Topic

Suggestions for UL inner tent – made for pyramid shelter.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Suggestions for UL inner tent – made for pyramid shelter.

- This topic has 13 replies, 6 voices, and was last updated 1 month, 2 weeks ago by

Sam Farrington.

Sam Farrington.

-

AuthorPosts

-

Nov 10, 2024 at 2:24 pm #3821889

Hi,

I’m currently building my own pyramid tent and am looking for ways to reduce the overall weight. Right now, the inner tent weighs 522g, and I’m hoping to bring that down. One idea I had was to use a lighter bug net mesh material. However, as always, there’s a trade-off between weight and durability. I’m considering something like this: 0.7 oz Monolite Ripstop Nylon Mesh.

https://ripstopbytheroll.com/products/0-7-oz-monolite-ripstop-nylon-mesh

As for the bathtub floor, I’m not sure what material to use. The current version of my tent has a double-layer silnylon floor with a 5000mm hydrostatic head rating. How much water resistance do I really need, and are there other materials you would recommend for the floor?

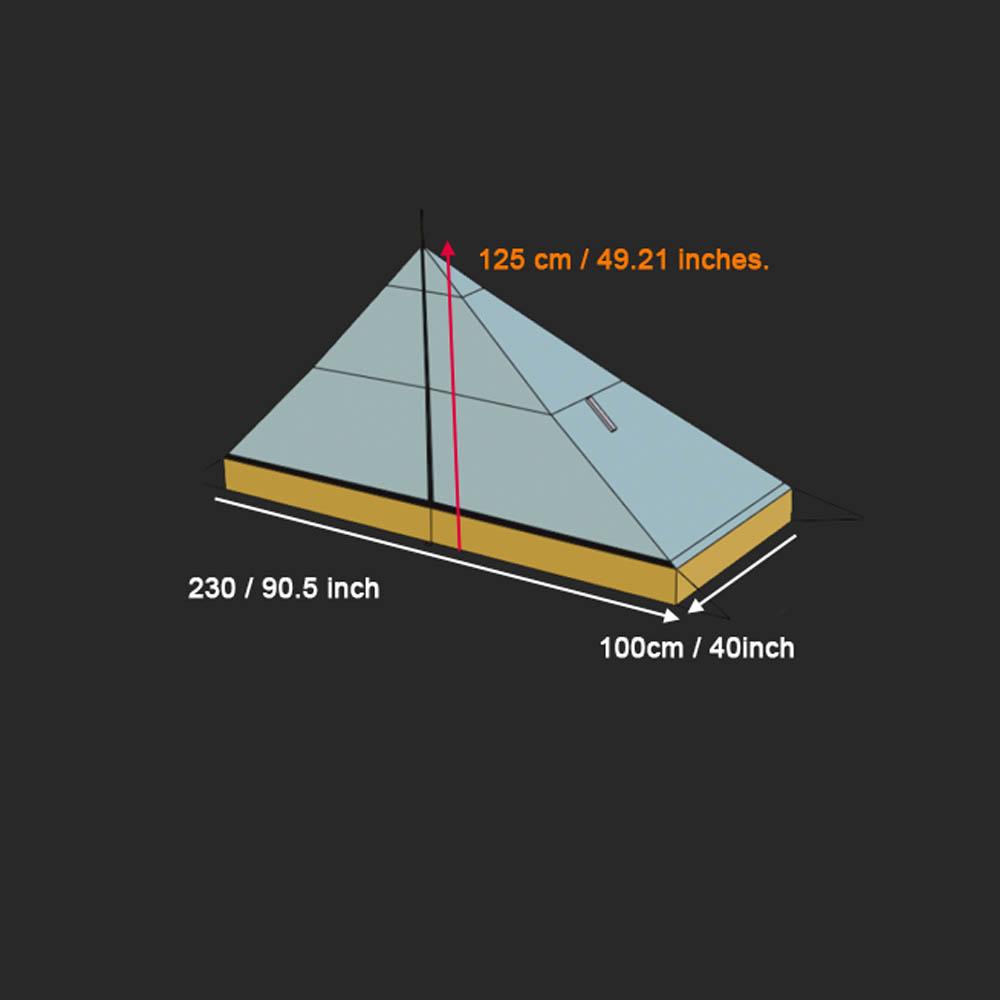

I have attached some measures.

Thanks for your help!

Nov 10, 2024 at 3:21 pm #3821897

Nov 10, 2024 at 3:21 pm #3821897522g (18 ounces) for inner tent seems like a lot. For a lightweight backpacking forum.

rsbtr has a 1.1 oz silnylon with thicker coating – 1.4 oz/yd2. Maybe a better floor.

is there just one center pole?

40 x 90.5 inches seems small, although with the short vertical sections on the sides it’s not so bad.

Nov 10, 2024 at 3:49 pm #3821898522g (18 ounces) for inner tent seems like a lot. For a lightweight backpacking forum.

Yes well everything depends on what lightwight level you are on i suppose.Yes this is a pyramid shelter so there is only one vertical pole. the max height on the rainfly is 160cm.

Unfortunately, there are no extra poles at the foot end to provide additional space for the feet.

However, I’ve added connections between the inner tent and the rainfly, which allow me to pull the inner tent out slightly. This creates more space around the head and feet areas.The shape of my tent is quite similar to the Lanshan. For comparison, the floor of my tent is 20 cm wider than the Lanshan. The height of my inner tent is the same as the outer tent of the Lanshan, which is 125 cm, but my tent’s maximum height reaches 160 cm. The angles at the edges of my tent are also steeper. That said, you’re right—my head does come close to the edges of the inner tent.

rsbtr has a 1.1 oz silnylon with thicker coating – 1.4 oz/yd2. Maybe a better floor.

interesting, I will look into this.

Nov 10, 2024 at 6:06 pm #3821907Ahhh,… i see, one side of the tent is verticle, the other slopes

Somebody makes a tent like that. One use was to put an injured person in the tent and then it’s easy to work on the person through the door on the vertical side

Nov 12, 2024 at 11:24 am #3822008MLD’s 2020 Solomid XL Innernet, which has similar although slightly smaller dimensions (229cm long x 81cm wide x 116cm tall) as yours, weighs 311g (11 ounces). It’s made out of 20D silpoly floor and .7 Nanoseeum bug netting.

Nov 12, 2024 at 2:52 pm #3822037

Nov 12, 2024 at 2:52 pm #3822037Thanks for the info, Wallace. Yeah, that’s a significant difference. I’ve been trying to calculate the materials myself, but I’m still not sure how the weight could vary so much. Now that I’ve got a few more features to consider, I think the bug net could definitely be a major factor.

Nov 23, 2024 at 10:10 am #3822850I built an A-frame style inner tent to go under a tarp that I used in Michigan this summer. It is floorless and will fit two people. I used the 0.7 oz NoSeeUm from RSBTR. It was a little annoying to sew, but not as bad as I expected. I would use it again.

Weight is about 8oz including tie-out lines and line-locs.

Nov 23, 2024 at 3:41 pm #3822873< are there other materials you would recommend for the floor?

After testing a number of silpoly tarps, I found the Yama Gear fabric to be lighter, stronger and more water proof. There may be lighter fabrics; but do not want sil/nylon for a variety of reasons that have been covered on BPL at length. For a floor, I want it to be fully waterproof, holding it’s shape when taut in all weather, and found that the weight of 1.08 OSY is substantially lighter than other fabrics of 20 denier. Also, based on BPL posts and my own tests of laminated fabric (DCF, TNT etc) I do not think they will hold up, plus cost much more.

Nov 30, 2024 at 3:00 pm #3823373Thank you for your response, Sam, and I apologize for the delayed reply. If I understand correctly, are you recommending a silpoly fabric for the floors? I’m not sure I fully grasped your answer. Would you mind sharing a link to a supplier?

Dec 1, 2024 at 5:18 am #382339630D silnylon 6.6 is the best choice for floor material. More puncture resistant and durable than comparable silpoly. Also sil/sil coatings are superior to sil/PU over time. Sure, PU allows mills to produce a very waterproof fabric for less cost and slightly less weight, but over time sil/PU just doesn’t hold up like quality 6.6 sil/sil coated nylon. RSBTR carries 30D MTN silnylon 6.6 for $13.50 per yard. Expensive but well worth it. Tarptent uses 30D silnylon 6.6 for floors with their tents and MLD uses 20D silnylon 6.6 as floor material on their mid innernets.

I made a floorless net for Pocket Tarps and Gatewood Capes awhile back with .67 noseeum, which is similar to what you have in mind. Weighs 6.5 oz and features a large L zip on front. I used 1.3 to 1.7 inch cat cuts on seams to attain a taut pitch. A 30D floor would add about 4 oz max, although you want a slightly larger innernet so that might increase the weight by another 1.5 oz.

If you want increased headroom and foot room with a 90.5″ long innernet, cantilevered corners are a great option. The SMD Serenity is made that way (among others). You can see in pic below of a net tent I made. Same principle applies for a mid innernet. I used bamboo sticks and 3/8″ flat elastic to do corners.

Dec 1, 2024 at 8:30 am #3823402Thanks Monte for the reply, that gave me some hope and inspiration.

I also got curious about this material for the inner net:

Dec 1, 2024 at 3:11 pm #3823412I would just use .67 nosseum instead of monolite for netting (at least for any noseeum which won’t be touching the ground). Far cheaper and a tad lighter. The .7 monolite would be plenty sufficient. 1.0 monolite would of course add some noticeable weight. RSBTR .67 is better quality than Dutchware.

The lightest and best floor option would be to buy an MLD pyramid floor and build your net around it. DIY’ers can’t get their hands on 20D silnylon of that quality and it would cut about an ounce off the weight compared to 30D silnylon. https://mountainlaureldesigns.com/product/pyramid-floors/

Dec 7, 2024 at 2:06 am #3823882When I see tents that sink inward, and sometimes need a lot of pegs and cord to stay put, I know it’s time to go back to the drawing board. And since I use only one trekking pole, there is no point in taking another just for the sake of the tent design. And often, the trekking pole is a blessing in fording rough and muddy wet spots.

Dec 17, 2024 at 12:47 am #3824582Please forgive me for stepping on my own feet; but a few things bare saying:

1. Granted, a pyramid shape does bring most of the weight and shape close to the ground, while also limiting height and shape; admittedly a logical goal.

2. But there are prices to be paid:

a. The approx. center pole is inevitably in the way; thus throwing the comfort out with the basket.

b. The pyramid design, with its sharply sloping sidewalls also inevitably gets in the way. Don’t take your hat off inside.

c. And those large flat sloping walls will collect a lot of wind and water, both of which are anathema to designs that seek to keep surfaces tautly flat.

3. If tents were shaped like clay, the lower surfaces would present a convex shape; sort of like an oval bowl turned upside down, with no obstructions inside the bowl. The curved bottom of the bowl would be turned downside-up to reflect the ravages of wind and water against the upper walls.

4. The goal then, is to create the bowl, elongated for human shape as much as possible, and that leads to poles that are ultra light, and connected to each other to add to their strength, and shaped as close as possible to the upside down bowl.

5. These concepts are not new, but all too often are neglected. Mostly, we see flexible poles, often carbon ones; but they slip back to struts that run crosswise to the longer poles. Thinking about this, it turns out that the weight of the tent poles ultimately turns out to be less than heavy poles, cords, and stakes used to immobilize many tents against the elements.

6. So the dread of poles in their sacks rules, to the fate of tents that might be better designed. Thanks for your consideration of all this. -

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.