Topic

guylines: "straight in" vs loop

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › guylines: "straight in" vs loop

- This topic has 19 replies, 8 voices, and was last updated 8 years, 10 months ago by

Bob Moulder.

Bob Moulder.

-

AuthorPosts

-

Mar 3, 2016 at 10:37 pm #3386631

i havent seen any discussion or testing about this on da intrawebz before … so ill kick it off

basically there are two main ways to set up guylines

- directly into the guypoint through something like a line loc 3 or a blakes hitch (zpacks for example)

- looped back to itself through and then through some kind of tensioner such as a micro line loc (most larger manufaturer tents)

the latter loop style HALVES the force on the tensioner vs putting it directly into the guy point … thus reducing the potential for slipping

what i find most interesting is that most of the stories of slipping you hear of are of line loc 3s set up directly through the guypoints … you hear much less of micro line locs slipping, likely because they need to be setup in a loop configuration

now going directly in has the advantage that the length is variable from 0 => the full length of the cord which may matter if you need to slam the walls to the ground

but where the guypoint is higher up, theres no real advantage other than a miniscule point of weight savings …. at the cost of doubling the force on the tensioner vs a loop setup

this is especially true on areas of high stress such as ridgeline guypoints

interesingly enough the great skurkas “pulley” method reduces the force even more by around 2/3 on the tensioner/knot as compared to doing directly in

interestingly enough ive never seen a discussion about it as all the numbers can be confirmed with a bit of testing and a cheap fishing scale …

;)

Mar 4, 2016 at 1:27 am #3386645Good points on the pulley factor.

One way to take advantage of the pulley effect with lineloc3s would be to double the line length, and have the fixed end of the line tied to the same loop as the lineloc3. Stake through big double loop.

Though, other slippage factors to consider :

- Most lineloc3 slippages can be attributed to not using 3mm line as they are designed for.

- Lineloks (by Clamcleats – note the k) work in a different manner, so grip the line differently. I have had micro Lineloks V-groove wear down and slip on 2mm line after a season on repeatedly bad windy weather (Scotland and England) on trips

Mar 4, 2016 at 1:44 am #3386646It seems to me … that most of the problems come from using a string that is too thin. But as you noted, the weight of the string is very small any how.

I was using 1.5 mm Spectra on ClamCleats and it was too thin (and Spectra is very slippery). I threaded the Spectra inside either nylon or Dyneema braided cord to get extra thickness – and it worked very well, even in howling storms.

Cheers

Mar 4, 2016 at 4:35 am #3386649Depends on the terrain. Mostly I use the straight in method. I leave some 16″ lines on my tarp. They are simple 60pound fishing line. The long line at the top of the apex is longer and simply wrapped around the tarp for carrying. Pulled out, they simply go into the duff. No adjusters. It works pretty well in the ADK’s. Sometimes I take a two man tarp. These have to lines wrapped at each apex. Loop-to-Loop connectors means I can switch between Lean-to mode and A-‘Frame mode rather quickly (takes about 1 minute to change locations.) On the 4 person tarp, Both long lines are simply wrapped around the tarp for storage, but these are heavier, too. I think they are actually 2mm or 3mm.

Generally they are good for up to a 40-50mph wind. I might run into a wind that is a bit stronger, but I am usually back in the woods for any storms.

Mar 4, 2016 at 8:21 am #3386678interestingly enough there have been reports of lineloc3 slips even with 3mm cord on BPL

https://backpackinglight.com/forums/topic/68352/

note that zpacks and tarptent supply their wares with 2-2.5mm cords with lineloc3s (or did at one time)

as Mole indicated one could easily halve the load with a lineloc3 by tying the guy end back to the guy point and using the loop for the stake

its just very interesting that ive never seen anyone bring up the fact that using lineloc3s in directly the guypoints doubles the loads on the tensioner vs a loop

;)

Mar 4, 2016 at 8:36 am #3386682I just added LineLoc3s to my Copper Spur and replaced all the guyline with Lawson’s Glowire 3mm. I’m going to tell you, there’s no way that line is slipping. I sewed grosgrain to my LineLocs to attach them to my tent (just like the ones Zpacks sells pre-sewn) and before I attached them to my tent, I put the grosgrain end in my vice with the LineLoc facing me and played tug of war with the thing – never slipped a tiny bit… Either the tent is going to explode into pieces or the LineLoc is going to break before that line slips. Actually surprised I didn’t break one during my test. For tiny plastic doodads, they’re pretty tough and even better with the 3mm GloWire. FWIW…

Mar 4, 2016 at 8:40 am #3386684I like the length to be adjustable next to the tarp, not next to the stake, because sometimes I put rocks on the stake or bury it or whatever

Mar 6, 2016 at 7:14 am #3387064Given solid tie-out construction, is the force reduction significant to real-world use, or just an additional safety factor?

I put a Prussik loop on a line with a standling loop on one end and a stopper on the other, then larkshead the Prussik into the tie-out loop. Easy adjustment from the tarp side and no linelocs. Nothing against linelocs, I just don’t see the point of having the weight of them on every tieout when I’m only using 6-8 at a time at most.

Mar 6, 2016 at 7:24 am #3387067taut line hitch

Mar 6, 2016 at 7:36 am #3387069actually the tie outs are fairly irrelevant in terms o whether you use the “direct in” or a loop configuration

for example say you have a tie out that takes 30 lbs of force to the stake … the tie out will see 30 lbs no matter what configuration you use

however

- in the direct in method the line loc 3 will see all 30 lbs as well

- in a loop configuration the line loc/knot will see 15 lbs … because the load is now being split between 2 strands up till the line loc/knot

- in the great skurkas pulley configuration the knot will see < 10 lbs as the load is being split between 3 strands

all this can easily be tested and verified with a cheap fishing scale, some weights and cord …

the most common failure in very windy conditions seems to be stakes pulling and line locs slipping … the former can be remedied with beefing up the anchors and redundancy

on the latter the line loc becomes a single failure point (for the guyline) … there are ways to prevent it just as tying additional knots, but that defeats the purpose of having and easy to adjust guyline …. especially if yr in conditions where you need to wear gloves in the freezing wind

youll notice that most of the major manufacturers dont use line loc with an “in direct” configuration on their guylines …

in addition i believe some smaller cottage manufacturers ship and recommend line loc 3s with 2-2.5mm lines with their tents in the “in direct” configuration which has led to folks reporting slipping issues

and them making additional instructions and vids on tying additional hitches to prevent slipping

has anyone actually done comprehensive testing on the slip/failure points of the various common UL cords and line locs/knots … in various configurations and published the results?

;)

Mar 6, 2016 at 7:44 am #3387071 jerry …

jerry …the blakes hitch makes the tautline hitch obsolete

it grips much better on slick.thin cords. is very easy to load/unload

here it is holding ~ 30 lbs of ropes in a “direct in” configuration on < 2mm cord

No slip at all

;)

Mar 6, 2016 at 8:00 am #3387073how easy is blakes hitch to untie? when it’s really tightened and used under load

Mar 6, 2016 at 8:06 am #3387074you dont untie it … you keep it permanently attached just like a line loc …

and just shift it up and down … which is quite easy even under tension if you do it properly

theres no point in always retying and untying knots in the field over and over again …

ANY knot under full tension is not exactly the easiest to untie … take that from a climber

;)

Mar 6, 2016 at 8:11 am #3387078occasionally it’s useful to untie, thread it through something, retie

Mar 6, 2016 at 8:28 am #3387080well if your talking about RELEASING the load then untying … the blakes is about as easy to untie as the tautline, slightly harder at most ..

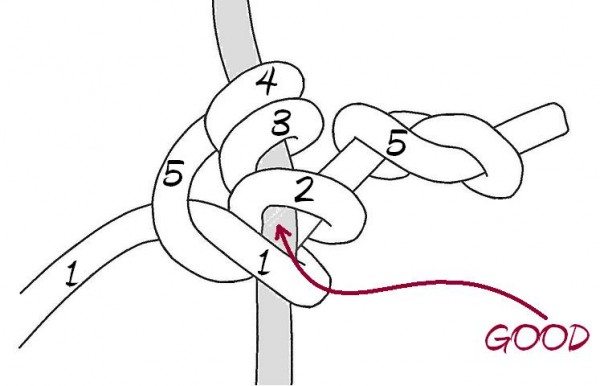

like the tautline the key is to pull on the outer loop … #5 in the diagram below on the left … note you dont need the stopper knot with sufficient tail

you can also put a separate loop of cord in the same spot (red coloured to you remember its the release) to pull on to very easily release or untie the hitch if you want … but it shouldnt be needed generally

heres folks drop testing a blakes hitch in a factor 1 fall … needless to say holding guylines is a pretty low force application in comparison

;)

Mar 6, 2016 at 8:31 am #3387081I’ve been using the Blake’s Hitch since a couple of years ago (when Eric turned me on to it!) and it has worked fine. On slick dyneema bear bag line the Blakes holds much better than a tautline hitch, though it can slip some under a LOT of tension. I’ve used it a lot on 1.2mm Zpacks line (the bright yellow stuff with the woven outer sheath and Spectra core) and it has never slipped even a micron.

Mar 6, 2016 at 8:37 am #3387082Eric

1 – would adding extra loops (past 3 and 4 in the diagram) increase friction?

2 – for a temporary application (say clothesline around a tree), you can make a bight as the tail so it can be pulled out very easily. I’ve done this and it’s very handy.

Mar 6, 2016 at 8:55 am #3387084Bob

i dont think the loop affects the friction much, assuming the same diameter cord

Here it is with a 4 rope+bags hand, around 35-40 lbs

no slip on ~2mm line and the pull cord makes releasing it (after unloaded) very easy … Youll probably want a stopper knot as in the diagram (#5 right) in my previous post though so you dont pull the entire knot apart

;)

Mar 6, 2016 at 9:08 am #3387088bob …

as to extra loops to increase friction … i realized i didnt answer that question above

the blakes is a 2×2 configuration

if you do a 3×3 configuration that would increase the friction substantially, but perhaps making it a bit harder to release

its called a Bellunese …

http://storrick.cnc.net/VerticalDevicesPage/Ascender/KnotPages/KnotBellunese.html

;)

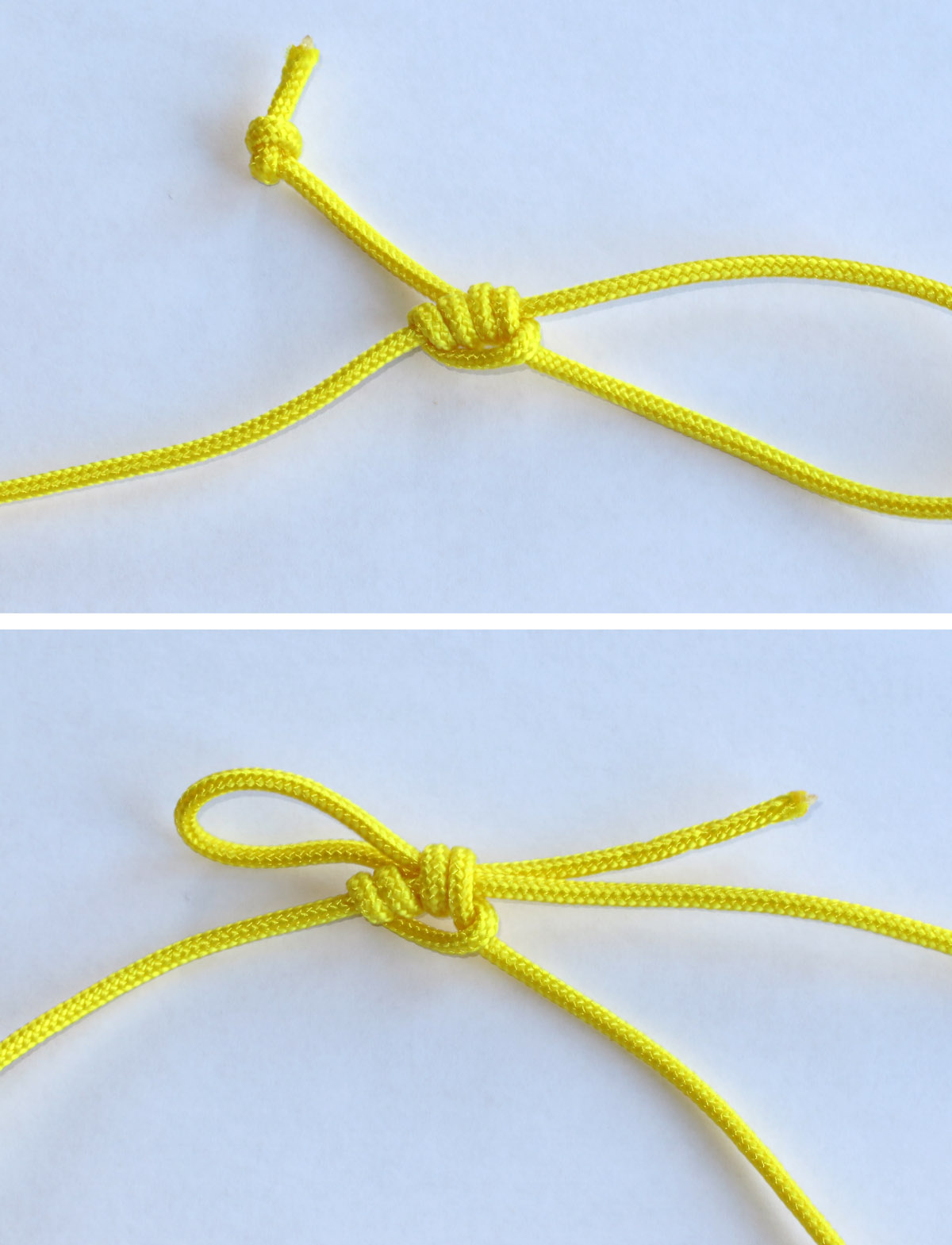

Mar 6, 2016 at 1:37 pm #3387125Tail on a bight….

If the old proverb is correct, 2 photos are worth 20K words. :^)

# 1 – Standard Blake’s Hitch

# 2 – What I meant by tail on a bight, so that it can be untied like a shoelace. Yes, Yes, a thousand times yes… this is only for non-critical, temporary applications.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.

jerry …

jerry …