Topic

MYOG 1P Silpoly Tent Cat Cut Ridge?

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › MYOG 1P Silpoly Tent Cat Cut Ridge?

- This topic has 12 replies, 7 voices, and was last updated 9 years, 1 month ago by

Jerry Adams.

Jerry Adams.

-

AuthorPosts

-

Jan 29, 2016 at 5:34 pm #3378985

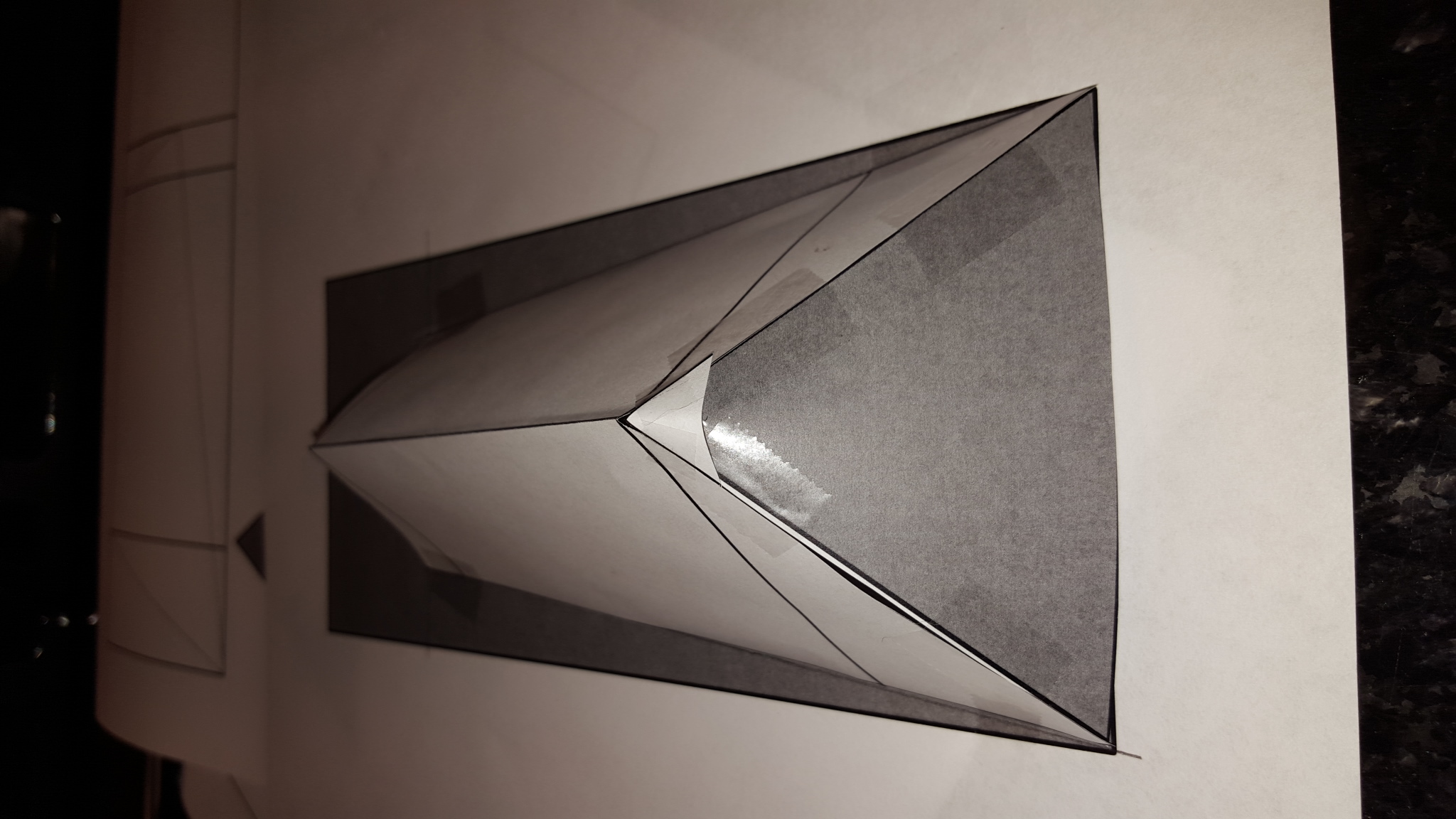

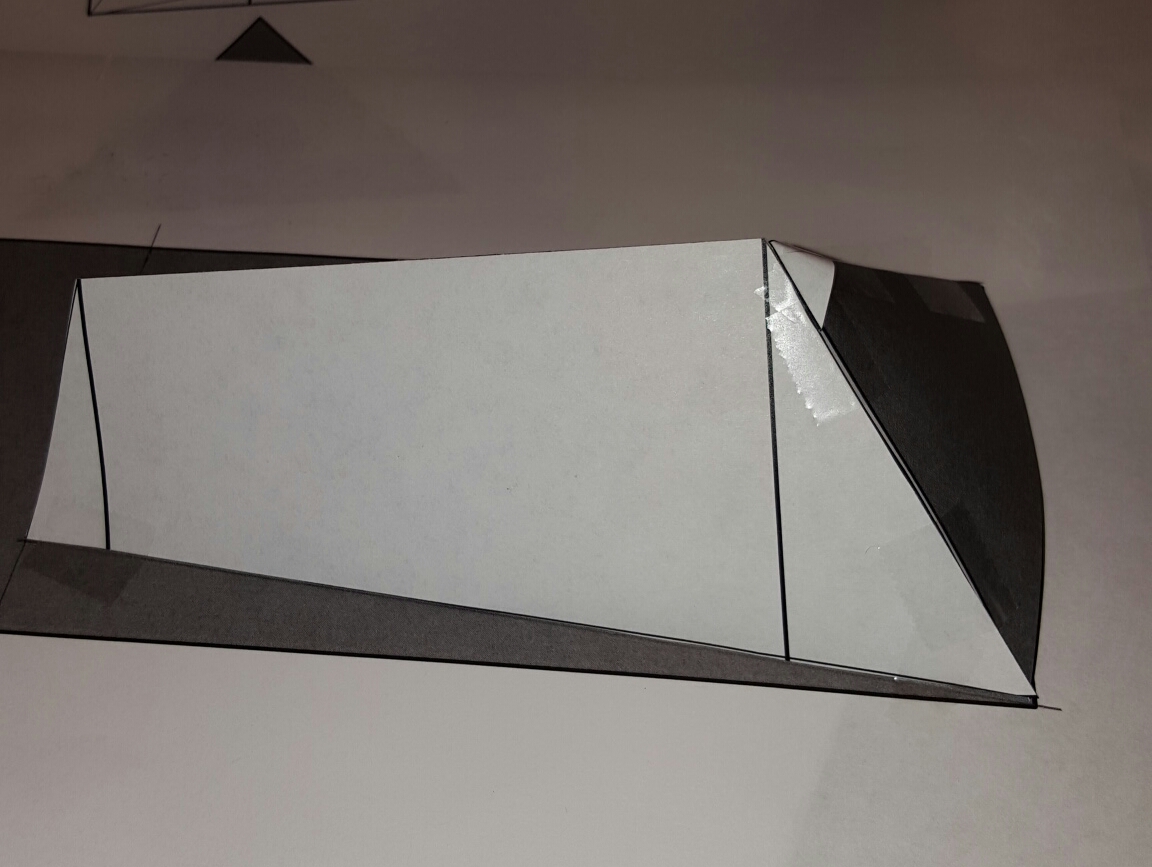

I’m planning out a 1P tent out of RBTR’s 1.1 Silpoly PU4000. It will be very similar to the Protrail, but with a removable inner net/floor. Here are a couple of pics of a paper model.

The Ridgeline will be 84″ to 90″ and the front height will be about 45.” Simple question: with the Silpoly, how much curve, if any should I put in the ridgeline? How about where the front “door” attaches?

Jan 29, 2016 at 6:36 pm #3378991If you haven’t seen this it might help. I think it has a template linked in the article.

http://backpackinglight.com/myog_tech_note_catenary_curves/

Jan 30, 2016 at 6:26 am #3379033Thanks. I hadn’t read that particular article, but have read others and understand the basic concepts. I also have used a couple of the cat cut calculators for other projects.

My concern in that the rules of thumb for the depth of the cut are silnylon. Since the Silpoly has a lot less stretch than stillborn, does the optimum depth of the cat cut change?

Jan 30, 2016 at 7:48 am #3379039I put about 2-1/2″ in my silmembrane tarp and silnylon tarps.search this myog forum and you will see their build.

Jan 30, 2016 at 10:54 am #3379077Edgar, because there is little stretch or sag with SilPoly, bad weather conditions does not exacerbate the problem as SilNylon does, I would say offhand, basically guessing, that it needs nearly none. Cat cuts allow a certain amount of pre-loading for other materials, usually SilNylon or PUNylon. This helps to redistribute loads if/when it stretches. BTW, SilNylon is considerably stronger than SilPoly. I don’t think you will need much more than a very light cat cut to set up a SillPoly tent. It just doesn’t need the stretch resistance (also making it far more fragile than SilNylon…I very much doubt it will survive a downed branch for instance.) Maybe no cat cut, since the reason for it has been removed. However a light cat cut will work to help in setting the tarp up.

Jan 30, 2016 at 6:20 pm #3379141Thanks for the input. I understand the tradeoffs with the Silpoly. On the flat tarp I made, I really like the lack of stretch and water absorbtion.

I think I’ll go with a little cat cut. As you say, it may make it easier to get a good pitch, even if not truly necessary. I can just sew the first row of stitches of my seam an see what I get. More depth in the cut can be added without ripping it all apart if needed/wanted.

Jan 31, 2016 at 9:07 am #3379202This may help. It’s very similar except for the entry

Jan 31, 2016 at 9:33 am #3379211The entry looks like a YMG Cirriform. Trekker makes it in nylon and poly. I wouldn’t expect then to have different patterns and the pictures show some curve in the ridgeline. This led me to look at the YMG site. The Cirriform in Cuben has a significant curve in the ridgeline.

I’m satisfied that 2 to 3 inches of depth in the ridge will be fine.

Jan 31, 2016 at 9:47 am #3379213I’ve done 2 to 3 inches deflection with silnylon

Maybe 1 inch with sil poly?

Maybe you actually want more deflection for silpoly because it doesn’t stretch?

Also, with nylon, the stretchiness hides minor measuring errors. With silpoly you have to be more careful?

Silpoly won’t stretch very much parallel or perpindicular to the threads, but probably will in the bias directions

Sorry, no answers, just questions. I haven’t used poly at all.

Jan 31, 2016 at 9:51 am #3379214You could make the ridgeline a flat felled seam, but do the felled part at only the ends, like 1/2 inch. With no cat.

Set tent up and see if it’s good. Maybe decide at that point to do a 1 inch deflection and look at that. Then maybe 2 inches. When it’s good, fold over twice and sew to complete the flat felled seam.

Jan 31, 2016 at 10:06 am #3379219“I’m satisfied that 2 to 3 inches of depth in the ridge will be fine.”

Perfect. Silpoly will still stretch, it’s just not affected by moisture the same way nylon is. So, in order to get that perfect pitch a cat curve will make it happen. I use the 1/3 of an inch per foot rule for cuben, silnylon etc and it always works fine.

Ryan

Jan 31, 2016 at 10:08 am #3379220Thanks Jerry I have made tarts with SIL poly with no cat curve. These were a simple diamond and square tarp for hammocks. Although there is minimal stretch with the cell Paula there is enough to be able to take out any wrinkles when pitching them.

I like the idea of starting with no deflection and gradually adding more deflection until the optimum pitch

Jan 31, 2016 at 10:16 am #3379222“tarts” “Cell Paula”

I think I will write a software algorithm to determine whether someone is using a real keyboard or a smartphone : )

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Trail Days Online! 2025 is this week:

Thursday, February 27 through Saturday, March 1 - Registration is Free.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.