Topic

Japanese influenced (JSB) alcohol stove

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Japanese influenced (JSB) alcohol stove

- This topic is empty.

-

AuthorPosts

-

Aug 28, 2005 at 6:28 am #1341005

This will be easy, if it is you who can burn delicious toast when busy in the morning.

The top end of bottle — a round — please burn lightly. Please sew the butter of a favorite quantity. It inserted into the thick board, and could have,,,,,,

It was differed from!

It strikes carefully in several stepsIs this ok? JSB

Aug 28, 2005 at 6:58 am #1341006flower arrangement — it is wonderful.

I can feel for the layout the subtle and profound world which continues to right-hand side.

Thank you.

Heaven, earth and manAug 28, 2005 at 6:51 pm #1341032I have spent a lot of time the last couple of days looking at Japanese web site’s (in Japanese) with small stoves on them. Clicking on everything that looked like an active link. I have found all sorts of interesting stuff. There are several Blogs with a lot of attention give to small stoves. Comments back and forth and some about us. I left a few comments.

If you have been reading the posts from Yukio-san and Hideaki-san you may have noticed that the English is a little strange. They are using a computer translation program. In reading their Blogs they sound very frustrated at the results. I have tried to translate things from Japanese to English and also have been frustrated with the results.

Anyway I am really glad they are posting here. I never cared much for the “hockey” puck soda can stoves. I do like these and made 2 more today.

The most recent 4 post from Yukio-san have been interesting. With the pictures they are getting easier to follow. I found several of their Blog’s” that come out in computer translated English. I left JSB a comment on his Blog and the reference to “Thank you for seeing comics”. I take this to mean “thanks for looking at my Blog”

Yukio-san thanks for the information and thank you for the nice comment about the Chabana (Tea Flower arrangment). Someone wrote “Sad is a home, however practical and economical, when decorated with plastic flowers”.

I have to up-load the pictures of one of my new stoves. I was able to achieve the cyclone effect on my second test with it after a little tune-up.

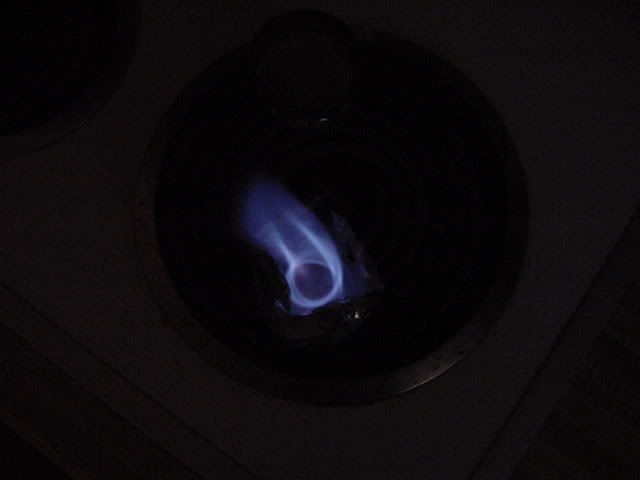

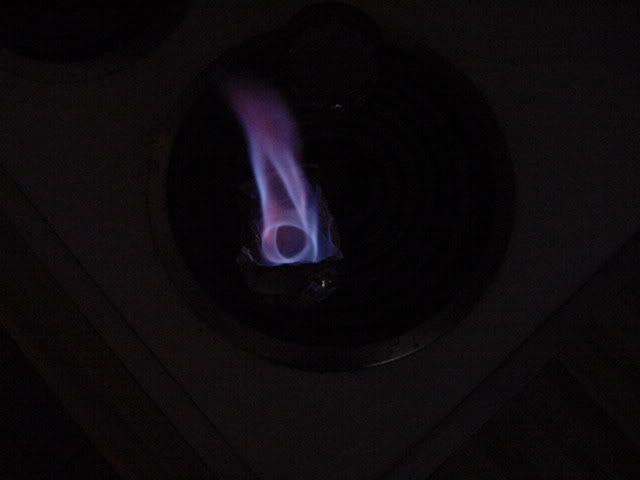

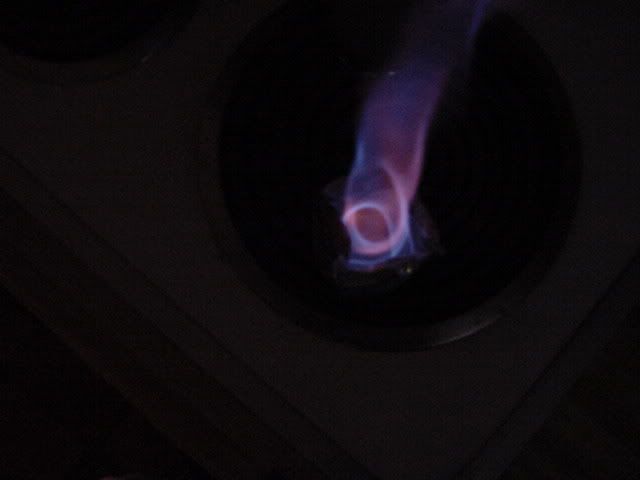

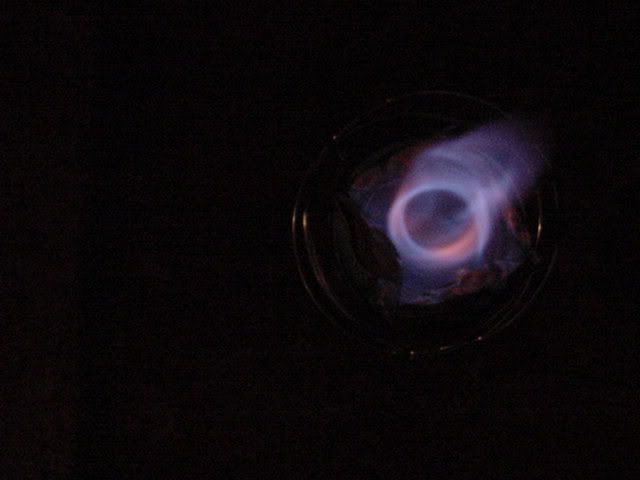

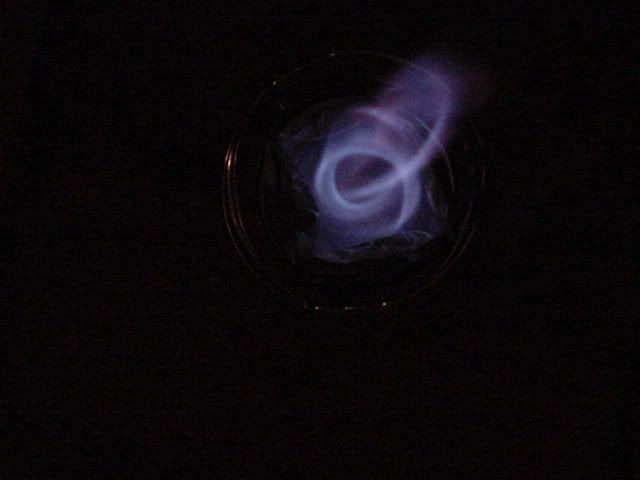

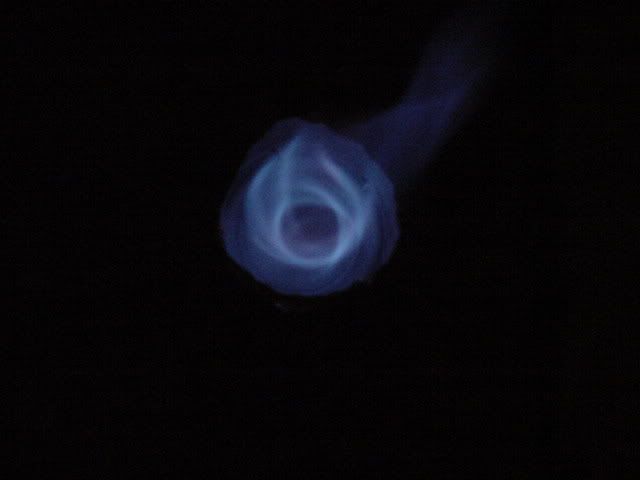

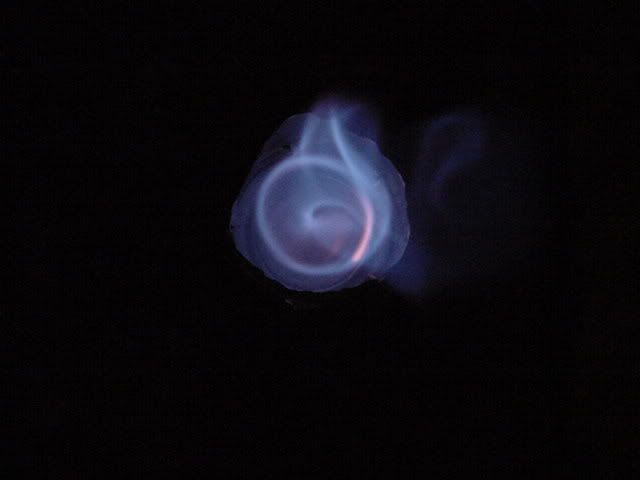

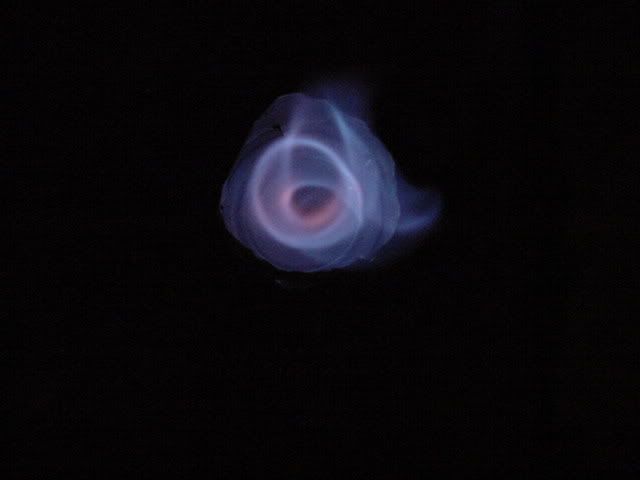

Aug 28, 2005 at 7:40 pm #1341035This afternoon I made two new stoves. The first was an attempt at a “Cyclone” stove. The first test fire did not achieve the “Cyclone” effect. It looked like it wanted to so I gave it a little tune-up. The second test fire was much better. Here are a few pictures from the second test fire.

Sorry, my digital camera does not have a video funtion.

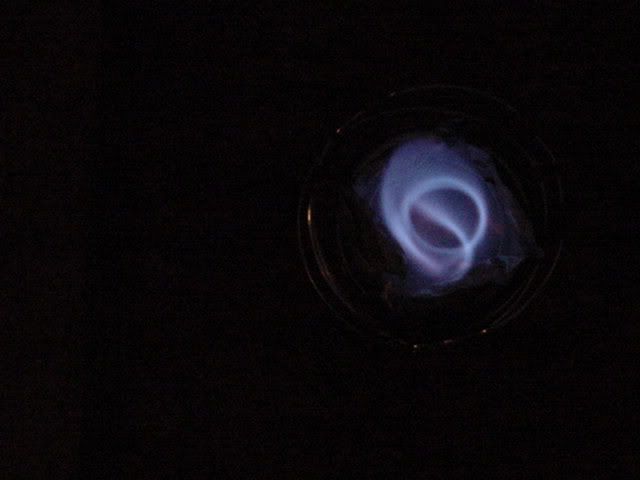

I did another minor tune-up and this is the third test firing. I think this is what I am looking for.

Monday I will do a few control tests to see how long this stove will take to bring water to a boil and how long it will burn on a given amount of fuel.

Aug 28, 2005 at 7:54 pm #1341037Hi Bill and Yukio,

I tried to make one of the cyclone stoves last night using a 100 ml beer can. I thought to follow the can stove idea (the rightmost can stove in the last picture posted by Yukio) which keeps the lid with lip intact, thinking that this would keep the can stronger. I managed to cut the triangular sides out, but when I tried to “fold” the spikes the corners tore, effectively weakening the whole structure. I finished the stove anyway, , trying to angle in the spikes and create the air holes for the cyclone effect. Unfortunately the angles of the spikes wouldn’t hold; they kept popping back out. When I tried out the stove with a little alchohol the results were unimpressive. Nothing I had done was right.

And the thing just looked like an ugly mess.May I ask how to get those folds? Is it necessary to cut the triangles free? Why exactly are the spikes necessary? Is there a certain height can that should be used? I’m thinking to use one of the steel, barrel-shaped “Fire Coffee” cans, which are a lot firmer than the aluminum ones, but am not sure I can cut it with a utility knife as easily as the aluminum can.

A little Japanese question for you, Yukio (for you others out there, you can read the Japanese characters if you change the text encoding in the “view” menu of your browser… usually Shift JIS is right, though sometimes one of the others or Unicode UTF-8 is necessary): 二回もストーブを作ろうとしたけど折る時にどうしても横の部分が破れちゃう。Yukioさんはやってる時手でやるのですか?ピンチを使うのですか?空き缶の大きさは大事ですか?昨日使った空き缶は100mlの札幌ビールの缶でした。ふたはそのまま残したけど取った方がいいですか?なぜ「柱」みたいな部分が必要ですか?色々試したけど今作ったものは見るものじゃない!酔っぱらいの浜辺パーテイの翌日の燃えないゴミ見たいだ。アドバイスはお願いします!

Basically I just asked the same thing in Japanese. I must say it’s weird writing in Japanese to someone who lives near me here in Japan through a site all the way in America…

Aug 28, 2005 at 9:11 pm #1341039I have tested my second and a little different “Cyclone” style stove. I changed the air inlet shape. What I have found is that I can refine the holes after the first stove burn. The Aluminum while still warm can be pushed easier than before the burn.

The flame on this stove is more active than it was on my first stove. I can see where adding some water in the alcohol might tone it down some. I will try that also later today.

Aug 29, 2005 at 7:47 am #1341043

Aug 29, 2005 at 7:47 am #1341043Those flames are awefully pretty.

Looking at those pictures of the flame patterns reminds me of a post I saw somewhere about the true hot spot of an alcohol burner being some 6″ above the burner due to a heat chimney effect. Which, if you understand (from fluid mechanics) that the column of rising hot air constricts itself much like the falling stream from a water facuet. Except, with hot air this may be more pronounced due to the compressibility of air… basically, the high hot spot (in zero wind conditions or full wind-break) concentrates all the btus released in the burning and also gaurantees the complete combustion due to pulling in plenty of air…

Anyhow, I wonder if this “cyclone” effect is not accomplishing a psuedo version of a simlar phenomena a full capturing of the btus and ensuring complete combustion… it also makes me wonder if this isn’t the grail that people have looked for to be able to use iso-heat (aka isopropanol)…

Aug 29, 2005 at 7:58 am #1341044バーナーで軽く炙ると柔らかくなります。

{柱}は、直接にポットを乗せる目的で

JSBは工作しています。別のスタンドを使う場合には、不要です。ゴトク無し。それは私の好みのスタイルではありません。

Aug 29, 2005 at 9:28 am #1341048古くからその効果が知られていた「煙突効果」

上に行くに従って、細径になり運動エネルギーが高まる。

これを中心部の真下に備えると、効果倍増する。

欠点は高さ方向を必要とすることです。10年ほど前に開発された「内向き燃焼」

幅広い火力を生み出す潜在力を秘めている。

そして熱効率もかなり良い。そして、5年ほど前に開発されて表彰された

トルネード燃焼(サイクロンも同じ現象)

すでに厨房用大型商品は市販されている。

大きい、重い

、、、、、、、、、、、、、、、、、、、、、、、、、、、、、、、、、

21世紀、超軽量で、世界最高熱効率を目指すのは、

上記の3つを併せ持った 1ozストーブ (笑)特に、内側のテーパー形状の煙突材料は

カーボン、チタンなどが必要かもしれない。Aug 29, 2005 at 9:35 am #1341049Hi Yukio Miguel and Bill

I am just trying to tranlate what he wants to say.

Yukio said.

” Heat the can with burner and you will cut and bend it more easily. The spike is only for support the pot. The spikes are unnecessary, if you use another pot stand.

I like the integrated style stove with pot stand.”Aug 29, 2005 at 9:55 am #1341051Next coment is more complicated.

Hi Hideake, Please help us.“The chimney effect has been well known from old age for good combustion. The tapered shape near the top of chimney is better for getting higher speed of air intake (draft). You may get more efficiency with setting the chimney shape air intake under the combusion room of the stove. About 10 years ago, the inner ward combustion was developed. This inner way has the high potential (possibility) for wide regulation of combustion and highly efficient one.

And about 5 years ago, finally the tornade combustion was invented in Japan. the company Rinnai have yet utilized this tornade combustion for propane burner in the market. However this burner is too big and heavy. I intend to develop the most efficient and lightest stove just weighning 1oz ! :-)

in the futre. maybe whilest 21 century .

Perhaps we need titanium or carbon made chimney air intake for this ultimate stove.”Aug 29, 2005 at 10:06 am #1341053Some scientific research reports that this tornade combustion is more than 30% efficient. That is you can save the fuel to some extent.

I heard so. however I don’t know where we get the report of the resarch.The principle of combustion about alcohole stove is a bit difficult for me and its explanation is beyond my English abilty.

Hajime

[email protected]Aug 29, 2005 at 11:08 am #1341057Thank you Hajime-san for taking your time to give us a better translation of Yukio-san’s messages. I thank Yukio-san for continuing to share his knowledge with us. I think we are learning fast.

Amoung the areas of Art that work in pottery is a big one. I have worked with clay for over 35 years and have built several pottery kilns. Today I have 3 electric kilns and 2 gas kilns. Over the years I have learned a lot about the different types of gas burners as used on the pottery kiln. I am re-looking at some of my books that have sections in them about gas burners.

Joshua, oh my, “fluid mechanics” class. I agree with your thinking. Part of the design trick as I see it will be to use more of the heat before we lose it to the atmosphere. There are a number of other challenges a big one is the small size and weight of the stove we want.

I use titanium for a lot of things and have a piece of some .016″ stuff to play with. I am about to go to titanium for a stove. I will work out the design with brass sheet I think and then try it in titanium. The brass sheet I think is like BrassLite uses for their stoves. The brass might even be strong enough to work for the Cyclone idea.

Aug 29, 2005 at 12:53 pm #1341068Bill,

What are you using to work with and weld Ti? I assume you are going to need to do some forming and working to get a Ti can stove turned out.btw, Yukio, that sketch of the funnel inlet bottom for the tornado burner is extremely interesting, talk about getting mental juices flowing…

Aug 29, 2005 at 5:15 pm #1341083I work with Titanium with what I call my Torch and Hammer – Pound and Form technique and use more or less primitive blacksmithing skills. I don’t have the equipment to weld Titanium. I fasten it together with pop rivets or really small sheet metal screws.

The pictures are from when I was working Titanium making my under 7oz Titanium and Carbon Fiber External Pack Frame. The finished frame alone as in the picture weighed under 7oz. The Titanium weighs 0.044oz per sq inch.

This is the same type of Titanium I made my Ti Spoon and Ti Trowel out of.

Aug 29, 2005 at 9:06 pm #1341090since the joinery for the stove will not likely need all the strength of pop-rivets you might look at some stuff called hts-2000 from http://www.aluminumrepair.com/ it might be able to braze / solder (not real sure of the correct term) any joins you need with the ti stove… or if you’re assembling with pop rivets, sealing the seams… tinny (minibulldesign) seems to like working with the material

of course, if you’re just needing to fill seams silver solder may work just fine.

Aug 30, 2005 at 8:27 am #1341099アルミ缶を重ねる方法は、既に紹介しました。

この方法を使って

缶底部分を重ねて(20mm高さ)

2重炎のCyclone stoveを試作しました。上の缶底に、十字架の形の切り込みを入れます。

そして上に向って、少し折り曲げます。

捻って折り曲げると、空気を回転させる効果が起きます。

缶を重ねる前に、この切り込み曲げ処理を予め実行します垂直まで折り曲げたら、結果はだめでした。

小さい面積で、早いスピードを誘うことが大切なことでした。そこで、十字形に戻してみたら、改良出来ました。

スピンは、ほんの少し掛かっています。

その面積はとても微妙で、神経質な反応を見せます。JSBはこのストーブを、「南十字星ストーブ」と定めました。

Southern Cross stove追記 Cyclone燃焼により、缶の中央下部分に

大きな負圧が発生しています。ほんの小さい穴でも、とても早い速さで充分な空気を吸い込みます

青い炎はそれを見事に表しています。

丁寧な調整作業は貴方に感動を招きます。(笑)Aug 30, 2005 at 8:48 am #1341101This is a computer translation of the last post from Yukio-san. I will try and rearrange the sentance structure and change a few words and see if I can make it easier to read and follow.

Thank you Yukio-san.

“The Southern Cross Stove”

“Already it introduced the method of piling up the aluminum can. Using this method Repeating can bottom amount (20mm height) Cyclone stove of the double flame was made on an experimental basis.

On the can bottom above, the cut of shape of the cross is inserted. And facing toward on, you bend a little. Twisting, when you bend, the effect which turns the air occurs. Before piling up the can, this cut bend processing is executed beforehand

When you bent to verticality, the result was useless.

In the small area, it meant that it is important to invite quick speed. Then, when it tried resetting to ten shape ofs character, it could improve. Spin catches just a little. The area being very delicate, nervousness shows the reaction.JSB decided to name this the “The Southern Cross Star Stove”.

With postscript: Cyclone combustion, in central lower part amount of the can Big vacuum occurs. Just even in the small hole, the sufficient air is sucked at very quick speed The blue flame has displayed that beautifully. Polite tuning causes impression to you. (Laughing) This is failure example

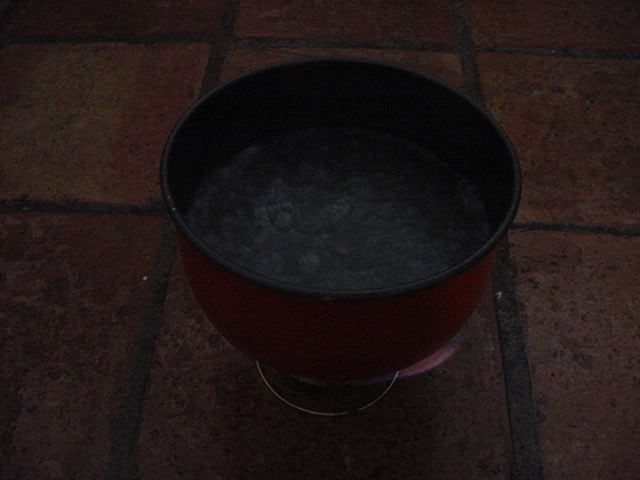

Aug 31, 2005 at 12:35 pm #1341157Matsukaze – 3 minutes

I just completed my first timed test with a newly designed Cyclone type stove. For the test I used a 1.5 liter Trangia cook pot with a home-made lid, 16 ounces of cold tap water, 30cc’s HEET, my stove, and I used the bottom part of my Ultralight Outfitters stove as a pot stand. My stove and pot stand weighs 0.75oz

From a cold start to Matsukaze (rolling boil) 3 minutes.

Sorry the pictures are a little dark. I did the test without a windscreen but on the floor in one corner of my kitchen.

Aug 31, 2005 at 1:25 pm #1341160

Aug 31, 2005 at 1:25 pm #1341160Anonymous

InactiveOne reminder all testing/results must be taken in the field at different elevations, wind conditions, air / water temperatures. It would be unwise to put any faith in the testing/results taken at home in someone’s kitchen.

Best of luck with your 2 pound kitchen kit

Sep 4, 2005 at 7:22 am #1341222アルミ缶ストーブを上下に2段重ねると

どういう効果になるのだろうか?もちろん、上側のストーブは

下からの炎の影響を大きく受けるので

総火力は2倍を遥かに超えるはず!ちょっと、試したら、、、

3倍ぐらいの 「火山噴火」になりました。

炎の高さは40cmを越えています。

(恐怖で、顔が引きつるほど)

燃費は、まだ測定していません。

やや悪いような印象です。ストーブに給油するときに

上のお皿と 下のお皿に巧く行うのが

かなり難しい。しかし、上側に給油して

溢れたものが下側に貯まる。

この方法ならば、簡単に実行できる。「2段重ねストーブ」

これも多分、世界初のものになるのかな? (笑)ガソリンを、火で炙ると凄いことになる。

アルコールの場合も、凄いことになるのだ!

Sep 4, 2005 at 7:27 am #1341224Sep 4, 2005 at 9:39 am #1341227I ran a computer translation of Yukio-san’s 09/04/2005-08:22:01 post. Then I re-worked the computer translation to made it easier to read. My version follows:

===============================

The “Comet” stove is made in a way to have 2 burner units stacked on top of each other. The top burner is made like the bottom half of a doughnut and the center hole lets the flame from the bottom burner mix with the flame of the top burner.The idea was to see if 2 burners would work together and increase the heat of the flame. It seems to increase the heat by two or three times over the heat of one burner alone.

The fire was like a “volcanic eruption”.

The height of the flame exceeded 40 cm.

I haven’t checked the fuel economy yet but I don’t think it will be good.

When refueling the stove, the small area of the top burner makes it difficult. If you refill the top burner first any fuel that runs over or misses the burner will go into the lower burner. A fuel bottle with a tube coming out of the cap would make the “refueling” easier.

I believe this “2 stacked burner” stove may be a worlds first.

===============================Thank you Yukio-san. aka – JSBJSB

Sep 4, 2005 at 11:05 am #1341231I ran a computer translation of Yukio-san’s 09/04/2005-08:22:01 post. Then I re-worked the computer translation to made it easier to read. My version follows:

This is a series of photo’s that shows how Yukio-san made the prototype Pot for the 2-burner Comet stove. He states that the “cook pot can” weighs 26gr and holds 400cc ( 13+ ounces) and the can used is 65mm diameter (the size of most 12oz soda or beer cans we see here – our 12oz Diet Coke can holds 355ml).

The total weight of the small stove and cook pot is about 41gr or 1.45oz. With 200cc (6.66oz water) it took about 4 minutes to boil. He observed a lot of wasted flame spilling out the sides and hopes he can make an improvement that will solve that problem.

He seems to be using some kind of “heat tool” in picture 134644AA.

Sep 4, 2005 at 10:34 pm #1341238缶の底をへこませる方法

はじめに、缶の底を焼きなましする。

バーナーで軽く炙る方法と

アルコールを注いで燃やす方法があります。棒の丸い先端部にバターを塗ります。後ろ側にパイプをセットします。

その間に、缶の底をはさむ。

そして、慎重に叩くと凹みが生成されます。ふたたび焼きなましをすると、ちぎれにくいです。

================

機械翻訳してみました

================

The bottom of a can is annealed at the beginning of the method of denting the bottom of a can. There is the method of pouring out and burning the method and alcohol which are lightly roasted over a burner. Butter is spread on the round tip part of a stick. A pipe is set to the backside. Between them, it faces across the bottom of a can. And a dent will be generated if it strikes carefully. It will be hard to be torn to pieces if it anneals again.Thank you Bill Fornshell-san

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Trail Days Online! 2025 is this week:

Thursday, February 27 through Saturday, March 1 - Registration is Free.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.