Topic

MYOG Ultralight, Fixed-Length, Collapsible Trekking Poles

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Campfire › Editor’s Roundtable › MYOG Ultralight, Fixed-Length, Collapsible Trekking Poles

- This topic has 48 replies, 18 voices, and was last updated 7 years, 6 months ago by

Bob Moulder.

Bob Moulder.

-

AuthorPosts

-

Oct 6, 2015 at 5:31 pm #1333176

Companion forum thread to: MYOG Ultralight, Fixed-Length, Collapsible Trekking Poles

Oct 30, 2015 at 3:52 pm #2235113Thanks for the feedback Keith. Here are the sources I used.. Carbon fibre tubes, 1 metre lengths, 10×8 mm roll wrapped, 8×6 mm pultruded. Tungsten tips. EVA foam grips"M". Rubber tips. 2 mm shock cord. Fishing line – local store Black polyester ribbon, 25 mm width, purchased from local sewing supplies store. Lying around in the garage, originally purchased from my local hardware store.. – Aluminium – had some 1 mm thick bar stock – Polycarbonate sheet, 2 mm thick,

Oct 30, 2015 at 3:55 pm #2235114The hyperlink for the "M" grips may have been to long to be accepted. Try.. https://www.therodworks.com.au/index.php?option=com_virtuemart&view=productdetails&virtuemart_category_id=676&virtuemart_product_id=6173&Itemid=165

Oct 30, 2015 at 4:04 pm #2235117They look great Bob, let us know how you go with the lighter tubes. I just used the fishing rod grips "as is" and find them very comfortable when coupled with wrist straps. Your Gossamer Gear grips are probably better if you don't use a wrist strap. p.s. I love the test venue!

Oct 31, 2015 at 7:09 am #2235188This is a cool project. I'm going to have to try making one. Thanks for sharing material sources and methods. Bob, that is some beautiful fall color! You have convinced me to go backpacking in the East some day.

Oct 31, 2015 at 1:27 pm #2235247Thanks again, Dave, for the inspiration! I had not previously used cork grips and was a bit relieved to discover I really like them. I concur with your observation that the GG grips are preferred when going strapless. They are also a lot lighter in weight than I expected.

Nov 3, 2015 at 6:21 pm #2235923Finally dawned upon me after using the poles a bit more that the GG grips are a simulated cork made from EVA or an EVA-like substance. Duh… Still like 'em, though, and they're a perfect fit for my 13mm-diameter poles. Durability should be excellent since the EVA grips on the BD Zpoles are holding up extremely well after quite a bit of use.

Jan 8, 2016 at 7:55 pm #3374666I’ve finally completed a longer and thicker version for comparison – I made a pair of folding poles 118 cm long (46.4”), using 12x10mm carbon fibre tubes, and 10x8mm tubes for the internal joining pieces. The final weight was 99g (3.5 oz). The construction was much the same as first time round with some minor differences..

- Two 500 mm lengths of 12×10 mm carbon fibre tube were used for the basic pole.

- The tungsten pole tips did not fit on the 12×10 mm tube, so I glued in a short section of 10×8 mm tube at the bottom, just the right length to accommodate the tip.

- The EVA foam handles needed a 10 mm tube to fit on, so I added a 10 cm (4″) long section of 10×8 mm tube to the top (bonded in place with epoxy).

- I also used ¾” thin and smooth black nylon webbing for the wrist strap in place of the much thinner ribbon I used previously, with conventional plastic triglide for adjustment. Webbing from eBay (http://www.ebay.com.au/itm/251148633603)

Conclusions – the poles were way too long for me of course, but would suit some of you giants. The 12×10 tubes are noticeably more rigid, but will still flex if you lean on them. They still feel very light, even though they are 40% heavier than the first pair I made. The webbing wrist strap was much more robust than the ribbon I used earlier, and at 8g doesn’t add much weight. Feels good and secure, though to be honest I still like the feel of the lightweight ribbon.

Some pics..

Extension piece at bottom, to accommodate the tungsten tip..

Extension piece at the top, to accommodate the EVA foam grip..

The nylon webbing wrist strap..

Top section assembled..

Folded for packing..

Jan 9, 2016 at 6:24 am #3374724

Jan 9, 2016 at 6:24 am #3374724Hey, Dave: Nice work! It is so nice that we can assemble our own poles to our exact specs, with a minimum of tools. I do find that Dremel quite handy!

I’ve continued the evolution with mine, still using 13×11, and now 11×9 as well for the bottom sections of a set that I made adjustable with 13mm Flicklock cams, which can be bought directly from Black Diamond.

My adjustable poles with straps weigh right at 5oz each, but they are very robust and I needed them to be adjustable for pitching my Duomid. As with your straps, I am using the polyester ribbon you suggested in your instructional, and also using your 3/4″ width. I haven’t used straps for a while, but I’m using these to experiment with their comfort and durability, and, at least thus far, they are quite comfortable. Durability unknown as I have only used them for about 30 miles of hiking. However, I’ve made it a point to give them harder use than I normally would and everything’s holding up fine.

Jan 9, 2016 at 7:44 am #3374727

Jan 9, 2016 at 7:44 am #3374727Bob – Wow. Awesome job, those look thoroughly professional.

Jan 9, 2016 at 2:25 pm #3374775Hi Bob, those look really good! I like the Flicklock cams – I looked up the Black Diamond website and they are only $2.48 each. I have a feeling that the ribbon straps might get bunched into “string” after a while if you let them; you just have to make sure they sit flat on you hand when you put them on.

Mar 8, 2016 at 10:36 pm #3387736Update – after a few dozen openings and closings the monofilament fishing line down the tube center of my first pole snapped at the point the pole was folded, apparently from abrasive wear of the line against the end of the pole. SO…

- DON’T use monofilament nylon fishing line, rather use some kind of lightweight braided and abrasion-resistant line.

- DO make sure you smooth the inside of the pole ends to reduce abrasive wear when folding.

- I might see if I can work out a joining method that doesn’t rely on a line down the center – will update if I find something ultralight that works.

Mar 9, 2016 at 5:31 am #3387742David,

Just throwing out an idea about a material for this purpose…

I have some personal experience with this, .038″ (1mm) vinyl-coated kevlar cord and it is amazing stuff. Absolutely zero stretch because it is used as rudder cables for very expensive radio-controlled aircraft, and it can be used with crimping ferrules (also on the site).

Maybe a bit of googling would reveal a source closer to Oz, but I did not search it out myself. Surely somebody else makes vinyl coated aramid fiber products…

[edit: perhaps something like THIS …]

Mar 20, 2016 at 8:32 pm #3390688I’m putting together a parts list to build trekking poles using 13×11 and 11×9 tubes for extra strength as shelter supports. I’m having trouble determining which parts will fit on these larger tubes than were used in article – can anyone point me in the right direction?

Tungsten tips, http://www.ebay.com/itm/231628601628 – will these fit an 11mm OD?

Grips, the Gossamer Gear cork grips look like they’ll fit 13mm but are there other options? Foam?

Mar 20, 2016 at 9:25 pm #3390703Without knowing the ID of the pole tips it’s hard to say with absolute confidence, but I have had good luck with 3 different tips using a 9mmx7mm tube as a ‘step-down’ section. Those tips look very much like one set of tips I’ve used.

The trick, however, is to get that 9×7 tube as far down into the pole tip as possible. This can be achieved by using a Dremel sanding drum to remove material from the end of the 9×7 tube and then cutting a couple of slots parallel to the tube length which permit the tip of the 9×7 to pinch together even more closely and therefore slide even deeper into the pole tip section. It’s not an exact science, but a little work will pay off. When you’re satisfied with the sanding and cutting (BTW don’t breathe in carbon fiber dust!), clean the tips and the 9×7 and glue the tips in with a generous amount of JB Weld or JB Quick.

I’ve been using GG Kork-a-lon grips and am still searching for an alternative. Those GG grips are indeed a 13mm ID and work extremely well with the 13mm OD tubes, glued on with simple 5-minute epoxy.

Mar 20, 2016 at 10:59 pm #3390728Excellent, thanks for the tips Bob.

Oct 1, 2016 at 9:43 am #3428811Hi,

Thank you so much for the great tutorial! I’ve ordered materials to make my own, but I’m wondering about the internal line to keep the two sections of the collapsible pole together, especially since David has had trouble with abrasion from the edges of the carbon fibre. I’m considering drilling a hole all the way through the step-down tube and outer tube and putting a bolt through this with a wingnut to keep the pieces together. It wouldn’t be as quick and easy to collapse the poles, but I don’t do so often, and I thought it might be an alternative to a line that might fray or break. However, I’ve never worked with carbon fibre before. Does anyone have advice on whether this is a bad idea? Is a bolt likely to put too much pressure in one section of the pole and cause splitting? I’m using 12mmOD/10mmID carbon fibre poles for the main shaft and 10mmOD/8mmID for the step-down sections. I don’t care if my gear looks unprofessional – I just want to build something that works.

Also, I love those GG grips, but it costs a fortune to ship them to Canada. Ditto with shipping GG poles – hence my DIY. American UL makers need a Canadian distributor!

Thank you,

Shannon

Oct 1, 2016 at 10:17 am #3428812drilling a hole all the way through the step-down tube and outer tube and putting a bolt through this with a wingnut to keep the pieces together

I would recommend strongly against that. It is the most highly stressed part of the system and any compromise of material there is going to cause problems, and likely sooner rather than later.

An easy solution is to use some duct tape to hold the sections together. I’ve done this with my fixed-length poles and it works quite well.

Oct 1, 2016 at 12:18 pm #3428825Hi Bob,

Thank you so much for the quick reply! You’ve saved me a world of pain. Duct tape sounds perfect.

Best,

Shannon

Oct 7, 2016 at 10:07 pm #3429970Shannon & Bob,

Sorry I’ve been offline for a while. I think I have found a much better way of joining the two pole sections. I made a prototype couple of months ago and have been trying them out as I was never very happy with the cord down the center of the pole and all the special fittings that had to be made – too complex! I have found this new method to be easier to make, easier to use, and more reliable.

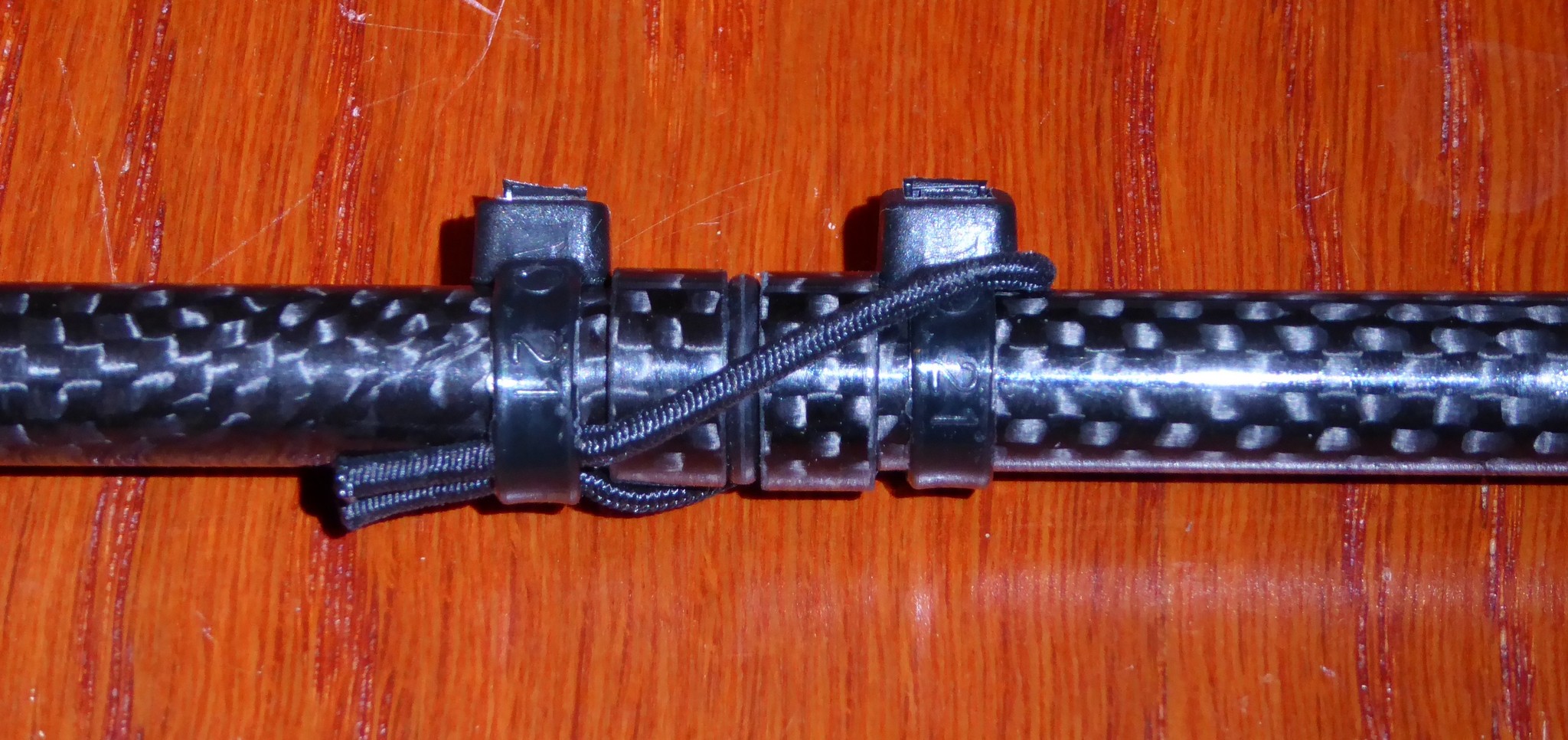

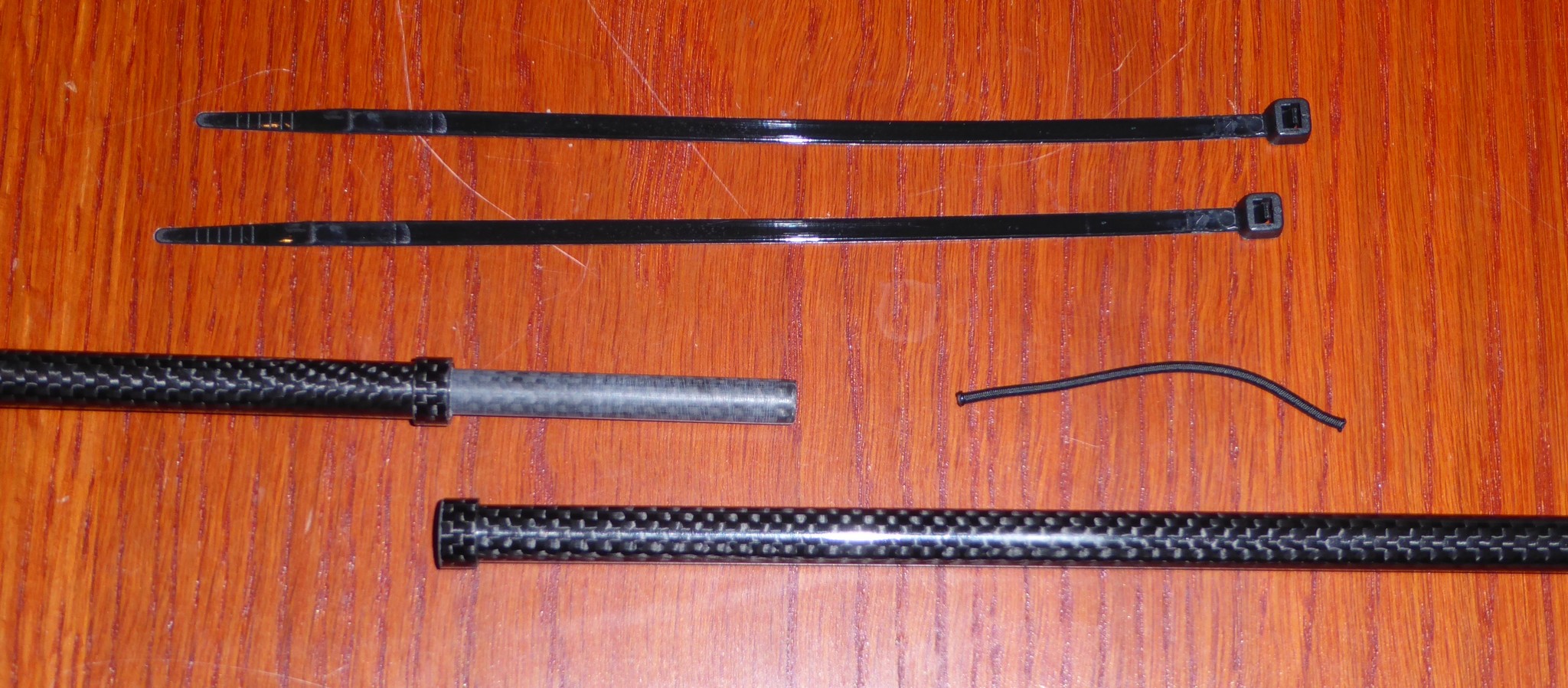

So… the first pic below shows what you need (based on my 10×8 mm poles) – two 10×8 mm pole sections with the 8×6 mm insert, and then epoxy bond a short (say 6 mm) ring of 12×10 mm tube onto the joining-end of each pole section. Plus you need two cable ties and a short piece of shock cord.

Use one cable tie to attach the shock cord to the pole section that has the 8×6 mm insert, as shown in the pic below. Make sure the shock cord loops around the 8×6 mm insert as shown. Then fasten the other cable tie around other the pole as shown. You could epoxy bond the cable ties and shock cord in place if you like, but I’ve found this to be unnecessary, so far they haven’t come loose after a couple of dozen short walks. And that’s it! To join the poles, push them together making sure the cable tie studs are aligned, and loop the shock cord over the stud of the other cable tie. It’s very easy to join or separate the poles this way.

And that’s it! To join the poles, push them together making sure the cable tie studs are aligned, and loop the shock cord over the stud of the other cable tie. It’s very easy to join or separate the poles this way. Oct 7, 2016 at 10:14 pm #3429972

Oct 7, 2016 at 10:14 pm #3429972… and when separating the poles, they will be in two pieces but you can use the shock cord to hold them together for convenience..

Oct 7, 2016 at 10:31 pm #3429975

Oct 7, 2016 at 10:31 pm #3429975and while I’m about it, here’s an idea for a fixed wrist strap that has been working well for me. Use a nylon screw (a metal screw would be fine), a nylon washer, and some webbing. Glue a plastic wall plug (not shown) into the top of the pole so the wrist strap screws into it…

So now we’ve got a completely different pole to what we started with :)

Oct 9, 2016 at 6:09 am #3430153Very clever UL solution, Dave!

My adjustable-length poles (which quickly became my ‘long-duration test bed’) have held up very well for quite a few miles for trips ranging from local trail walks with my dog to 3- to 5-day trips. They’re coming up on a year in service, and while I am careful not to abuse them, I also don’t ‘baby’ them.

The only problem I have encountered occurred last week on a 2-night trip when toward the end of the 2nd day I noticed a grip getting loose. I could have done a field repair with CA (“Crazy” glue) but had only a short, easy hike out the next morning and decided to wait and repair it at home with 5-minute epoxy. All done, and back in service.

For a few hundred miles I used some straps similar to yours and they worked well, but I did it just to test them and have gone back to the strapless setup that I prefer.

As an addendum for strapless aficionados, some months ago I used a Dremel sanding drum to remove material from the GG grip in the area of the index finger which creates a notch that allows the finger to wrap around the grip a bit farther and thus get a better ‘lock’ with the overlapping thumb. Although it is, of course, a subjective and individual judgment, after using this particular tweak for a few hundred miles I am ready to pronounce it a definite and worthy improvement. At least for me.

Oct 9, 2016 at 6:41 am #3430155

Oct 9, 2016 at 6:41 am #3430155Thanks for the durability report Bob. I’ve only done short walks with mine due to various constraints like work and teenagers at school ;-) but we’ve booked a couple of walks in New Zealand in January and I’m looking forward to seeing how they go there. Doing the Kepler and Routeburn tracks, about 100 km (60 miles) total over 7 days. The Kepler walk was my first “ultralight” experience (two years ago), and I enjoyed receiving comments from other trekkers like “where’s your stuff?” as we set off in the mornings. One looked at my kids’ backpacks and said I need to start making them carry more, then my wife and I lifted our packs and said “we’re all carrying the same” :)

Oct 9, 2016 at 9:48 am #3430168The reaction of trad folks to UL is always interesting… a few times I’ve gotten the “Really??” or “Are you sure you’ve got enough gear?” response!

Sounds like a wonderful trek you’ve got on the calendar. I have never been to that part of the world and will have to look online for a ‘sampler’. I hope you have great weather and a great time!

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.

And that’s it! To join the poles, push them together making sure the cable tie studs are aligned, and loop the shock cord over the stud of the other cable tie. It’s very easy to join or separate the poles this way.

And that’s it! To join the poles, push them together making sure the cable tie studs are aligned, and loop the shock cord over the stud of the other cable tie. It’s very easy to join or separate the poles this way.