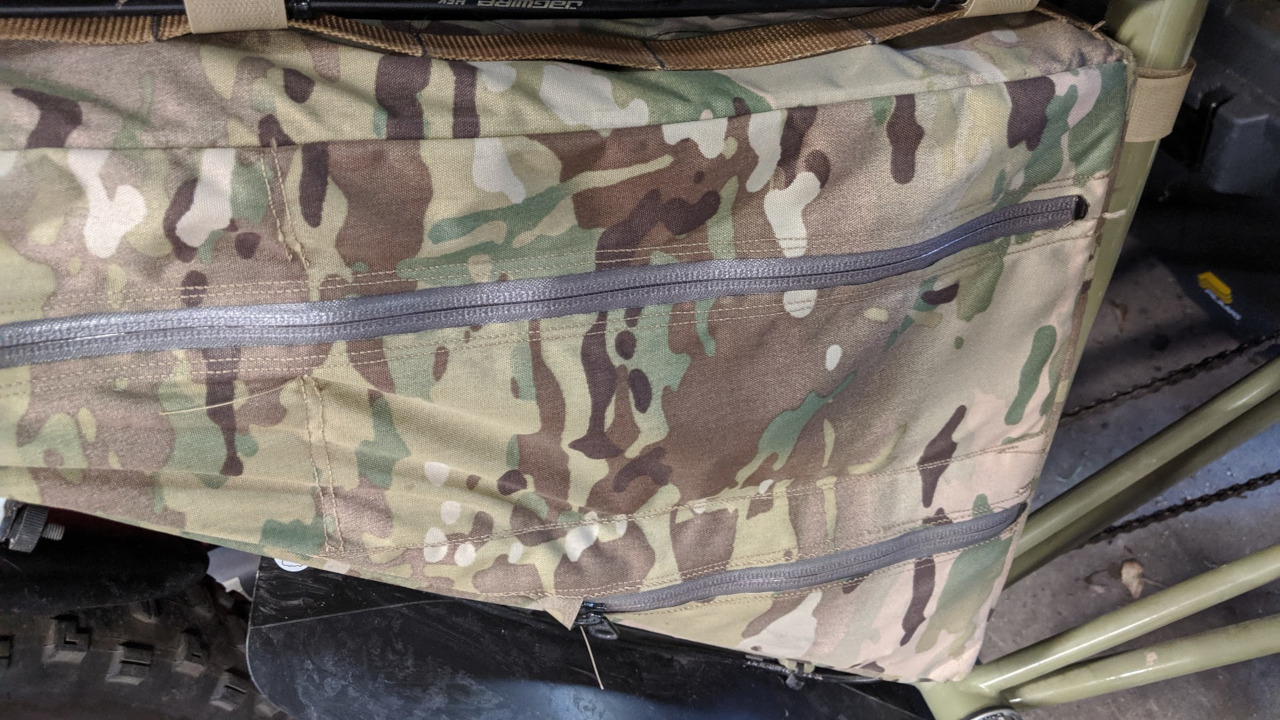

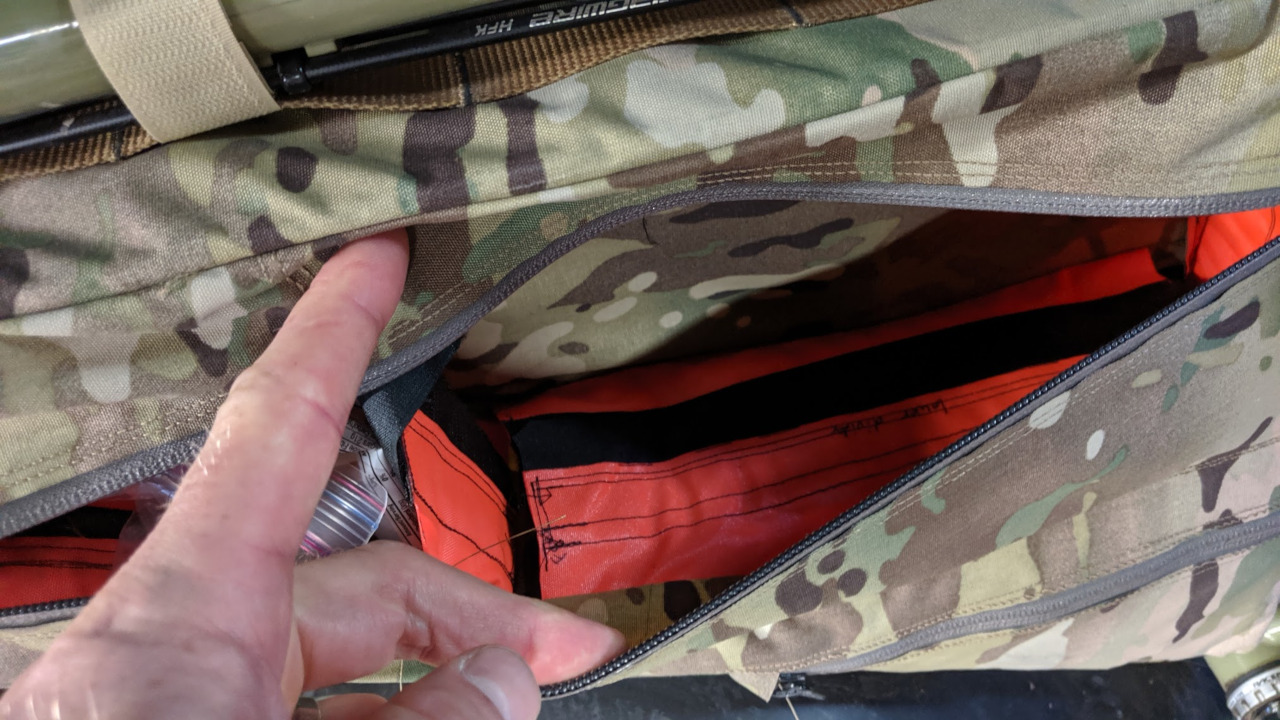

Sep 25, 2019 at 6:39 pm #3611705as an example of the non-UL stuff I’ve been working into; this was my first attempt at any sort of pack; turned out great except for stitch quality… picture after several weekends of use.

inner horizontal + vertical reinforcement to prevent barreling.

Sep 25, 2019 at 7:06 pm #3611706

Sep 25, 2019 at 7:06 pm #3611706Singer 20u?, switch out the clutch motor for a DC electronic unit.

Have you looked at the Sailrite stuff?

Sure there are many more experienced users out there with experience of better/ more expensive machines but these are the two I have experience with and seem pretty versatile.

Sep 25, 2019 at 8:41 pm #3611708It seems reading around that sailrite isn’t great for ultralight things (and seems to have mixed reviews for the heavy canvas it’s geared towards ??) The Sailrite ultrafeed LSZ-1 (straight + zigzag) looks (on the spec sheet) to be just about perfect … but the reviews, especially for UL don’t look good.

Do you have experience with that one?

Sep 25, 2019 at 9:19 pm #3611709I have an almost 30-year-old Swiss Bernina 1001 (now called the 1008, which appears to be identical to my machine…) which does light to medium work very well. It lacks a walking presser foot though and bogs down when asked to sew multiple layers of hypalon or lots of folded layers of coated fabrics (or the needle deflects and breaks), so I just got a Sailrite LSZ-1. The Sailrite is a very basic machine and does core tasks well but is not very refined. You get what you pay for, which is not necessarily a bad thing since it is pretty inexpensive. It certainly does stab through thick jobs without much hesitation plus the walking foot is excellent, but I am doing most of my panel creation and detail work on the Bernina and then switching to the Sailrite for joining the backpack panels to each other, adding webbing, and so on. You could probably use the Sailrite for lighter jobs, but if you have experience using a smoother, higher-end machine you may find it a bit kludgy. I would only consider it to be a do-it-all machine if cost were the overriding factor. If you are ready to spend a few thousand dollars and want one machine to do all tasks, then get something nicer. I’m glad I got the Sailrite, but that is because I still have my Bernina.

Sep 26, 2019 at 1:36 am #3611735For a “last” machine – consider the Juki 1541 for heavier materials – like 70d nylon or heavier. The 1541 has needle feed and walking foot, extra large bobbins and plenty of presser foot height and arm length for sewing think, bulky items. You can get it with a quiet servo motor with needle synchronizer. The servo give you precise low to high speed control and the synchronizer lets you control where the needle stops when you stop sewing, either in the up or the down position. You can sometimes find a used 1541 on Craigslist for around a $1000 or so with a clutch motor and then add a servo motor later.

For lighter materials, look at the Juki 5410 or keep using your existing machine.

Sep 26, 2019 at 6:09 pm #3611798The Sailrite machines are pretty crude with obvious finish and function shortcomings. And, as reviewers state, not very smooth for UL or even medium-UL!

The 1541 is a beast, but it’s also exceptionally high quality. Even then it wouldn’t be my choice for the ‘only’ and ‘last’ machine. It’s made to sew extremely heavy duty projects like thick leather, circus tents and safety hardware. I heard one cottage pack maker say it’s his least used machine and only keeps it because it was so damn hard to get up to his shop!

If I were to have just one main machine it would be a needle feed (as opposed to walking foot) medium duty model like a Juki 5410 or 9010. Get the small and big needles with the appropriate thread and tents and packs will be a dream to sew. And you can easily switch out the dogs etc to accommodate anything from 7d to multiple layers of 1000d ballistic, extending the range of gear one can sew. Save up and buy once.

For reference I own a 5410, 9010, 1541 and three 8700.

Sep 27, 2019 at 2:33 am #3611853Yup, +1 to @roamer’s recommendation. I also own a Juki DLN-5410N-7 and a Juki DDL-5550 (clone of the 8700, or other way around). I’ve got both the heavy and light feed dogs/presser feet for the 5410 and have sewn the lightest 0.66 Oz fabrics up to 1/8″ thick solid plastic HDPE sheet with it. You can follow the tale of how I acquired it a couple of years ago if you search for “Industrial Needle Feed Sewing Machine” here. I’ve only had the need for a zigzag stitch once when I made a beanie hat (did that on a 50 year old home machine). Otherwise, the straight stitch has been fine. I’ve made many jackets, a wind shirt, a couple of sleeping bags, a couple of backpacks, and am now starting on a tent, all with the 5410. And by the way, I never tack anything together before sewing, it’s that good!

Sep 27, 2019 at 4:18 pm #3611892@kurogane / @roamer (Nunatek – great gear! Thrilled to get a reply here! :) )

Thanks for the input. I have heard several recommendations for the 8700, although it obviously doesn’t have any of the feed “assist” features. The 5410N looks interesting; middle-high in the price range, but searching the model number it does seem common for lightweight.

I have some confusion about needle(only) feed: Several sources have said that this is harder on fabric than walking foot, due to the the needle’s small surface area (compare to say walking foot) taking all the sheer-loads not handled by the drop-feed. Sounds like not a concern?

Also, since posting I’ve become aware of “Pin Feed” as seen on the Brother pq1500s / “Babylock Jane” – this would be pretty similar mechanism to needle feed; any thoughts on those particular machines or pin (on feed dog) vs needle feed?

Thank you!

Sep 27, 2019 at 10:04 pm #3611916No, I have not noticed this re needle feed.

We find them more precise and accurate than the walking foot variety, and the sewing experience is less jack hammer and more… sewing machine like.

Also, for most garments and quilts you will want to use maximum tex40 thread/NM90 needle size. Some walking foots does not come recommended for sizes this small.

Imo, for most pack making, all tent/tarp work and quilts the basic 8700 in the light/medium config, is the second choice after needle feed – and can be had for far less. If one is only doing packs the 8700H (for heavy duty) is a steal (for packs use tex70 and 90 thread and NM110/120 needles).

Sep 28, 2019 at 1:22 am #3611930I’ve never observed the needle feed elongating holes in the lightest weight fabric due to the top layer of fabric dragging on the presser foot. Before I used it, I had imagined that might be a problem, but it definitely has not been. I can’t remember exactly, but my impression after researching walking foot machines or combination walking foot/needle feed was that they were too heavy duty for light weight fabrics, or way out of my price range (like many thousands of dollars).

As for the pin-feed machines, they might be similar. I can’t remember if the ‘pin’ on the feed dog goes through both layers of fabric or not. They might be a cheaper alternative to the industrials, but they won’t give you the same power or precision. It’s pretty fantastic to be able to do single stitches at a time without worrying if the needle will actually go through all your material! The pedal-activated presser foot raise and the automatic thread cutter are pretty fantastic as well.

Sep 28, 2019 at 3:00 am #3611942Alright, if good enough for nunatak, good enough for me;) so I’m leaning towards either the needle or pin feed systems,straight only stitch.

I’m trying the babylock Jane (pin feed, undercarriage bobbin) next week, and IFF it does well on silpoly I will likely get them to order that or the cheaper brother 1500s.that would leave me enough to also upgrade my home machine next time I really need zigzag.

Else, it’s looking like the juki 5410n

Feb 28, 2020 at 2:13 pm #3633610So I picked up a 1541 not really knowing what I’m doing and now that I read this and after having done some test runs on X-pac and such I think it’s too heavy duty for those fabrics. I can trade it out for the DLN-5410N-7 and am thinking I should do that. I get a lot of puckering in the fabric with just two layers. I want to get your opinions though, I don’t have the room for two machines so I’d like to get the most flexible option I can. Can you all give me some feedback on it?

Feb 28, 2020 at 8:34 pm #3633654I’m going though the same process, but on a tight budget.

I’m just about to pull the trigger on a vintage Singer 201 – a specialist straight stitch machine with an industrial-style full rotary hook and a drop-in bobbin.

There were built to insanely high standard – allowing for inflation they would cost around $3000 today.

They were sold as “artisan” machines – for professionals working at home or in small workshops rather than full-on industrial settings. Though it’s claimed that Rolls Royce used them for sewing light leather on their door panels. So very much at the heavy end of the domestic spectrum.

I’ve tried one and the stitch quality is something to behold. You’ll find many people with the same opinion. It’s widely regarded as the best domestic machine that Singer ever made. It’s also gratifyingly smooth and quiet (I’m often sewing when everyone else is abed).

As a domestic machine, it was designed to handle a wide range of fabrics from light to heavy. At the top end, I’m prototyping packs with a very dense double-coated ballistic nylon that the UK army uses for artillery gun covers. I can barely scratch it with the tip of my sheers at full force. It sewed 4 layers + 2 layers of heavy webbing without a hitch, and that’s with the original 70 watt motor – the gear train is very efficient. It also handles very light quilt fabrics just as well. I’m told it’s not so good for stretch fabrics, but it does everything else I’ll every need. The only drawback is that the low-shank foot won’t lift very high, so I’ll have to design around that for hip-belts and the like.

Plus you get high-quality bar-tacking using the button-hole attachment. It also has a zig-zag attachment, but they are hard to find and reviews are mixed.

The mechanism is superbly engineered and easy to maintain. The service manual is available for download online and spares are plentiful and affordable.

Plus if you get a hand-cranked model or a model with an external motor you can upgrade inexpensively to a good quality 120 watt motor, which will turn it into an absolute beast. It’s a 5 minute job that I’ve done before. An experienced engineer has assured me it can take the power.

They are easy to find – over 60 on eBay.co.uk right now, and it’s common in the US too. You can get a tatty one for $100, and a fully serviced one with nice cosmetics for a bit over double. So you’re getting a semi-pro setup for not very much. And if you’re short of space, you’ll find plenty that are set up for table-top work. And it’s luggable too – you can take it to workshops or on holiday.

No walking foot, unless you use an attachment. But I find I can avoid that requirement with liberal use of basting tape to keep the top and bottom layers together. Probably not practical for a commercial operation like Nunatak, but as MYOG builders our time isn’t quite so valuable.

So – affordable, high-quality, reliable, easy to maintain and repair and a pleasure to use. Good enough for me…

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

LAST CALL (Sale Ends Feb 24) - Hyperlite Mountain Gear's Biggest Sale of the Year.

All DCF shelters, packs, premium quilts, and accessories are on sale.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.