Topic

Air Permeability – Converting CFM to cc

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › Air Permeability – Converting CFM to cc

- This topic has 28 replies, 7 voices, and was last updated 1 year, 8 months ago by

Krishna M.

Krishna M.

-

AuthorPosts

-

Jan 28, 2020 at 5:22 pm #3629116

I have been pouring over the various forum articles and link regarding Windshirts recently.

Thanks to Richard Nisley’s awesome work I now know I need a fabric with 35 CFM. Can someone (hopefully Richard) provide me with a conversion to the cc measurement? I have googled a lot but the numbers don’t match up.

I think 35CFM equals 17.8cc, is this correct? I used this post to find that equation:

Which came from this thread https://backpackinglight.com/forums/topic/87696/#comments

The conversion calculators online give a very different number.

Thanks in advance, Scott in NZ

Jan 28, 2020 at 6:36 pm #3629127I don’t know anything about this, so take my comments with a Matterhorn of salt…

Richard states that CFM with respect to air permeability really means ft^3/min/ft^2 (in other words, it is CFM per unit area, where area is defined also in feet). The unit equivalent of this is ft/min.

If you want to convert this to cm, it becomes cm^3/s/cm^2, or cm/s.

1 ft/min * 12 in/ft * 2.54 cm/in * (1/60) min/s = 0.508 cm/s (or cm^3/s/cm^2).

So, 1 ft^3/min/ft (confusingly labeled “CFM” with respects to garments) is equal to 0.508 cm^3/s/cm^2.

This agrees with Richard’s math anyway (40 divided by 0.508 equals 78.74).

So, to convert 35 CFM (garment CFM!) to SI, multiply by 0.508, and you get 17.78 cm^3/s/cm^2. So, you were right!

Online calculators are probably wrong, because they’re probably converting ft^3 to cm^3 (and perhaps ignoring the change in units of time). This ignores the per unit area dependence, which Richard points out is defined in ASTM D737.

For example:

1 ft^3 * 2.54^3 cm^3/in^3 * 12^3 in^3/ft^3 = 28,316.8 cm^3So (when using the non-permeability meaning of CFM), 1 CFM = 28,317 cc/min, or 472 cc/s. You may have gotten one of those answers out of an online calculator (but they’re not relevant to garment permeability calculations).

Be warned, though–I remind you that I know nothing about this.

Jan 28, 2020 at 6:41 pm #3629128Taking into account your Matterhorn of salt this is awesome and seems to answer my question perfectly.

I figured the online calculators were missing something and I’m too dumb to nut it out. Thank you so much this helps immensely.

Cheers, Scott in NZ

Jan 28, 2020 at 6:45 pm #3629129Scott,

Yes, you are correct.

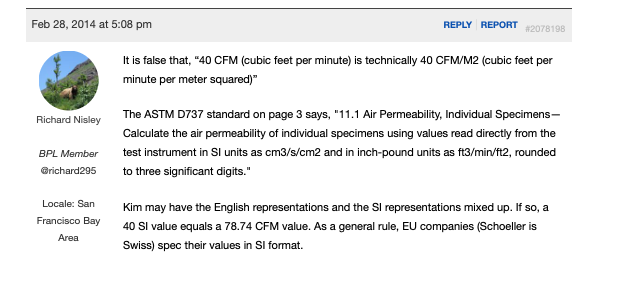

The ASTM D737 standard on page 3 says, “11.1 Air Permeability, Individual Specimens—Calculate the air permeability of individual specimens using values read directly from the test instrument in SI units as cm3/s/cm2 and in inch-pound units as ft3/min/ft2, rounded to three significant digits.

To convert CFM to cm3/s/cm2 per ASTM D737, multiply the CFM value by .508.

To convert CFM to l/m2/s per ISO 9237, multiply the CFM value by 4.

Jan 28, 2020 at 6:53 pm #3629130Richard, thank you so much.

I am looking to purchase some sampling fabric and the A/P is stated in cc’s. Now I can order the one(s) with the closest permeability to the holy grail of 35CFM! Do you have any experience/tests of Pertex Quantum Air fabrics? Or know of any commercially available garments using this fabric perhaps rebranded?

Thanks again for coming back to me.

Scott in NZ

Jan 28, 2020 at 9:48 pm #3629151Scott,

I have not tested Pertex Quantum Air.

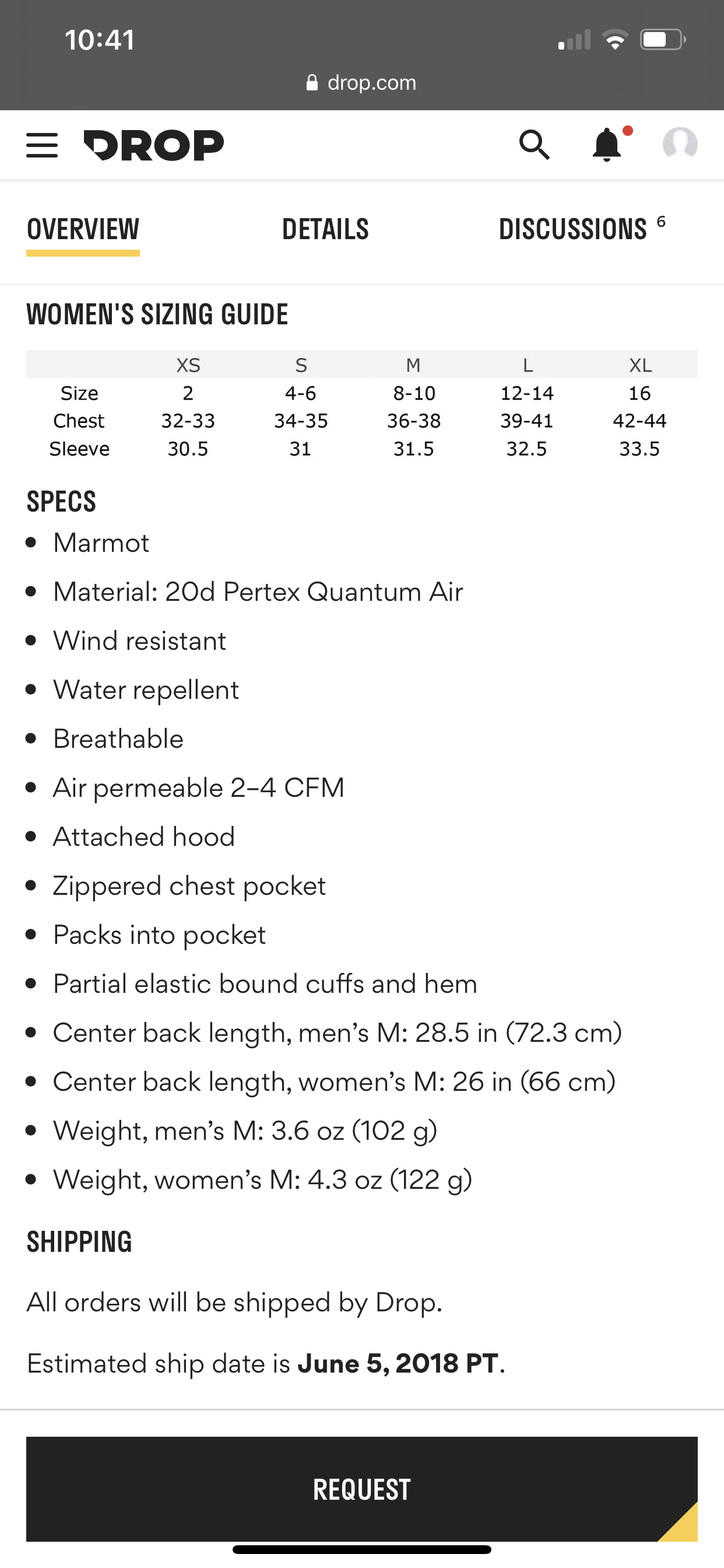

Marmot has a garment made with it speced at 4 CFM. Another garment with the same fabric trade name is speced at 13 CFM.

Many years ago I tested Pertex fabrics with the same trade name and varying CFM ratings; so, I don’t feel confident that there aren’t many more CFM variants with the same trademark name. Below 10 CFM, I can’t feel the heat and air from expelling air into my hand. I suggest you try this yourself before going through the labor of a DIY project.

Jan 28, 2020 at 9:57 pm #3629153Marmot has another garment with the same fabric trademark name speced at 20 CFM

Jan 28, 2020 at 10:26 pm #3629158Scott:

I just did a test on Mountain Hardware Kor Preshell. The Permeability was 23 CFM/Ft2, HH was 231mm/wc. Breathability was 3300g.M2/24hr. Breathability is 3rd best on all the wind shirts I have tested.

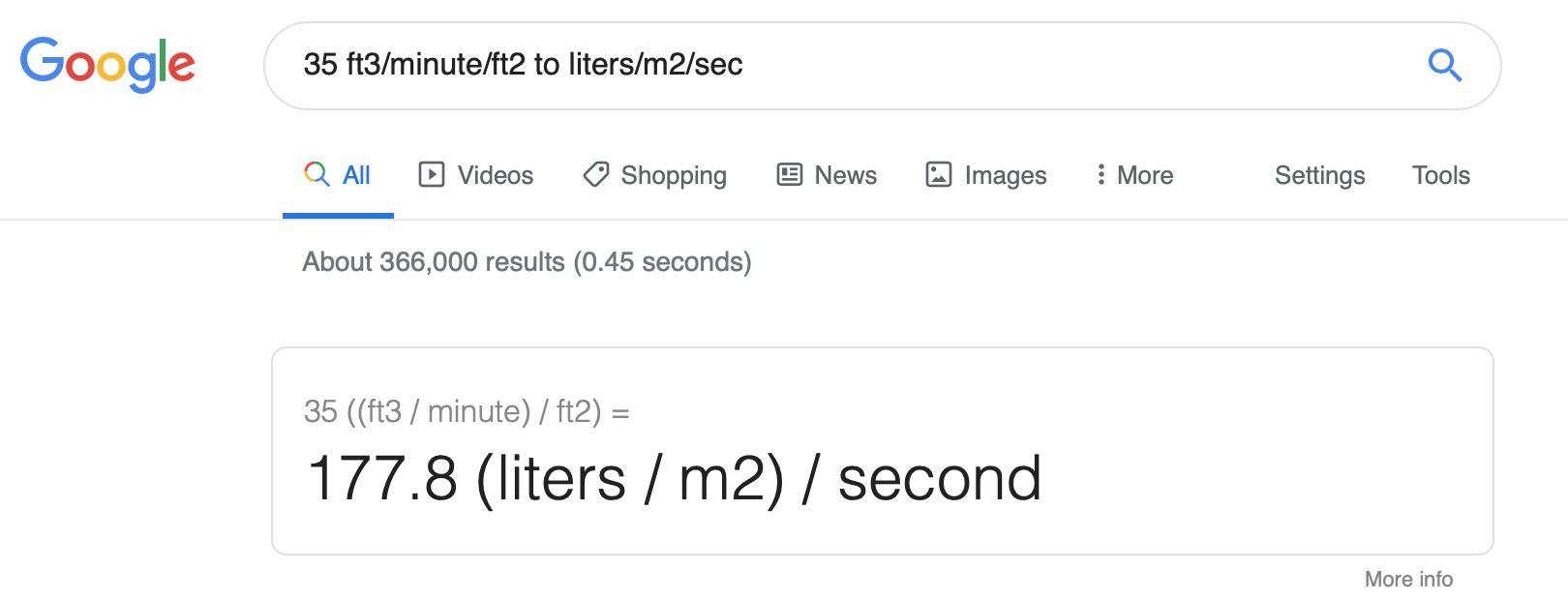

Jan 28, 2020 at 11:14 pm #3629161If you ask Google just right, you get these conversions:

Looks good.

WolframAlpha.com makes the same conversion:

Not sure why the ISO 9237 conversion (35 CFM times 4 is 140 liters/m2/sec) would be ~27% off.

— Rex

Jan 28, 2020 at 11:38 pm #3629163Just to add a third party, the aptly named permeabilities.com provides the following table for unit conversions:

It agrees with Google, Wolfram, and … well, math … that to convert units of cfm to units of liter/s/m^2, you multiply by 5.08 (not 4, which is what Richard indicated ISO 9237 indicated).

No idea why ISO 9237 suggest 4, but I haven’t read it.

Jan 28, 2020 at 11:55 pm #3629166

The above info is for the MARMOT AIR LITE JACKET jacket on Drop, which used to be called Massdrop. This image allows you to bypass their requirement to log in via an account in order to see their CFM rating for their Quantum Air variant.

Jan 29, 2020 at 12:50 am #3629169“Below 10 CFM, I can’t feel the heat and air from expelling air into my hand. I suggest you try this yourself before going through the labor of a DIY project.”

Nice. Thanks Richard-very useful.

Jan 29, 2020 at 2:16 pm #3629235Thanks Richard.

There are 27 variants of Quantum Air available which vary in A/P from 4CFM to 137CFM! There is no HH figure available for any of them. I have read mention about a “2 Cup Test”, can you explain how this works please?

Also you say “Below 10 CFM, I can’t feel the heat and air from expelling air into my hand. I suggest you try this yourself”, by this do you mean by trying to blow through the fabric onto your hand?

Thanks again, Scott

Jan 29, 2020 at 5:30 pm #3629253Scott,

Thanks for documenting that there are 27 variants of Pertex Quantum Air; that is valuable information.

I think it is empowering for each individual to have their own ability to simply test approximate CFM and HH for themselves. This in turn, allows them to share their experience on the BPL forum for our collective increase in knowledge.

Patagonia currently offers three windshirts that approximately covers the typical range of air permeability availabity in windshirts, soft shells, and shelled active insulation garments. The vendors test values, as reported by a various Ryan Jordan product reviews are adequate for this approximation.

Houdini ~2CFM

Houdini Air ~20CFM

Air Shed ~55CFMOther CFM test values, for these garments, including mine, may vary slightly but are generally within the ASTM inter lab test tolerances and ignored here for the sake of simplicity.

Go to any store carting Patagonia windshirts. Alternatively press two fabric samples, one with a known CFM and one with a unknown CFM, tightly to your lips and pass air (aka Darth Vader test) with a hand behind the fabric to feel the change in air flow an heat from your expelled air. You can closely determine the approximate air permeability for your unknown sample’s CFM using these three reference samples.

I generally can’t accurately field differentiate fabrics between ~0CFM and 10CFM but others might be able to.

You can approximate the HH of your unknown fabric or garment by placing it in a large cooking bowl to form a receptacle and then pour in two cups of water. Gather the excess material to form a ball and place it above the bowel. If you have no leakage, you have a >~2,000 mm HH fabric. If you can squeeze the fabric ball, as you would a tightly filled party ballon before breaking, you have a > = ~3,000 mm HH fabric. That is the upper limit of what can be achieved.

In summary, if the CFM test was >35 CFM and the HH was >=3,000, then you have a rare sample of the best than can be achieved for aerobic (sustained 4MET backpacking) mixed conditions.

Jan 29, 2020 at 7:13 pm #3629262Thank you Richard,

Interestingly out of those 27 permutations of Quantum Air there are only three plain weave versions and I note, having spent the last couple of weeks reading (not continuously – after all, I am working ;-) ) various posts here that ripstop weaves adversely affect HH values. The Pertex agent here in NZ could not provide HH values for these fabric as they are not designed to provide any water “resistance” per se. I will try the two cup test on some Quantum (not Quantum Air) fabric I have to see what happens.

Unfortunately in New Zealand the Patagonia distributor doesn’t bring in the Air Shed range and I don’t know of any retailer that stock both the Houdini versions!

I am most of the way through the “A Good alternative to WPB gear for active backpacking” thread currently. It seems that the Epic fabrics are some of the few that meet the >300mm HH/35CFM requirements for active windshirts, is their advantage the permanent nature of the DWR (encapsulation)? What roll does the DWR play in these wind shirts, ie. is the CFM adversely affected when the fabric is wetted out? I understand this in a 3L WPB fabric as trying to “breath” through a layer of water will never work – but don’t the higher CFM fabrics “breath” in a different manor?

Do you have an opinion of how these higher CFM fabric work for cycling? Are they too air permeable?

Thanks in advance, Scott

Jan 29, 2020 at 7:28 pm #3629268Think I may have just found the answer to the question about the fabric wetting out and affecting the CFM here

Jan 31, 2020 at 12:25 pm #3629404Scott,

The ripstop weaves impact HH on coated fabrics but not DWR treated fabrics. Typical coatings (silicone and PU) are typically smoothed out with an angled knife which skips on the thicker ripstop threads.

The US military uses EPIC because the DWR is permanently water repellent. It is not generally available for commercial clothing.

The US Special Forces are instructed to only wear a WPB (Gore-Tex Paclite) when stationary. For active use they are trained to wear an EPIC soft shell or windshirt over a grid fleece base.

EPIC largely avoids the up to 20F surface temperature drop from wearing a saturated surface fabric.

High air permeable windshirts work well for any aerobic activity including cycling .

Feb 2, 2020 at 7:38 pm #3629636Thanks once again Richard for your input here.

I tried the HH test at the weekend, it was enlightening for sure. Can you confirm something though, you mention figures of >-2000mm HH and >-3000mm HH, they’re significantly higher than the >300mm HH I’m after. Any hint’s on what to look for for a >300mm HH fabric?

In your later reply, in answer to my question about ripstop weaves, you say “EPIC largely avoids the up to 20F surface temperature drop from wearing a saturated surface fabric”. By this do you mean a 20°F temperature difference between the inside of the fabric and the outside due to failed DWR?

Thanks again, Scott

Feb 3, 2020 at 12:23 pm #3629710Scott,

A saturated outside surface (from failed DWR) will be up to 20F colder than an outside surface not saturated; this is caused by the latent heat of evaporation

I am not aware of a DIY method to approximate HH significantly better than 3,000mm HH other than getting a strong hint from a medium to high quality microscope. Very uniform spaces between the fibers is what yields the better windshirt fabrics.

Feb 4, 2020 at 11:22 am #3629816I just did a test on Mountain Hardware Kor Preshell. The Permeability was 23 CFM/Ft2, HH was 231mm/wc. Breathability was 3300g.M2/24hr. Breathability is 3rd best on all the wind shirts I have tested.

Which were the 1st and 2nd best Wind Shirts in terms of breathability?

Feb 4, 2020 at 11:58 am #3629819Air Shed and Westcomb Crest Hoody. These wind shirts will offer very little protection from wind. Perhaps they should be called shirts and not wind shirts.By the way, I had a piece of a T shirt sitting here, so I just tested it. Permeability is 71 CFM/Ft2. Airshed is 58. I think you should consider the conditions under which you are using this, what the activity is and what expected output level in Mets you will be achieving. The market does not really offer what you are seeking and there may be a good reason for that-namely, if you are using a wind shirt for protection from winds, higher CFM garments will not provide much of that.

Feb 4, 2020 at 12:17 pm #3629825I reread your post and see you asked about breathability. Just to be sure, breathability refers to vapor transfer through the fabric. I measure MVTR. I was unable to measure MVTR for air shed, it was not compatible with my test instrument. The highest MVTR for wind shirts is BD Alpine Start and Westcomb Crest Hoody. The Alpine Start was new, probably 2018 or 2019. The Crest Hoody was used. Not sure of the age.

Feb 4, 2020 at 1:39 pm #3629862Richard, you say “I am not aware of a DIY method to approximate HH significantly better than 3,000mm HH other than getting a strong hint from a medium to high quality microscope. Very uniform spaces between the fibers is what yields the better windshirt fabrics.”

What about testing for around 300mm HH rather than 3000mm, any ideas?

Cheers ScottFeb 4, 2020 at 8:04 pm #3629912Scott,

I mistakenly changed 200 to 2000 and 300 to 3000; sorry.

Feb 4, 2020 at 8:27 pm #3629915I did wonder if you’d done that.

Thanks for the clarification.

Regards, Scott -

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Trail Days Online! 2025 is this week:

Thursday, February 27 through Saturday, March 1 - Registration is Free.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.