Topic

Carbon Felt Simmer Pad

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Commerce › Gear Deals › Carbon Felt Simmer Pad

- This topic has 28 replies, 10 voices, and was last updated 7 years ago by

DAN-Y.

DAN-Y.

-

AuthorPosts

-

Feb 18, 2018 at 5:16 pm #3519060

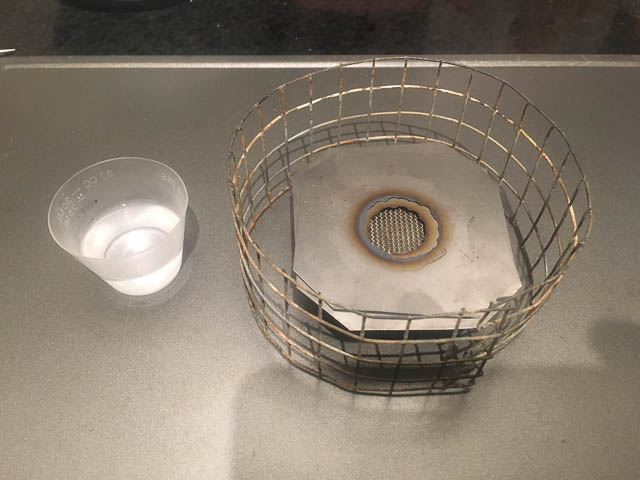

I’m looking for feedback on the use of carbon felt as a simmer device. One of Don Burtons’ photos(1st page) shows degrading and also shows the felt having red hot fibers around the edge of the hole. Those fibers are being fused together. Oxidation is also occurring.

Those of you that have used carbon felt, please let us know what your findings are.

Don Burtons’ simmer disc

Feb 19, 2018 at 4:24 am #3519196

Feb 19, 2018 at 4:24 am #3519196I have a Home Depot carbon fiber DIY summer disc that I’ve used on my 12-10 stove a couple of times, and most recently on a homemade stove similar to a Starlyte once this weekend. It seemed to me, though I may be wrong, that the most recent use started fusing/oxidizing it much more noticeably than it had been. But it was also a longer simmer than I’d done before.

Feb 19, 2018 at 7:42 pm #3519268When using a open top alcohol burner (like the Starlyte) for dry baking I think is important to recognize two different “functions” of the “chock” used to slow down the stove. 1) reduce the size of the flame by reducing the opening of the stove and 2) shield the stove from Thermal feedback. I think carbon felt does #2 better than #1, as it has been reported many times with use the opening of the carbon felt degrades and increases in size. This can be slowed down (but not prevented) by using a small ring of aluminum on top of the carbon felt. I have recently started to experiment (thanks to James Marco Suggestion) with a simmer device made out of Titanium. The titanium has low thermal conductivity so it helps with the thermal feedback and stands up to the open flame much better than the carbon felt. I use two layers of titanium and the plates are much larger than the stove (again the goal is to shield the stove from thermal feedback). This seems to work well. I get slighly hotter burns than with the carbon felt but I don’t have to worry about the carbon felt “wearing” out.

Feb 20, 2018 at 12:49 am #3519363

Feb 20, 2018 at 12:49 am #3519363Thank you dk and Mario for your reports. It’s important for folks to realize that carbon felt is not a good choice for use a a wick in stove making. As the fuel is consumed and the flame front moves from the outer edge of the burner towards the center, the flame front is actively oxidizing the surface of the felt. It will eventually become clogged and not allow fuel to be added to the stove/burner. Carbon felt works well for it’s intended purpose as a heat shield for welding. When it’s used in a DIY fancy feast type stove, the oxidation takes place when the stove is left to burn out all of it’s fuel. When it’s at it’s lowest flame is when the oxidation occurs. The surface of the wick will become clogged and perform poorly. The tiny fibers of the felt glow red hot and become fused…watch for it.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

LAST CALL (Sale Ends Feb 24) - Hyperlite Mountain Gear's Biggest Sale of the Year.

All DCF shelters, packs, premium quilts, and accessories are on sale.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.