Topic

Reinforced Silpoly mini tarp vs non reinforced version, experiment/testing

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Reinforced Silpoly mini tarp vs non reinforced version, experiment/testing

- This topic has 18 replies, 4 voices, and was last updated 5 years, 7 months ago by

Anonymous.

-

AuthorPosts

-

Jun 14, 2019 at 7:08 pm #3597861

Anonymous

Inactivevvv

Jun 14, 2019 at 7:49 pm #3597865Anonymous

InactiveThis is sort of related to the Polycryo thread, with a similar, but modified approach for Membrane Silpoly fabric, which is a somewhat fragile fabric, but has some otherwise nice properties.

Instead of using UHMWPE/Spectra fishing line like before, I’m now using thicker (1.1mm) 300lb black Kevlar cord. It is attached to the Membrane Silpoly mini tarp (1 ft2) so far, by a combination of largish strips of 1.1 oz/yd2 Silpoly bonded to the Membrane Silpoly with silicone. Then to extra reinforce it (once the Silicone is cured), 1.6 oz/yd2 Silpoly will be sewed around the perimeter, going over the kevlar cord+fabric/silicone reinforcements.

The strips of 1.6 oz/yd2 Silpoly will be between 3 to 4″ wide, and then folded in half.

I cut two 1 ft2 pieces of same Membrane Silpoly fabric. The other will be the control piece–they will have the same exact size and material guy outs sewed to them in the same way.

Then weights will be hung from the guy outs, until the fabric fails. The starting weight will be 30 pounds of water+bucket, which if it survives that, 2.5 lb weights will be loaded into it slowly and one at a time.

Because the thicker Kevlar cord will be MUCH better secured onto the Membrane Silpoly fabric vs the Polycryo w/ thin, Spectra fishing line, I predict that the reinforced mini tarp will be able to take much more weight than the non reinforced tarp. Anybody want to throw out some predictions in general, or as to how much weight per each mini tarp?

Another difference is, much less cord is being used this time. There will be 8 guy outs, each with an end of Kevlar cord attached to same, and thus 4 lines of cord. This definitely cuts down time. (Though the silicone curing does add static time to the process, especially since it’s wise to do one half at a time imo).

The reinforced mini tarp has the 8 connecting Kevlar ends + 1.1 oz/yd2 Silpoly/Silicone attached to it, but the silicone is curing currently. It should be ready for testing tomorrow after the 1.6 oz/yd2 Silpoly border perimeter and DCF guy outs are sewn to it. I’ll probably have to do video documentation.

It probably sounds like more work than it really is. I’ll be testing Polyrcyo again in the future, with some modifications as well.

At some point today/tonight, I’ll take a pic of the uncompleted reinforced Membrane Silpoly mini-tarp.

Edited to correct thickness of cord from 1.3 mm to 1.1 mm.

Jun 15, 2019 at 3:02 am #3597929Anonymous

InactiveGot home too late tonight, am too tired, will have to wait till tomorrow.

Jun 16, 2019 at 12:29 am #3598031Anonymous

InactiveJust finished the testing. I am actually quite surprised and impressed by how well the reinforced mini tarp did against the un-reinforced one.

I’m about to leave to go to a social gathering/party, so I will either upload the video later on tonight or earlier tomorrow.

Jun 16, 2019 at 3:23 pm #3598081Anonymous

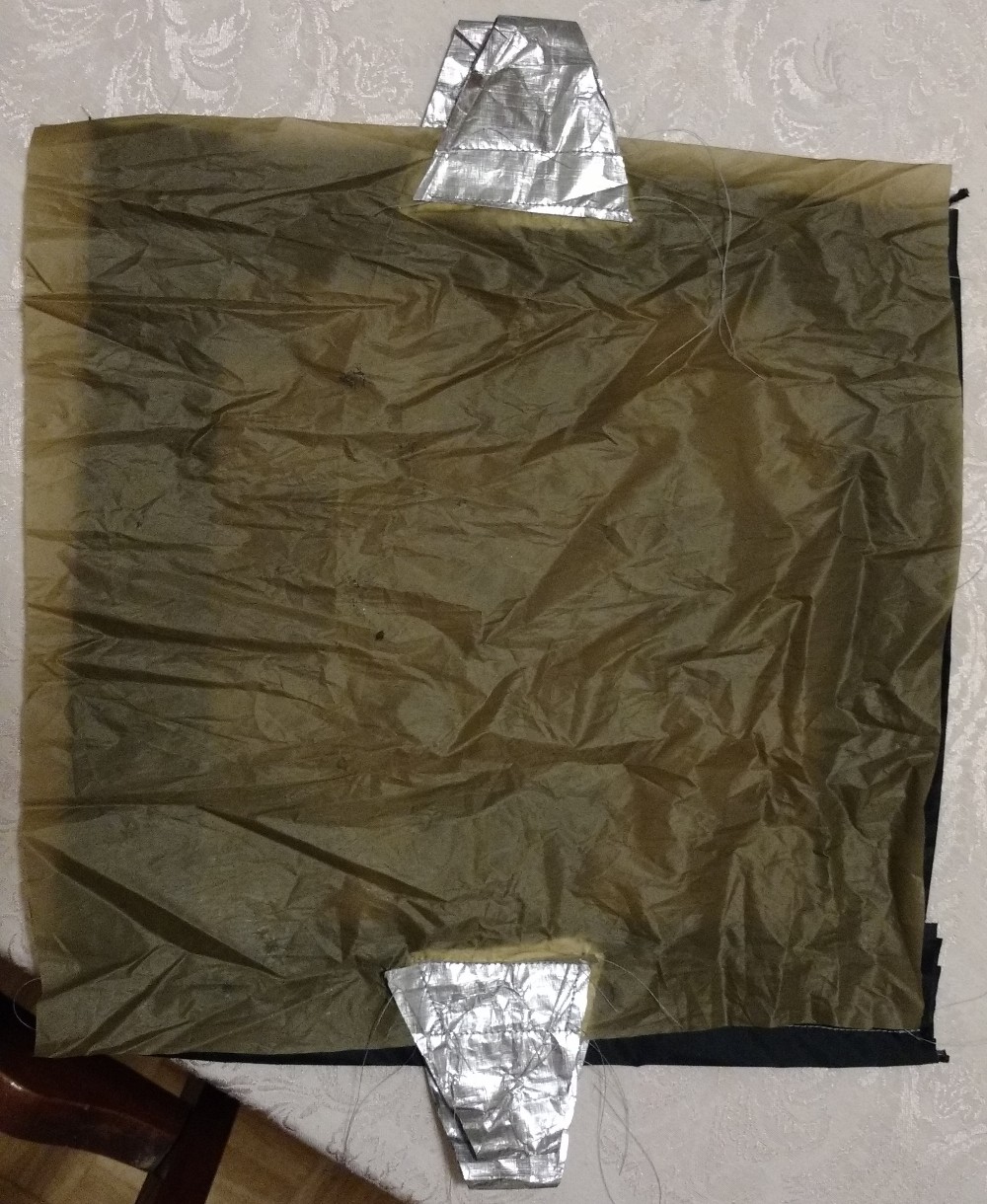

InactiveThere was another experiment going on at the same time. Wanted to see what the differences between two different silicones were–one was a clear, silicone caulk and the other an automotive, black, gasket maker silicone. That’s why some of the strips look darker, and there are some dark spots. I didn’t like working with the latter, as it was more messy.

Pics:

Reinforced Membrane Silpoly Mini Tarp

Non reinforced MSP Mini Tarp, on top of and slightly offset from the top one:

Next post will have video links to the testing

Jun 16, 2019 at 3:28 pm #3598082Anonymous

Inactivehttps://www.youtube.com/watch?v=Y6h_mHnK8v8

The bucket did lose a bit of water in the first test, but wasn’t significant.

Jun 17, 2019 at 5:26 pm #3598201I’m curious as to what the goal was with adding the black cord. The first test did seem to test the fabric tear strength. It would seem to me the second test was just testing the strength of the black cord and maybe the stitching through the cord and pull tab?

If a fabric was not strong enough to do the job would it not be better, stronger, simpler to just use a different (more appropriate) fabric? Constructing a network of reinforcing cords has got to increase weight too.

Just an observation.

Jun 17, 2019 at 6:50 pm #3598219Justin,

Thank you for this interesting study. It appears to demonstrate that a light fabric with added tension cords is similarly strong and light, but cheaper than Cuben. From that it logically follows that a comparably strong conventional fabric would be much heavier

Before you sell tarps using this concept it would be beneficial to demonstrate that the heavy reinforcement cords don’t chaff (resulting in a light fabric leakage) from prolonged wind flutter. You could accelerate wind flutter aging by hanging a panel perpendicular to large fan.

Jun 17, 2019 at 8:07 pm #3598232yeah, good study

the question is, is it lighter to have a lighter weight fabric with reinforcing cords or a heavier fabric.

cuben does something like that but it’s expensive

Jun 18, 2019 at 3:18 am #3598282Anonymous

InactiveHi Ken,

See Richard’s post below yours for the point of it.

Just to briefly add, for a 10’x10′ tarp, the total weight of the cord will be about .6 oz. The 8 silicone bonded strip reinforcements might add another .25 to .4 oz, and then the border perimeter of 1.6 oz/yd2 will add about about another ounce and maybe a little change.

The larger the tarp or the more material used, the more gains at less weight vs an all around heavier fabric you will see. And I suspect it will still be stronger/more durable in relation to higher winds and/or snow loading.

Plus, say you use one of the 7D silnylons instead of the Membrane Silpoly. With such a material, you will likely experience significant stretch sag with exposure to rain or even just very high, constant humidity.

But with this reinforcement, you likely won’t, as the tension will be on the non stretch cord more than the fabric.

Jun 18, 2019 at 3:38 am #3598285Anonymous

InactiveHi Richard,

Your welcome, and thank you for the good idea for testing that potential issue. I have thought about that some, and thought of a 2 bird, 1 stone approach. Kevlar has rather poor UV resistance and while the black Kevlar is definitely better than the yellow etc. Kevlars, long term it still may be a potential issue. However, if one puts a light coating of silicone on the cord, it will greatly increase the UV resistance and likely cut down on any potential abrasive issues.

I would probably still do some testing on it, but I suspect this should work fairly well, since silicone is a soft, somewhat absorptive (like any rubber), and low surface energy material. Depending on the viscosity of the silicone slurry applied to the cord, it will also potentially be filling into the various spaces between the yarns, thus making it more like a mono filament in structure, which also will cut down on abrasion potential.

Any further feedback/thoughts would be welcomed.

Jun 18, 2019 at 3:58 am #3598286Anonymous

InactiveHi Jerry,

In a 10’x10′ tarp, total extra weight will be around 2 oz (a little more if you silicone treat the cord as per my reply to Richard). But besides radically increased tensile and shear strengths in relation to wind and snow loading, you also will see much less stretch sag.

If you use a 7D silnylon and compare it to a 1.3 or so oz/yd2d, you’l see the most weight reduction.

It won’t be as much in a Membrane Silpoly tarp, but the nice thing about M.Sp is how quickly it dries/low little moisture it absorbs. It’s also significantly less expensive than the 7D Silnylons.

There are different trade offs depending. The obvious tradeoff in relation to DCF is cost. We’re not talking a lot of extra money to reinforce. 100 feet of the Kevlar cord cost around 15 dollars (and is enough to make 2 10’x10′ tarps). 1.1 oz/yd2 and 1.6 oz/yd2 Silpoly is quite inexpensive, though you will need at least 4 yards of the latter to get long enough continuous pieces (but you’ll have enough for another tarp if not two). Few ounces of 100% clear silicone caulk is a couple to few dollars. Even with using a more expensive fabric like one of the 7D ones, you’re still saving quite a bit of money vs DCF.

It’s a little extra work, but not really that much. Most of the extra time involved is static time–waiting for the silicone to cure.

Plus, when asked by others, you can say, “That thing? Why, that’s my super reinforced Spider Web Tarp, pretty cool huh?” And they’ll likely nod their head in agreement, saying, “yeah dude(t), yeah dude(t)…”

; ) J/K bout that last part.

Jun 18, 2019 at 4:37 am #3598295Anonymous

InactiveFor a little extra weight, you could take some of that much thinner/lighter Spectra fishing line, and create sort of a loose netting by tying to the main support cords.

For those of us (like myself) who sleep a lot underneath trees with UL tarps , there is always the worry and potential of a branch falling onto and causing damage to same. Having the cord/fishing line side up, would greatly minimize that.

Jun 18, 2019 at 2:34 pm #3598317Justin… Interesting idea you have going here. Lighter and cheaper than CF even if a bit more labor intensive. You seem to have this figured out…I am processing the idea and have a few doubts (not criticism). I say build us a tarp and see what happens.

Thoughts/questions…

Could you use grosgrain for the perimeter instead of silnylon? That might not offer enough stretch resistance? Would you need a perimeter of kevlar also?

Since you will sew / glue down the cord…could you just use a thicker kevlar “thread” and sew in the web and then seal to reinforce the needle holes?

Your “web” will have triangles sides of 5 x 5 x 7.17 ft (12 sq ft). Will that expanse of unsupported fabric be a problem? Just wondering.

Time for a full size prototype. -Ken

Jun 18, 2019 at 2:58 pm #3598319Justin,

The GE silicone, used for sealing sky lights and windows, has UV inhibitors mixed in.

Jun 18, 2019 at 4:23 pm #3598330Anonymous

Inactive“Could you use grosgrain for the perimeter instead of silnylon? That might not offer enough stretch resistance? Would you need a perimeter of kevlar also?”

Hi Ken, 1.6 oz/yd2 (really 1.77 oz/yd2) SilPoly was chosen due to a balanced combo between weight, price, stretch properties (low stretch), and tensile+shear strengths. The latter is probably similar to regular Silnylon’s, but it’s definitely a lower stretch material, and since there are two layers, I think it will be sufficiently strong and low stretch enough for this application.

“Since you will sew / glue down the cord…could you just use a thicker kevlar “thread” and sew in the web and then seal to reinforce the needle holes?”

Interesting idea, thank you. I haven’t ever worked with kevlar thread, but if I can find some for reasonable price, definitely worth trying. And yes, sealing is a great idea. This could probably be done just by some silicone as one would do anyways to seam seal.

However, I was pretty impressed by how the regular, polyester thread handled the weight stress it was subjected to. No doubt, heavier duty polyester thread would work even better. Kevlar might be a case of over kill, plus it will definitely add time as one would have to switch between the two.

“Your “web” will have triangles sides of 5 x 5 x 7.17 ft (12 sq ft). Will that expanse of unsupported fabric be a problem? Just wondering.”

I don’t know. I suspect most of the stresses will be experienced between a combo of the guy outs and then border perimeter. The idea is that the fragile, UL fabric is mostly just providing the shade and waterproof barrier. It’s ok if the UL material experiences a little stress–it can handle a bit of stress.

“Time for a full size prototype.”

Indeed. I have some 7D Silnylon from RBTR. My spouse will be doing a month or so long solo trip coming up later in Summer. I will be making her a roughly 10′ x 10′ tarp for this trip, and also winter trips (more for myself, but also occasionally with her, and she will be more likely to come with the below being the case..).

It will be bit of a strange creation, as besides the 7D silnylon + reinforcements, it will also also have a layer of aluminumized mylar (“spaceblanket”) and then polycryo. My spouse gets cold rather easy, the idea is to use this odd tarp in a mock Pyramid type set up, combined with 1 or 2 medium sized beeswax candles.

It will still be a relatively lightweight set up, but should have internal temps boosted quite a bit in comparison to a regular “double wall” set up.

Now, if I had the money, I would just forgo the more involved reinforcement composite like part and the polycryo bottom layer, and just use a combo of 7D nylon + space blanket (w/ silicone or open cell foam dots for space separation) + .34 oz/yd2 DCF.

However, I’m too broke for that. And the polycryo will at least allow for a really cool internal light show, and plenty of illumination while you have a candle or two going.

Jun 18, 2019 at 4:26 pm #3598331Anonymous

InactiveThank you for the info/suggestion Richard.

Jun 18, 2019 at 6:26 pm #3598352I love it !!! You brain-storm up a new design and then send it out with your SPOUSE to test it out.

(laughing)

Why didn’t I think of that? Ken

edit… My wife just called you a coward for not trying it yourself !

(more laughing)

Jun 18, 2019 at 11:41 pm #3598389Anonymous

InactiveHmmm, I might be hesitant to send her out there if it was being made with Membrane Silpoly, but since it’s being made with RBTR’s 7D Silnylon + reinforcements, it will work out just fine. CO testing will be done at home before she leaves.

And my spouse…she’s the kind of person who at 17, took her 16 year old sister and gallivanted around Spain and Morocco for a summer, and “encouraged” me to break into a castle (non lived in) surrounded mostly by a Loch with her in the middle of the night in Scotland. I literally only went in case she got in some trouble. Headstrong, fearless, adventurous, independent. She’s got bigger huevos, more competency, and resourcefulness than many men.

She didn’t want to pay for a pre-made tarp or tent, nor bring the Oware 9’x9′ Pyramid Tarp tent we have, so we talked about the new designs, and I asked, so do you want as light as possible, or warm and relatively light? She chose the latter.

I would love to go with her on this trip, but I don’t have the money nor especially the time.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.