Topic

'mid set up issues, got advice?

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › General Forums › General Lightweight Backpacking Discussion › 'mid set up issues, got advice?

- This topic has 44 replies, 12 voices, and was last updated 8 years, 1 month ago by

Emmanuel Romo.

Emmanuel Romo.

-

AuthorPosts

-

Jan 4, 2017 at 9:31 pm #3443278

Yes, that photo is what I’m after. Will keep tinkering. There must be a way…

… finally got a decent pitch. I would say if you had any kind of condensation though, it’s really a two person, maybe three person (w/ angled pole) shelter. W/ four people the folks on the sides are gonna be soaked. And, even w/ two, if you pitch it to the ground, high probability of feet and head brushing…

Seems like it’s really a winter shelter for me. Or maybe for after bug season with my kid.

For future reader’s reference, the trick seems to be to stretch the corners just enough that they’re fully extended, but put no tension on them at all when staking.

Jan 5, 2017 at 1:47 am #3443298Wear a blindfold, and do it by touch and feel a few times.

(But if you use a DPTE, be careful of the pole tips falling out of the DPTE during assembly and striking the tarp).

Jan 5, 2017 at 9:53 am #3443322Are you trying to pitch the inner bug nest & outer fly? If so, focus only on the outer’s stake points and once it’s nice and taut, slip the inner’s loops onto the stakes (extra guy line may be needed to reach).

Jan 5, 2017 at 10:23 am #3443326Back on the first page Franco posted a picture of a blue and grey 1980’s vintage Chouinard pyramid, which is the predecessor to the current BD Megamid. That picture is my pyramid pitched in the backyard. A bit of history… Chouinard (who founded Patagonia) also started Chouinard Equipment in the 1950’s. In 1989 Chouinard had to place his equipment company into bankruptcy and the assets were purchased by a group of former employees and investors; and thus Black Diamond was formed from the former Chouinard Equipment Company. Anyway…

To properly pitch most mids you are going lay it out on the ground, but you cannot pull the corners too tight. The tension on the panels needs to be finalized after the pole is inserted. Also with mids, proper final tension is often a combination of adjusting and readjusting pole height and guyline tension. It just takes practice. If you are using a fixed length pole, it is often best to start with the pole at a slight angle, so the final pole adjustment is achieved by straightening the pole, thus giving it additional height.

Assuming the Megamid is the same design and cut of the panels as the original Chouinard Pyramid, you cannot pitch it to the ground and achieve proper tension. Go back and look at the picture Franco posted. The bottom is curved and with proper tension at the corners the center tie-out will be higher — then tensioning the center of the side will make it taut, but you cannot achieve a good tight pitch with the bottom too close to the ground. Plus with a mid like this, getting it too close to the ground is going to cause an ungodly amount of condensation. About 30 years ago on a clear night in Joshua Tree the temps got down to 18F, and I had pitched this mid pretty close to the ground. In the morning all the panels inside were covered with a sheet of ice.

This post on my blog shows several mids pitched and all are tight with the bottoms off the ground. However, there is one picture of my Chouinard, which is not pitched perfect and the bottom is pretty close to the ground — this is due to a combination of factors (1) the site was not large enough with some large rocks and shrubs blocking the perfect stake location and (2) my hiking staff was not long enough as a center pole (I had left the standard pole at home to save weight knowing the hiking staff would be a little short and planned to use rocks for final pole height. I used a flat rock to raise the pole, but couldn’t find the perfect rock to make the perfect height; not to mention it was cold and windy and I was in a hurry to set it up and get warm. But it handled the wind well and there were no problems during the night other than excessive condensation.

Mids are generally really simple to set up, they just take a little practice. By adjusting guys and pole height back and forth, you will begin to see how each affects the pitch. Also a well constructed mid can take and needs a lot of tension at the guys, especially the corners — if you start out with too short of guyline to adjust (stake too close to the shelter), you will not be able to pull the guy tight enough to achieve the needed tension. You need real stakes like the long MSR groundhogs or 9″ Easton stakes, not 6″ wire Ti stakes.

Jan 5, 2017 at 11:20 am #3443334On John Brown’s picture, and like others have mentioned, the corners are on the ground, but the middle is several inches off the ground.

That’s what my mid does.

This can be a problem, if it’s windy, dirt or snow or whatever will blow under and get onto my stuff inside. I would rather be able to have the edge of the mid at ground level all the way around.

My theory is that this is because the fabric stretches more on the bias, than along the grain. The ridges are on the bias so they stretch more. The middle of the mid is on the grain – thus, it’s off the ground.

But, this should be easy to fix, just make the panels longer down the middle. That is, rather than laying out the pieces as right triangles, make that angle a little less than 90 degrees. That is, make that long side a couple inches longer, leaving the distances along the ground and along the ridge the same.

I wonder if anyone has done this

Jan 5, 2017 at 11:42 am #3443342Jerry,

I’m not an engineer. To me, the structure of a mid needs primary tension against the pole, this gives it the strength it needs. The tension from corner to corner is secondary and a by-product of the primary corner tension against the pole. Take a suspension bridge, the cable suspending the bridge is curved. Take a look at my Trailstar, which handles wind better than any shelter I have ever used.

The Trailstar, like most larger mids, has a large foot print. That is a lot of material spanning a long edge and it is just going to curve. The material is physically straight, but the corner tension forces the edge to curve. Now if we sewed a piece of steel cable in a seam along the bottom edge, we could probably eliminate a lot of the curvature… ;)

BTW, this picture of the Trailstar was my initial first pitch so I could seam seal it. Like any single wall mid, they are pretty easy to set-up once you have practiced. And again, success on a mid set-up is lots and lots of tension on the corner guys, which is why I have lineloc 3’s and use 3mm cord on all my mids along with beefy stakes. Saving weight on guys and stakes with a larger mid isn’t the smartest thing to do. I also use some pretty stiff and larger diameter carbon poles on my mids

Edit: when I bought the Trailstar I was interested in a CF model. But reading reviews from several well known hill walkers in Scotland, I went with silnylon. The CF just didn’t stretch like sil, and these experienced people often had problems getting good pitches with the CF version because of this.

Jan 5, 2017 at 1:44 pm #3443358same thing on your picture, in the middle it’s off the ground more

Thought experiment – if the mid was under tension/stretched the same as currently set up, but some extra fabric was added in the middle (also under tension/stretched) you could make it the same distance off the ground all around

Some day I’m going to try that. Actually, my current mid is a kludged prototype that I keep adding things to to see what works, I could just add a triangle of fabric – 2 inches wide at the center tapering to 0 inches wide at the corner.

Jan 5, 2017 at 2:22 pm #3443372For me, a single walled mid pitched low to the ground causes too much condensation. I have never had any serious problems with the space above the ground getting my gear wet or keeping me from being warm and dry.

Jan 5, 2017 at 4:04 pm #3443379occasionally there’s some strong wind that blows dirt under the edge, so, for example, the side of my sleeping bag will have a lot of dirt on it. Not a huge deal, when I pack up I brush it off. Sometimes I’ll put some branches to block it. Sometimes the dirt will get onto my pillow which is unpleasant.

it’s not that rain gets in

if it’s clear, then the tent material will cool down maybe 10 F. If I was near the dew point before, there’ll be a lot of condensation. Even when as a test, I’ve just suspended some fabric in the air so there’s a large amount of ventilation. I question if having that air space between ground and tent is going to make much difference.

If it’s not raining I’ll leave the door open all the way. Then air can get in down below and up above, I think that’s the best way to get ventilation

I’m not stating anything absolutely, more just trying to figure it out

Jan 5, 2017 at 4:10 pm #3443380My thoughts on this derive from my primary sewing experience being in dressmaking where bias in a fabric is ‘used’ to make ‘shape’ in a garment.

IF the bias was along the bottom hem, and likewise along the line from pole to center tie out, ……..then stretch generated along these directions might allow the panel to pull out further – so the hem is closer to the ground, and also make a small ‘beak’ of the otherwise ‘flat panel. The overall shelter footprint shape would no longer be a square (4 sides) but tending towards an 8 sided shape (but not as much as a real octagon) ??? Seams from corners to pole are not stretching which is easier to pitch too.

This is to my mind a more wind resiliant shape and gives a little extra internal space.

Why is this not the way mids are constructed ? (-apart from the difficulty of putting a zip along the bias)

Different qualities of silnylon would give different amounts of stretch along the bias…….but that can be planned in.

What are your thoughts ?

Jan 5, 2017 at 4:20 pm #3443383That is a good idea, better than mine of making non right triangles

I think maybe that’s what David was suggesting midway through page 1, but he never elucidated

Your idea of a bias cut will cause a little more waste, but not that much.

Jan 5, 2017 at 4:35 pm #3443387

Jan 5, 2017 at 4:35 pm #3443387I made a 6 side mid in cuben (-I didn’t want to ‘mess with silnylon’) – hence I’m not planning another mid in silnylon, but have thought a lot about how different shapes of mid would work/function. I camp in a windy climate and the MLD Duomid/solomid don’t seem the best for that. The Trailstar is good in wind but has other drawbacks re. living space and egress.

http://www.trek-lite.com/index.php?threads/myog-cuben-shelter.711/

Jan 5, 2017 at 6:38 pm #3443405maybe cuben doesn’t stretch differently on the bias, than along the grain

it’s a sheet of mylar that’s the same in every direction

but the reinforcing threads have a grain, so…

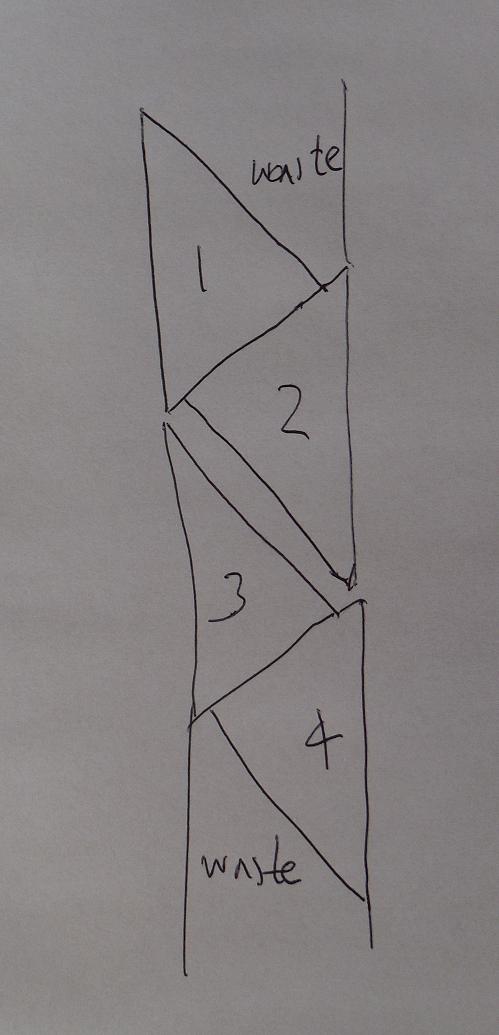

Jan 6, 2017 at 1:20 am #3443441Jerry says “But, this should be easy to fix, just make the panels longer down the middle.”

This is also my philosophy, based on the realization that the classic rectangular Mid (Khufu, DuoMid), is not in fact rectangular, but structurally wants to become a stretched octagon in plan, though the midpoints of the rectangle sides are not fully developed as such – they just tend towards moving out from the center a bit, and in doing so, want to be a little longer in ridge length, so closer to ground, so all 8 points of similar height off ground.

Then I decided, the shape becomes even better when formally it is rotated by 45 degrees (if first considered as a square) to a diamond, then stretched along one cardinal axis (EW), then the “NE/NW/SE/SW” points move outward, moving towards an ellipse, but not fully so. Maybe a form of super-ellipse. Using a variety of Pythagorean Triangles, first in plan, and later for the triangular panels (each of which is composed of a major and a minor Pythag. Triangle), and the sections (not all at once – it becomes far too complex). I developed several prototypes, of which this was the latest, though I’ve not developed it any further for some years. There are just two types of panels (and their reflections – the end pairs, and the side pairs (front and back). The shape is pretty satisfying, and of course I managed to work in various cosmological ratios into the proportions. It has N/S symmetry and E/W symmetry, and when flat, end pairs of panels form an (inverted) kite, and so do side pairs of panels (but a broader kite). “Corner” NE/NW/SE/SW points form a rectangle; cardinal points are on the main NS and EW axis. Good height for solo use, raising head from prone position. Also, note windsock vent (which works well, despite appearances). I calculated the volume to surface area (hence theoretical weight), and it was more efficient than the Khufu and the DuoMid, i.e. higher volume for similar surface area. Last photo is not very good pitch, but quite uneven ground.

Jan 6, 2017 at 10:31 am #3443479

Jan 6, 2017 at 10:31 am #3443479Nice looking tarp, I think I follow you : )

Amazing that anything as simple as a pyramid can still be innovated on

I assume you lay out the panels on the grain, rather than on the bias? That is, the middle of each panel goes on the grain, and the ridges go on the bias.

I think if a mid was designed to be a rectangle, and laid out on the bias, because of more stretch on the bias you’d end up with something that looks like what you have.

“Last photo is not very good pitch, but quite uneven ground.”

Yeah, that’s the problem with real setups, one corner is high or low which makes it difficult to get a taut pitch.

Jan 8, 2017 at 11:41 am #3443814“Why is this not the way mids are constructed ? (-apart from the difficulty of putting a zip along the bias)

Different qualities of silnylon would give different amounts of stretch along the bias…….but that can be planned in.”

Because, as mentioned, it takes more planning and usually generates more fabric waste. Doing so does really tap into the potential of sil and can make for a fantastically strong shelter.

Pictured below is our (Seek Outside) Redcliff, a mid way bigger than most here want, but shows well the subtle octagon built into the footprint. Gives 90% of the easy pitch of a mid, and 80% the strength of a circular tipi.

Jan 8, 2017 at 2:13 pm #3443847

Jan 8, 2017 at 2:13 pm #3443847so that must be laid out on the bias

on the left and right, the center of the panel goes out a little

they must have been cut out as right triangles? If there was no tension, it wouldn’t go out but be straight? The only reason they go out is they were laid out on bias so it stretches out?

As opposed to other mids where the center goes up in the air a little?

Jan 8, 2017 at 2:23 pm #3443851This thread makes me happy and reminds me why I joined.

Jan 8, 2017 at 5:17 pm #3443879David ……..”thumbs up smilie”.

Jan 15, 2017 at 10:28 pm #3445365Very nice design.

It it looks like a single door Seek Outside Cimmaron. I own their Silvertip which is more hexagonal in its fair weather base shape but becomes elliptical when all 12 points are staked.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Trail Days Online! 2025 is this week:

Thursday, February 27 through Saturday, March 1 - Registration is Free.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.