Topic

UL Cot (primarily for extreme cold use)

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › UL Cot (primarily for extreme cold use)

- This topic has 25 replies, 8 voices, and was last updated 1 year, 10 months ago by

Justin W.

Justin W.

-

AuthorPosts

-

Feb 23, 2023 at 7:53 pm #3774030

The last few weeks have been taking away a lot of my energy (birthday of a loved one and multiple celebrations for same [she’s an extrovert and can be a bit extra], death of a loved one, chronic sleep deprivation, etc) and so I haven’t yet fully finished this cot project, but things are starting to improve in that area some. I’m starting this thread ahead of time to also try to light a fire under me arse a bit, to get it finished this week–preferably this coming Saturday.

So far, what I have done: Cut 8 22″ bamboo pole sections and reinforced each with a couple layers of 3.7 oz/yd2 S glass fiberglass and lamination epoxy on the outside and spray foam on the inside (the spray foam makes them even more stiff).

Took 2 EVA foam blocks sold for yoga use and cut them up into 8 cubes ( had some material left over) and then used a hole drill to cut out holes for the bamboo poles to slot in (well technically the corner pieces are not cubes because they are longer in proportion).

Cut various sections of 300lb continuous tensile strength (and 900lb temporary) black polypropylene webbing (1″ wide) and put Dragon Tension Locks (a plastic length adjuster for webbing etc) on each end.

What’s left to do: Need to sew loops on the other end of the above PP webbing.

General concept: Bamboo poles slot/fit into the EVA foam “cubes” to make a rectangular full length frame (I’m about 5′ 7″) and then there will be 2 lengthwise PP webbing straps and around 6 width wise PP webbing straps that will connect to the poles to support a full length, thicker EVA foam pad and to which a shorter, torso length egg crate type foam pad will go on top of.

Note, if the EVA foam cubes don’t hold up over time, I will probably switch them out for balsa wood blocks that will be waterproofed. Look for pics and total weight of finished project this coming weekend (most likely Saturday). Though this is somewhat bulky, the idea is for use in extreme cold, on longer duration trips, and with use of a pulk and/or extra large volume pack. In situations where you want/need something very reliable unlike an air mattress (still plan to use air mat for more regular and/or shorter backpacking trips).

I was thinking that if I could get the height of the webbing to around .4″ or so off the ground, and put very low CFM fabric all around it (like a fabric sleeve), this might cut down on convective thermal transfer some and add a bit of insulation to the total system. I also plan to put a some mylar space blanket type material underneath the cot to reflect IR back up. I don’t remember how much of an air gap is needed or ideal for this though (just remember that you need some for it to work properly).

Feb 24, 2023 at 5:17 am #3774050Any photos? I’d be curious to see this.

Feb 24, 2023 at 4:54 pm #3774124Hi Matthew,

When I finish the project this weekend, I’ll upload pics this weekend.

Meanwhile, anybody happen to know how much of an air gap is needed and ideal for IR reflectivity? I see different figures online so far.

Feb 24, 2023 at 5:15 pm #3774126If you have an air gap, like in a double pane window, you get some insulation value. The bigger the gap, up to about an inch, the bigger the insulation value. More air gap than that doesn’t add any insulation value.

If there’s a reflective surface, like an aluminized space blanket, then you get more insulation value from that air gap, than without the reflective surface.

So, I think that if there’s more than an inch it doesn’t add any insulation value.

I am deducing the bottom of your cot is a reflective surface, so a bigger gap up to about an inch produces more insulation value, but above an inch it doesn’t add anything

Feb 24, 2023 at 5:32 pm #3774131Thank you Jerry.

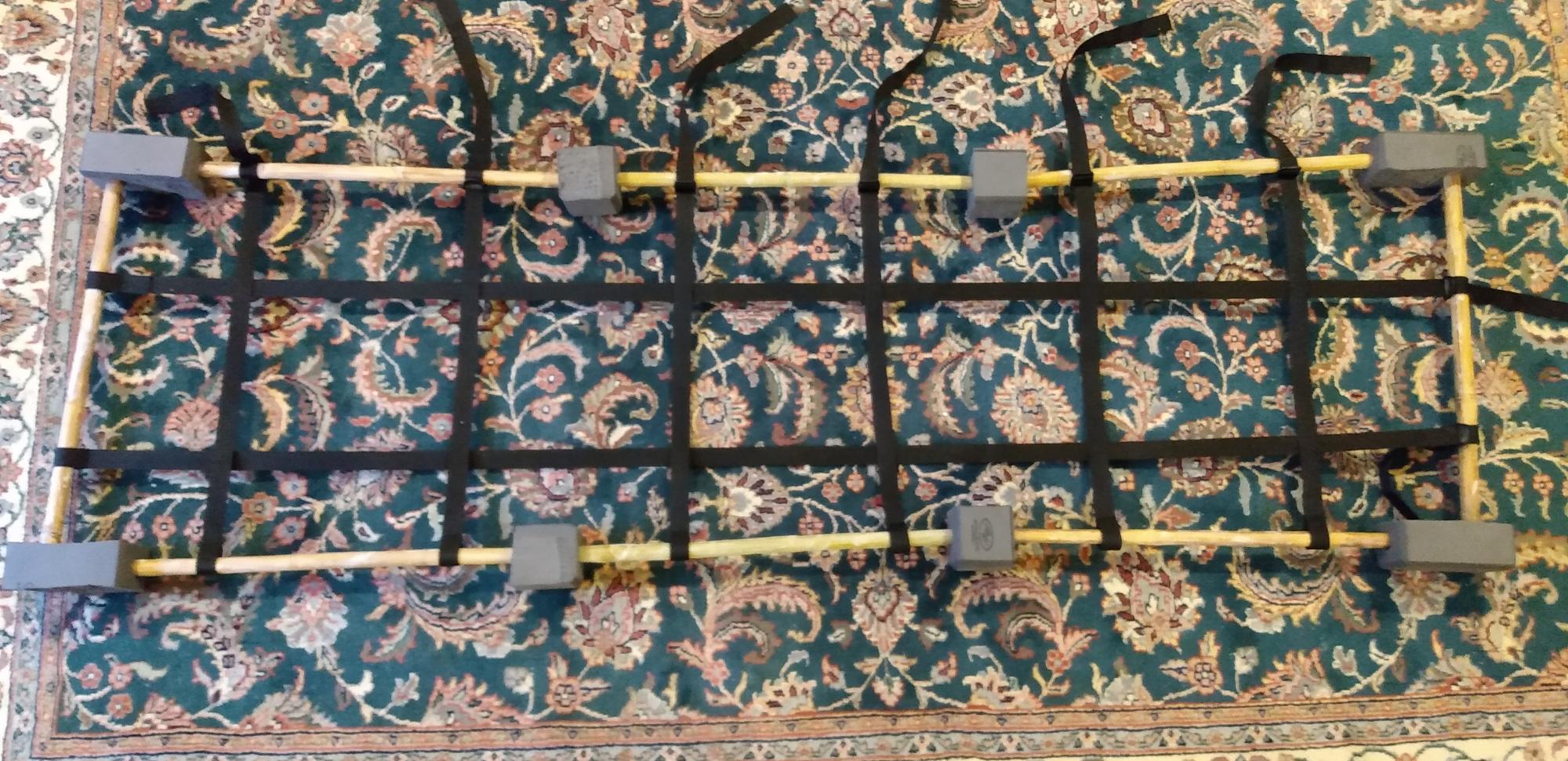

Feb 25, 2023 at 4:32 pm #3774227Welp, it’s very clear that I need to make some definite changes to the design and that I will need to develop a prototype 2. It doesn’t work in the current prototype and I can clearly see/understand why. But first, here is a pic:

It is too wobbly and so I can’t tighten up the straps enough to get it all rigid enough to put and hold weight on it. It needs a rigid cross beam (i.e. an extra width wide reinforced bamboo pole). Also, I don’t think the foam is the ideal material besides the weight. I think balsa or paulownia wood (preferably) would be better.

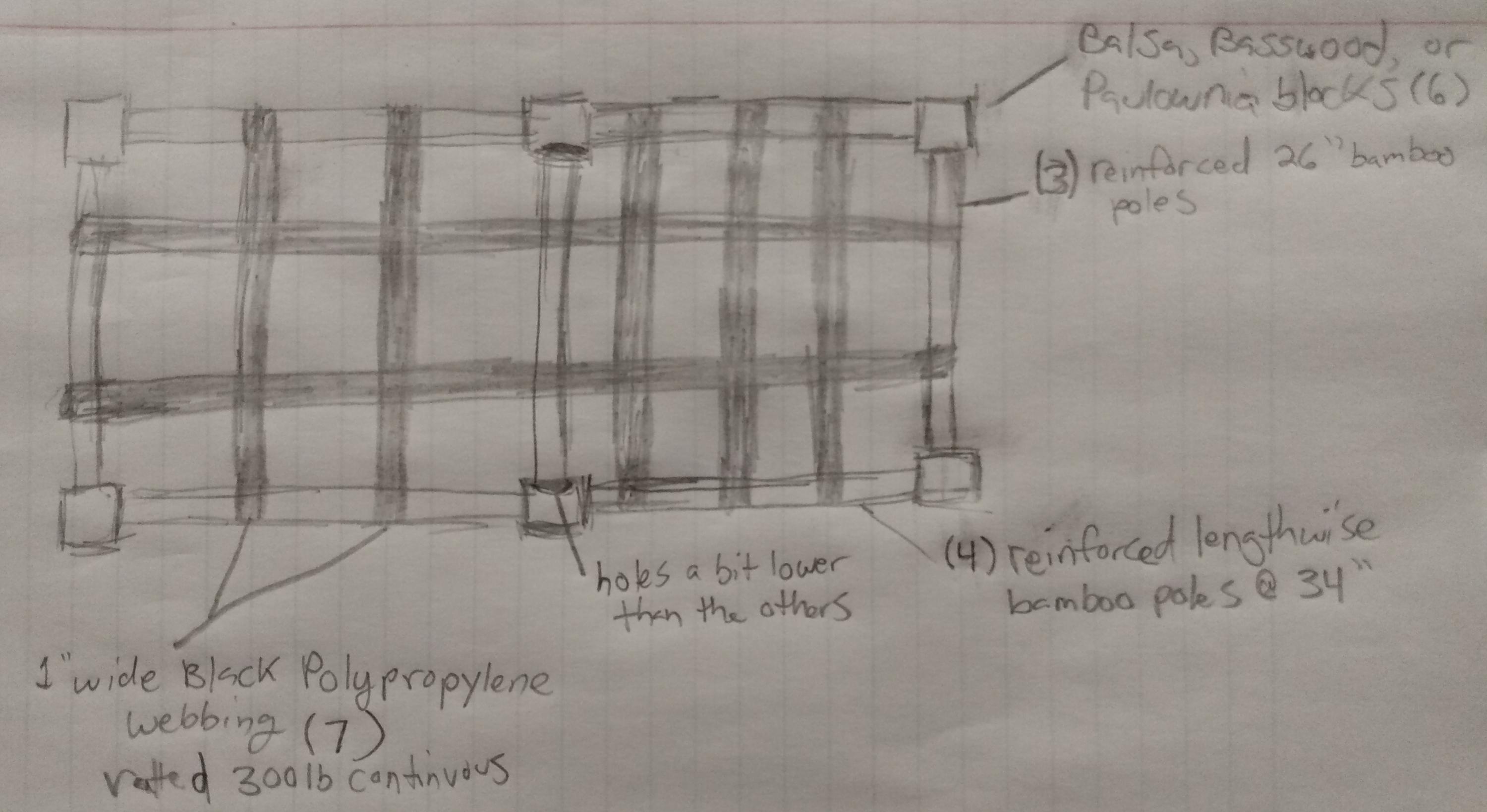

As the below pic shows, I plan to take out one of the middle blocks, and just have one connecting block in the middle, but with a cross support pole going across it (with 2 less blocks, it will take up less pack volume). The lengthwise poles will be lengthened from 22″ to 34″ and instead of 3 on each side, just 2. I also need to make the width-wise poles longer. I need the CCF pads and my body to fit in between the blocks, because the blocks are higher than the webbing straps. So I will lengthen these from 22″ to 26″ or so inches.

In case anyone was wondering, the bamboo poles are plenty strong with the S glass cloth+epoxy+spray foam inner reinforcing. I have a hard time bending them over my knee, let alone breaking them. But since the length wise poles will be significantly longer, I may want to use a bit larger diameter poles than I did for the above prototype.

One other change that I will probably make, is rather than drilling the holes in the middle of the blocks like I previously did, I will probably go up a bit higher to have more space/height underneath. I didn’t weigh it because the weight now will not reflect the weight of the finished, working prototype. But if anyone really wants to know the current weight, I will weigh it and get back with it.

Feb 25, 2023 at 7:36 pm #3774234Looks like a fun project. A couple of thoughts for you:

- Put your new crossbeam in the middle as close to the ground as you can – it will become uncomfortable very quickly if you have enough sag for the pad to touch it

- I know they will be easy to add, but I think you’ll need more straps across – especially near the middle

- Since you’re using bamboo, I’m guessing that the end diameters vary by a fair amount. Think about color-coded tape or writing numbers on the blocks and the ends of the bamboo so that you can put it together consistently the same way. I know you’ll have tension from the straps holding it all together, but I still think you’ll want the poles to go into the blocks with as snug a fit as possible – especially for your crossbeam.

- Make sure you can assemble it with winter gloves on – keeping in mind the subject of this thread

Looking forward to photos of the finished product!

Feb 26, 2023 at 12:07 pm #3774299Hi Kevin,

Thank you for the well thought out feedback/recommendations. To address your first comment, yes, I was planning on putting that middle cross beam significantly lower to avoid that potential issue. I also plan on using a thinner, lighter material for that middle cross beam. I have some Easton carbon fiber arrow shafts that I haven’t yet cut down to length, and with some spray foam in the middle, it should be sufficiently stiff and strong to act as the cross beam since it will not really be all that load bearing.

Straps: Good point. I’m also thinking of re-purposing some 1.7 oz/yd2 6.6. breathable nylon (Mountain from RSBTR) and rather than using so many straps, sort of make a partial hammock over the frame. The fabric will be cut up in two pieces and connected by 3 short sections of the webbing, and it will be sewed as to have sleeves on the side (of the Mountain fabric) that the poles can fit through. Then straps at the head and foot area to stretch it out. This way, I could also use the cot in summer/warm weather trips and w/out CCF. I’ll have to get the dimensions perfect though if I do this.

Poles: Good idea. But since I have to make/use new poles for prototype 2 anyways, I’ve decided to abandon the bamboo poles because of time and uniformity issues. I briefly thought about carbon fiber poles, but combo of expense and more so potential brittleness at severely cold temps made me think twice. On the other hand, 7075 T9 Aluminum is one of the relative few materials that actually gets stronger in severely cold weather. So I bought some .490″ (12.5 mm) Easton Al poles from Questoutfitters (which hopefully should arrive fairly soon since they are not super far away). I will still be spraying foam in the core to increase stiffness, so I’m hoping that they will be able to hold my 165 to 170 or so lbs. (Maybe Roger might have some feedback on this?).

I think putting it together with gloves on shouldn’t be too much of an issue, especially since I will be using more uniform materials in the future. I plan to drill the holes in the wood slightly bigger than the pole diameter, and put silicone caulk in the inside of the hole and on the outside of the poles so that it fits snug in there with some friction.

Some other changes. I’ve ruled out using balsa wood simply because it seems like a PITA to drill well. I would ideally like to use paulownia wood as it is only a little heavier than balsa but stronger and more durable, but I can’t find proper sized blocks readily so far. So I’m internally debating about whether to use basswood blocks (ubiquitous, cheap, fairly light, and easy to carve/whittle and drill) or laminate some paulownia boards together that I have, to make the blocks. I’m not sure how Titebond III or lamination epoxy will fair at -30 * F and colder though, I just know that a lot of adhesives lose significant strength at super cold temps.

Whatever the case, after I drill holes in 2″x 2″ x 2″ wood blocks, I plan to carve/whittle some of the top and side volume down to reduce weight and volume. But I want to keep the base at those dimensions for stability. It might tend up looking a little pyramidal like in nature.

Feb 27, 2023 at 8:49 pm #3774390FWIIW:

I think you will need at least one, if not two, cross beams in the middle.

But they will need to be curved so you are not sleeping right on them.

The legs on my ancient inherited steel-and-canvas cot look like a stretched out W, with a very low peak in the middle. The two bottom points on the W are where the cot rests on the ground. The two upper ends connect to the lengthwise steel rods.HTH

CheersFeb 28, 2023 at 7:59 pm #3774506Thank you for the feedback Roger. Do you think that a frame made out of 12.5mm OD 7075 T9 Al alloy Easton poles will hold 75 Kg, keeping in mind that there will be spray/expanded foam in the core?

Feb 28, 2023 at 10:59 pm #3774516Hi Justin

Hum, well, not sure.

I strongly doubt that filling the core of the tube with expanded foam will have a measurable effect on the bending rigidity. Sorry about that, and of course I may be wrong. the analysis of dual-component structures like that is ‘not simple’. Translation: I suspect the foam would just crush.I will have a look later this evening (Oz time) at my figures for the bending stress of these tubes. That will be theory, not experiment.

Um – I need the ID or the wall thickness for your 1/2″ tubing. Can you let me know please?

Also, crucially, what is the unsupported span? That is essential!Cheers

Mar 1, 2023 at 9:05 am #3774527I’ll get back with specifics later on today after I get home from work.

I’ll just briefly mention for now, that I’ve sprayed expanding foam in carbon fiber tubes, aluminum tubes, and bamboo tubes and all of them have the stiffness increased noticeably. I haven’t tested specific strength increases but it is noticeable.

Cyclists sometimes do it to their bikes to increase stiffness and to dampen vibration.

Mar 1, 2023 at 12:00 pm #3774539I would be inclined to agree with Roger. You are increasing the stiffness but not the strength significantly. Do you get too much flex without the foam?

The foam can also help with localized failure. For instance, places where the tube is being pinch, the expanding foam might prevent a failure. I haven’t done the calculations, but I would expect you have plenty of strength, on paper, with a 1/2″ tube. What is important is how stresses concentrate as you move around on the cot. That is harder to quantify theoretically.

Mar 1, 2023 at 3:07 pm #3774551I should have qualified my doubts. It will depend on the density or hardness of the foam. I am not up to date on what is available there.

Cheers

Mar 1, 2023 at 4:31 pm #3774553I concur that foam-filling a hollow member (tubing, bamboo, etc) will add stiffness. It will also increase ultimate strength because failure arises from bending too much.

I’ve played some with “foam-core” construction, given how very well it works on interior doors. I’ve created shelves in my garage that span 16 feet and carry a lot of weight with 1/4″ plywood skins with a 2″ gap between them. And small, strong objects. So could your support blocks be polyisocyanurate foam or some other rigid closed-cell foam skinned with 1/8″ plywood?

More cross beams will definitely help. Looking at commercial versions of cots, especially UL ones, there are 4 to 6 cross members. As Roger says, they’ll need to bent to pass below the person’s body. Each one can be lighter if there are more of them. Aluminum tubing from crutches at Salvation army would be about the right strength.

Use a fabric instead of straps. Any fabric will have plenty of tensile strength for less weight and provide much more uniform support. You could do a mock up with just blue-tarp material secured with duct tape.

Bamboo is a great construction material. It used to be the standard for ski poles and is still used for scaffolding in China, sometimes up to 20 stories in height. But there many different species and I certainly don’t know which ones have the best strength to weight, stiffness or even when/how it should be harvested and cured for maximum strength.

Mar 1, 2023 at 8:56 pm #3774573Hi Roger,

The ID is 11.12 mm, the wall thickness is .66 mm (I very slightly rounded up earlier on the OD, it is listed on the site as 12.45mm).

The side poles are a combo of 2 45.7cm poles fitted together. The head and foot (horizontal poles) are each 66cm.

On the sides and at the foot/head, the poles will be roughly about 2.5cm deep (on each end) into the raising material/structure. So the free/unsupported length of the side and head/foot poles will lose about 5cm length from the totals just mentioned.

(On a side note, we had 2 trees in our yard cut down today and while they were doing the work, they accidentally took out our cable i-net service and so I have to solely use my phone. Tedious).

Mar 1, 2023 at 9:06 pm #3774574Hi Ben, I just received the poles today (nice job QuestOutfitters, that was fast!).

A little worried. They are easier to bend than I had expected/wanted. But I haven’t done the spray foam process yet. I may skip that and lather up some carbon fiber arrows in plenty of epoxy (to avoid galvanic corrosion potential) and stick them in. (I will spray foam the arrows though).

I realize the UL way would be to just get larger poles… but I’m also working with an UL bank account and the above are materials I already have on hand.

Mar 1, 2023 at 9:27 pm #3774576Hi Justin

Well, what I can tell you is that your poles are 2.63x stiffer then the Easton 355 ones, which are fairly standard across many tents. Well, they used to be, although DAC seems to be taking over from them. Reasons unknown, although poor marketing and management might figure in it. Easton have long had the rep of being very difficult to deal with.

Is this stiff enough for a cot? Dunno. Sorry. you will have to test. Many bricks weigh ~7 lb each. But I am fairly sure you will need at least one, if not two, inner braces along the length.

we had 2 trees in our yard cut down today and while they were doing the work, they accidentally took out our cable i-net service

Ha! Don’t complain. When we have a big storm (which is kinda regular) a tree falls on the grid somewhere and we are without power and internet for a few days each time. Little stoves to the fore for dinner. Headlights in the evening.

And ‘they’ will be taking down another of our (very tall) trees in a few days, right next to the power lines. However, the tree loppers seem to be suitably scared of touching the wires. I suspect the tree drowned after one long spell of heavy rain. It happens.Cheers

Mar 1, 2023 at 10:10 pm #3774577Fell asleep, will get back tomorrow David.

Mar 2, 2023 at 8:41 pm #3774659Hi David, interesting stuff, thank you for sharing. Funny enough, a few days ago, I was thinking after handling some basswood and finding a little too heavy for my liking, that maybe I could do something like this? Get like between 2.5 and 3.5″ diameter bamboo and cut like 4″ long sections. Reinforce them with S glass and epoxy. Epoxy some similarly reinforced squares of birch plywood or the like to the bottoms, carefully drill .5″ holes through the sidewalls of the bamboo, insert/epoxy a metal sleeve into that, and then spray foam into the rest of the structure (obviously with some kind of top cap on it as well). Should be considerably lighter than solid wood blocks–minus maybe balsa. The only issue is that bamboo is not really strong nor durable when drilling into the side like that (hence the various reinforcements mentioned above).

It may be at least worth experimenting with. If that doesn’t work, I’ll probably try your idea of a plywood container with spray foam, or the like.

Yeah, I hear you on the fabric rather than the webbing. I’m hoping the fabric sleeve I made for the previous project is long and wide enough, because I plan to re-purpose that material.

Mar 2, 2023 at 8:53 pm #3774660Hi Roger,

7lb bricks? You mean wood blocks? I’m a little confused about that part. Thank you for the information about the relative stiffness compared to the fairly standard tent poles.

Yeah, we get storms that take out the power (the worst being ice storms, and very occasional hurricanes), but it is not that often and it is usually back up within a couple of days. The cable/I-net company already reattached a new cable line, but they plan to bury it further down the line. But we do have I-net now.

What with all the poisonous and venomous animals, the crazy brush/bushwhacking conditions, and the climatic extremes, Oz sure does sound like a fun place. Well, more seriously, I think I would like to visit at least once, but probably wouldn’t want to live there.

Best of luck with the tree removal.

Mar 3, 2023 at 12:11 am #3774668Hi Justin

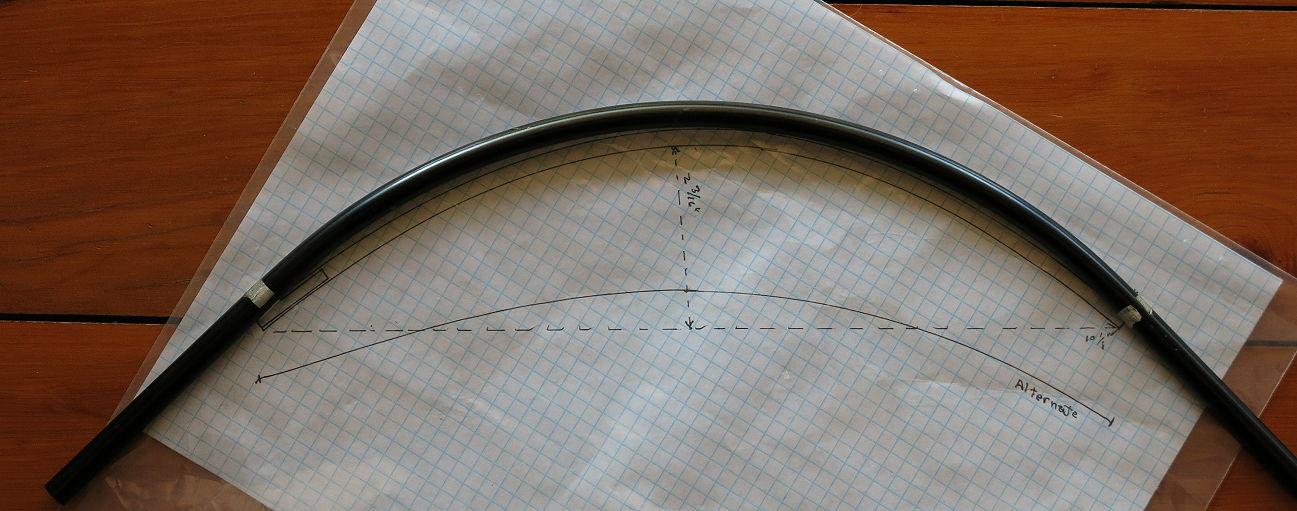

I have included some pics of my MYOG pack frame. They may give you some ideas. The curved tubes push the verticals outwards, against a tight bit of LenoLock mesh. The use of mesh here means my back does not get too sweaty.

This might resemble your cot?

This is one of the joiners down the side. Pressed aluminium sheet – I had to make the die for this. The black colour is Loctite Black Max: a slightly flexible superGlue.You might need to have ferrules here, into which your 12.5 tubes could slide. Tight fitting!

I don’t have a really good photo of the LenoLock mesh strung across the back, but this should give you an idea of how I had it. In your case you would want a breathable fabric instead, with some strength.Now, the big problem is how to get the curved cross-members. It IS possible to curve Easton tubing without breaking it; in fact keeping most of its strength, but you need special equipment for this. I did some bends for Sam F many years ago, for his pack with side-wings:

Does this help?The 7 lb bricks are standard house bricks: fired clay, usually a red sort of colour.

What with all the poisonous and venomous animals, the crazy brush/bushwhacking conditions, and the climatic extremes, Oz sure does sound like a fun place.

It is not THAT bad! The snakes and spiders don’t trouble us: we leave them alone and they go away. The scrub – yeah, thick in places, but there are (always) ways. The weather extremes – true, but one gets used to it. To quote one of our early iconic walkers: “There is no such thing as bad weather, just inadequate gear.”

Chuckle.Cheers

Mar 8, 2023 at 8:04 pm #3775258Hi Roger, thank you for the pics and for the further feedback/suggestions. I get the brick reference now–standard weight to test the strength of the poles. Not sure why it didn’t click earlier, except that maybe it was partly because it was very late here when I read and responded previously.

(Haven’t had a chance to work on prototype 2 yet, but will update when I do).

Mar 8, 2023 at 8:35 pm #3775260Just a thought: suppose you design a cot with 4 cross members and find you are overloading the cross-members when you lie on it. Well, no problem to add an extra cross member, is it? Etc.

Cheers

Mar 17, 2023 at 12:43 pm #3776069Hi Justin,

I’m wondering what the weight is so far? I switched to a cot after I couldn’t sleep on foam pads anymore. I may not have been careful enough in the past, but I also didn’t want to wake up because my inflatable pad deflated. So I got the Helinox Lite Cot, which is lite for a cot, but still twice as heavy as the pad it replaced. And I sleep so much better that it’s worth the weight for me.

One advantage I hadn’t thought about before buying was camping in the heat. It’s nice and cool sleeping on it in just my bag liner.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.