Topic

punching holes in cuben?

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › punching holes in cuben?

- This topic has 12 replies, 10 voices, and was last updated 6 years, 8 months ago by

Brook / MtGL.

Brook / MtGL.

-

AuthorPosts

-

Jun 10, 2018 at 4:29 am #3541229

I have this big piece of lightweight cuben (that’s all I know, I don’t know if it’s 5.1 or whatever the designations are). Unfinished edges, just a big piece of cuben. Can I use a grommet kit to punch holes in the corners and put grommets in without harming it or weakening it or whatever?

Jun 10, 2018 at 5:35 am #3541233Doug,

the UHMWPE fiber that makes up the cuben sheet is very cut resistant so your grommet tool may not punch through it cleanly. But it is a cross plied unidirectional so you might be able to open up a hole for the grommet by using an awl and moving the fibers making a hole. You will also have to deal with the Mylar on the surfaces. Keep in mind that the grommet might just move the fibers and pull out since there is no locking of the fibers like in woven fabric, just the binder resin and the Mylar surface. You may do better bonding on tabs.

Jun 10, 2018 at 5:47 am #3541234Thanks Clifford!

Jun 10, 2018 at 2:40 pm #3541255Doug, you might just ‘burn’ a hole with a wood burning tool or something. That will melt both the aramid fibers and the mylar, and it will leave everything sealed up and ready for your grommet. This is just theoretical on my part, since I’ve not tried it, but it seems like it should work. The key would be to make the hole for the grommet to precisely fit. Try it out on a small scrap piece and see how it works.

Jun 10, 2018 at 7:38 pm #3541306That will melt both the aramid fibers and the mylar

Cuben/Dyneema uses ultra-high-molecular-weight polyethylene fiber, not aramid. That’s good, because aramid fibers do not melt.

Jun 10, 2018 at 7:57 pm #3541308I have used a hole-puncher from a grommet kit with DCF before. I hit the punch tool multiple times (and hard) with the hammer. Usually, it cuts through about 70% of the circle, and then I use a little nail scissors or a razor blade (with cutting mat) to finish up the full circle.

Jun 10, 2018 at 8:10 pm #3541310if you have extra fabric, try it on scrap first. Assess if it’s strong enough.

Maybe reinforce both sides with a piece that you glue or tape, grommet through 2 or 3 layers of fabric

Jun 10, 2018 at 8:57 pm #3541319As Jerry suggested, I always bond/tape a few layers and then punch my holes when using cuben. I tend to use cuben hybrid for this purpose since I have so many small scraps.

Jun 10, 2018 at 8:58 pm #3541320Thanks for that info, Bob. I just figured that the fibers were some type of aramid. They do melt when I put a Bic to the material for one (intended) reason or another.

Jun 10, 2018 at 9:14 pm #3541324Thanks all for the input. Much appreciated.

Jun 11, 2018 at 12:56 am #3541354I can say for sure that a single layer of .51 DCF will rip right out. I made a stuff sack for my hammock with a round bottom and a grommet in the center for my hammock suspension to thread through. It came right out with minimal force. I added three extra layers and it has held up fine since.

Jun 11, 2018 at 12:39 pm #3541414I have cut holes in DCF with a scalpel that works really well. I just use a sharpie to outline the hole and hold the material a little taut and above my cutting mat. It cuts a perfect hole. A hole punch catches on some of the threads. I just cut a hole in 5.0 DCF yesterday.

Jun 14, 2018 at 5:38 am #3542043Hi, Doug, as some one put it it’s 70% cut-through by using a grommet tool (hammering), and then you can use a sharp blade to gently cut the entire hole.

One tip, if you grommet is 5mm in diameter, then use a little bit smaller grommet tool (4mm or 4.5mm) to drill the hole.

First patch/stregthen the fabic before you make the hole, that makes a much more stronger grommet tie-out.

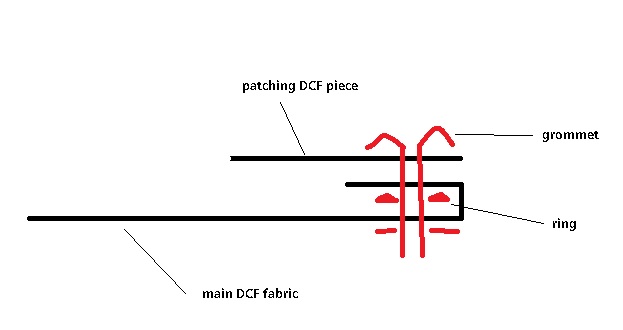

Such as the way I used on my ground sheet corners:

There was even more art in my design. I first buried a plastic ring (a padding typically sold with grommet) in between two layers of DCF, to make an micro “S” curve in the fabric, this way is to dramaticaly increase tie-out strength….

So such a grommet-style tie-out should be typically strong enough, if not as strong as a sewn-style tie-out to be made with similar elegance.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

LAST CALL (Sale Ends Feb 24) - Hyperlite Mountain Gear's Biggest Sale of the Year.

All DCF shelters, packs, premium quilts, and accessories are on sale.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.