Topic

Anyone here ever use an ultrasonic fabric welder?

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Anyone here ever use an ultrasonic fabric welder?

- This topic has 5 replies, 5 voices, and was last updated 2 years, 1 month ago by

SIMULACRA.

SIMULACRA.

-

AuthorPosts

-

Dec 22, 2022 at 10:50 am #3768311

Ultrasonic welders are used for all sorts of stuff from plastic packaging to face masks and so on. They can basically weld many materials together with intense vibration.

Asking because I royally hate sewing machines, and most of my projects could go pretty fast and efficient if I used a sonic welder. I think. ;)

I don’t find many people using these for MYOG, but since folks around here are often more savvy with tech, someone might have experience. If you have used one, what’s your experience? Do they weld permanently enough or do the welds come loose without extra care or steps? Stuff like that.

They run from around $400 and up, with $600 being the cheapest one you can get that has timing controls. Cheaper than $600 only allows a set timer and has to be done multiple times for extra welding.

Dec 27, 2022 at 9:59 am #3768504Some time ago, I was also wondering whether ultrasonic welding would work for light fabric. I asked SONOTRONIC about it and they tested their ultrasonic welding of some fabric samples I sent them. All the fabrics were under 1 oz. Result was basically that while properly welded together, the welding had very significantly weakened the fabric, so that it would easily tear along the weld.

Maybe ultrasound spot welding could replace tape or pins to facilitate the sewing.

There is obviously a whole industry around ultrasonic welding, but, unsurprisingly they tend to have relatively expensive equipment… I do wonder whether any manufacturer has ever tried them out. Though personally, so far, I have never seen any equipment that seemed to have been welded.

Dec 27, 2022 at 1:10 pm #3768539Is this the way they make inflatable pads?

Dec 27, 2022 at 2:59 pm #3768563Maybe.

https://solutions.covestro.com/en/highlights/articles/theme/processing-technology/welding-films

Apparently there are multiple ways of creating and applying heat to fabric materials. So instead of a metal welding torch or soldering iron people invented other things with pointy ends that get hot in different ways. The fabrics are held together with tapes/pins and heated. Im under the impression many solutions use pressure, ie a heat press/ industrial hair straightener type tool but I’ve never seen/done it.

Video of diy welding of a packraft https://youtu.be/mQS_veP1V0A

Dec 27, 2022 at 5:33 pm #3768580Thanks for replies. Seems like I would be venturing into slightly untested waters, which could get costly experimenting with different systems and materials. Let alone the effects of the sonic welder on the material strength like mentioned.

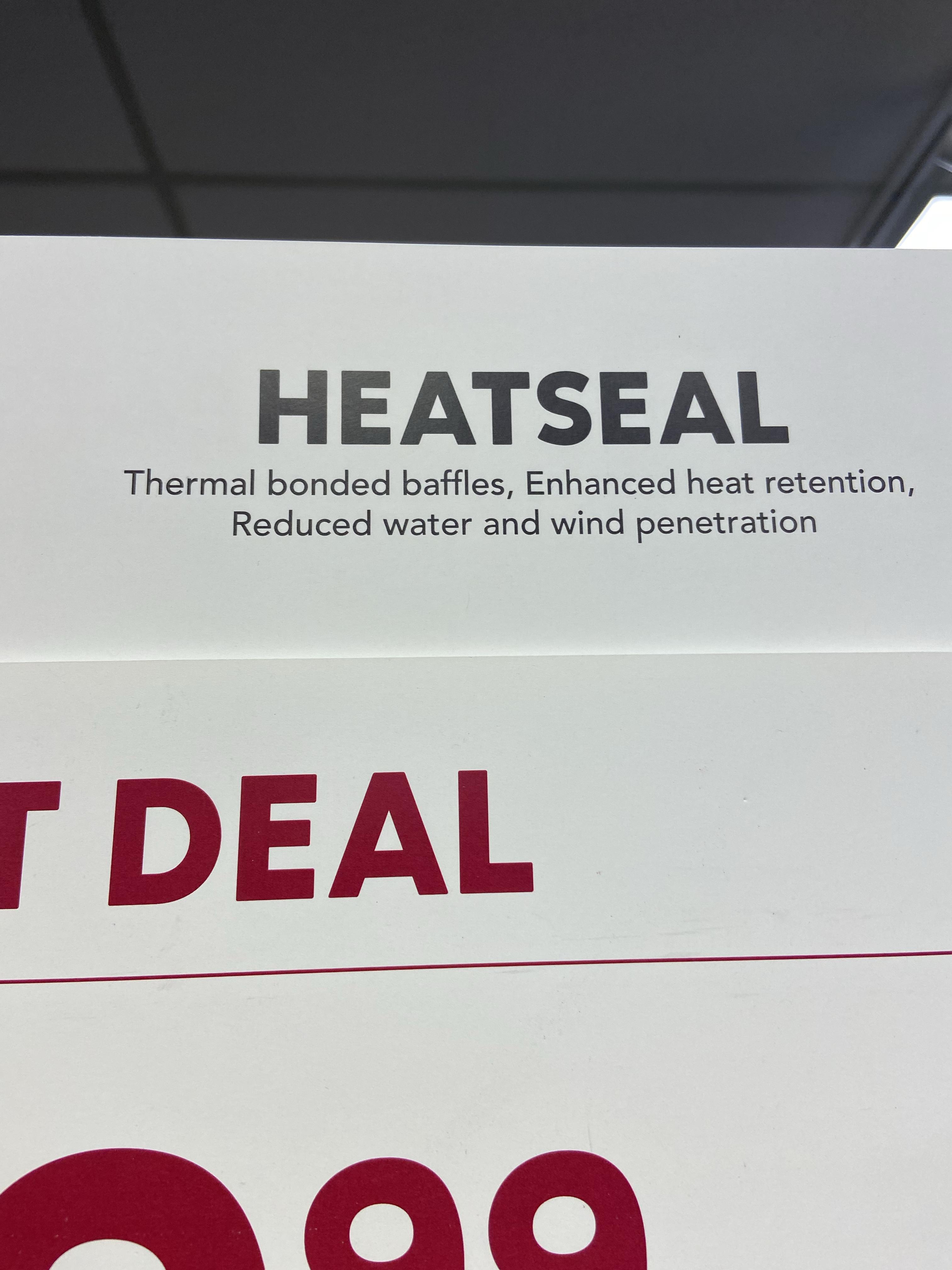

Dec 31, 2022 at 6:37 pm #3768908Interestingly enough I just ran into this at a Columbia store. First thought was, “Why hasn’t this been done with down before!?” Reducing heat loss from fabric sew through, down shift and the need for traditional baffles. Is it hype? Are there pitfalls to this process? Should this be the wave of future garment design?

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.