Topic

Calling all fuel canister engineers!

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › Calling all fuel canister engineers!

- This topic has 86 replies, 12 voices, and was last updated 8 years, 1 month ago by

Roger Caffin.

Roger Caffin.

-

AuthorPosts

-

Dec 22, 2016 at 1:20 pm #3441525

good work : )

the stove radiates IR in every direction

the higher you make the reflector, the more of the IR will be intercepted and reflected down to the canister

I am awaiting your results. I have only experimented down to 25 F

Dec 24, 2016 at 1:22 pm #3441774Sorry guys, the weather forecast got busted. When I woke up Thursday in Fairbanks and all morning as we drilled (pushed, actually) four soil borings, my weather app said the cold front would arrive in 2-3 hours and it would drop for +/- 2F to -25F very quickly. We could see the cold front to the southwest and it just sat there unmoving. OT1H, I’d packed up all those canisters and stoves and gear for nothing. And I’d thought I’d get to extend my bragging rights for work-place temps (previously -20F to +117F) a little closer to my recreational range (-44F to +120F).

OTOH, it is LOT easier to drill wells, sample soil and water, and, you know, generally survive the workday, at 0F than at -25F. It’s always kind of impressed me how being 25F colder is just like being 25F colder over a huge temperature range. If you haven’t been in seriously sub-zero temps, you might think the same gear would suffice – that once you get to “hella cold” and you’re wearing your warmest clothes, you’re set. But, er, no. -25F is as much colder as 0F as 45F is colder than 70F. Would you wear shorts and cotton t-shirt for a long day at 45F the way you would at 70F? This was brought home to me when I’d try to explain to au pairs from the tropics what -30F could be like. Since the coldest they’ve ever experienced was reaching into the freezer to get out the ice cream. That ice cream at 20F is 50F below room temperature. And -30F is as much colder than that ice cream as the ice cream is colder than room temps. What would you wear to spend all day in the freezer? Double that to spend much time outside at -30F.

Anyway, sorry guys – the sub-zero tests of the Moulder Strip and the Adams IR Oven will have to await some colder temps in my town or my next trip to stupider climates. At least I’ve got all the gear packed up and I might put together more variations of Moulder Strips to test out a few of my ideas.

Dec 24, 2016 at 3:06 pm #3441782thanks for trying, maybe you’ll get another opportunity

Dec 24, 2016 at 3:47 pm #3441793I was screwing around with Roger’s spreadsheet. (Nice Excel programming by the way)

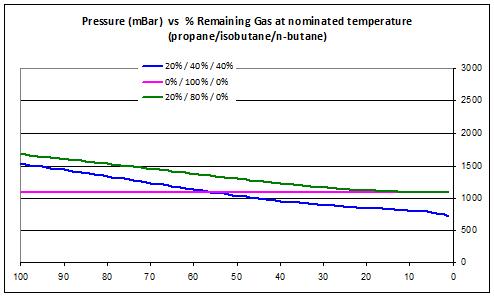

Example that shows why the important thing in fuel is to minimize N-butane:

This was at -10 C (14 F). The X axis is fuel percent remaining in canister. The Y axis is the pressure in mbar – if it’s greater than ambient (1000 at sea level) then there’ll be fuel flow to the stove.

For the straight isobutane case (purple), the stove will work all the way to the end of the canister.

For the 20% propane/80% isobutane case (green), it’s better when the canister is full, but when it gets down to 20% or 30% full, there isn’t much difference with straight isobutane.

For the 20% propane/40% isobutane/40% n-butane case (blue), it works better when the canister is full, but when it gets down to about half full, it won’t work – straight isobutane is better.

So what’s important is the amount of n-butane, propane doesn’t matter too much if you want to be able to use most of the canister.

This is only for upright canister, for inverted, propane is fine, you can go down to 0 F (-20 C) (although Bob does that with upright and Moulder strip)

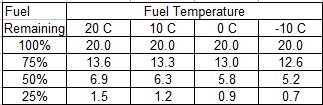

Dec 24, 2016 at 4:11 pm #3441795I did one other thing with Roger’s spreadsheet. The question is, is their more propane depletion when it gets colder?

I looked at fuel that was 20% propane/40% isobutane/40%n-butane.

I looked at 4 different temperatures – the fuel was burned on an upright canister stove until all the fuel was burned.

And I recorded the percentage propane when the canister was full, 75%, 50% and 25% full.

At 100%, for every temperature, it was 20% propane – that’s what we started with. Operating at 20 C, when the canister was 75% full, that remaining fuel contained 13.6% propane. etc…

As the fuel is used up, the propane is depleted more at colder temperatures, but the effect is small.

For example, when the canister is half full, if it was running at 20 C, there’d be 6.9% propane in the remaining fuel. If it was running at -10 C. there’d be 5.2% propane. Not a big difference.

This corresponds to about 1 C (2 F) difference in the minimum temperature that will run at.

So, propane depletion is about the same regardless of what temperature you’re running it at, but it’s a little worse when you run at colder temperatures.

Dec 25, 2016 at 12:29 am #3441818Hi Jerry

You need to bounce that one off Stuart Robb, my co-author. The figure for +20 C and 50% of 6.9% propane doesn’t feel right to me. It does not seem to accord with normal experiences with an upright canister stove. But I may be up the creek.

Edit: up some creek. I can’t see any fault in Jerry’s figures so far. INTERESTING!

Cheers

Dec 25, 2016 at 5:42 am #3441823Thanks for the update, David.

Lots of winter remaining, however!

Dec 25, 2016 at 7:26 am #3441827you mean there is more propane depletion when it gets colder?

I think that result is inconsistent with excepted wisdom

Hmmm… must be some way to measure that…

Dec 25, 2016 at 1:39 pm #3441844It might be more helpful to say there is less butane depletion as it gets colder – the butane (either) has a higher boiling point. Semantics, I know, but easier to understand when put this way.

A little unexpected though.Cheers

Jan 5, 2017 at 2:59 pm #3443376OK, Jerry, here’s my update. This morning it was +4* F on my patio, thanks to this brutal cold snap many of us are enjoying. After shoveling 8″ of snow off my patio, I did another test of the “Adams IR reflector.” I used the same setup as I showed above, with the circular heavy duty aluminum reflector, the titanium foil base plate, and the mini thermometer. This time I happened to use a Coleman F-1 Ultralight stove, which I used at 5 AM today to drain as much of the propane from an Optimus canister as I could. After letting the canister chill to ambient for an hour in temps near zero, I fired the stove up on a medium flame setting and placed the pot. In about 5 minutes, the little thermometer showed +45* F. After 5 more minutes it went up to +50* F, which was the highest it would go.

So this confirms to me that your IR reflector will work at pretty cold ambient temperatures. Certainly it will warm up the canister sufficiently to allow the lowly n-butane to vaporize. There was virtually no breeze at all this morning, which I am sure helped with the success of this test.

For my money, I will probably just stick with the Moulder Strip concept, mainly because I know that it is a dependable and foolproof way to warm up a fuel canister. It also allows for use of a 3/4 windscreen if needed (which would block the IR photons needed from reaching the aluminum reflector). At maybe just a 1.0 oz. penalty over the Adams Reflector, my Moulder Strip seems to be a dependable and more durable solution (for me). I think it’s great that we have several good solutions to the problem of winter canister cooling.

PART 2:

OK, I also did some other tests while I had near-zero F temperatures this morning. You might remember the photo I posted on another thread, where I showed the people what the inside of a fuel canister looks like. Here it is again:

Note the intake stem. It’s about 1.0 cm long. I got to thinking that when the canister is inverted, not all of the liquid fuel would be able to get utilized, as a small amount would pool below the intake opening of the lindel valve. Here’s a photo of my MSR Windpro II, which I had used this morning to empty a 220 gram MSR fuel canister (there happens to be an empty 110 g. canister in the photo). As best as I could determine, the canister is tilted at 20 degrees when it is in inverted mode. The folks at Cascade Designs aren’t fools, so I assume that they know the best angle to position the canister.

My interests in this this fuel-wasting test were the following:

- Could an 8 oz. canister containing a bit less than 2.0 oz. of fuel even fire up at +4* F? If so, how well would it perform in the inverted mode at this temperature?

- How much, if any, fuel would remain when the stove finally went out?

The results:

The stove fired right up with the canister in upright mode. After 3-4 minutes, I inverted the canister and went back inside for more coffee. I checked the stove every 5-10 minutes to see how it was doing. I noticed that the flame wasn’t ever all that robust, even after opening the fuel valve incrementally until it was finally open all the way. I think that the cold had limited what the stove could do. Keep in mind that I had a fairly tight windscreen (and a ti foil floor) like you saw in the photo, which should have helped keep the stove a bit warmer. I did NOT place a pot on the stove, as I wanted to be able to see the burner head through the window. Keep in mind that the flame was usable, but not robust. I doubt that it would have worked well for melting a lot of snow, but it certainly would boil water for meals OK, if rather slowly.

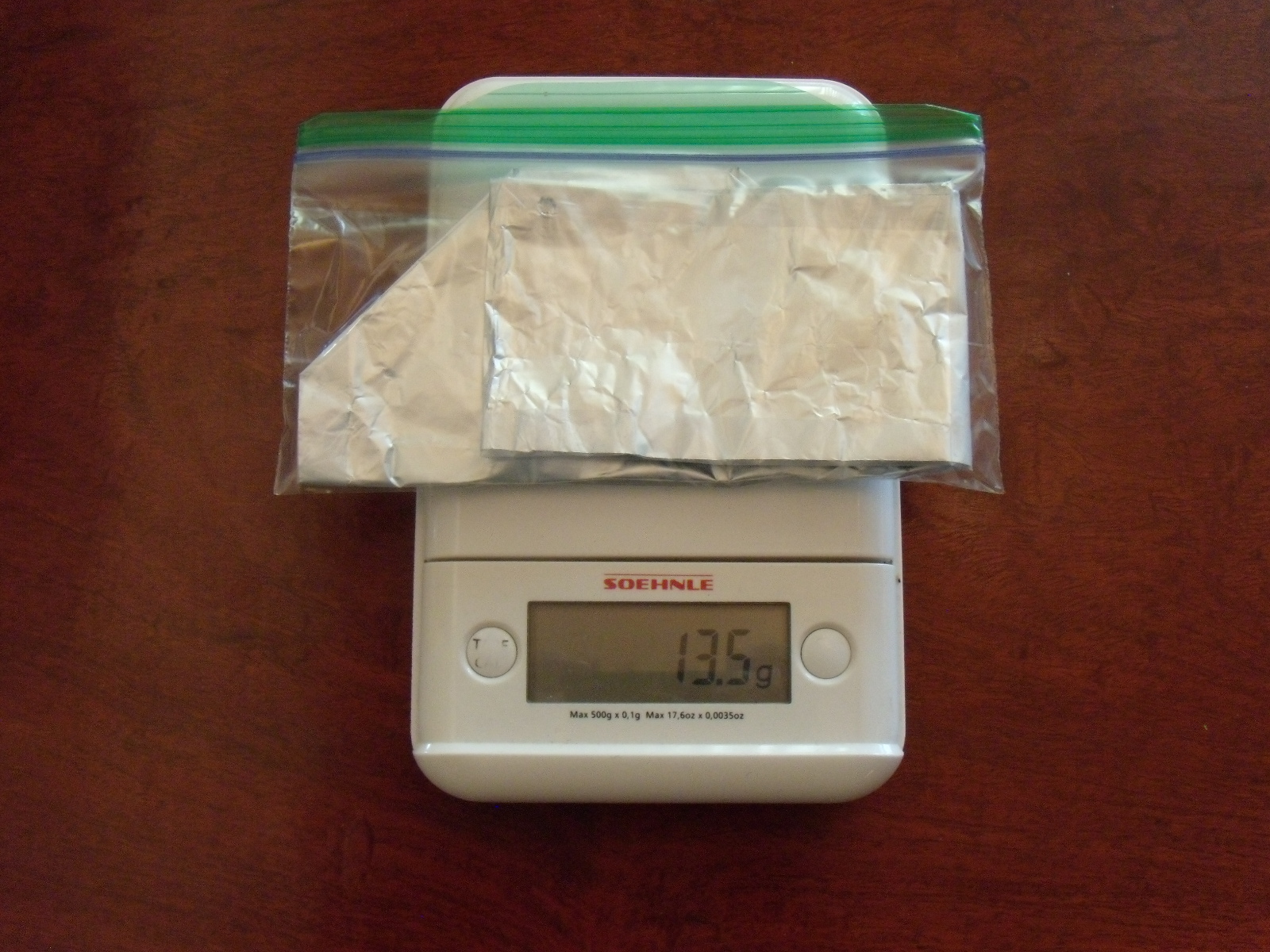

So now to weigh the canister, and figure out how much fuel remained. This is a preliminary result, as I will have to weigh the actual empty canister once I burn off what’s left (when the temps get up past +50* F around here). Based upon the average empty weight of identical canisters, it appeared that there was 20.4 grams of fuel remaining, which would be 9% of the purported 227 gm. when full. I find this to be somewhat significant.

I had earlier done some rough measurements of the amount of liquid that would be retained when a 110 gm. canister was inverted a various angles. I used that canister with the bottom cut off, so the accuracy of my measurements would be suspect. The steepest angle was maybe ~ 30 degrees, and it retained 16.5% of the 110 gm. of fuel. The Windpro II retained 8.25% of the 110 gm, and a canister that was positioned vertically was the winner at 3% of 110 gm. So the angle that the canister is tilted determines the amount of fuel that is unable to reach the intake hole of the fuel valve.

I assume that MSR knows what they are doing with their 20 degree tilt. I am guessing that the tilt is to minimize the chance that solid impurities can find their way into the intake opening of the Lindal valve.The Jetboil Joule is intended to have the canister be vertically positioned in the inverted mode, but I’m thinking that any solid impurities would have a tough time climbing up the fuel line to get to the burner. Then there is the question as to whether we even need to worry about solid impurities in the Korean canisters. But, man, a clogged jet would be a bummer in the winter. I suppose the way to play this is to use a certain MSR-type of tilt until you’re about to run out of fuel, and then position the canister vertically and hope for the best.

OK, I’m done.

Jan 5, 2017 at 4:10 pm #3443381thanks for doing that : )

yeah, there are many techniques that each have strengths and weaknesses

one thing about the foil is, you can just stick a piece of foil 12″ x 18″ in your kit and if you discover it’s too cold, it’s available

Jan 5, 2017 at 4:13 pm #3443382Hi Gary

Most excellent work. We are all glad you are ‘enjoying’ the brutal cold snap!

However,

I assume that MSR knows what they are doing with their 20 degree tilt.

You may be ascribing a shade too much enthisiasm and knowledge to MSR management here. I can’t help feeling that the angle of tilt just ‘looked good’ on a CAD screen, and that was it. From past experience with them, I am not sure they are that into the ultra-techie these days. I might be wrong of course.I am guessing that the tilt is to minimize the chance that solid impurities can find their way into the intake opening of the lindel valve.

I know that I am far too cynical, but I do wonder whether the managers at MSR even know there is dirt in some canisters? They put the Reactor on the market with lethal levels of CO emission, but refuse to even contemplate the idea that trying to run a stove outside a tent or hut at -15 C and 100 kph could be fatal for the operator. They still insist on absolutely banning the use of any stove inside a tent or hut.Now, some more work for you!

Can you get the same enhancement with a conventional Ti foil or Al foil windshield wrapped 3/4 of the way around the stove? My suspicion is that you might.

Next: how much extra heating of the canister do you get when you put a suitable pot on the top with the windshield no more than 15 mm from the pot? That would be due to some warm air being trapped around the canister.

My experience is that you do get some warming of the canister when you have the pot in place and the windshield wrapped around in the classical manner. It seems to work well for me.This should be turned into a good techie article for BPL, shouldn’t it? I am happy to help with the editing if you want.

Cheers

Jan 5, 2017 at 6:36 pm #3443404If you wrap 3/4 of the way around, then 1/4 of the radiated heat won’t be reflected to the canister, so it will warm up the canister a little less

but that’s a small factor, you need a place to adjust the valve, not a big deal

Jan 6, 2017 at 9:12 am #3443464Hi Jerry

So, propane depletion is about the same regardless of what temperature you’re running it at, but it’s a little worse when you run at colder temperatures.

Yes, I remember observing that effect. It is pretty much negligible tho’

Great thread BTW altho’ I am unfamiliar with the imperial units!

Jan 6, 2017 at 11:08 am #3443484This morning was the coldest of the season so far, and likely the last really frigid temperatures we will have this winter. While the mountains will probably see colder weather than we will have here in Boulder, it’s more fun to do my testing from the comfort of my own house. At 5 AM today the ambient temperature was minus 5 degrees F, with minimal breeze.

I mainly wanted to test my Moulder Strip and cozy with a 110 gram canister, as I’ve not yet had a chance to try it below zero (F). Yesterday morning I burned off as much propane as I could from a 110 gm. Optimus canister. Hoping that it was now mostly butane, with some iso-butane and a wee bit of propane, I used the remaining 2 oz. (~55 gm) for this test. I left the stove with canister, cozy, and copper strip, along with a plastic lid with 1/8″ evo foam for an insulating base, outside all night to fully reach ambient temperature.

The stove would not light, of course (minimal propane, right?). I used a Bic lighter to warm up the underside of the canister for 15 seconds, and the stove fired right up. It had a fairly weak flame at first, but after several minutes the copper HX strip did its work and the flame became pretty good. I then placed my MiniMo pot (with water) on the BRS-3000T stove. After just a couple of minutes the stove was roaring.

I am convinced that a pot with a fairly wide bottom (like a 4.5 to 6 inch bottom diameter) will reflect a significant amount of heat down toward the canister. We will want to watch this effect carefully during the warm summer, but it can be quite beneficial during the colder months.

The various other techniques discussed in this thread can also contribute to warming up the canister. For example, Jerry’s “Adams IR Reflector” and also Roger’s tight fitting 3/4 windscreen. Then there are hand warmers and water baths.

Next, I wanted to see how a combination of the Moulder Strip and an “Adams IR Reflector” would perform. I replaced my lid/foam base with a titanium foil disk that fit inside the Adams reflector, and I of course placed my cute little thermometer next to the canister (which still had the cozy on it, as well as the copper strip). I swapped out the MiniMo pot for a Titan kettle, and I let everything return to ambient temperature (which by now had warmed up to a ‘balmy’ minus 2* F). It was the same drill–I had to warm the bottom of the canister for 15-20 seconds in order to light it. The flame was weak, but when I placed the pot, within 5-7 seconds the stove’s flame improved dramatically. As the water came to a boil, I shut the stove off. The mini thermometer read +57* F. This “belt and braces” approach might have improved the stove’s performance, but it’s hard to tell for sure. The Moulder Strip likely would have done fine on it’s own. It was interesting to note the temperature next to the canister though. Here’s what the combination looked like. Note that I had to use a couple pieces of roofing angle flashing to act as a ‘breeze screen”. I expect that they had some type of effect, other than blocking the breeze, such as maybe trapping any warmth and possibly also reflecting some radiation back to the canister (being aluminum…).

My final test was to see what effect the 6″ diameter titanium disk might have, so I used it in place of the plastic lid with the foam. I removed the circular IR reflector, but I kept the little thermometer next to the canister. By now the ambient temperature had soared up to a torid +4* F! The technique was the same as the others–I needed to heat the canister for 15 seconds with a Bic, the flame was mildly weak until I placed the pot, then it took off as the Moulder strip and the pot did their work. Just as the water was about to boil, I shut the stove off. The thermometer showed +45* F.

So it seems that the titanium disk collected some radiated heat from the pot (possibly reflected by the angle flashing), and retained some due to titanium’s low conductivity. I expect that during the 5-7 minute burn some of that warmth was conducted to the bare bottom of the canister. That would help, wouldn’t it? So it appears that the titanium base might be superior to the foam/lid base. It looks like this might be a decent approach, but it doesn’t work quite as well as if one employed a reflective Adams reflective circle. And in my opinion, nothing works better than the Moulder Strip.

This has been a fun couple of days, to learn what the various techniques can/can’t do. I hope I haven’t bored you with all this–I just wanted to share what I ‘think’ I’ve learned. I also want to thank everyone for what you have taught me, about partial pressures and how the 3 gases behave during the burn, etc.

Jan 6, 2017 at 11:32 am #3443491thanks, interesting…

Jan 7, 2017 at 12:25 pm #3443630Thanks for all the testing, Gary!

I’d like to help out but thus far we’ve had another disappointing winter, although there’s still plenty of time for things to turn around. Thankfully we’re getting some snow, and it was fun doing my daily hike with Cyrus as the flakes were falling… too bad it wasn’t on top of a 2-foot base as it was a couple of years ago.

Jan 7, 2017 at 12:55 pm #3443637we just had two nights 18 F and 14 F

it never got anywhere near that last winter – I was disappointed because there were no good testing opportunities

The 14 F night I slept out on patio. I had a couple pieces of new clothing so I wanted to see how cold I would be warm at. At 3 AM I needed to use bathroom and was a bit cold so I just stayed inside. It was 16 F. I’m working on a new quilt, which is a little warmer, so that should be better. I’ll have to test that, but it may be a long time before I have good cold opportunity.

Jan 18, 2017 at 5:52 pm #3445902Jerry (“If you get a chance, also try using an aluminum foil reflector. 12 inch square. Under canister. Fold the sides up to reflect the IR from the burner onto the canister. . . it never gets cold enough here to do good tests”)

After I tested my Moulder Strip at -21F and wrote that up, I tried 12″ x 12″ of aluminum foil. Air temps had risen to -15F. I stated with a cold-ish (0F) canister and it lit but not vigorously. It didn’t self-start, but petered out. I tried twice to boost its output with a Bic to the canister below the liquid level and while that momentarily bumped the flame up, it decreased soon after removing the Bic flame. It kept going, but it when I went out 20 minutes later, it had only gotten the uncovered pot to 120F or so.

So it helped. Not enough at -15F, but I’d imagine it would have been plenty at 0F.

Also, if I’d used heavy-duty instead of normal-weight foil, it would have been easier to optimize the shape. I suspect I didn’t have the side quite as vertical as I should have.

Maybe a shiny pot would have reflected more IR from the flame to foil and on to the canister. I was using a dark-gray, anodized pot so the most intense IR from the flame was absorbed and turned to heat but the metal would have been right at water temperature (30 to 100F) and radiating a lot less IR because radiation goes by the fourth power of absolute temperature.

Jan 18, 2017 at 6:16 pm #3445909thanks for trying that

maybe it doesn’t work so good at colder temps

maybe the aluminum foil wasn’t angled to reflect the heat to the bottom part of the canister where the liquid fuel level was

Jan 18, 2017 at 6:54 pm #3445926This was the first set up which didn’t quite keep up at -15F:

The forecast is for -12F tomorrow morning and it’s usually colder than forecast. I’ll get some heavy-duty foil for the next run and get the sides more vertical.

Jan 18, 2017 at 7:13 pm #3445931Yeah sides more vertical

The way you angled it, the IR will reflect back to the burner, not down to the bottom of the canister where the fuel is

There is an air gap at the bottom which is good, so the IR can get reflected onto the bottom of the canister where the fuel is

IR reflected to the top of the canister above the fuel liquid level doesn’t do much good, because the steel canister isn’t a real good conductor

Jan 19, 2017 at 6:59 am #3446021I am jealous of your temperatures… call it “Cold Envy”…

I’m backpacking Fri-Sun in CT and the overnight low temperatures are forecast to be in the 34-36°F range!

Jan 23, 2017 at 10:43 am #3446704I have been playing with several iterations of the vertical walled “Adams Reflector,” to see if I could learn the optimal design. The photo shows the 3 that I have made from 3 layers of heavy duty aluminum foil. I protected the edges with regular Scotch tape (pretty high-tech, no?). The one on the left, with the titanium foil base underneath, is the one I used at about 0* F. It worked well, with the base of the canister being warmed to +50* F. It is 2.25″ tall and weighs .58 oz.(16.5 gm.) with the 6″ ti foil base.

The monster on the right was intended to also function as a windscreen, so it is 5.75″ tall. It was fun to make, it has it’s own 3-layer heavy duty aluminum floor, and it looks cool. So what’s not to like? Well, for one, it weighs an ounce (28 gm.). Secondly, when I tested it on a 30* F day it reflected (and trapped) so much heat that the canister base reached 100* F fairly quickly. I shut the stove off and decided that no matter how cool it looks, it would be banished to the materials re-purpose pile as soon as I took this photo of it. It was just TOO effective. Maybe it would work nicely on a 0* F day, but not one that was any warmer than that. I could have shipped it to David-in-Kenai, but postage costs would make that silly. He can make his own for that matter.

So I settled on the middle one, which I will test on a chilly morning of maybe 17* F this week. It is a bit taller than the first one, at 2.75″, and it weighs .57 oz. (16.2 gm.). It includes a 3-layer aluminum foil base, and also a disk of ti foil that extends 1/2″ beyond the edge of the canister. The 4 corners of the square aluminum base fold up to keep the circular reflector from escaping in a stiff breeze. The ti base disk might not be necessary, but I found that it might be beneficial when doing earlier tests with my first reflector. It weighs just 4.2 gm. (.15 oz.), so the weight penalty isn’t that bad.

One thing I really like about my chosen version is that if I leave the circular ti disk at home, the other two components can be folded up and stored in a snack baggie. 13.5 grams (.48 oz.). It would make for a nice, and light, little insurance policy in case the temperatures drop below freezing unexpectedly. By the way, the 3 layers of heavy duty aluminum foil make these things pretty durable. They can be folded and re-folded many times without problem.

I have become a believer in having vertical walls for this reflector, and I also think that a circular design would be best. It doesn’t make sense that a scrunched up and wrinkled piece of aluminum would be as efficient as a smooth and shiny piece. But I am not engineer, so what do I know?

Jan 23, 2017 at 11:03 am #3446712great! thanks for testing that. that worked pretty good

I think the disk at the bottom helps a lot, so IR will be reflected back up to the bottom of the canister where the liquid fuel is.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Trail Days Online! 2025 is this week:

Thursday, February 27 through Saturday, March 1 - Registration is Free.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.