Topic

Functional Secondary Air System

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Functional Secondary Air System

- This topic has 32 replies, 8 voices, and was last updated 6 years, 4 months ago by

DAN-Y.

DAN-Y.

-

AuthorPosts

-

Jan 26, 2012 at 7:15 am #1284700

Now keep an open mind when reading this and try to understand how we can apply this to our backpacking size wood stoves. We all like talking about bushbuddies and hobo stoves, single wall and double wall.

Recent discussion indicated that an individual seems to come to the conclusion that a fan is necessary to create a good working woodgas stove. His findings are common to those that design stoves for 3rd world countries. All of the big names designers revert to fan operated stoves for commercial sales here in the U.S. Stoves that are geared toward campers. One of the smaller ones have been used by backpackers on the AT and other trails. All these stove builders claim to get secondary combustion by introducing warm air into the center of the fire box via the holes in the double wall. In the case of the Bushbuddy, the length of air travel up the double wall is approximately 2.5 inches before it enters into the firebox. My question to all of you is: does that 2.5 inch travel get the air hot enough to cause secondary combustion of gasses?

Read the following information and see if you can come up with an answer to my question.

I have this information also stored at my web site bplite.com in the Wood Stove Forum

I just wanted to store this information in this thread for future use. It's pertinant to single wall v. double wall and the need for secondary air for combustion. It's a good read for TLUD experts.

"Theory of Design of a Functional Secondary Air System"

The JUCA design does not depend on air-starvation (air-tight) operation so the problems of excessive creosote production and carbon monoxide production do not represent the great problem existing in most wood burners on the market. For this reason, it was unnecessary for us to try to arrange a functioning secondary air system even when that was the current rage. We quietly said for years that it was unlikely that any of the secondary air systems worked very well, if at all. Independent researchers eventually showed that we were right all along. With this preface, we herein will give the reasoning why all existing secondary air systems don't work well; and the design considerations necessary to make a system that does work as intended (again, for AIRTIGHT products where it could be important).

See other sheets of ours for a description of the overall theory of airtight products and that of products like the JUCA (Sheets 128, 120, 310, 314 and others).

Since the lack of enough oxygen in the fire's vicinity is the cause for the incomplete combustion in an air-starvation burner, it would be advantageous to supply air to it later on to complete the combustion. The hitch is that the primary reaction that needs to occur (carbon monoxide plus oxygen gives carbon dioxide) will only occur above about 1200°F. If it didn't happen while it was still in the flame tips, we may have trouble keeping it hot enough for the reaction to go.

Let's consider an example. The actual flame temperature of a wood fire can range from about 900°F to 2500°F. An "average" fire will commonly be around 1900°F. Almost instantly on leaving the flame tip the smoke mixes with other air or smoke, quickly reducing the temperature. The amount of this temperature reduction is dependent on many variables, some of which are not yet fully understood. For argument's sake, let's say it is at 1400°F. In order to permit substantial secondary combustion to occur, it will be necessary to supply a decent amount of secondary combustion air, generally on the order of the primary air supply.

This is necessary so that the statistical probability of CO molecules being able to "bump into" O2 in the hot zone is high, preferably at least 90%. The molecules will only be in this environment a very short time, but we want the great majority of them to have the opportunity to combine with the oxygen atoms. These conditions are mandatory to ensure substantial and consistent secondary combustion over a wide range of firing conditions.

Some currently available products do seem to be able to support secondary combustion SOME OF THE TIME and TO A LIMITED EXTENT. Under optimal conditions maybe 1/3 of the available fuel is recovered. Under most other conditions, less. The amount of air supplied is too small to allow high probability of the CO and O2 reacting. Just do a molal analysis to see the lop-sided proportion of many CO to few O2 molecules. Actually if pure oxygen was fed, it would work fairly well. Air being 80% Nitrogen just reduces the probabilities of reaction.

And it represents more material that must be pre-heated so as not to chill the smoke to below 1200°F. Getting back to our example, if we mix our 1400°F smoke with an equal amount of room temperature secondary air, the resultant temperature of the mixture will be less than 800°F, far less than the necessary 1200°F. No reaction. Poor efficiency. A lot of creosote. A lot of pollution. Bad. You can probably see that you are going to need a source of secondary combustion air at about 1000°F or higher under these conditions. A pre-heater will be necessary to boost the room air to 1000°F.

Unfortunately, there are some conditions of low fire (severely held back) where the smoke itself is under 1200°F within inches of the logs. In that case secondary combustion is almost out of the question. It is ironic that in the situation of a severely suffocated fire that most needs the effect of secondary combustion, it is most difficult to obtain. When the fire is burning relatively freely (and therefore cleanly), that is when it is easiest to initiate secondary combustion.

Again let's get back to the example at hand. We need to pre-heat air to 1000°F. It will be necessary to use a heat exchanger to do this. Some current products have a 6" long tube to pre-heat the air as it passes through. We'll see that this isn't even close to enough exchanger surface. Assuming that the stove consumes 35 CFM of primary air for the fire, we will also need 35 CFM of secondary air as described above. To heat 35 CFM from 70°F to 1000°F will take about 35 x (1000-70) x 0.24 / 28 * 60 or approximately 17000 Btu/hr. The 0.24 is the air's specific heat; the 1/28 is the air's specific volume at the mean temperature; 60 is the number of minutes in an hour.

When we are talking about a unit that is only going to develop 20,000 or 30,000 Btu/hr, you can see that we are going to have to use more than half of the capability for pre-heating. The secondary combustion might add 25% to the output (maybe 7000 Btu/hr) but you use 17000 to do it. A losing proposition. Except for the safety considerations, it would be foolish to consider.

Conventional heat exchange analysis (see other sheets in the 300 series) will give the necessary areas of heat exchange for this pre-heater. We will avoid the math here. A two stage boost heater is most logical and effective here, where the first stage heats the air to (600°F in our example). The necessary area in a 700°F part of the stove for this exchanger is 1.6 sq. ft. The air then passes to the second exchanger to be heated further (to 1000°F) in a hotter part of the firebox right over the flame tips. The necessary area of this exchanger is 1.5 sq. ft., assuming the smoke temp is 1300°F in that part of the firebox.

If the supply tube is 2" in diameter, the first exchanger must be nearly 9 feet long (wrapped around inside the firebox) and then the second will also be about 9 feet long. The secondary combustion air supply would have to pass through a total of 18 feet of specially located heat exchanger to ensure good secondary combustion. There would not be much room left in the firebox in most stoves for any exchangers for USEFUL heat. And remember, even then there are conditions when secondary combustion still won't occur. Is there any wonder why currently available products with a stub tube pre-heater don't work?

Home Page of JUCA

Jan 26, 2012 at 8:27 am #1829919That is pretty interesting but all that article talks about is turning CO and 02 into CO2. There are other combustibles in the "smoke" to burn, that I'm more than sure doesn't take 1400F to do.

In the inverted combustion process you have a bed of charcoal above the pyrolysis zone. As I understand it, the pyrolysis process produces "smoke", which consists of many of complex combustible gasses. As these gases filter through the bed of charcoal, the carbon, at high temps, strips the oxygen, and cracks many of those combustible gasses down to hydrogen and CO. Then, the secondary air combines with that, and burns. The combustion of the hydrogen and other hydrocarbons generates the high temps required to turn the CO into CO2, as long as there's enough oxygen present (why many a fan). I read one paper that even stated the CO acts as an oxidizer to combine with the hydrocarbons, but I'm no chemistry major so I'll leave that to the experts to debate.

To produce clean wood gas you need a HOT pyrolysis zone, and a good charcoal bed to filter the combustibles (the reduction zone). Look at some diagrams of how wood gas generators work. A wood gas stove is a wood gas generator AND a combustor stacked together in a neat small package. The secondary air stage is only need for the combustor part of the assembly. The problem with all of our little tin can stoves is that we lose a great deal of heat preventing efficient pyrolysis. Our charcoal beds have a lot of "holes" in them, i.e. space in between our sticks that allow gases to rise past the charcoal without passing through it. I think that is part of the the reason why rice husk gassifiers (or wood pellet) have such good results. They form a nice solid layer of charcoal above the pyrolysis zone causing good filtering of the "smoke".

Notice that in this diagram the wood gas is cooled before being fed into the engine. Any gear head knows that cold air and fuel is denser, so more can fit into the engine at a time to produce more power.

http://www.russellecon.com/images/gasifier-lg.jpgHere's a simple diagram of the gassification process

http://4.bp.blogspot.com/-Ii3cM6euyCo/TjJAWq-tlGI/AAAAAAAAAac/Q1NULB3jaFA/s1600/gasification.jpgBM

Jan 26, 2012 at 9:13 am #1829944Most of the math is right. Except for the 1.6 square feet of HX giving 9 feet of 2" pipe. Either they left out pi or they are talking only about view angle and radiant exchange which they may well be.

The specific volume of air in English units isn't 28, it's 13 – the reciprocal of its denisty, 0.0766 pounds/cubic foot. It goes in at that density. Yes, it comes out at a lower density due to its higher temp, but one does all these mass, volume and heat capacity calcs on "standard cubic feet" (except for things like velocity).

Anyway, on their main points: Preheated air isn't preheated enough to do anything, expecially if you add air flow equal to your primary air flow. Sure. I agree. Unless your smoke and CO is rich enough that its combustion adds some heat in the mixed air stream. They don't factor in that additional source of heat.

Also, I debate the statement, "necessary to supply a decent amount of secondary combustion air, generally on the order of the primary air supply." I get what they are saying about wanting a decent mole fraction of O2, but time and temperature are other important variables and trade offs. More O2 means more secondary air which tends to quench the reaction (the thrust of this article). And more time to combust is always good and rarely designed in because everyone is trying for a very small package whether in a BP stove or a home woodstove. Yet with adequate time and temperatures, all reactions go to completion. In my work, where I'm held to 99.5% to 99.9% combustion of hydrocarbons, a common design criteria is 1 second of combustion at 1400F. In a BP stove, you're not trying to be that complete, so you could reduce the volume needed by several fold.

Especially in BP stoves where you want a high temp to do HX to a pot, less secondary air but more reaction time (higher chimney) reduces smoke, CO and provides natural draft (no fan!). Chimney sizing is tricky – they can be too narrow, too wide and often too short. But they can not be too tall. Many, many home wood stove issues would go away if they'd just installed with one more section of flue pipe.

Dan, as to your statement that, "All these stove builders claim to get secondary combustion by introducing warm air into the center of the fire box via the holes in the double wall." I suspect if they are introducing air into the burning wood, they are simply getting (1) a hotter fire, (2) a more oxygen-rich fire/smoke and therefore (3) more complete combustion with less smoke and CO. If they are introducing "pre-heated air" above the fire and after only a short HX distance and then for a short time post-mixing, I'd agree that there's not much secondary combustion taking place. The bigger benefit may well be the insulating effects of the outer wall which keeps the inner wall hotter and that decreases the conductive and radiant heat loss and keeps the firebox hotter. A hotter firebox absolutely helps combustion and BTUs/hour.

Jan 26, 2012 at 11:05 am #1829998"Dan, as to your statement that, "All these stove builders claim to get secondary combustion by introducing warm air into the center of the fire box via the holes in the double wall." I suspect if they are introducing air into the burning wood, they are simply getting (1) a hotter fire, (2) a more oxygen-rich fire/smoke and therefore (3) more complete combustion with less smoke and CO. If they are introducing "pre-heated air" above the fire and after only a short HX distance and then for a short time post-mixing, I'd agree that there's not much secondary combustion taking place. The bigger benefit may well be the insulating effects of the outer wall which keeps the inner wall hotter and that decreases the conductive and radiant heat loss and keeps the firebox hotter. A hotter firebox absolutely helps combustion and BTUs/hour."

I disagree to the statement that there's not much secondary combustion taking place in my stove. I'll need to take some more detailed pics of my build when I get a chance (maybe tonight, I have a far too busy schedule). It may be true of some stoves, but many stoves I see on youtube and various blogs have something in common- way too many and too large primary air holes, and way too few/small secondary air holes.

"Pyrolysis is a thermochemical decomposition of organic material at elevated temperatures without the participation of oxygen." (taken from Wikipedia). You need high temperatures and little oxygen. The catch is in the process described here is the heat used for pyrolysis is generated from the combustion of the organic material we are trying to pyrolyze. Too little oxygen and that combustion won't get hot enough to pyrolyze the material, too much and we don't get any pyrolysis (or not much), most of the fuel will be just consumed in that combustion process.

IMO, you can't have too much secondary air. My stove has very few, small (1/8" I think, maybe 5/32") primary holes, at something like 16 or more, maybe as much as 32, (trying to recall from memory) 3/8" diameter secondary holes. I wish there was a simple way to block those holes during operation, but that would probably result in many burned fingers. The best I could do is construct an inner can w/o any secondary holes and do back to back burns. Each burn takes about 30 mins, which is a lot of time to try and fit into my life right now. My hypothesis is that w/o the secondary air holes all I'll produce is a ton of smoke.

David- I don't know if you looked at that original woodgas thread, but here's a photo of my stove running at it's sweet spot-

The stove goes through "stages" as it operates. When it's first lit, it's pretty much just a wood fire, nothing too special. But as the wood burns from the top down, you create that layer of charcoal needed for the reduction zone. About half way into the burn, that layer reaches (I hypothesize) a sufficient thickness to do a good scrubbing (reduction) of the combustibles released by the pyrolysis zone. I've tried adding some charcoal from a previous burn to the top of the stove after it was first lit, but it just snuffed the flame.BM

Jan 26, 2012 at 11:32 am #1830020I'm guessing this is the thread Dan's referring to.

One thing I noticed there was the 55k BTU/hr output of the Mega Stove being discussed. Likewise the 17k, 20k to 30k BTU/hr mentioned in Dan's post.

Now, converting those to units I can understand, we're talking burners in the order of 5kW to 16kW. My meths burners chuck out about 600W…

So, how well do wood stoves scale? I'm pretty sure I wouldn't want a 55kBTU/hr backpacking woodstove; it would probably incinerate my dinner in a flash…

Jan 26, 2012 at 11:39 am #1830026> I wish there was a simple way to block those holes during operation

I pondered making a stove with isolated primary and secondary feeds, and using rings of holes with mating, adjustable baffles around the outside to allow experiment with primary and secondary air flows.

Discussed on this OM thread, where the basic idea was taken up by some else (R_Mac). I never took it any further…

ps. BM, is that a 'baffle' in the centre of your stove, under the pan supports? Because that might be forcing the hot gases through a small gap, thus changing the primary/secondary mix to keep the average temperature up (thinking out loud here…).

The flame certainly looks like a good CO burn, to judge by the colour. I spent many a happy hour staring at coal fires in my youth, and the flame colour is familiar…

Jan 26, 2012 at 3:11 pm #1830160Ultra Magnus!!!!

The article was suppose to give us some insight into the temperature necessary to support secondary ignition of gasses being produced inside a stove. Your first link to russellecon.com suggests we introduce cold air because it's more condensed. That is contrary to what we are led to beleive by most "woodgas" stove designers. They say we should introduce hot/warm air.

In a previous thread, you said you were having a hard time getting enough oxygen into the flames to make the stove efficient and thus you attached a fan to accomplish that. Do all backpacking stoves need a fan? I say no. No fans needed at all. I also say, no double wall is needed. My extensive testing shows that there is no significant difference in the end results between a double wall and a plain single wall stove.

Your second link shows an inverted system. I have never seen an inverted feed system incorporated into a back packing stove. I think what you are showing is an industrial application used in high efficiency units.

The type of stove you are trying to build would be great if you can get it to be consitant in start up and burn. (without a fan) I know you indicate that your type of stove would burn nice with rice hulls and wood pellets. Reallity shows us we don't have that fuel available on backpacking trails. Let's not even consider those.

I have acheived the nice blue flames that you talk about. I tested the "garlington" design. My first attempt was a success. all subsequent tests failed. flame lift off and flame out was driving me out of my gourd. I tested the "beaner" stove and witnessed the same thing. The designer of the "beaner" suggests beggining with the use of "wood pellets" and then work your way into twigs. He also says the remaining charcoal is to be buried so as to have a " carbon negative" effect on the environment. What kind of deal is that!!!! The "garlington" stove had the same amount of charcoal remaining. These designs are of a type that burn in a oxygen deficient chamber. That's the reason for the remaining charcoal. Most of the wood burning stove(DIY) have no charcoal remaining because we want fast, hot stoves with plenty of oxygen to get the job done.

Secondary air exists all around the entire stove body. Most wood stove have secondary air entry holes within 1/2" of the rim. Why not let the air just enter over the top of the rim???? It does anyway. Is 1/2 inch going to make a dramatic difference? I don't think so.

Adding holes to a single wall stove within 1/2" from the rim will cause air to enter and "focus" the flames toward the center, keeping the flames more under the center of the pot. That's good, that's what we want. We don't need the double wall.

I'll return later with a diagram and give comment to other info that has been submitted.

Jan 26, 2012 at 3:58 pm #1830179Ultra Magnus,

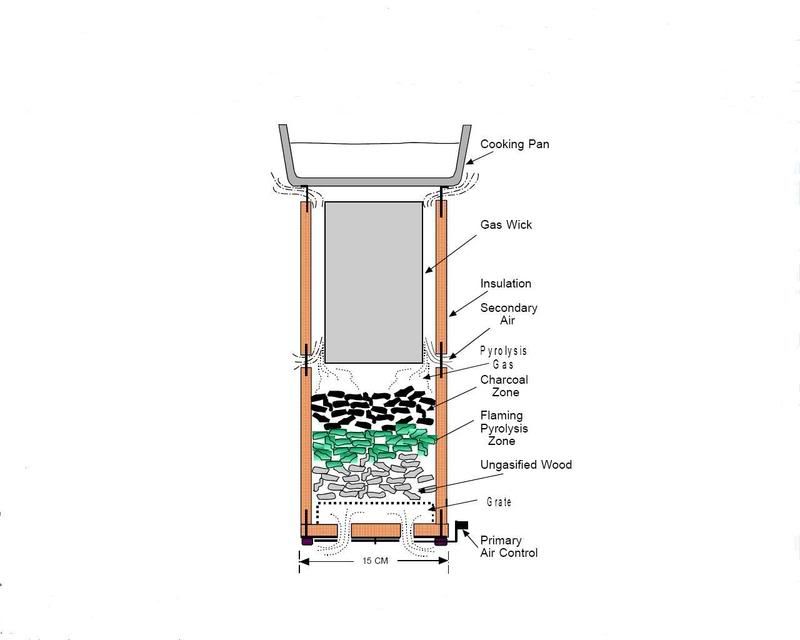

You were wondering how to control the amount of air coming up through the base, under the grate. Along with the following information is a diagram of a stove that has a control device on the bottom of the stove that controls incoming air. The diagram is for a TLUD design. This info is also good for CaptainP.

I'll return to comment more.

Ultra Magnus,

You were wondering how to control the amount of air coming up through the base, under the grate. Along with the following information is a diagram of a stove that has a control device on the bottom of the stove that controls incoming air. The diagram is for a TLUD design. This info is also good for CaptainP.

I'll return to comment more.

T. B. Reed and Ronal Larson

The Biomass Energy Foundation, Golden, CO., USAI quote a small amount of what they said:

(quote) In 1985 we developed the “inverted downdraft gasifier” (also called “upside downdraft,

or pyrolysing gasifier) operating on natural draft. The name comes from the fact that the fuel

charge is lit ON THE TOP, and forms a layer of charcoal there; the flaming pyrolysis zone is

below that; the unburned fuel is on the bottom of the pile, and primary air for pyrolytic

4

gasification enters at the bottom and moves UP, forming gas in the flaming pyrolysis zone, as

shown in Fig. 2.

At that time we built a clean, efficient stove using a jet of compressed air to mix

secondary air with the gas and a venturi burner to hold the flame. However, developing country

households typically do not have compressed air, so we began development of a natural draft,

close coupled cooking gasifier. In 1991 we described a cooking stove based on the inverted

downdraft gasifier with natural draft secondary air entering the gasifier above the charcoal zone.

The combustion in this stove was relatively clean, but the poor air-gas mixing resulted in a

unstable, partly yellow flame. The stove is marketed under the name “GAS-I-FIRE”. [4](end of quote)This is a diagram of the stove of which they refer to as figure 2:

Jan 26, 2012 at 4:58 pm #1830210Here is a better diagram to include where the secondary air enters this design of stove. Notice they are not located at the top of the stove. The height of the stove is tall to incorporate the "chimney" affect. You can see how modern day backpacker pyros have deviated from the original design.

Notice in the diagram they say "secondary air" There is no mention by the designer of "secondary combustion" That's a very significant piece of information.

</center>

Jan 26, 2012 at 5:12 pm #1830217What does the term "gas wick" mean?

Jan 26, 2012 at 5:21 pm #1830220Hi Dave Heiss.

I suspect it is the can inside of the second can or let's call it a "plug" described in the article and I quote part of it:

""Many burner designs have been tested for the wood-gasifier. The simplest is a series of holes in the gasifier above the level of the charcoal (as discussed for the Hottenroth stove above). However, this does not give good mixing and complete combustion. A better burner consists of a second can mounted a distance of about 1 cm above the first can. Air enters through this annular ring and mixes with the gas and burns. We have developed a "blue flame" burner (Fig. 4), using a "gas wick" to burn the gas in a very clean manner. In order for the amount of combustion products to have maximum draft, the area must be adjusted. (Conventional gas stoves typically have a ring of fire about 70-120 mm in diameter and about 5 mm across the ring.)""

Maybe we can say that the plug is somewhat of a venturi producer. Narrows the opening in order to mix the gasses and incoming air (secondary air)

Jan 26, 2012 at 6:03 pm #1830242BM,

Whatever you're doing with your stove, it is burning great in the photo.

Not talking about anyone's particular design, but in general: It seems to me that you want different amounts of combustion air during lighting versus early high-flame operation versus when burning/gassifying more charcoal-like material – as one does in many home wood stoves. So either an adjustable air inlet(s) or clever air hole placement such that early, high-flame operation sucked more air while later, charcoal operation pulled less air in.

Jan 27, 2012 at 7:55 am #1830425DavidT, thank you for your imput. seems you have the technical knowledge to build a good wood burner. Here is some information that comes from one of the pioneers in wood stove design for 3rd world countries:

Larry Winiarski's Rocket Stove Principles

Dear Friends,

I was typing up Larry's latest simple stove principles for Aprovecho's

newsletter, "News From Aprovecho", (two to three times a year, $30/year,

describes activity, I'm editing number 59) and thought I'd send it along.

Reflecting on the Rocket I might point out a interesting point: no secondary

air. I've tried adding heated secondary air into the top end of the internal

chimney above the combustion chamber but haven't noticed an improvement in

amount of smoke or in fuel efficiency. I ended up thinking that enough

primary air is left at the top of the combustion zone anyway. Adding air may

just reduce temperatures. I'll test this further with better equipment.

The Rocket stove is trying to create supportive conditions for complete

initial combustion which seems to pretty much work when the right amount of

fuel is introduced. The added draft created by the insulated chimney above

the fire pulls in lots of air, which like a fan, makes a hotter, vigorous

burn.

Jan 27, 2012 at 9:19 am #1830464>"seems you have the technical knowledge to build a good wood burner."

No, I only have enough knowledge to be dangerous.

On the chemistry, physics, reaction rates, heat transfer, air flow, etc, yeah, that's my academic training and some of my professional work.

I've used a lot BP stoves, a lot of home wood stoves, and cooked over many open fires. I haven't gotten into BP stoves, but suspect that when I do, I'll lean towards a taller assembly with more natural draft.

The mismatch for me is that by experience and inclination, I'm always seeking better efficiency. With free, found fuel, wood stoves don't reward efficiency in the way that gas stoves, cars, or buildings do. Ease of operation, flexibility, safety, stability and the usual weight and volume seem the important criteria.

I respect custom fabricated / machined stuff, but tend to design around mass-produced stuff. Give me a Home Depot, Radio Shack, Auto Supply and a credit card and I can (and do) clean up toxic waste sites. So in small wood stoves, I'd look to soup cans, aluminum duct work, etc as the materials of construction.

I concur with Larry's thoughts – often, just adding more primary combustion air would be the way to go, depending on stove configuration. I'd lean towards an adjustable air inlet.

Vastly more than dino-fired stoves, I think wood-fired stove success depends on the operator's skill, experience, fuel source and weather. I know a guy deep into 3rd world stove design (I saved his butt on his grad school work on water pasteurization) and it amuses me how we Western geeks argue the finest points of design while if any design takes off, it's got to be built by an illiterate local using dried mud and burning old wildebeast turds. I totally agree with their lofty goals of saving wood supplies and reducing lung disease. But my wife the MD who actually worked in Bangladesh and Zimbabwe pointed out – if women aren't walking 5 hours a day for wood and water and are home more, it doesn't mean more of their kids will graduate high school. It may just mean they have more kids.

Jan 27, 2012 at 10:20 am #1830482Dan Yeruski!!!

I really feel as if you misunderstood most of what I've written.

"The article was suppose to give us some insight into the temperature necessary to support secondary ignition of gasses being produced inside a stove. Your first link to russellecon.com suggests we introduce cold air because it's more condensed. That is contrary to what we are led to beleive by most "woodgas" stove designers. They say we should introduce hot/warm air."

I read that article, and I see no mention of any gasses other than CO and O2 and the necessary temperatures needed to combine them into CO2. Are you stating that the only gas produced by the gassification process is CO?

"In a previous thread, you said you were having a hard time getting enough oxygen into the flames to make the stove efficient and thus you attached a fan to accomplish that. Do all backpacking stoves need a fan? I say no. No fans needed at all. I also say, no double wall is needed. My extensive testing shows that there is no significant difference in the end results between a double wall and a plain single wall stove."

I never said that. When I first started out I had more burner configurations that ran rich than didn't. I also stated that 99% of what I see on youtube shows burners with way too few, way too small secondary air inlet holes, which makes them run rich. They don't allow sufficient oxygen flow from natural convection. All I mentioned was that adding a fan is a simple solution to the problem. I also said I don't use a fan, because I feel it's like cheating and ruins the elegant simplicity of the design.

"The type of stove you are trying to build would be great if you can get it to be consitant in start up and burn. (without a fan) I know you indicate that your type of stove would burn nice with rice hulls and wood pellets. Reallity shows us we don't have that fuel available on backpacking trails. Let's not even consider those."

I did not state that my stove would burn nice with rice hulls or wood pellets. I have no idea how it burns. I wouldn't even know where to get rice hulls. And using manufactured fuel, while it may be fun, is also cheating since you can't find it on the trails. I admit that even with my testing I split 2×4's into my pencil sized sticks, which still differs from what you might find on the trail, but I do it in the name of consistency.

"These designs are of a type that burn in a oxygen deficient chamber. That's the reason for the remaining charcoal. Most of the wood burning stove(DIY) have no charcoal remaining because we want fast, hot stoves with plenty of oxygen to get the job done. "

My stove produces charcoal. Some of my earlier experiments had too large primary air holes and would burn the charcoal down into ash, but that's not an issue anymore. After a burn, all the wood comes back out in almost the same shape and size as it did when it went in, just in charcoal form. It's really neat to see.

"Secondary air exists all around the entire stove body. Most wood stove have secondary air entry holes within 1/2" of the rim. Why not let the air just enter over the top of the rim???? It does anyway. Is 1/2 inch going to make a dramatic difference? I don't think so."

I do think so. I also think that letting the air enter in the lowest possible location on the inner can produces the best results. My goal is to have as much of the combustion process possible occur INSIDE the can, not 6" above it. I feel this concentrates the heat production where it matters most, improving pyrolysis and the reduction process. I also feel this elevates the combustion temperatures leading to higher combustion efficiency. If you look at my stove again, you'll see that my design prohibits air from entering over the top of the rim. I don't want cold air anywhere near the bottom of my pot. Once the combustion gasses leave the stove (combustion chamber) they are dramatically cooled by the relatively cold pot. At this point, efficient combustion is no longer possible, and much soot and tar buildup occurs on the pot.

"You were wondering how to control the amount of air coming up through the base, under the grate. Along with the following information is a diagram of a stove that has a control device on the bottom of the stove that controls incoming air. The diagram is for a TLUD design. This info is also good for CaptainP."

No I was not. I fully understand now to regulate air flow. My only question was in regards to how to simply control the SECONDARY air flow into MY stove. It'd be a simple matter if I designed something from the ground up with dampers on all the varying air inlet ports, but that would be expensive and time consuming. My stove is made from a single keg can and a single soup can. I'd like to keep it simple and avoid complicating the design more than necessary.

"Here is a better diagram to include where the secondary air enters this design of stove. Notice they are not located at the top of the stove. The height of the stove is tall to incorporate the "chimney" affect. You can see how modern day backpacker pyros have deviated from the original design.

Notice in the diagram they say "secondary air" There is no mention by the designer of "secondary combustion" That's a very significant piece of information."

I've studied that diagram in length. I've read the pdf it came from several times, and I've posted links to that pdf in almost every thread asking about gassifier stoves. I feel that the lack of that vertical height above the secondary air inlet holes is definitely detrimental in our (an my own) stove designs. The gas wick is the key- it is was causes the natural convection to draw in fresh air. It also provides in insulated chamber for combustible gasses and oxygen to burn. What you suggest is that the outer can and secondary air holes are unnecessary, which is pretty much that diagram with everything above the secondary air holes removed. The twin can setup moves the gas "wick" if you will, down around the outside of the pyrolysis chamber. This benefits the backpacker by making the stove more compact. The cost of this design change is thermal efficiency. Now we are sucking heat out of the primary combustion chamber (pyrolysis and reduction zone) to heat the air TO CAUSE CONVECTION. I firmly feel that heating the secondary air is irrelevant to the function of the stove. The only reason we need it, is that it's what causes convection to feed the secondary combustion processes. In that original design as described by the pdf, "A wood gas stove for developing coutries" by T.B. Reed and Ronal Larson uses the secondary combustion process to feed its own convection. You will also note that in their design (assuming it's their design) the secondary air is in no way heated. To quote them- "The stove operates using natural convection only. It achieves clean “blue flame” combustion using an “air wick” that optimizes draft and stabilizes the flame position." And also we can't forget the caption form under that diagram you posted (added emphasis)- "Fig. 1 – Wood-gas cooking stove showing lower gasifier section, UPPER BURNER section and pan heating". You say that it is siginficant that they only mention the gas wick and do not mention secondary combustion, but in the caption under the same image they call it the UPPER BURNER section… interesting. A burner w/o combustion.

http://journeytoforever.org/biofuel_library/WoodgasStove.pdf

They split their design into two sperate components. The gassifier section (Sec. 2.1) and the wood gas BURNER section (Sec. 2.2).My apologies if this reads poorly. I've written it over the past 2.5hrs with many interruptions.

Jan 27, 2012 at 10:25 am #1830487>"On the chemistry, physics, reaction rates, heat transfer, air flow, etc, yeah, that's my academic training and some of my professional work.

"

Very interesting background and comments, thank you!!!A question for you about heat transfer. Make an educated guess.

How much heat transfer is there in degrees taking place inside the double wall of the Bushbuddy stove when it is burning full bore. Fuel is at a level even with the bottom of the holes where incoming "secondary air" enters the fire box. Incoming air is at it's maximum rate of speed governed by the rising column air that encircles the entire stove.

Air around the entire stove is feeding the flames. Plenty of oxygen evrywhere.

Next question: How much benefit to the fire/stove is the incoming "secondary air" that is entering the fire via the holes in the double wall?

If it helps, there is approximately 2 inches of wall that air will pass over in the double wall befor it exits through the holes.

Question #3: Based on your recent thoughts, do you think it's necessary to construct a backpacking stove with a double wall? I base that question on a recent thread that asked a question about the bushbuddy stove and the reason for a double wal. Is it necessary.

Jan 27, 2012 at 10:42 am #1830497"Air around the entire stove is feeding the flames. Plenty of oxygen everywhere. "

But the only oxygen that matters is the oxygen in the vicinity of the fuel. And the more concentrated they are, the cleaner and hotter it will burn.

"Next question: How much benefit to the fire/stove is the incoming "secondary air" that is entering the fire via the holes in the double wall?"

That totally depends on the stove design. I can fully guarantee that my stove won't operate without secondary air holes.

"If it helps, there is approximately 2 inches of wall that air will pass over in the double wall before it exits through the holes."

I don't fully understand what you are trying to say there, but I'll take a stab at it. I assume you mean the vertical height of the air being heated in the outer chamber. Well, if it is short, then yes, I would also agree that it's probably not going to much, but that also depends on the stove design. My stove is based on a keg can, and is like 5" or so tall. When it's first lit, the inner can is cold, but as it burns down a bit it get pretty darn hot (as evidenced by the browning of the keg can) and it builds up convection. As I've also said before, efficiency improves as the stove gets further into its burn cycle. Convection improves and the bed of charcoal builds up for a better functioning reduction zone.

"Question #3: Based on your recent thoughts, do you think it's necessary to construct a backpacking stove with a double wall? I base that question on a recent thread that asked a question about the bushbuddy stove and the reason for a double wall. Is it necessary."

No, I do not think it is necessary for a backpacking stove to have double walls and secondary air inlets. A wood burning back packing stove and a compact inverted downdraft (i.e. top lit, updraft) wood gassifier stove are two completely different things. If you want a light weight wood burning option, imo, there's pretty much nothing you can do better than a TD Tri/Ti inferno setup. It's flexible, mutli-fuel, light, etc… win-win. but that is not the focus of this discussion.

BM

Jan 27, 2012 at 11:04 am #1830503Here are a few more pics of my setup-

This is the inner and outer can-

Here's a view of the bottoms of two cans I've tested. The one on the right has too many, too large, primary air holes.

To light it I use a PJCB. I load about 60 – 70 grams of wood in vertically stacked in very tightly. I toss on one PJCB and a couple more bits of kindling and give it a light. It need to run for a couple of minutes (about 3, really) to build up some internal heat for convection and pyrolysis, and a small bed of charcoal for the reduction zone. Here's a pic after first being lit-

Also not the tall centralized flame. I feel this is a bad thing. Laminar air flow focuses wood gas fuel into a centralized column of really rich air leading to poor combustion efficiency and evidenced by the sooty smokey smell and tar buildup on the bottom of the pot.But- after it's running relatively hot, it set on my diffuser disk.

The diffuser disk has two possible functions. 1- force the fuel to the perimeter of the stove to cause the air and fuel to mix better and 2- it might reflect heat down into the combustion chamber to help with pyrolysis and reduction (maybe). The pot stand, windscreen, heat reflector, and diffuser disk are all one assembly in my design. There is definitely room for improvement, but I haven't had the time to play with it. I'd like to experiment with the height of the diffuser disk in relation to the secondary air inlet holes, as well as different diffuser disk designs to try to incur some turbulence to better mix air and fuel.Here's the complete assembly with pot sitting on top-

As I've said before, the wood gas stove development is a hobby in and of itself. My go to setup is still the alcohol stove. It's just to easy. Sometime in the future I may take the wood stove out for a trial by fire (pun intended) but I'm sure I'd still bring my alcohol setup just in case.

BM

Jan 27, 2012 at 1:01 pm #1830585Dan,

I just watched the video at http://bushbuddy.ca/ and after 3 minutes, I see a rich fuel gas coming out the upper set of holes. I say "rich" because I see a yellow flame burning where the fuel gas meets oxygen-rich air. If it were more fully "pre-mixed" as in a butane canister stove or a fully primed white gas stove, you'd see a hotter blue flame.

My best guess is that the gassified hydrocarbons are being generated in the coal bed, go down through the screen and flow up the annular space through chimney effect. Upon exiting the upper holes, there is mixing with atmospheric air at the outer surface of the fuel-gas stream and combustion in a yellow flame. It seems to run steady, consistent, I'm sure it boils water quite nicely. I suspect it leaves some soot on the bottom of the pots.

If it ain't broke don't fix it is one approach.

If you're in a mood to fiddle around, I wonder what would happen if those lower holes were larger and the whole unit taller (increasing the distance between lower and upper holes) to increase chimney-effect induced flow of ambient air up the annular space. My thought is that if you could pre-mix more air in that annular space, you'll get a hotter, blue flame, more complete combustion, less soot and less CO. This is what all bunsen burners, home and BPing gas stoves do. BUT emphasis *BUT* when you pre-mix in those settings you need the function of a flame arrestor – a small enough hole such that either (1) the metal edges of the flame arrestor deactivate the transient high-energy compounds that advance the flame front and/or (2) have a jet velocity greater than the flame front velocity. Mechanism (2) seems out of reach with such a short chimney to build draft / chimney-effect, so I'd imagine doing technique (1) – a flame arrestor.

Your home range does that with small holes around the burner. A butane stove does it with little holes drilled in the burner head. An MSR whisperlite or Coleman stove does with those layers of corrugated and flat steel discs that create little passages. A gasoline storage can does it with a little brass mesh screen. I'd suggest a fine brass or steel screen and I'd go a little coarser than the gas cans do for better flow. Those gas can screens are conservatively designed for worst-conditions – 20.8% O2 and perfect fuel ratio because that can arise sometimes. You (1) never have 20.8% O2 after gassification, (2) have some CO2 and CO in there, (3) rarely have ideal air/fuel ratio. So arresting your flame front is easier.

Why arrest your flame front if you get more air and a nice pre-mixed ratio coming up the annular space? Because I suspect if you don't, periodically the flame will travel "backwards" into the upper holes, into the annular space, overpressure it momentarily and distrupt the nice smooth flow you current get.

But don't play with flame arrestors unless you notice a problem. Try a taller assembly and bigger/more bottom holes first.

Maybe you don't want to go that route. It seems to me the bushbuddy is a nice stove as is, and gets the job done with flames somewhat akin to a candle (but I think with a little more pre-mixing going on). Acheiving complete pre-mixing is tough and MANY people including combustion engineers (who should know more about it than some ChemEng in Alaska) underestimate the flame-quenching affects of CO2. As I tell anyone who listens – CO2 is used in fire extinguishers because IT WORKS! and not just by excluding O2. Those bent, triatomic CO2 molecules have a lot of heat capacity and they suck up heat as they rotate and vibrate to higher temps. So achieving consistent gassification with wood is tricky. More so, the gassification PLUS pre-mix is very tricky because of the CO2 and H20 in that gas stream.

Q1: I'm not even sure which way the HX is occuring across your inner wall. The firebox has some flame exhaust and more ambient air coming down, there's IR bouncing around and a little conductive contact with the coals. The annular space has hot gases from the coal bed mixed with ambient from the outer holes. What's the surface temp of the outer wall from top to bottom? (Don't use an IR thermometer unless you've painted the surface). Can you hold it indefinitely (140F)? Can you touch it for a bit (160F)? Is it hotter on the top or the bottom? That right there will tell you if the upflow in the annular space is gaining or losing heat.

Q2:I think that "secondary air" coming in the bottom holes pre-mixes some atmospheric air with your fuel-gas flow and makes for a cleaner-than-a-candle flame. Any pre-mixing you do helps.

Q3: The bushbuddy would be a totally different stove without that double wall. It would very hot to the touch on the outside and you'd need a much taller (less stable) arrangement to get good combustion without the premixing that you are getting now.

Jan 27, 2012 at 3:26 pm #1830665I want to throw this out for reference and then I'll be back tomorrow to respond to comments.

This video is a photobucket version of my youtube video. I can't get the youtube to load so click on the photo for the video to play.

The 2 stoves on the left are double walled commercial built. The one on the right is single wall made of stainless steel 1/2" hardware cloth with stainkless steel fire box liner.

Clothes pins of the same size were used for fuel and weighed so that each stove had 2 ounces of fuel. Fuel was verticle stacked and top lit.

This video is the 3rd test of 3 performed.

The results: all three stoves boiled 2 cups of water with 2 ounces of wood.

Keep in mind my question put fort previously. Do we need to have a double wall on our backpacking stoves? (not asking again)

The comments so far are greatly appreciated and informative.

Jan 27, 2012 at 3:42 pm #1830675"I just watched the video at http://bushbuddy.ca/ and after 3 minutes, I see a rich fuel gas coming out the upper set of holes. I say "rich" because I see a yellow flame burning where the fuel gas meets oxygen-rich air. If it were more fully "pre-mixed" as in a butane canister stove or a fully primed white gas stove, you'd see a hotter blue flame.

My best guess is that the gassified hydrocarbons are being generated in the coal bed, go down through the screen and flow up the annular space through chimney effect. Upon exiting the upper holes, there is mixing with atmospheric air at the outer surface of the fuel-gas stream and combustion in a yellow flame. It seems to run steady, consistent, I'm sure it boils water quite nicely. I suspect it leaves some soot on the bottom of the pots."

It's a common misconception that wood gas exits the bottom (primary) holes and travel up the annular chamber in between the inner and outer cans, re-entering through the secondary air inlet holes. No wood gas travels down through the bottom holes. What you are seeing when looking down the throat of the bushbuddy is the combustion of the wood gas as fresh air is being fed in through the secondary air holes. In that, it's very similar to looking down the throat of a chimney alcohol stove.

Dan- and since you posted the question again, no I do not believe you need the outer can for a backpacking wood stove. If all you want to do is burn wood to heat water, you don't need anything very sophisticated. A backountry boiler, TD inferno setup, one of your hardware cloth tlud designs, etc., do the job just fine. Heck, a few rocks arranged in a circle would work fine, and have worked fine for thousands of years.

And I wont have time to follow this thread again until Monday.

BM

Jan 27, 2012 at 4:05 pm #1830686Jan 27, 2012 at 4:51 pm #1830708BM,

>"No wood gas travels down through the bottom holes. What you are seeing when looking down the throat of the bushbuddy is the combustion of the wood gas as fresh air is being fed in through the secondary air holes. In that, it's very similar to looking down the throat of a chimney alcohol stove."

So those jets of flame from the upper holes are oxygen-rich air from the holes mixing with gas/soot/CO-rich wood-gas from the fire below? And the firebox is completely enclosed on the bottom. My bad. I've never used one, obviously I should.

If so, there's a lot a smoke/CO/organics going unburned off that little fire.

Does anyone do an hour-glass-shaped stove? With the fire at the smaller diameter in the middle? A wide base is good for stability and a gradual constriction minimizes frictional losses in the air flow. The fire would get a lot of air velocity past it and then the larger volume chamber above would give residence time before combusting gases got quenched on the pot bottom or by dispersing in the atmosphere.

Jan 27, 2012 at 6:28 pm #1830733>"No wood gas travels down through the bottom holes. What you are seeing when looking down the throat of the bushbuddy is the combustion of the wood gas as fresh air is being fed in through the secondary air holes. In that, it's very similar to looking down the throat of a chimney alcohol stove."

David, I agree with your statement.

Here are some photos of what the BB looks like inside the fire box etc.

Jan 28, 2012 at 6:48 pm #1831060 -

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

LAST CALL (Sale Ends Feb 24) - Hyperlite Mountain Gear's Biggest Sale of the Year.

All DCF shelters, packs, premium quilts, and accessories are on sale.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.