Topic

Sewing is difficult, sewing machines are worse

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Sewing is difficult, sewing machines are worse

- This topic has 89 replies, 14 voices, and was last updated 4 days, 6 hours ago by

Terran Terran.

Terran Terran.

-

AuthorPosts

-

Jan 20, 2025 at 3:45 pm #3826780

Delivery date for the Liteway is March 25- April 10th. Double currency exchange. I’m not sure if that matters.

Jan 20, 2025 at 5:24 pm #3826782You guys are making me feel bad I didn’t try sewing today when I had the day off.

Jan 21, 2025 at 6:57 am #3826811Don’t feel bad. I have every day off…

Still eyeballing the Janome 8100 though the price has increased a couple times in the past couple days. I wonder what happened?🤡 I’ll keep looking for a used machine. Check the shops. Stay away from the Facebook hacks. Something a little heavier for heavier tarps for truck camping.

The 3f uf poncho is a pretty good deal. I hesitate to buy from China unless it’s something we don’t make or it’s a tool used to increase value of homemade products such as a sewing machine. Not that I haven’t. Buying from Ukraine, unfortunately is a bit of a hassle. I’m still looking at the MLD. Not just for backpacking. That helps me excuse the cost. Around the house. Along with a small cot and my bivy, it would make a nice kit for road tripping in a small car. Cowboy camp at the rest stops. As long as you don’t pitch a tent on the grass, they don’t get too upset.

Jan 21, 2025 at 7:10 am #3826812The OneWind Extended Length Poncho that I linked above is also a good deal, and is from a Wyoming-based company. It has some unique features, including sleeves on a poncho-tarp.

Jan 21, 2025 at 10:43 am #3826824With sleeves a poncho seems to have less ventilation. I have a very light Pertex Shield jacket I could supplement with if necessary. Admittedly, I let price guide me somewhat as there’s a large variation. Thirty dollars up to and over three hundred. Not a whole lot of explanation to as why. Perhaps I bought my fears, but I put in an order for the MLD pro poncho. These Colorado rains can be fast. In the past, I’ve just found a spot, sat and waited them out. I’m sure I’ll end up using it as a tarp as well. Orange citrus color. I’ll look like Cinderella’s pumpkin.

Jan 22, 2025 at 4:59 am #3826843MLD quality is supreme. The only thing that would deter me from buying the Pro Poncho is its huge size in poncho mode. But as a shelter it of course provides far more protection than a conventional poncho tarp. And Ron puts small cat cuts on the Pro to make for a drum tight pitch.

The MYOG 7D cat cut tarp below is also 5′ 6″ wide at head end, just like the MLD, so it gives you an idea of how much space you’ll have. Foot end is a tad narrower than the Pro Poncho’s 5′ width.

Jan 22, 2025 at 6:08 am #3826845I use a 96″ x 50″ DCF tarp now in case of rain. The rain here can come down hard, but it usually blows through pretty quickly. They do come in the evening, leaving very little time to dry off. I’m not making time or distance. I find a spot and sit them out. Get away from the lightening. The MLD should be more convenient. I may decide I like a poncho and get a more dedicated one. I know that I can always use a tarp. Trying to make up my mind. It seems ponchos are more popular in Europe with fewer choices in the states. I kind of gave up and ordered. Like any other piece of gear, you learn it’s strengths and limitations, then make it work by adapting to it. I envy the MYOG crowd for that reason. I think that can be a slippery slope in itself. Another expense. I like your setup. That’s one reason that I started getting into tarps.

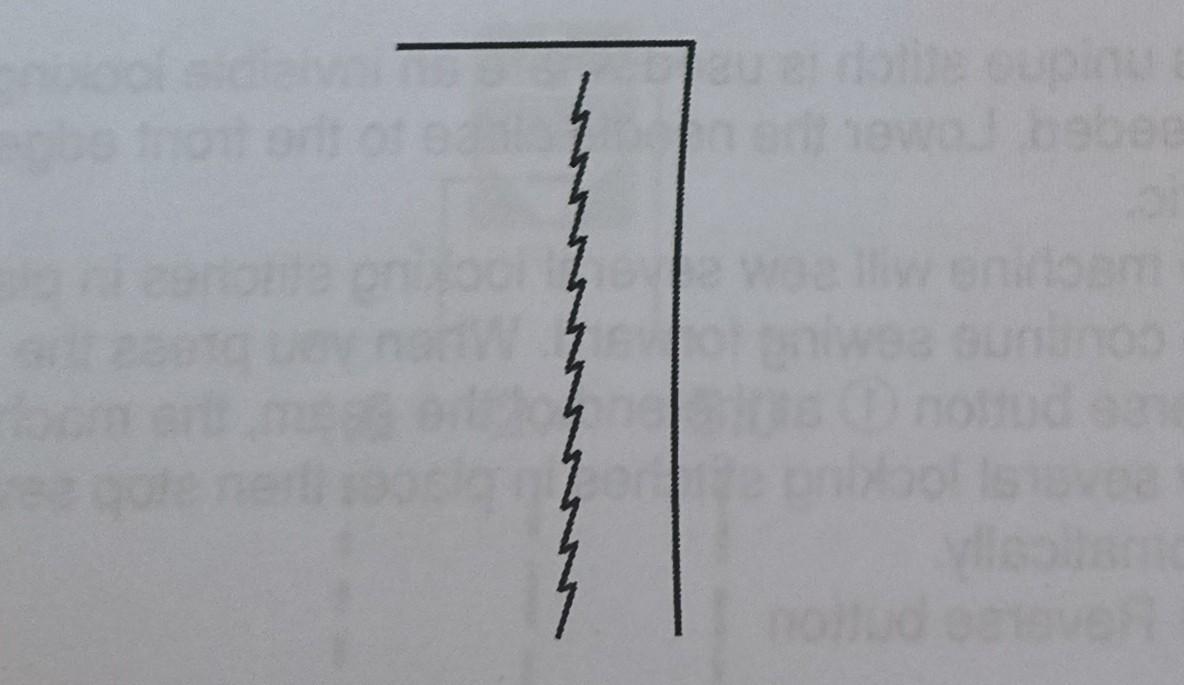

Jan 22, 2025 at 7:52 am #3826848so : sewing of many of the siliconized fabrics can be a bit of a pain. more than a pain actually. we, or I suppose it’s “we” are mostly all using the traditional bottom feeding dog type of machine. whenever I leave the gentle embrace of my sergers and head off into single-needle-singer-land (1964 mod 223) I find that the fabric really really wants to shift on me. tried various many types of glues and bondings to see the top sheet aligned with mr bottom sheet, mostly to “ok” effect. but ya know .. the top sheet is dragging on the foot, while the bottom sheet is more-or-less getting fed by the little grippers (feed dogs, I think). thusly the sheets slip in relation to each other. these days I just rubber cement the silnylon at the edge and its works mostly decently.

what kills it was to build a tape feeder device for my serger, and then just lay the sheets on top of the tape. that trick has reduced slipping to acceptable levels, as well as making hella tough seams on account of 6 threads and a tape seam all coverstiched and serged. it’s overkill, but makes concave curves easier to control. all that may not help much, but ok, try this. .. I use a LOT of oil on my units, even the “no lubrication needed” babylock’s. they run smoother when wet. everything I have sits in it’s own case/tray, so I just fold up a towel under there to blot up the dripn’s.

maybe it’s the oil the lets me get away with using rubber cement. and also maybe it’s like welding aluminum, I sell speedy machines that do that, and always warn the buyer “it’s like if I sell you a guitar on Friday afternoon, don’t come back here Monday morning whining to me that it won’t play Stairway to Heaven.

good luck,

v.

Jan 22, 2025 at 8:11 am #3826853I saw dual feeder feet with top feeds. IDK

Jan 22, 2025 at 8:28 pm #3826889Yeah, lightweight sil fabrics are tricky. The top piece sticks to the foot and slips relative to the bottom piece.

But if you can figure it out, it’s possible.

Take two test strips as long as anything you’ll sew. Make a mark at the beginning and end on both pieces so you can tell if it slips. Use pins or hand stitches at the beginning and end and several places in between on the two test pieces. As youre sewing, hold the next pin/hand stitch with your fingers and hold back a little pressure as it gets pulled into the machine.

Whatever your exact technique, practice on some long pieces until you can get them not to slip.

Jan 30, 2025 at 6:08 am #3827402I picked up a Janome S3 on the used market. One owner. Not refurbished by some unprofessional hack. There seems to be quite a few of those. Resellers. Some may be okay. You take your chances. More features than I need, but it has the features I wanted.

I plan on sewing syliconized fabrics as well as Alpha Direct. I’ll start with a beginner pattern and remnants from Walmart. Sun hoody maybe. I kind of remember the basics, but it’s been nearly 60 years past. Sometimes knowing a little is worst than knowing nothing.

I need advice and recommendations on putting together a basic kit as well as patterns. Scissors and adapting patterns for different fabrics. Do I need different seam allowances for Alpha. Ripstop has a limited number of patterns, besides I’d have to buy a printer. I think I’d rather adapt one from Simplicity.

I need to get on Google, but firsthand knowledge is always best.

Jan 30, 2025 at 7:23 am #3827405LearnMYOG has great patterns, instructions, and other info. It is an excellent starting point.

I don’t know how you live without a printer, but libraries and package stores (FedEx, UPS) may have printers available to use (perhaps for a fee).

A hot knife is nice for untreated synthetic fabrics that fray easily. Doesn’t have to be fancy — some soldering irons have knife tips. Cardboard is adequate to cut on. Pros use glass.

For siliconized fabrics, a rotary cutter or a new/sharp pair of scissors are fine.

For super tough UHMWPE, Kevlar/Spectra, etc, people seem to like electric rotary cutters.

The paper patterns from RSBTR don’t come with the actual digital pattern by default (unless they specifically say that they do). I was surprised (and disappointed) to learn that. Better to get digital patterns directly from LearnMYOG, Prickly Gorse, RockyWoods, ThruHiker, etc.

Jan 30, 2025 at 9:42 am #3827432The paper patterns were out of stock at RSBTR. I do have an old HP. It just seems like I have to spend $100 on cartridges every other time I use it. I put some cheap recycled cartridges in, but they didn’t work very well. I really only used it for doing business. The local library is on my way into town. That’s a good idea.

Edit: I looks like I could use a projector instead. I ordered a printer from Ali Express. It was cheaper than buying ink.

Jan 30, 2025 at 10:44 am #3827437I had an inkjet printer that did that. I didn’t use it very often. The ink kept drying out so I had to get new cartridge.

I got laser printer and it doesn’t do that. I only have to replace cartridge when it runs out of ink. Which is seldom because I don’t use it very much.

Plus, the laser printer ink is waterproof. The inkjet ink would bleed when it got wet.

Jan 30, 2025 at 10:47 am #3827439but, I use unfolded shopping bag for patterns. I use a ruler and a square to make lines that are square, and the desired distance apart.

Sometimes, I’ll decide I want to make a shirt a little tighter and then lay out the pattern with a shorter distance between lines. Or wider. Freehand curves.

Jan 30, 2025 at 11:40 am #3827440I was thinking of packaging paper.

I meant to say I ordered a cheap projector. I didn’t order a printer. See how it works out.

Jan 31, 2025 at 5:15 am #3827455

Jan 31, 2025 at 5:15 am #3827455RSBTR highly suggests using a serger with Alpha Direct. Is it possible to sew it on a regular machine? Double zigzag perhaps? Or just learn to roll? If you get it, you get it…

Jan 31, 2025 at 1:26 pm #3827513My experience with sewing Alpha Direct, no serger: normal seam allowance of 1/2″, sewed a slight zigzag – full width but not tight. Stretched the two pieces a little while I was sewing. Plain seam, no rolling or anything. No issues in the finished garment – but I don’t care how it looks, as I was making pants that are base layer or pajamas. Stuff does not seem to fray – on my lighter pair I did not do anything with the cuffs, just left the raw edge, and it works fine. Used lycra edge binding on the cuffs of the first, heavier pair, and at the waist of both, length of binding adjusted to get the amount of stretch I needed. I expect a serger would be easier, and you should definitely get a better looking seam than did. But functionally, a regular machine can do the job just fine. I find the tricky things are laying it out flat without stretching it before laying the pattern down, and marking it. I used a sharpie, and you better have something sacrificial underneath if you use a sharpie!

Jan 31, 2025 at 3:53 pm #3827518Thanks. That’s encouraging. I found a knit stitch in my manual. A modified zigzag. Maybe start with a buff. Practice on an old tee shirt Something simple.

Feb 3, 2025 at 7:29 am #3827701

Feb 3, 2025 at 7:29 am #3827701I found RSBTR very responsive to emails. I was told a serger isn’t necessary for AD and that a knit stitch was adequate. Slightly stretching the fabric as mentioned should give about the same results. I did find AD on Etsy for about half the price. While some sellers were selling seconds, this one didn’t appear to be. They had good reviews and promised some extra fabric scraps. I also ordered a few yards of Polartec Delta from them. However, do to great customer service, I will still give RSBTR my business even if it costs a little more. Sending emails and answering questions, it’s all work on their part. Advice is priceless.

Feb 3, 2025 at 10:11 am #3827725Re: Sewing machines. If you buy a Singer, make sure it is an *old* one. Singer went through acquisitions and bankruptcies starting ca. 1990’s and quality fell over the edge. Modern Singers have a reputation for breaking a lot. Is why they’re cheap, leading to frustration for beginners such as our OP here. Repair costs are more than the savings from buying cheap. I have not researched other brands personally. I learned to sew on a 1920’s (?) Singer treadle machine my mother had. Then she inherited an electric cabinet model. Both of these machines were forward straight stitch only. In the 1970’s I made Frostline kits including a tent and a jacket with the cabinet one. It was eventually lost. For the last 40 years I’ve used my other grandmother’s 1941 Singer Featherweight which–such luxury!–sews both forward and backward. Used it to make everything from dresses and halloween costumes for my kids, to curtains and other household products. Haven’t been making my own backpacking gear in recent years, but I expect the Featherweight could do it just fine. As far as modern sewing machines, the only thing I know is that one of my sisters and also one of my nieces sew all sorts of complicated projects and they both now have Juki machines.

Feb 3, 2025 at 10:40 am #3827728same here – my mom had a treadle machine but I don’t think I ever used it. It currently sits in a museum (my sister’s house)

then my mom got an electric machine, I don’t remember which brand. I used it to make a mid tent in 1970s. I remember there were diagrams of about 20 places where you periodically had to put a drop of sewing machine oil. I think maybe I broke it. I don’t know where it went.

Then, my wife got a janome maybe 20 years ago. She never used it, but I have quite a bit. It has sealed bearings so I don’t need to use sewing machine oil. I’ve never serviced it, just used it. I think maybe it has a problem because I noticed it occasionally dropping stitches. I should take it to someone. Once something stuck on the foot pedal and it went at top speed until something catastrophic happened – some pieces of metal were knocked out of place. I took it apart a little, then reassembled, and it’s been working since.

I think janomes work pretty good for home sewers. I can get it to sew light weight fabric. Not so good to sew through 1/8″ foam padding.

My only complaint is to reverse, I have to hold this button down. I wish it was just a switch so I could set it and use both hands to manipulate the fabric.

Feb 3, 2025 at 12:48 pm #3827736In my research I found out that Singer, Husqvarna, and Pfaff all have the same parent company. I read some bad reviews about Singer, so I avoided all three. Juki has a loyal following, however I only found ” straight stitch ” machines on the used market. Janome had pretty decent reviews. I do have to hold the button for reverse. Easy to program and overall seems like a well made machine.

Feb 3, 2025 at 2:29 pm #3827745You can do so much with a simple machine that works well.

I have sewn on one Elna sewing machine for 36 years and it was second hand when I was given it.

I’ve sewn my wedding dress, kids ‘pocket nappies ‘, bike panniers, fleece jackets, quilt, apex jacket, tent repairs etc etc on it. For stretchy stuff a slight zig zag is my friend!

But, yesterday, I bought my second ever sewing machine- a second hand Janome overlocker (serger). I don’t need it to sew the alpha direct I ordered….I just want it!

I’m very excited- which possibly means I need to get a life.

Feb 4, 2025 at 8:11 am #3827790Janome acquired Elna in the 90’s. Pfaff is also ran by them. They produce some machines for Baby Lock, who also has machines produced by Brother. Janome produces machines for other brands as well. While there are multiple brand names, there’s really only a couple manufacturers. Everything’s consolidated.

I wanted a machine to make a poncho, but then I bought a poncho anyway, so my reasoning went out the door….I just wanted it….I’ll make up a reason later. Keeping the mind occupied. Following my belief of lifelong learning. It’s a slippery slope. Like chicken math. You don’t stop at one. Now I have to keep it fed with fabric and thread. Needles and sewing pins. Scissors, rotary cutters, boards and all to prepare the feasts. Repeat over and over to myself, ” I don’t need a serger, I don’t need a serger.”

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

HAPPENING RIGHT NOW (February 11-21, 2025) - Shop Hyperlite Mountain Gear's Biggest Sale of the Year:

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.