Topic

Cuben – The 422 mm hydrostatic head dirty little secret

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › Cuben – The 422 mm hydrostatic head dirty little secret

- This topic has 330 replies, 84 voices, and was last updated 5 years, 9 months ago by

Henry Shires / Tarptent.

Henry Shires / Tarptent.

-

AuthorPosts

-

Mar 25, 2011 at 1:17 pm #1714670

This morning I received an email from forum member Ken L with an idea to independently test a constitute component of Cuben which is Mylar. His question was, “Have you ever tested Mylar balloon material through the HH tester?

I had a new in the package “Original Space Emergency Blanket” which I promptly unwrapped, measured its thickness and HH tested it both pre and post Ziff Aging. An important caveat is I have no idea if this is the same formulation of Mylar used in Cuben. Further clouding the applicability is that it was coated with aluminum.

Thickness: .01mm

Virgin Hydrostatic Head: >3,515 mm H2OI then followed Ziff’s “scrunch and un-scrunch 5 minute aging cycle”

Aged Hydrostatic Head: >3,515 mm H2O

According to ISO 811, materials with a hydrostatic head of more than 1,500mm H2O can be designated, in general, as rainproof. So in the strictest sense, .01mm Mylar, used in the “Original Space Emergency Blanket”, is rainproof both in its virgin form and in its Ziff Aged form.

Picture of virgin Mylar pretest

Picture of Ziff Aged Mylar pretest

Picture of Ziff Conditioned Mylar at 3,515 mm H2O

Mar 25, 2011 at 9:12 pm #1714912

Mar 25, 2011 at 9:12 pm #1714912Nice test Richard. Did you happen to notice if the mylar failed dramatically (ie. a small rip occurred?) or did it just start seeping through?

Mar 26, 2011 at 5:50 am #1714974Dan,

There was NO leakage during either test.

Mar 26, 2011 at 5:56 am #1714976Just a thought, Here are some of the makers specs:

http://www.cubictechnology.com/index.htm (Note that it is advertised as waterproof.)

http://www.cubenfiber.com/cfhistory.html

http://www.cubictechnology.com/CTF3%20PRODUCT%20INFO%20PACK%2007192010_4c.pdf

http://www.cubictechnology.com/Technical%20Fabrics%20for%20Aerospace%20Applications.pdfMar 26, 2011 at 9:55 am #1715037Richard – so if there was no leakage is that 3515 the limit of your tester's pressure capability?

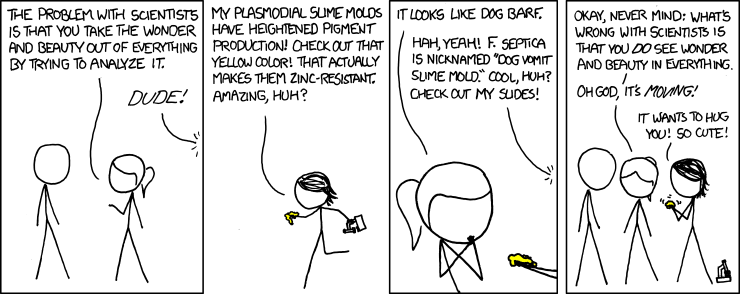

Mar 26, 2011 at 12:33 pm #1715083I found this very fitting :)

Mar 26, 2011 at 12:43 pm #1715087

Mar 26, 2011 at 12:43 pm #1715087Paul,

Yes, that is the current limit. I can modify the configuration for higher pressure testing in the future, if required.

For my current UL shelter material testing, the critical range where I want the most measurement granularity is between 1,500mm H2O – 2,112mm H2O to test rainproofness. Per the International Standards Organization 811, materials require a MINIMUM hydrostatic head of 150 cm (1,500mm) to be designated, in general, as rainproof. For US weather, 2,112mm H2O is a prudent level to be rainproof. Some US storms will require more than 2,112mm H2O HH to be rainproof.

The term waterproof is frequently used as a marketing buzz word; it has no precise meaning without qualifying it in each context used. For example, water jets are routinely used to cut metal and so even metal is not waterproof without a precise qualification of the water pressure force.

Only if I were doing rainproof tests for UL shelters to be used in the Brazil and Marshall Islands areas would I have to configure my tester for measuring pressures higher than 3,515mm H2O. Also if was focusing on flooring material, would I have to configure my tester for measuring pressures higher than 3,515mm H2O.

Mar 26, 2011 at 2:08 pm #1715119Roger,

"Basically, the drag force is exerted by the surrounding air. If the air is doing 60 kph sideways (ie wind), the raindrop will soon be doing 60 kph sideways with the air. Think leaves and dust."

So if the rain drop is going sideways at the same exact speed of the wind, then it would not fall to the ground? Or would the wind slow its downward velocity (resistance)? Does the wind cause the raindrops to hit each other resulting in spliting rain drops or possible allowing some to merge and gain size?

Mar 26, 2011 at 3:08 pm #1715138Hi Nick

Separate out the two directions. The rain will likely travel sideways with the wind at the wind speed, but gravity will still have its way as well. The rain will fall.

Mind you, having experienced rain going upwards in places … :-)

> Does the wind cause the raindrops to hit each other resulting in spliting rain drops or

> possible allowing some to merge and gain size?

I rather doubt it. I would imagine that all the rain drops would fall together at the same rate. They might even drag some air with them.Cheers

Mar 26, 2011 at 3:32 pm #1715154Stuart Robb was the first to submit a Protocol B submission. His air mail envelope arrived from Scotland about 1/2 hour ago. His test results were immediately emailed to both Stuart R. and Roger C. I am going to start a new thread this evening entitled "Protocol B Test Results". A complete report of Stuart's submission, sans the aging test cycle, will be included. Without divulging the results, this pure silnylon tested higher than pure silnylon I have tested from any US source so far(his source was Denmark).

Mar 26, 2011 at 3:36 pm #1715156Roger,

I am just throwing out these thoughts, as it is hard to consider/measure all the factors relating to rain versus static pressure. Plus, I have the flu and it is hard to sit still :)

Mar 27, 2011 at 9:05 pm #1715762"Just a thought, Here are some of the makers specs:"

James,

The links don't say much about water resistance.

In the last one, CT says:"B. Surface Coatings

Film coatings, such as Mylar (a biaxially oriented PET), are used for their high tensile strength, toughness, chemical and dimensional stability, gas barrier properties, high temperature resistance and low coefficient of friction."No mention of water resistance.

Mar 29, 2011 at 8:14 pm #1716925This darn thread was the final factor in my decision to put 1 oz rather than .5 oz cuben on the underside of my splash bivy. I'm sure the .5 would have been fine, but after reading this thread that little voice of doubt really worked away at me.

Mar 30, 2011 at 1:48 am #1717038> No mention of water resistance.

How … interesting!

Cheers

Mar 30, 2011 at 5:44 am #1717069No, that's right. They do, however, mention it in the front adds. The one about the inflatable rafts.

Mar 30, 2011 at 9:19 pm #1717579From the Protocol B thread in the MYOG section, Ben Smith's samples of 0.51oz (CT1K.08) and 0.69oz (CT1K.18) both were waterproof beyond the testing limit of Richards's machine (3500mm). That's a huge difference between the 420mm observed here and elsewhere.

Mar 30, 2011 at 10:44 pm #1717603I forgot that the testing results would be posted in another thread in a different forum. Too bad they aren't here. Richard, thanks for conducting and posting results.

Based on the photos of the cuben fabric in the MYOG thread, there appear to be different weaves for the same weight of fabric or the photos are not all of the same magnification. The one submitted by Ken Larson has a wider weave and the picture appears to indicate black areas, possibly breaches/holes etc. in the material. Whereas the samples submitted by Ben Smith seem to have a tighter weave and less or none of the black areas noted in the Ken Larson sample.

Konrad posited that the Ken Larson sample must be used and therefore the use has caused the degredation. A good idea. Can this "stuffing" really be the cause to degrade the fabric that much? Or is it that the samples of .51 oz cuben from Ben/Ken are different grades or types of material? It is noted that Ben's samples have exact nomenclature numbers and Ben's do not. Maybe Ken's is significanlty older than Ben's? Not the newest iterations of the material? -This is all very interesting. I just hope that stuffing/general use of the fabric cannot/does not degrade the material in such a way.

Richard, did the samples from Ken and Ben(.51 oz) look all that different to the naked eye? What was the porosity of these individual samples?

Mar 30, 2011 at 11:42 pm #1717621Warren,

Air permeability testing is MUCH more time consuming that HH testing. Ben Smith wanted to test some non-coated fabrics and I agreed to do it for him as a one-time favor. The objective of protocol B is HH testing of coated fabrics only.

All micrographs were taken with the exact same magnification (200x) and the exact same bottom lighting level. Unfortunately heavy polyurethane coatings are opaque and so little light reaches the fabric to illuminate it. Fortunately UL fabrics are either silnylon or Cuben and the light more clearly shows the weave structure.

I do not know why the first three samples tested with low HH. Two different samples were tested by me and one by Ziff. It is OK for the readers to guess now. I prefer to conduct the aging tests and study their results before I make a guess.

Mar 31, 2011 at 5:05 pm #1718005WoW! What an evening's entertainment. Big diff between 3515 ( maybe higher? who knows? since that's where the machine stops right ?) and 422

Mar 31, 2011 at 5:38 pm #1718023Cola,

Per the International Standards Organization 811, a shelter fly needs to have a minimum HH 1,5000 mm H2O to be "rain proof". You are correct, that there is a BIG difference between the first two Cuben samples I tested plus the one Ziff tested at approximately 422 mm H2O versus the last two I tested at >3,515 mm H2O.

Submissions from two other people just arrived in the mail a few minutes ago. So, stay tuned later this evening for updates on the Protocol B thread to what you called, "WOW, What an evening's entertainment".

Mar 31, 2011 at 7:13 pm #1718073Richard,

Thanks for the education on permeability. Didn't realize it was time consuming.

I thought that all the graphs indicated a magnification of 200x.

I figured you'd want to wait for ALL the data to come in. And thats statistically smart. Thanks again for all your work. This is some interesting stuff.

BTW, It would be great if the fabrics undergo a 200x magnification before and after testing, both being completed before the aging.

Mar 31, 2011 at 8:36 pm #1718105Although it's still early in the testing, it is clear that the HH results are varying widely for supposedly the same fabric (CT1K.08).

The main question left seems to be 'why are the results varying widely?'. It seems to me that it has to be either:

A) Some Cuben is created far more waterproof than other Cuben (manufacturing issues)

B) Cuben deteriorates in waterproofness (abrasion? time? creasing? stretching?)At this point, I don't see any strong evidence indicating whether it's A or B, but testing on B should indicate whether B is true.

Mar 31, 2011 at 9:48 pm #1718149Warren,

Only if there is a dramatic degradation from the Protocol B aging cycles for a Cuben sample, I will take another micrograph of that sample at the end of the aging to help in problem resolution.

Keep in mind that each aging cycle is more than 8x the work of the initial test. There are some people understandably impatient for a quick anomaly resolution.

Mar 31, 2011 at 10:15 pm #1718167Check the calibration of you equipment?

Mar 31, 2011 at 11:07 pm #1718187Warren Greer, I have been studying some 4 year old Cuben and it has the same black specks that are in the Ken Larson sample. I have been putting it through stress tests. Under my microscope at the same magnification the specs do not appear like breaches in the Mylar but simply are microscopic grist in the adhesive. They do not appear structural or to be breaching structure at all. It's too bad the photos supplied here cannot be of higher quality.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.