Topic

DCF waterproof breathable over quilt

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › DCF waterproof breathable over quilt

- This topic has 32 replies, 11 voices, and was last updated 3 years, 8 months ago by

Tom M.

Tom M.

-

AuthorPosts

-

Dec 6, 2020 at 9:06 am #3687483

The materials I’m using:

1.2 oz Dyneema Composite Fabric Waterproof Breathable CTB1B3-1.0/H2

Climashield APEX – 2.5 or 3.6

0.66 oz MEMBRANE 10 taffeta nylon

My design idea will incorporate a partial sewn foot box that will anchor the bottom under my pad. This will be used as an over quilt to increase bag temps and trap moisture for extended winter trips. Using Tyvek for my pattern.

Dec 7, 2020 at 12:16 am #3687607Would you be using this as a bivvy of sorts? Why would you need a waterproof quilt? Seems like it might be expensive insurance, but the WPB material would probably help keep the warm in a little better than the typical options used.

Dec 7, 2020 at 12:33 am #3687608I love this idea, especially for short trips where the cumulative accumulation of moisture isn’t a big deal…! Keep us posted!

Dec 7, 2020 at 6:32 am #3687622Micheal B,

It seams like any gear now days I purchase or build is geared towards the Bob Marshall Open and winter travel into the Bob. I’m hoping that I can use this in at least two ways:

1. As my sleep system for the BMO (a kind of quasi FKT bivy) It would require a spruce to complete the system. :)

2. as an over quilt to add some temp but primarily to trap moisture from thermal transfer keeping my down bag dry. Also when using a open tarp in winter conditions a little added security from spin drift.

I bought a Djedi dome last year and have really been impressed with how the DCFWPB material performs in our areas climate. Yes the material is expensive but doing all the labor will save me some dough.

Thanks for the comment

Tom

Dec 7, 2020 at 7:07 am #3687624Huzefa has made quilts that use a mesh liner and had good success with them… perhaps that is an option here? 0.50oz mesh will also save a bit more weight. I mean, you want to maximise the ability of water vapour moving towards the outer of the outer quilt. Last thing you want is for it to meet some resistance once it leaves the outer fabric of your inner (presumed down) quilt, then soaking into that layer and then wetting your inner quilt?

A mesh inner also means that you can turn it inside out in the sun and dry it much faster when you have the opportunity.

Perhaps this also a nice idea for an FKT quilt/bag, obviously with a tighter cut sans inner quilt/bag. A short zip, waterproof base. One piece shelter/sleepingbag. Minimum fuss, save time, etc. I mean, its never fun sleeping in a WPB Bivy, but then, FKTs aren’t fun either ;-)

Dec 7, 2020 at 7:39 am #3687627Thanks Ryan,

I will keep you up to date. Here is my Tyvek pattern.

Dec 7, 2020 at 9:18 am #3687638

Dec 7, 2020 at 9:18 am #3687638I don’t see the gain over a bivy with a breathable DWR top and waterproof bottom. Is this a SUL exercise? Would a DCF poncho accomplish the same and give dual use?

Dec 7, 2020 at 9:59 am #3687642I guess I don’t quite understand why you would want to trap the moisture inside your sleep system, but you know more about your gear requirements than I do – I am a newb. Looking forward to see what you come up with. If it was me, I’d probably make a full WPB bivvy instead, and just increase the size of my main quilt. The BMO seems like a fun challenge.

Dec 7, 2020 at 10:19 am #3687646Adam,

The mesh is a good idea it would be ideal for transfer although I’m not sure how the mesh and apex would coexist. My current design will allow you to turn it inside out exposing the apex for drying. hopefully it works because sometimes vision and reality are worlds apart. I have tried a lot of different w.p. bivy’s over the years with no success. The only one I have left in my gear closet is a moonstone from the 90’s just because I’m sentimental. Thanks for the input

Tom

Dec 7, 2020 at 10:21 am #3687647The top fabric of the bivy I use (Titanium Goat Ptarmigan) is much more breathable than waterproof/breathable DCF. It is water repellent but not waterproof.

It is a fairly common approach to make bivy bags for use under a tarp with a waterproof bottom and a breathable top fabric with DWR properties and perhaps a bug net built into the head end. It’s really a wind shell for your sleep system, providing protection from rain splash and condensation as well as wind. With the insect net, they work for “cowboy camping” in hood weather. In the Pacific NW, it makes an excellent dew shield.

Dec 7, 2020 at 10:46 am #3687649Mesh has been used on some UL quilts here and I can confirm the .5 Noseeum feels fine (I use it for mesh tent and it feels soft enough when I brush up against it), but it is really stretchy to work with and may not be suitable for gear you want to last, as it doesn’t seem super durable. I plan to use .6 Membrane taffeta on my next quilt, and hope it is easier to sew with than the Noseeum.

Dec 7, 2020 at 1:00 pm #3687662Michael B,

The warm most air your body produces in your sleeping bag transfers to the outside of your sleep system then freezes and or collects. With no way of drying a down bag the problem compounds as days go on wetting out your down bag. By using this outer bag it moves this process to the outer bag which is can be dried fairly easily. Its like a sacrificial lamb. The problem that I have with a non insulated bivy is it will still wet a bag out. I encourage anyone to come out for the fun that is the BMO!! Have you used the mesh in conjunction with apex insulation? Im wondering if the apex would migrate through the mesh? Thanks for the comments.

Tom

Dec 7, 2020 at 1:31 pm #3687665You are saying that a WPB bivvy top will still wet out? I think I get what you are saying, but I figured that the moisture would just go through the WPB bivvy in the same way it would through a WPB quilt top you are proposing to make. If the WPB material is not actually that breathable, then I could see the apex absorbing the moisture as a good option. If that is the case, I’d just use 2.5 Apex for the weight savings, and also just skip the WBP fabric on all but maybe the very end of the quilt, and just use some cheaper calendared HyperD for the rest.

The apex is a pretty solidly connected sheet. If it was going to go through the mesh, it might be a similar way in which leg hair migrates through a pair of Lycra bike shorts; that is to say, it might not look attractive, but it will stay in its place. As the apex sheet moves relative to the mesh a little might “poke out” (but likely not) but it is going to stay intact to the sheet, not come apart.

Dec 7, 2020 at 4:58 pm #3687680The process of fibers sticking out like down leaking is called “bearding” and has been one of the challenges in designing highly breathable “active insulation” garments. That’s why down and most synthetic garments are windproof and not very breathable.

Dec 7, 2020 at 8:33 pm #3687729Why not 0.7 Robic fabric?

It was used to make my overquilt and so far I have noticed no condensation problems even in very soggy wet snow seasonsDec 8, 2020 at 6:25 am #3687760Dale,

Thanks for the information. This is my first attempt at building anything with fabrics and its been a real eye opener on how the different dynamics and textures of materials effect the over all finished look and performance. I’m more comfortable building stuff with metal or plastic.

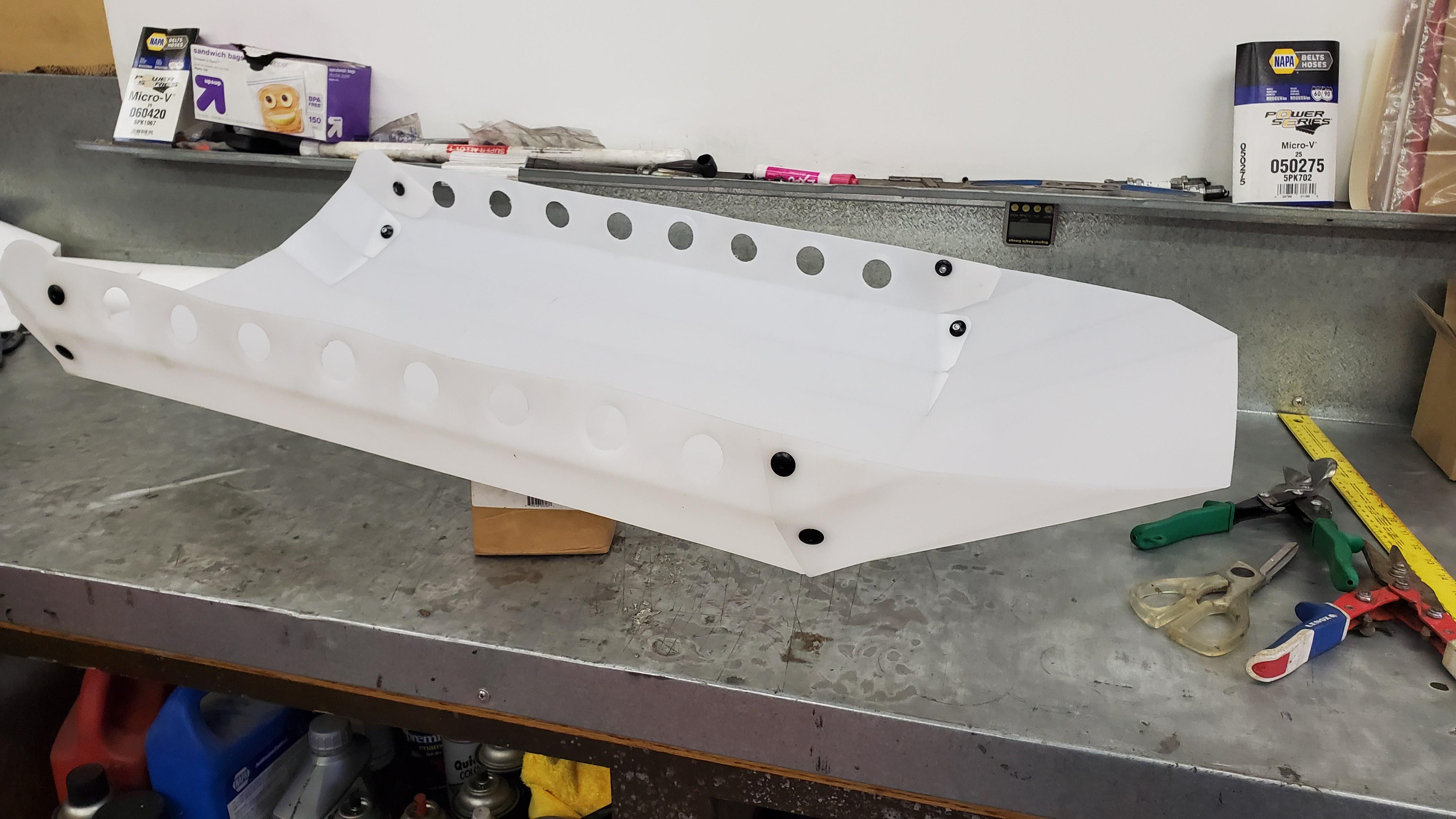

My versions of a Pulk Sled:

Dec 8, 2020 at 12:18 pm #3687813

Dec 8, 2020 at 12:18 pm #3687813Is that sled for when your back is tired :). Forgive my ignorance and the thread drift, those are rad sleds. I want to do an adventure where I might need one of those. My experience is all in the high sierras in seasons other than winter.

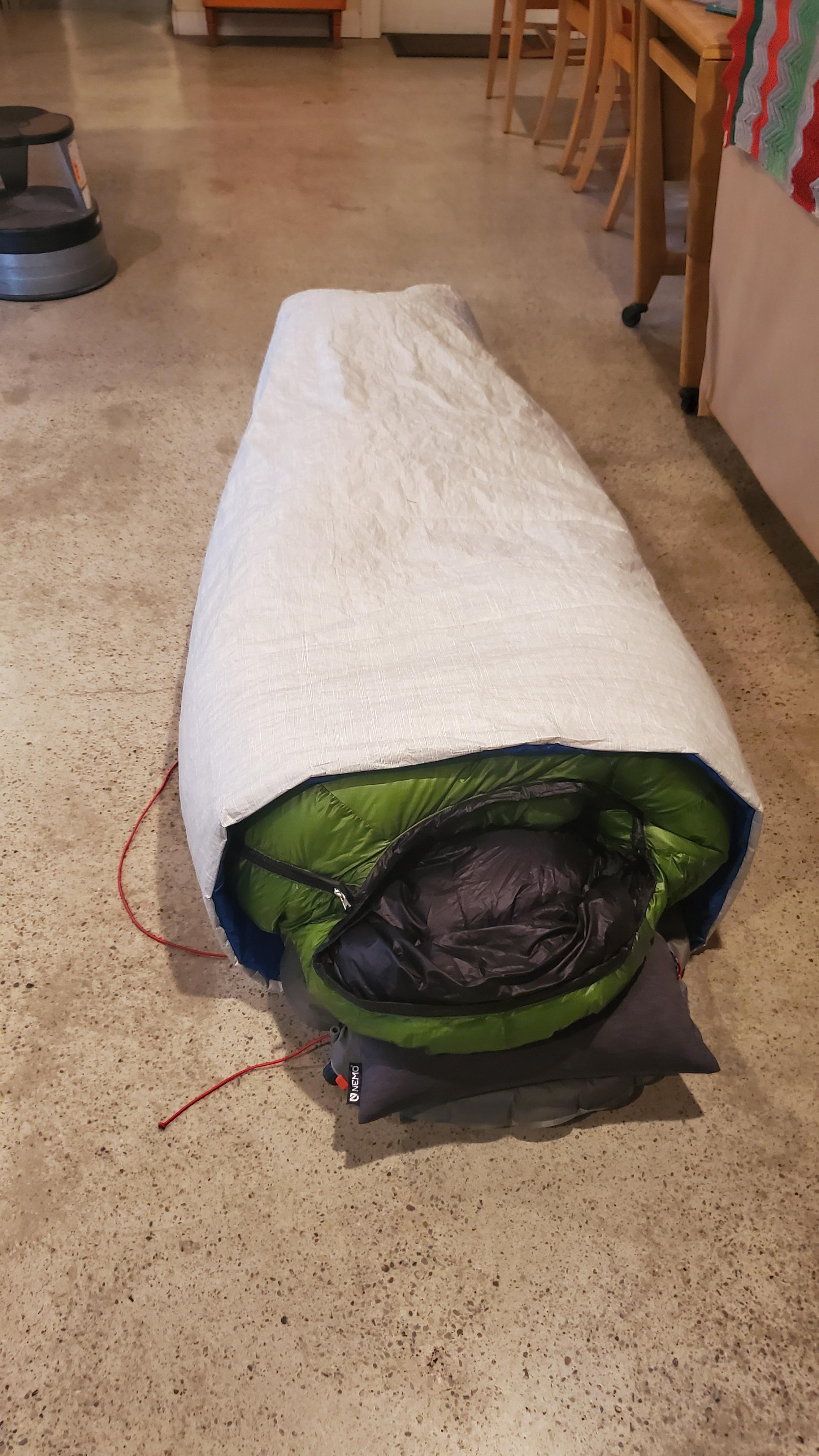

Dec 9, 2020 at 7:19 am #3687931I decided to use 3.6 apex. The difference in weight over 2.5 was only 2oz. I’m super stoked on how this turned out. The foot box anchors the bottom well and a bungie at the top to keep it in place. I’m a typical rotisserie sleeper so hopefully it stays in place. The entire thing can be pulled inside out through a small opening at the top to expose the apex for drying. Total weight came in at 13.2 oz

Dec 9, 2020 at 2:06 pm #3688010

Dec 9, 2020 at 2:06 pm #3688010Seems very “cozy”, not likely to be usable on its own, right? I imagine drafts would be bad if it was used solo, but that is not really what you designed it for. Nice weight. Seems a little short :-)

Dec 9, 2020 at 3:09 pm #3688013Michael B,

Thanks, the sleds are for winter travel and help your efficiency. I will be using the over quilt on its own for the Bob Marshal Open and possibly the Franck Church Open where you are basically sleeping just enough to take the edge off then get moving. Mike M and I are headed into the Bob this weekend so I will give a report on performance in cold conditions. Forecast looks like 17 highs lows in the singles with 17 mph winds gusts to 45mph.

Dec 27, 2020 at 8:00 pm #3691046Does anyone know how WPB DCF is made. Certainly, the mylar film on both sides of DCF is WP, but not at all breathable. Some years ago received a gift of a WPB DCF (or maybe it was Cuben-before DCF) rain pant, which never got around to trying. It was coated with a white coating on the inside. Also bought a little, which have not used, and it had white coating, which I suppose could be dyed to another color.

Maybe something besides mylar is used to sandwich the Dyneema. Anyone know? Thanks.

Dec 27, 2020 at 9:08 pm #3691054https://ripstopbytheroll.com/products/1-2-oz-dyneema-composite-fabric-ctb1b3-1-0-h2

“1.2 oz/yd 2 Dyneeema® Composite Fabric (formerlyCuben Fiber) waterproof breathable. Utilizing a combination of non-woven polyester, Dyneema fiber, and an ePTFE membrane, this fabric combines the lightweight strength of Dyneema with extreme waterproofness and breathability.”

I would want more room inside. Interesting approach anyway.

Dec 30, 2020 at 9:43 pm #3691473Thanks, Dale. The dyneema fibers must be in the sandwich somewhere. The ePTFE membrane can fall apart just by being touched, but the nonwoven polyester is used in filters, so sounds like a good possibility:

Wow, and it is expensive, but only 2.5 yards left. An expensive solution searching for a problem.

Dec 31, 2020 at 12:34 pm #3691532Hi Tom,

Great job on the overquilt!

Sorry to derail your thread, but I’m interested in your sled. Do you use cords or rigid connections to your harness? The metal one is gorgeous, how did you form the lightening holes? Is the plastic one made of coroplast? How does it handle on slopes?

Dec 31, 2020 at 3:45 pm #3691599ePTFE was in the old WPB Cuben Fiber.

It seemed pretty tough. Held stitches pretty well.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

HAPPENING RIGHT NOW (February 11-21, 2025) - Shop Hyperlite Mountain Gear's Biggest Sale of the Year:

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.