Topic

Durston X-Dome 1.5 order shipping

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › General Forums › General Lightweight Backpacking Discussion › Durston X-Dome 1.5 order shipping

- This topic has 31 replies, 15 voices, and was last updated 2 months, 2 weeks ago by

Dan @ Durston Gear.

Dan @ Durston Gear.

-

AuthorPosts

-

Nov 20, 2024 at 2:12 pm #3822636

Hikers that got in on the first round of X-Dome orders just started getting email notice that rents are shipping. Anybody order one?

If you did, could you post a first use review as there precious few reviews written or YouTube.

I’ve only seen enough info on the X-Dome and Tarptent Arc Dome to see they are very different tents with different purposes in mind. The X-Dome seems to be a challenger to BA Copper Spur/Tiger Wall and Nemo Hornet/Dragonfly and similar tents.

Nov 21, 2024 at 5:04 pm #3822714Arrived today.

No thoughts yet, other than it is a very innovative tent. 2.2 pounds without stakes.

Nov 22, 2024 at 7:08 am #3822723

Nov 22, 2024 at 7:08 am #3822723there are a lot of folds or wrinkles

just an aesthetic thing, although maybe having taut, flat panels would do better in the wind

Nov 22, 2024 at 7:26 am #3822727Might do better when staked to the ground. Unfortunately, no elevated winds around here for a while, but more snow shortly. More later.

Nov 22, 2024 at 9:25 am #3822729good point. Sometimes when I set up my tent there are more wrinkles depending how I set it up

Nov 22, 2024 at 10:08 am #3822738Mine is scheduled to arrive this afternoon. An atmospheric river is hitting California after a bomb cyclone brought heavy winds and rain to the region, so I’ll be able to give it a decent test even though it’ll only be in the backyard. Stay tuned.

Nov 22, 2024 at 10:33 am #3822739There is one on sale on reddit….ulgreartrade

Nov 22, 2024 at 7:11 pm #3822809Murali, thanks for posting that. Ironically, the guy selling lives in Canada. With tax and shipping it’s $561. About same as MSRP Copper Spur HV UL 2 with tax (REI sale 30% off).

Nov 22, 2024 at 9:12 pm #3822817I think he is saying 561 Canadian dollars which turns out to be US $400….and I guess it is US $383 from Durston’s site….you could always negotiate.

Nov 23, 2024 at 2:34 pm #3822870First impression of the x-dome in my living room: The materials look and feel like premium ultralight materials. I was nervous about the carbon poles but I admit I would’ve bought carbon even if aluminum were an option 😁. I accidentally popped the ceiling with one of the poles and it didn’t shatter or crack so I’m optimistic they’ll work out like typical UL gear. This may be the most significant con compared to the Xmid: the poles really sprawl when setting up and I’ll need to be careful not whack them on rocks. I now understand the clip system to achieve outer only or inner only pitch; it’s simple and clever! Separation between the walls is perfect. The tent is extremely spacious. Compared to my Copper Spur 2p, it doesn’t feel much smaller. Imagine the Copper Spur 2p without vestibules and you’re pretty close. I think I’ll prefer the square footprint of the xdome; the protruding Copper Spur vestibules are difficult to get tight on uneven ground. I think it’ll be easier to fit in small spots than the Copper Spur. Compared to my Xmid and Dipole, I love the headroom! From my perspective given what I value in a shelter: the Xmid has more serious competitors than this thing does, all things considered. I have a feeling it will be difficult to not choose this tent for every outing, and I’m already trying to justify its weight with a couple of gear upgrades. Now to test its performance in the field!

Nov 23, 2024 at 8:10 pm #3822885Received my X Dome a few days ago and have set it up fly first/inner second and with fly/inner tent attached.. a cool design that’s different than the freestanding/semi freestanding tents I own… while the set up process isn’t complicated I prefer setting up my copper spur/quarterdome SL tents.. that may change over time as I set up the X Dome and use it in the field.

One interesting design detail is the corner of the foot end on the vestibule side of the inner tent is attached a bit differently to the tent poles than the other three corners… on those corners the grommet is attached via a short piece of fabric creating a direct connection to the pole right at the corner of the inner tent.. on the front right corner (narrower foot end) the grommet is attached to a long thin cord (similar to a guy line but much thinner) that is stretched out to secure the grommet to the tent pole using the grommet. .. kind of similar to a semi freestanding tent where the corners must be staked out on the foot end using a small piece of line or cord… with the X Dome that front right corner on the foot end is connected to the pole in a similar fashion except the grommet is attached to the end of the cord so the pole can be inserted into it…kind of difficult to explain without pictures but something I’ve never seen in a freestanding tent… Its a cool design that creates a vestibule area which doesn’t require staking out the fly using extra stakes to create that space.. its there even if no stakes are used at all..

A lot of thought went into this tent and while familiar as “freestanding” it breaks the mold if you will and given its usability and features will be difficult to leave at home except when going on a trip where weight savings is the number one priority….

Nov 24, 2024 at 8:00 pm #3822965Great detail on your post! Durston X-Mid uses a similar format to accommodate the angled interior. The difference being the X-Mid doesn’t need grommets for tent poles.

Nov 25, 2024 at 9:25 am #3822994Only have set mine up in the living room so far. Very happy with the materials. They seem more robust than my previous Copper Spur. I also found the sprawl of the poles a bit unexpected so caution if setting up indoors! The efficiency of the space is everything I had hoped for. Looking forward to getting it out on the trail. I really like the vestibule design. On the CS 1p the widest part of the vestibule was at the zipper, which meant my pack ended up in the way often. On the X dome the widest part is in the back of the vestibule at the foot end of the tent. Plenty of room for my 58L pack and out of the way. Only quibble at all so far is the cord’s David K mentioned that attach the inner on the foot end to the pole in the vestibule corner. There are 2 thin cords and about half the time would get caught on my pack when I put it in the corner of the vestibule. Hoping the cords will lay flatter with the fly staked out and that will minimize it. Since I know it’s a thing now I will be careful when putting stuff in the corner. Overall I’m very happy with the design and quality. I think my first mod is to put different color pull tabs on the 3 way inner zipper so I don’t have to sort through them to find the one I want.

Nov 25, 2024 at 11:04 pm #3823043We had some shipping delays with our X-Dome pre-orders due to Canada Post going on strike, and then an outage with our DHL service, but we have almost all the preorders sent now. 95% are shipped and the remainder should be out tomorrow.

Glad the first impressions are good. Yes it is an interesting mix of being familiar yet different. As Dave mentions, I quite like the layout of having the main part of the vestibule beside the door instead of blocking it.

“there are a lot of folds or wrinkles”

Partly that is because it is not staked out, so there is only the pole tension available with which to try to perfectly tension everything. It is hard to get that perfectly balanced but I think it turned out quite well. Once the 4 corners are staked out then the fly should pitch really nice. Also though, the base of the fly would pull tighter here without the corners cinched as much. It doesn’t matter if it’s staked out, but if it is purely freestanding then too tight at the corners is tight on top but loose around the edges, and vice versa.“I think my first mod is to put different color pull tabs on the 3 way inner zipper”

Yeah good idea. I recently was thinking the same thing myself, and we are going to color code those zipper pulls for the second run. Easy to swap them out. I am going to do one white, one black, and one the same green as the fly.“could you post a first use review ”

There is a good YouTube review today in a blizzard. The fun parts are right at the beginning and then starting around 26 minutes.

Nov 26, 2024 at 7:33 am #3823049

Nov 26, 2024 at 7:33 am #3823049my observation of folds and wrinkles was really just aesthetic, probably doesn’t affect performance, most tents have some folds and wrinkles

I wonder if having all sides tight as a drum would result in less flapping in the wind and a higher max wind speed before failure?

Nov 26, 2024 at 7:49 am #3823054When the wind blows hard enough, something has to give. Is it better to flex or to deflect? Given the 25% proposed tariffs on Canada and Mexico, China only 10%, does it really matter anyway?

Nov 26, 2024 at 8:45 am #3823057I think the proposed China tarrifs are an additional 10% above current. Whatever that is.

I can sort of see china tarrifs because of the huge trade deficit, but we have balanced trade with Canada so that makes no sense.

It would have to be an experiment to see if stiffer panel is better.

A curved shape as different aerodynamic properties

If the wind puts steady load on guy lines it would be better. If it flaps then there would be moments with lower load, moments with higher load. The highest load would be higher than a steady load.

Nov 26, 2024 at 9:05 am #3823059“I wonder if having all sides tight as a drum would result in less flapping in the wind and a higher max wind speed before failure?”

It is ideal to have the tent pitched tight, and it is quite possible to do that. Tents will rarely pitch drum tight when they aren’t staked out, but you can see in that video the pitch is quite good once it is staked.Nov 26, 2024 at 9:57 am #3823060Polyester has some elasticity. Dyneema is just going to stretch. Trying to get a perfect pitch on uneven ground…it may depend on fabric.

The 25% tariff is meant to strengthen the border. To stop the flow of immigration as well as the drugs. I guess they’ve never been to Desert Hot Springs or Landers. I wonder if a tent made in China and imported from Canada would have a 35% tariff.Nov 26, 2024 at 10:48 am #3823065Not to hijack the thread but it’s sorta related. I have always had aluminum poles so this is my first one with CF. Looks like the Easton 3.9 has an OD of 7.5mm. Dan will you be offering repair sleeves or does anyone know where sleeves for that size pole can be had? I’ve looked around the internet and the only sleeves I saw were for bigger OD than that.

Nov 26, 2024 at 11:18 am #3823066We are going to have repair sleeves in a few months, and also repair sections. If you want something sooner, Easton Syclone tubing or Easton .344 aluminum tubing will fit fairly well.

Nov 26, 2024 at 12:13 pm #3823079Thanks Dan!

Nov 26, 2024 at 12:44 pm #3823083I received the X-Dome last week and erected it in my basement. I decided to try this without viewing Dan’s video. I got stuck on the fly crossbar and then watched the video. The video pointed out the crossbar should be installed before clipping the fly to the carbon fiber poles. I then watched the rest of the video, particularly the part about pitching in the wind.

After a while, my wife came down to the basement and asked why I spent so much time lying in an empty tent in the basement. I explained to her that I was taking in all of the tent’s features that I had not previously seen in other tents, particularly the volume of space present in a single-person tent. I have never owned a single-person tent. The single-person tents I had used felt claustrophobic, and avoiding contact with frost or condensation-covered surfaces was difficult. I felt these issues would be less likely in the X-Dome.

On Saturday night, the weather forecast called for moderate winds (15-25 mph) in Rocky Mountain National Park. So, I packed up and headed to Wind River Bluffs, which features camping with decent exposure to west winds, the expected wind direction. The trail was generally covered with frozen snow, so it was a microspike day, and the winds were pretty much as forecast.

I reached Bluffs, selected a camping spot that took full advantage of the west winds, and erected the tent. The inner was already clipped to the fly. I spread the fly, with the head end facing the west wind. I staked each corner of the fly as I spread it to form a rectangle. I wanted to stake the inner and outer at each corner as I laid it out, but the inner was a bit tangled, and untangling it with the gusting wind was not an attractive option, so I simply staked the four corners of the fly. This was a mistake, and I realized I would have to stow the tent next time so that all the corner stake points remained together and easily accessible.

Next, I installed the pole set.

The carbon fiber poles are inserted through small aluminum (I think) plates. The clearance between the hole in each plate and the pole is fairly tight. The pole is easily inserted through the hole when it is perpendicular to the plate. Holding both plates together, with the holes lined up and the pole perpendicular to the plate and the plates staked to the ground to restrain the fly against the gusting wind, was a challenge. I figured out the best way to do this was to release the stake at each clip as I attempted the assembly. After a pole was inserted, I then would tap the stake back in.

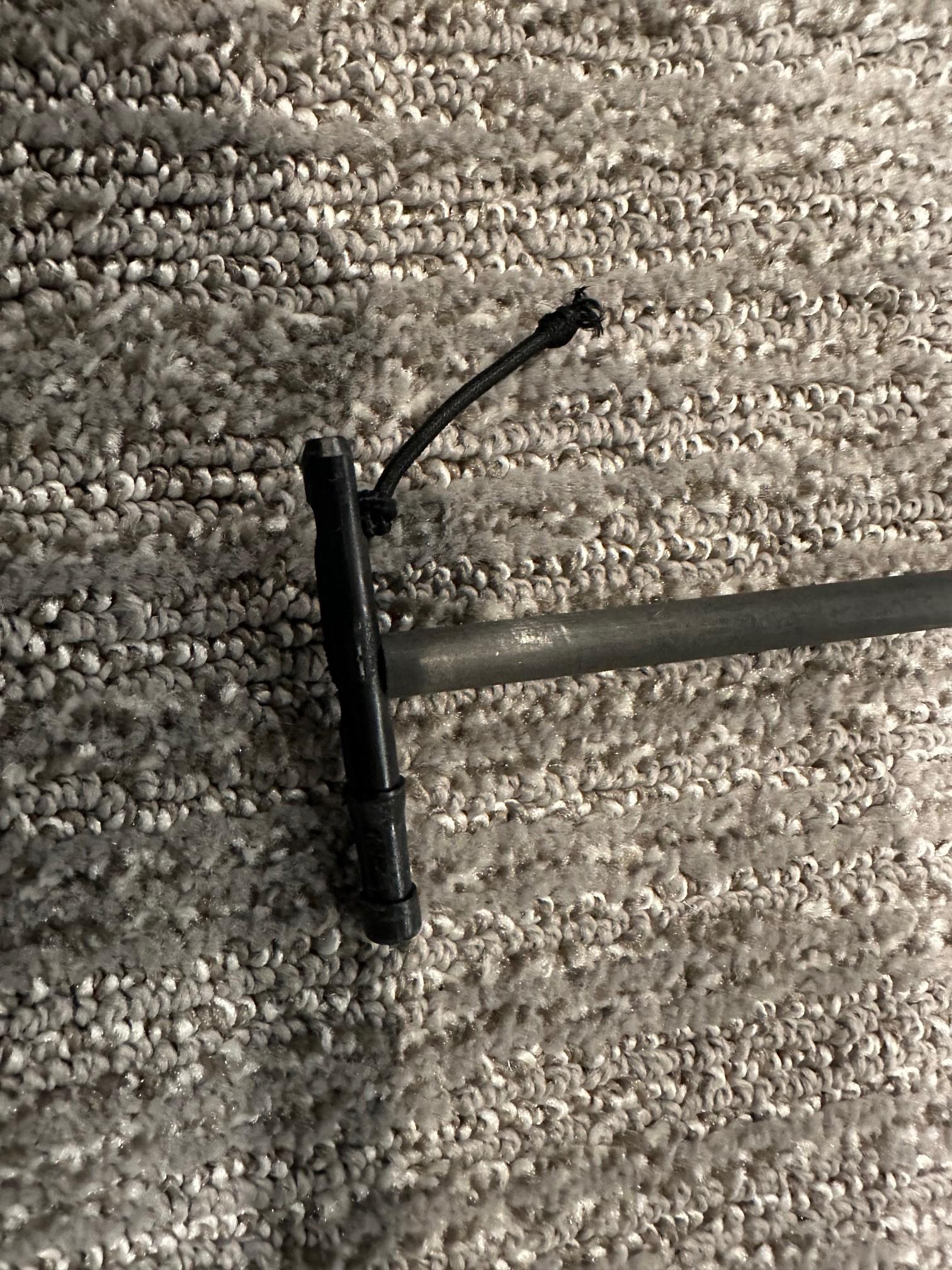

These photographs illustrate the plates and poles. When I initially set up the tent, my attention was drawn to the small diameter cord attached to the plates, and I wondered whether the plates might cut through the cord when under tension. The third photograph shows a nick in one cord I found when I returned home. The other cords showed no damage.

A final point on the pole set: When poles are removed, they need to be perpendicular to the clips to permit easy extraction. This is always an issue because poles are angled in the clip before removal.

The plug at the end of the pole that is inserted through the plate is not glued into the pole. This is probably so the cording can be replaced if it ever fails. I found that two of these plugs slid out of the pole when I tried to pull the poles out of two clips that were not adequately lined up.

I expect these issues to be resolved as I get more practice pitching and stowing the tent.

Once I inserted the poles into the fly and all four inner attachments, I staked the five guy points at the tent perimeter and the door and erected the tent. Then, I experienced a welcome surprise: The erected tent was quiet in the steady breeze and had minimal flapping in the gusts, which might have been 20 mph. The tent demonstrated good structural rigidity and probably good aerodynamics.

I moved my gear into the tent, inflated my pad, and set my pack in the space next to my pad. There are two pockets at the head end of the tent. They are well-supported and did not cause the supporting mosquito netting to sag. I set my temperature/humidity monitoring instruments at three locations. One was attached to one of the two loops at the top of the net inner. One was clipped to the top of the tent pole structure, and the other was clipped to an “attic” attachment point. (I am calling the space between the fly and the top of the net inner the attic. You could lay small damp articles in there to dry.)

I decided to cook in the vestibule since the winds were still elevated and the bears were in bed.

The inner door has a three-way zipper; one way, of course, is vertical. The other two ways are horizontal on either side of the vertical zipper. This allows expansive use of the vestibule and easy access to the clips that secure the inner to the fly. More on this in a bit. My shoes and insulated pouch, provided some wind shielding for the stove.

The wind was supposed to diminish, starting at 6:00 PM, so I didn’t install extra guy lines when I pitched the tent. However, the wind, especially gusts, appeared to grow, and by 7:30 PM, I decided to secure the tent.

I went out and took a look at the tent. I found the wind was now coming from the southwest and hitting the tent on a diagonal. I installed a guy line at the southwest guy loop. I wrapped the extra-long guy loop around the adjacent pole and attached one of the four guy lines I brought along. This produced a substantial reduction in horizontal tent deflection.

I decided to install my trekking poles in the sleeves to see what impact they would have. The pole that is installed by the door is very easy to install. Since no door was on the other side of the tent, the other pole seemed more challenging to install. It actually wasn’t. I laid the pole on the snow, slid it beneath the fly, and stood it upright. Next, I entered the tent and dropped two clips that secured the inner to the fly. This provided easy access to the other pole sleeve through the attic. When you use the poles, you want to extend them so that the pole grip is tight against the top of the sleeve. The pole tip is securely embedded in the ground (or, in this case, the snow). Angle the pole outward as far as possible so it is contacting the door/side wall fabric. This will provide maximum rigidity. Ensure you have staked the guy line installed at each bottom, adjacent to the pole, so the extended pole does not lift the tent away from the ground.

After I installed the poles, I went outside and pushed the tent horizontally at the roof crossbar. The entire tent structure was remarkably rigid laterally and vertically. Using the poles for extra support is a great feature that adds no additional weight (if you use trekking poles) but substantially enhances the strength of the structure.

I went back in and watched a video, free from the disturbing sound of a tent flapping in strong winds.

I had a good night’s sleep. The outside humidity was low, and the outside temperature reached about 28F. I may post the data later. The sky was clear, and no tree canopy was over the tent. When I woke up, I checked for frost inside the fly. A few ice crystals were reflected in the headlamp, but by and large, the fly was frost-free. I had the leeward vent open, and the windward vent closed. I had piled snow along the fly perimeter to seal it against the wind. Some wind got under the door, which I did not seal with snow. The tent seemed to ventilate well, but these were not very challenging conditions as far as condensation/frost go.

This is a thoughtfully designed tent, with good tradeoffs for comfort, ease of use, weight, and strength. I expect that a little more experience will ease the setup process. Perhaps Dan can weigh in with tips on efficiently securing the poles to the aluminum attachment plates. I recognize that the tent is not designed as a mountaineering tent. I don’t anticipate spending my nights on exposed ridges above the tree line, so I think the X-dome will serve my needs as a winter tent. I expect to update this post after more overnights.

Nov 26, 2024 at 1:00 pm #3823086Quest Outfitters has .296 carbon poles and ends in stock. https://www.questoutfitters.com/Tent_Poles_CF_3.9.htm#3.9_Carbon_Fiber_Poles_&_Parts

I had some from another project laying around and it looks like almost all the pole sections are 16″ so i cut one to throw in for a big multi day ski trip i have planned.

Nov 26, 2024 at 1:31 pm #3823093Glad you’re liking the tent Steven and thanks for your report. Here are a few notes on a few topics:

“The clearance between the hole in each plate and the pole is fairly tight. The pole is easily inserted through the hole when it is perpendicular to the plate. ”

Yes the hole is fairly tight around the pole tip such that the tip needs to be added and removed straight (not angled). The challenge here is that the diameter of the pole (7.5mm) is hardly larger than the tip (about 6.9mm) so I have to make a hole that fits over the tip but won’t slide up the tubing. That is a hole about 7.2mm. If I made the hole larger it would risk sliding right up the pole, so I sided a bit towards being harder to put on, since potentially sliding up the pole is a much more serious situation. This is how the Easton pole tip part is designed. I am working with them to redesign the pole tips so that the end tips a little smaller and easier to fit into the holes. Usually I bend/turn the metal tabs to be parallel to the pole and then slide them on/off (rather than trying to bend the pole to be in line with the tab).If you would like to improve this, the best approach is to reduce the diameter of the pole tips (e.g. sand them down). They are solid plastic so they can be sanded. If you reduced them from 6.9mm to 6mm they would operate noticeably more easily. Just keep a little bit of a ridge and they’ll continue to work fine. Conversely, if the metal hole is made larger it would create a risk of sliding up the poles so I wouldn’t try to do that.

“my attention was drawn to the small diameter cord attached to the plates”

Yeah I did go quite light on this cord. The rationale is that it is something that is easily swapped if it wears out, gets damaged, or the owner prefers something more robust, so I opted for the lighter 1.5 mm cord here. It is true that this might be a touch “stupid light” and about 2.5mm may be a better balance, but since it is so easily exchanged I figured we’d try the lighter option.“The plug at the end of the pole that is inserted through the plate is not glued into the pole.”

Yes this is for repairability/servicing reasons. Shockcord often loses some elasticity over time, where if we glued the tips in then it would be impossible to replace the cord, whereas like this it is a fairly easy job to replace the shockcord if it needs it after a few years. It is true with the tight holes on the ends it is possible to inadvertently pull out a tip. I find it is fairly easy to put it back in, and over time I got accustomed to making sure the plates are being pulled off straight to avoid this. If you do sand the pole tips smaller, this will reduce the risk of accidentally pulling them out.“The erected tent was quiet in the steady breeze and had minimal flapping in the gusts, which might have been 20 mph. The tent demonstrated good structural rigidity”

Yes it is quite a sturdy tent for how light it is. It may not compare to a much heavier 4-season tent, but compared to similar ultralight tents I do find it is quite a bit sturdier. We have had people use them in winds over 40 mph.“After I installed the poles, I went outside and pushed the tent horizontally at the roof crossbar. The entire tent structure was remarkably rigid laterally and vertically. ”

Glad to here it. I tried to get this tent pitching very well and worked a lot on the strength over the years, so it’s good to hear that is noticed. -

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

HAPPENING RIGHT NOW (February 11-21, 2025) - Shop Hyperlite Mountain Gear's Biggest Sale of the Year:

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.