Topic

Ultralight Titanium wood stove for hot tent set up

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Ultralight Titanium wood stove for hot tent set up

- This topic has 44 replies, 12 voices, and was last updated 7 years, 2 months ago by

Eric Blumensaadt.

Eric Blumensaadt.

-

AuthorPosts

-

Jan 26, 2016 at 5:59 pm #3378261

Anonymous

InactiveThanks James. Sounds quite a bit heavier than i would be interested in unfortunately.

Haven’t ever tried it in a bottle Franco. I never expected it to be fast or efficient, but during winter trips, i tend to have a lot of free time. Thanks for the other suggestion. By “painting”, i was being lazily inclusive of spray paint as well.

Jan 29, 2016 at 9:29 am #3378870Howzit coming along Justin?

Jan 29, 2016 at 4:53 pm #3378977Anonymous

InactiveRight now, pretty slow Dan. I’m still trying to figure out what i want to use for the pipe, whether SS or using Al and painting it and stapling some heat resistant cloth to the first couple feet.

I need to put up a WTB for some SS foil and see what i get. Anyone know what’s the thinnest stuff i can go with? I’ve never handled SS foil before. Offhand, i’m thinking .003″ might work, but i don’t really know.

And how is SS foil as regards emissivity?

Jan 29, 2016 at 7:15 pm #3378998I wouldn’t be concerned about emissivity;)

Use .003 stainless half hard. See if you can find it in 12″ wide rolls on ebay.

Jan 31, 2016 at 3:02 pm #3379293Anonymous

InactiveHi Dan, i might modify that to say, “one shouldn’t be too (or overly) concerned with emissivity”, but i think it’s a factor if efficiency is a goal. The smaller the stove, and the less fuel, the more efficient the system needs to be. I can see Richard’s point about that.

But, turns out that anodizing less emissive metals significantly increases emissivity. See:

http://www-eng.lbl.gov/~dw/projects/DW4229_LHC_detector_analysis/calculations/emissivity2.pdf

Titanium is fairly easy to heat anodize (by either building a very hot fire within the stove, or treating with a propane torch). (Either one is easy enough to do).Aluminum is fairly easy to electrically anodize (and then also dye).

So the new, tentative plan is to rough sand a bit, and then heat anodize the titanium stove, use a couple feet of rough sanded SS for the first part of the pipe, and then the rest will be roughened up + electrically anodized Al.

All of this will be lighter and longer wearing than painting. Anodizing the Al pipe will help it’s heat resistance some, especially if it’s already a couple feet up. Aluminum oxide has a much higher melting point, while being fairly non conductive, so the combo of the 3 above factors should allow it to be used safely if the first couple of feet is SS.

Thanks for the suggestions, i’ll check out ebay. Btw, for combining the SS pipe and Al pipe, i’m thinking of folding down a couple inches on the top of the SS pipe, and then folding up some of the folded down section, so that i can fit/nestle the Al pipe in that double walled section. For extra structure, i could put a hose clamp on that section, but i might not have to.

Jan 31, 2016 at 5:45 pm #3379354Anonymous

InactiveUpdate:

After looking around a lot on ebay and amazon, and some more stove specific sites, i decided to go with Titanium Goat again because they sell by the foot at reasonable prices. So instead of spending 30 dollars for 50 inches, twice of what i need, i bought 12″ x 24″ SS shim/foil at T.G.’s for 11 and some change with very reasonable shipping, and no wasted material. They sell .004″ stuff, so it’s a bit heavier than i wanted, but not that bad. (2.6 oz per foot vs .005 Ti at 1.85 oz per foot).

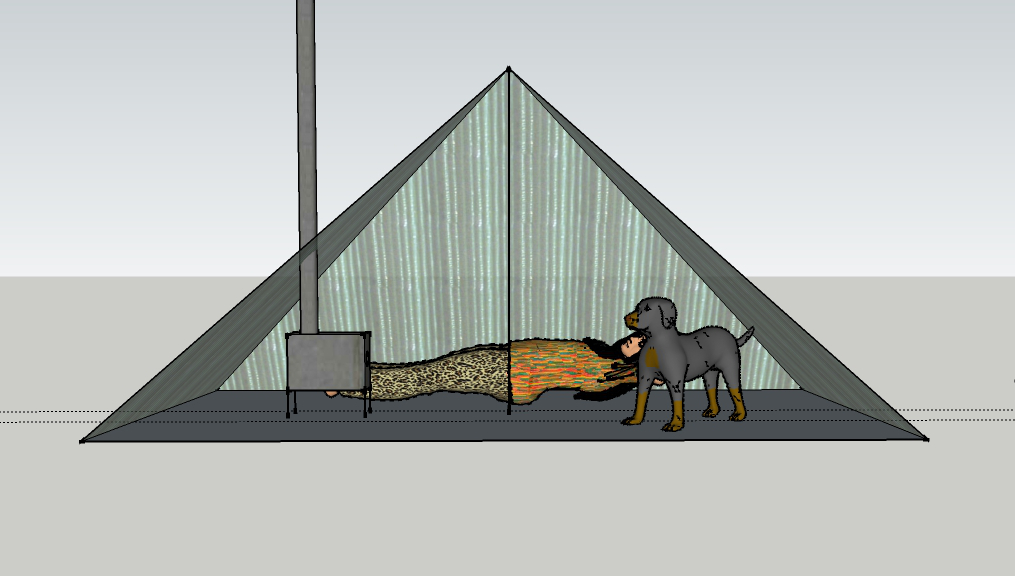

Feb 21, 2016 at 2:11 am #3383451Hi Justin any updates? Having thought more about your idea, I’ve tried modelling something similar – but with a Duomid….. Using Ti-goat small wifi stove, 11x5x12(h) total dimensions, plus pipe.

Where do you plan to position the stove in a Solomid, i.e. how far from the walls?

Feb 21, 2016 at 8:25 am #3383490

Feb 21, 2016 at 8:25 am #3383490Anonymous

InactiveHi Monkey,

I’m a lot more focused on/attached to the backpack project than the stove one currently. I should point out that i don’t plan on using it while sleeping, laying down etc, but rather sitting up (i mention that because in your modeling pics, you have the person lying down). I would like to put it as close to the apex of the tent as i can because i’m a bit worried about the cuben material becoming overly warm–though the IR reflective material + air gap it helps to create, should definitely mitigate that.

Frankly, the tent’s just too small to put anywhere else without worrying about the cuben.

I’m not an expert, but i would say in your modeling pic, the stove is probably a bit too close to the ceiling. You might want to contact Kevin from Seek Outside–he posts here occasionally and i’m sure could, if he’s inclined, give you some more expert advice or suggestions on this issue.

Since there is some actual interest in this project, i will update the thread with pics and reports when complete. Sometimes i say i’ll post pics or what not for a project, but if very little interest is shown, i don’t usually bother. (Like the insulated silicone bottle project).

Btw, earlier i said that i was going to anodize then dye the Al (to greatly increase emissivity) because it was “easy”. Doing some research into it, while it’s a fairly easy process, if you’re doing large amounts of Al at a time, you need a bit specialized equipment (a higher amperage, variable/adjustable AC to DC electrical unit), which i don’t have and is expensive (the simple car battery chargers that some use, likely isn’t strong enough for the amount of Al i’m doing). So likely i’m just going to paint the outside to increase emissivity, though i will heat anodize the titanium stove.

Feb 21, 2016 at 10:56 am #3383531I agree. The difficulty is, the closer the stove is to the centre, the closer the pipe is to the walls at the top (the panels of the mid that meet at the apex), potentially replicating the same problem. In a large tall mid this is not an issue as at that height the pipe is less hot. But with shelters like Solomid and Duomid being fairly short, the pipe is still very hot at the point where it is exiting the ceiling….

Looking forward to your updates, and more thinkering!

Feb 22, 2016 at 5:29 pm #3383876Hi Monkey

I had a Tigoat Vertex 5 with the stove jack at the apex behind the pole. The V5 is only about 6″ taller than the Duomid and I found this jack position worked perfectly and had no issues with melting fabric. I would do the same if I were attempting a Duomid conversion. For me personally, I consider the Vertex 5 to be about the ideal size (54 sq ft) for a solo hot tent (and without the stove a comfortable two man shelter).

Mar 28, 2017 at 7:17 am #3459956If you can find a durable way to keep the inside and exterior of the stove and chimney BLACK, like carbon black, it should greatly improve the transfer and radiation of heat.

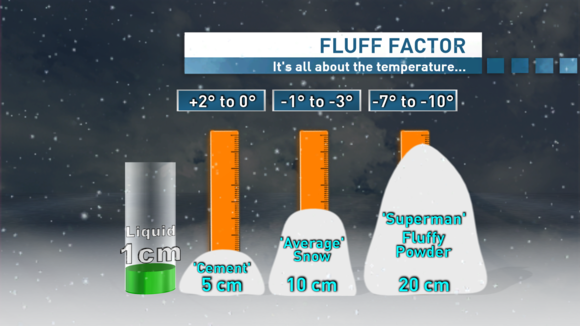

Mar 28, 2017 at 5:11 pm #3460112I did not bother with the safety aspect at the time because I did not expect the project to go anywhere and anyway was too busy visualising someone shoving snow through a 1 liter bottle so that an hour later they would get about 200ml of water…

The safety bit is that a stove like that will not support a stove pipe. Any movement (wind/bumping into the fabric) would tip that stove over particularly if the stove comes apart/deform easily.

Anyway, it would not work on snow.

Apr 13, 2017 at 1:29 pm #3463066Justin, Check out “Winter Trekking Forums” and the woodstove sub forum for any help you may need from those experienced hot tenters.

Apr 20, 2017 at 6:31 pm #3464252Justin, why not consider Kapton film as a heat barrier, as an alternative to the DP stuff? It would withstand much higher temperatures than the DP stuff, for a similar weight, but it would be more fragile. Kapton, in the relevant thicknesses, is very IR transmissive, which is obviously undesirable, but aluminized Kapton occasionally pops up on Ebay.

Aug 18, 2017 at 8:20 pm #3485914Anonymous

InactiveI abandoned this project primarily because of safety concerns. Contrary to what Franco said, it’s easy enough to create a thermally resistant, fairly lightweight base to put it on snow–provided there is any to begin with. Where I most often hike, even in the dead of Winter, there is not often much snow that lasts (because of fairly often wide temp. fluctuations above and below freezing)–so that was never a big consideration for me. Course, people often judge by their own conditions, experience, and perspective–somewhat understandably, but yet myopically.

Mainly the issue is lack of space and height–figured it just wasn’t worth the risk. I’m all for experiential experimentation and the like, but not at the risk of serious safety concerns and the potential to severely damage an expensive material/item (cuben-dyneema). Currently I’m thinking of increasing a tent’s thermal efficiency and using a couple of candles plus body heat primarily.

I may sell it, not sure.

Thank you all for the further feedback. Of late, I tend to go in long periods of not checking the site or posting much, and I wasn’t trying to neglect folks and their responses–I truly do appreciate the feedback and/or interest.

Aug 18, 2017 at 8:51 pm #3485915Contrary to what Franco said, it’s easy enough to create a thermally resistant, fairly lightweight base to put it on snow–provided there is any to begin with.

Where did I write that ?

I questioned how you can melt snow inside an aluminium bottle (how do you shove the snow inside it for a start…) to then melt next to YOUR stove

nothing about how is done on a stove like the TiGoat types and using pots.

Aug 18, 2017 at 10:04 pm #3485922Anonymous

Inactive“The safety bit is that a stove like that will not support a stove pipe. Any movement (wind/bumping into the fabric) would tip that stove over particularly if the stove comes apart/deform easily.

Anyway, it would not work on snow.*”

*(My use of bold and italic). Excerpted from the following post on this thread:

https://backpackinglight.com/forums/topic/ultralight-titanium-wood-stove-for-hot-tent-set-up/page/2/#post-3460112Btw, pretty early on, I agreed with you and said that likely hanging a bottle next to the stove/pipe was probably too inefficient of a way of melting snow and that I would probably just bring a dedicated cook stove for that purpose. See this post:

https://backpackinglight.com/forums/topic/ultralight-titanium-wood-stove-for-hot-tent-set-up/#post-3378075(I actually listen to others and consider what they say–even you, when you occasionally make holistic sense and speak logic thereof. It’s one of the reasons why I post a lot of my more experimental, expensive, or more difficult projects before I commence–for the collective knowledge and experience bank of BPL)

Yet, for some reason you beat it like a dead horse even after; can’t imagine why though. ; )

Aug 18, 2017 at 10:32 pm #3485924I can’t contribute much to the thread but I’m watching to see if I can get ideas for my own small tent heating stove.

Going a lot lower tech myself tho and using a small stainless steel stockpot for the firebox.

I had thought that the consensus was titanium foil as the most practical of the LW flue materials.

My own problem is getting a change of angle as I want to exit the flue though an existing doorway via a partly opened zipper and I can’t find a small angle flue joiner

Aug 19, 2017 at 12:19 am #3485934Anonymous

InactiveFrom listening to others more knowledgeable than myself, Ti for this use is best if it’s pure Ti, because a number of common alloys of same apparently have a problem with becoming increasingly brittle and non flexible/malleable with use, and eventually start to completely break down as it oxidizes more and more. The hotter and bigger the fires, the worse and faster it happens. In a little stove like the above, with a small, little fire, it probably would be less an issue.

Other than that, the other issue is it’s high expense. If I was still focused on this project (for small and lower heat stoves), I would probably go with a few feet of SS (thinner than what I got) for the lower part, and the rest treated Al. By treated, I mean a combination of anodized and dyed/sealed black (makes it MUCH more IR emissive and provides a bit of heat protection, though thermal cracking of the oxide layer can happen). If you get the right balance of SS and Al it will weigh similar or less than all Ti, and no matter what combo–definitely less expensive. I’d might line the first foot or so of the Al with some light, insulating, high temp material still, just to be on the safe side.

It would be a good idea to do some testing in the back yard and measure the average temps at different heights of the pipe system. 3 feet of base SS might not be enough for the Al.

As far as connecting the two pipes, I would bend down/fold over a lip to nestle the other half, and maybe also secure it with a steel based hose clamp.

If you have the spending money though, it would just be easier to use all Ti for the pipe.

Nov 30, 2017 at 9:39 pm #3504866A KEY to keeping warm tent air from going up the flue is to bing in cold air from the outside, under the tent floor and up to the combustion chamber. A 2″ diameter pipe is all that is needed. A cold air pipe will keep the stove from requiring tent air for combustion. Good sealing stove doors also help with this pipe. This setup likely would also cut down on the amount of fuel needed to heat the tent since it has that effect on home stoves with a cold air pipe.

Personally I’d like to have a stove with a flat surface for cooking/melting snow and a small titanium sheet wood stove with about the same surface area may be the answer (for me).

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

HAPPENING RIGHT NOW (February 11-21, 2025) - Shop Hyperlite Mountain Gear's Biggest Sale of the Year:

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.