Topic

HH test of ExtremTextil 20D Silnylon

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › HH test of ExtremTextil 20D Silnylon

- This topic has 19 replies, 9 voices, and was last updated 5 years, 5 months ago by

J-L.

J-L.

-

AuthorPosts

-

Aug 23, 2019 at 3:18 am #3607248

Sam Farrington asked me to measure the HH of this fabric.

The results are as follow:

As delivered: 8964 mm/wc

Aged: 8296 mm/wc

Both aged and unaged samples produced a fine spray when they began to leak.

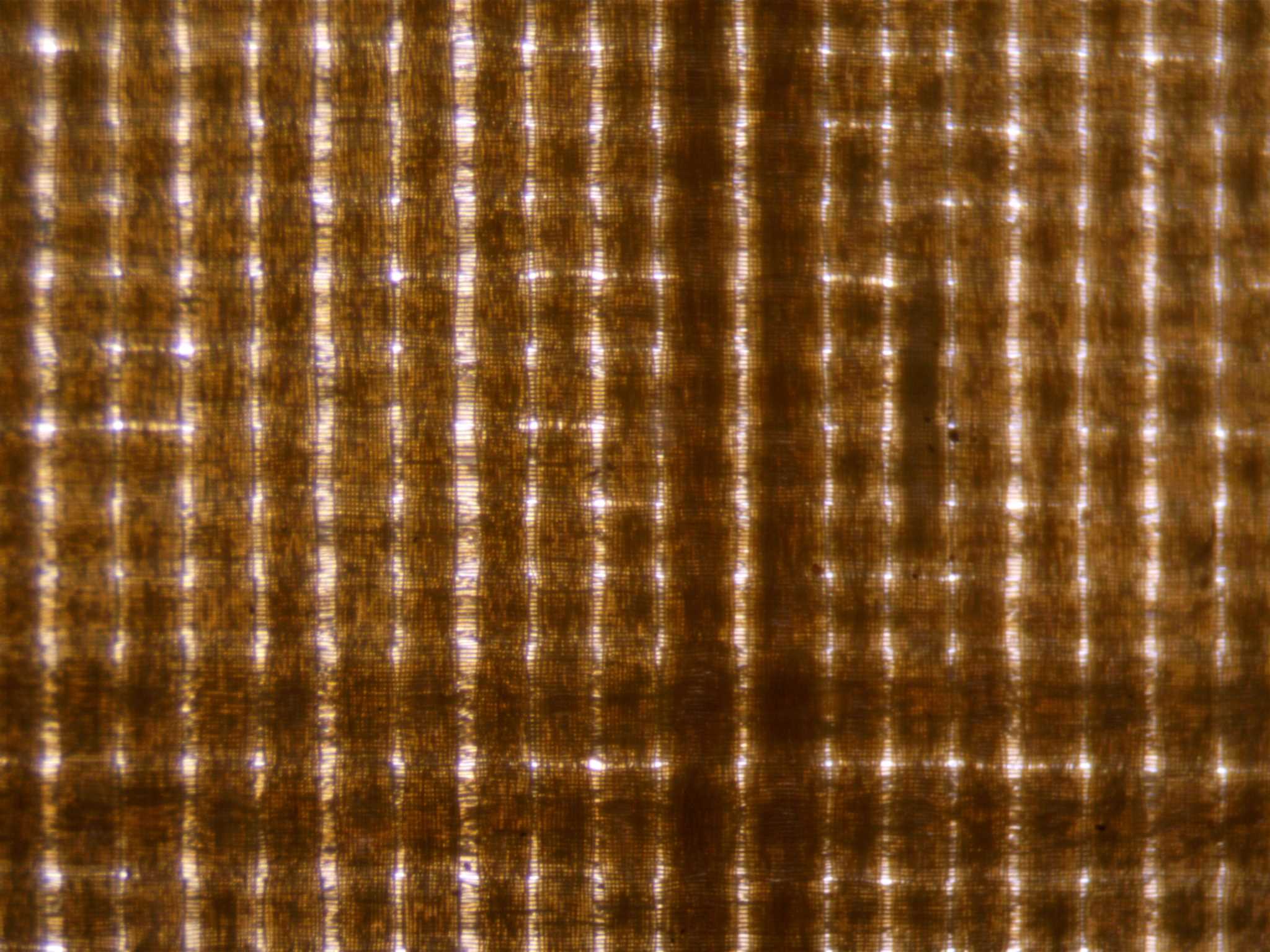

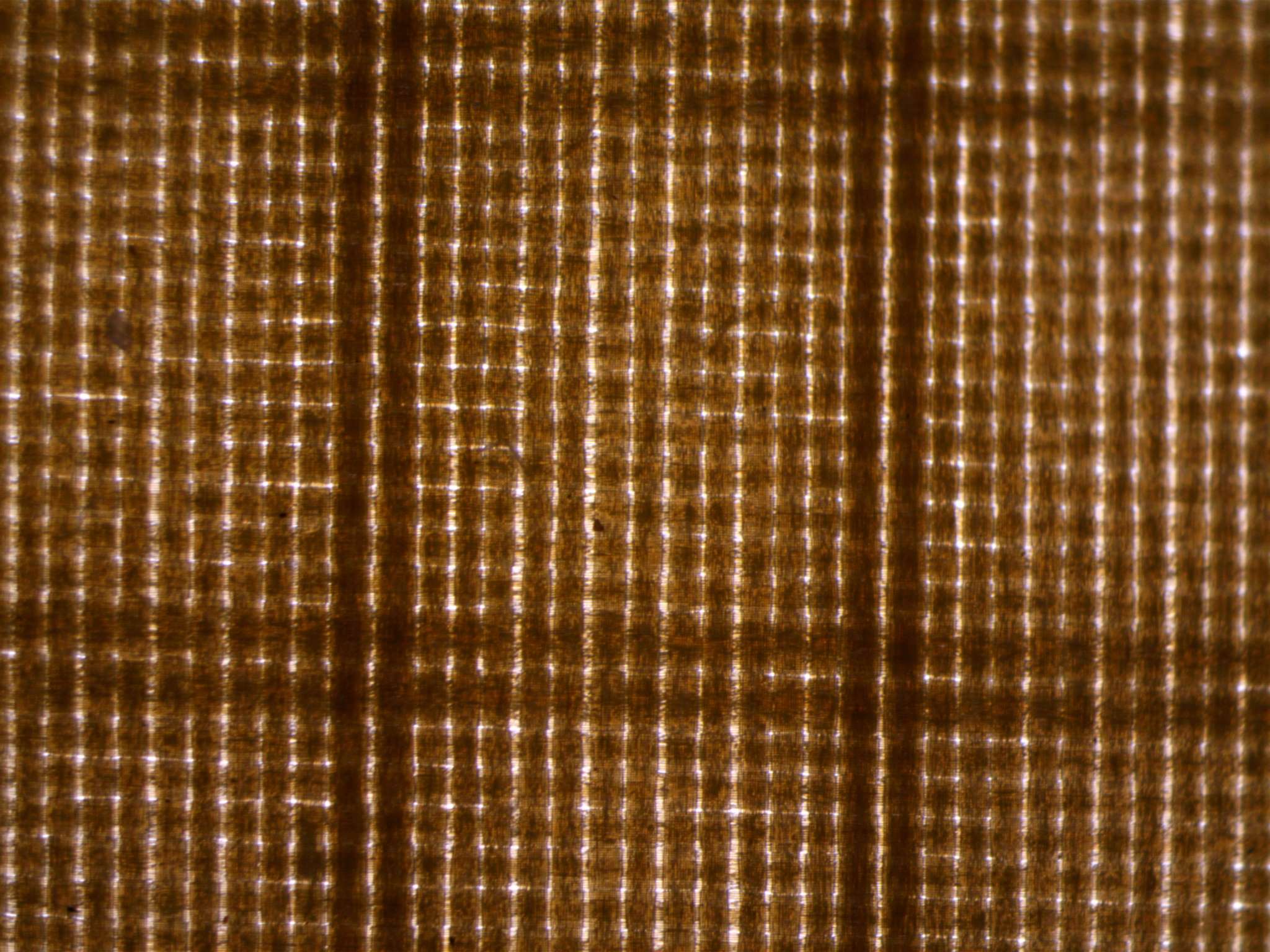

Sam Farrington mentioned he felt that the fabric may have a loose weave. The weave is shown in the photo-micrograph below, along with some dimensions.

Aug 25, 2019 at 7:57 pm #3607559

Aug 25, 2019 at 7:57 pm #3607559Stephen/Sam, are you referring to the following fabric?

https://www.extremtextil.de/en/ripstop-nylon-tentfabric-silicone-coated-20den-36g-sqm.html

If so, then those 8964 mm/wc / Aged: 8296 mm/wc values are way more than spec’d.

Aug 25, 2019 at 11:09 pm #3607579Hi David:Thank you for the question. I noticed that also. That is the fabric. Article # 70777. They list two specifications: 1400-5000mm under “Properties” and 2000mm under technical specifications. ISO 811 is the relevant standard. It requires an instrument that can read up to 1000mm/wc for loosely woven fabrics such as gaberdine or 2000mm/wc for tightly woven fabrics. I am guessing that the specification of 2000mm was produced by an instrument limited to 2000mm. I suspect that the higher reading was produced on an instrument that is limited to 5000mm. I took five readings for each of the two fabrics. On the unaged fabric, the lowest reading was 8577 mm/wc. The lowest reading for the aged fabric was was 7,382mm/wc. I don’t know how much variation there might be from fabric batch to fabric batch. Nor do I know how old the published readings are and whether their production methods have changed since they were published.

Aug 27, 2019 at 9:28 am #3607766Good one for groundsheets then?

Aug 27, 2019 at 10:52 pm #3607834Adam: I will leave that question for all of the BPL experts on tent design and construction to answer that question.

Steve

Aug 28, 2019 at 11:34 pm #3608017I’m following this post but could we please move this or duplicate it in MYOG. I feel like we may get more responses.?

Aug 29, 2019 at 2:34 am #3608041Hi Eric:

I have no problem with placing it on MYOG. I am not sure how to do that. Perhaps someone who knows can explain it or simply do it.

Your concern is interesting. I have had issues with light weight fabrics bursting before leaking. With a light weight fabric, such as the one tested here, once it passes 1500 mm/wc, I place a screen over the fabric to prevent it from bursting before leaking. It avoids making a mess. This is actually the basis of testing under an alternate HH test, ISO 1420, which is designed for testing rubber or plastic coated fabrics. These can have very high hydrostatic head performance. That test is performed somewhat differently and the device is built differently to accommodate a perforated plate and much higher pressure than instruments built to meet ISO 811.

My expectation is that this reinforcing mesh may raise the HH higher than normally achieved. To my thinking, the mesh might provide a truer test to simulate standing or kneeling on the fabric than the more typical non-reinforced test. If anyone has an opinion on this, please post it.

On the last tent fabric that I tested, which was Dyneema/Cuben, I did not use the mesh and it withstood pressure without bursting until drops started leaking through.

I will try testing the fabric tomorrow without the mesh and post the results.

I will check for your PM. I am happy to test some more tent fabrics.

Steve

Aug 29, 2019 at 3:55 am #3608056Thank you so very much for the testing and sharing of this info. It will be very valuable for my next tent project.

Aug 29, 2019 at 8:56 pm #3608140I did a retest on the aged fabric sample at two locations with no additional reinforcement, as I described above. I got an average of 7910 mm/wc. So, it appears without the extra reinforcement in place during the test, the HH is reduced a bit.

Aug 29, 2019 at 11:58 pm #36081628000mm or so for 20D silnylon sounds phenomenal to me given that , for examplke, the 20D used by Big Agnes is rated by them as 1200mm.

https://www.bigagnes.com/Tiger-Wall-UL2

Same for the MSR 20d sil/Pu material.

https://www.msrgear.com/blog/understanding-tent-fabrics-part-1-fabric-specs/

Even the 20D Kerlon 1000 and 30D Kerlon 1200 by Hilleberg are rated at 5000mm.

https://hilleberg.com/eng/about-our-tents/materials-uncompromising-quality/

Aug 30, 2019 at 1:11 pm #3608236Yes, I believe the test has been skewed due to the mesh preventing the actual fabric from stretching and breaking the bonds to the silicone treatments. This, of course, in no way matches the actual strength of the fabric, hence places the water pressure only on the silicone. In actual use, the strength of the fabric would determine HH, if what you are saying is correct. I think it would start leaking long before actual bursting pressure, though. I an thinking that on a soft ground, such as grass and duff, you would stretch the interstitial coating to the point of breaking when you kneel on it. This would allow water to penetrate the fabric. Any abrasion would exacerbate the issue. Despite the high readings you got, I doubt it would make a good ground cloth or floor.

Silicone coated fabrics can be considered a “rubber” coating over a reinforcement. As such, a light nylon reinforcement (with it’s stretch) would leak with any heavy pressure concentrated in one spot. You are avoiding this issue with a topping of reinforcement mesh. While it would likely make a good fly (roof) on a tent, unless it was heavily treated with some form of anti-abrasion (to compensate for sand bits in any soil) it wouldn’t last very long. I think 2 or 3 uses would start showing some wear spots, and potential leaks, with any light fabric. ‘Corse, the fabric in NeoAirs remains water proof (air proof) for quite some time, but I don’t know how theirs is treated (especially inside where it receives no abrasion.)

Sep 1, 2019 at 3:48 am #3608447I agree that the test results seem high and since we do not know the materials used for the coating process, we do not know why. Also, we do not know anything about abrasion resistance or cut resistance or a host of other characteristics of the fabric, at least not from the test that I did. So, I agree that based on these test results, as James Marco pointed out, this fabric may be unsuitable for some or all tent components. I understand that others are looking at various characteristics of this material and I presume there will be more postings to come. So, I guess we can watch for posting to this thread or to MYOG for any follow up information. If I can find out anything else about the construction of the fabric from extremtextil, I will post it here.

Sep 1, 2019 at 4:30 am #3608455I did a little more poking around on their website. They have 3 silnylon fabrics listed for tent use.

Here is the info on each:

Item 70777, 20 den, 36g/sqm–properties:waterproof from 1400mm-5000mm, Specifications– Water Column 2000mm. Tear Strength: 9.2kg

Item 71936, 30 den, 40g/sqm–properties:waterproof from 1400mm-5000mm, Specifications– Water Column 2000mm. Tear strength: not listed.

Item 70773, 40 den, 55g/sqm–properties:waterproof from 1400mm-5000mm, Specifications– Water Column 3500mm. Tear strength: 17.8kg

I have sent an email to extremtextil about this. Perhaps they can explain their product descriptions.

Sep 2, 2019 at 1:20 pm #3608590I submitted the following question to extremtextil:

I was looking at comparable fabrics to item 70777 on your website and found two others. The product descriptions included the following for each:

Item 70777, 20 den, 36g/sqm–properties:waterproof from 1400mm-5000mm, Specifications– Water Column 2000mm

Item 71936, 30 den, 40g/sqm–properties:waterproof from 1400mm-5000mm, Specifications– Water Column 2000mm

#0000ff;”>Item 70773, 40 den, 55g/sqm–properties:waterproof from 1400mm-5000mm, Specifications– Water Column 3500mm

Is there a reason that the three different fabrics show identical water proof ranges under “properties” and different water column results under specifications.

I received the following answer, you are all welcome to interpret what it means and whether you can accept these as actual measurements:

In the range of the properties: waterproof from 1400mm-5000mm, you will find the articles with the different watercolumns. The range is pre-defined and then there are the specific water columns of the individual articles listed.

That sounds great when you’ve reached even higher levels. Unfortunately, we do not have another feature for the specification available.

Mit freundlichen Grüßen,

Connie BatzkeSep 2, 2019 at 2:21 pm #3608602Hi Stephen, I have some left over of the 40d fabric (Item 70773, 40 den, 55g/sqm–properties:waterproof from 1400mm-5000mm, Specifications– Water Column 3500mm. Tear strength: 17.8kg).

I can send you a sample for testing if you’re interested and if it can help your research. You only have to PM me the details.

Thank you for all your testing!

Cheer

Sep 3, 2019 at 5:35 am #3608720Stephen,

Thank you for testing this fabric. It must be different from the Extrem Textil 20D sil sold a few years ago when Richard Nisley tested it at much lower HH levels.Like James, I’m concerned that the use of the screens may have prevented the fabric from expanding, and thus provided a much higher HH. The concern is reinforced by the looseness of the weave at many points, and that without the screen, the material would expand, create rifts in the coat, and leak. Note the earlier thread about the fabric unraveling, which I’ll link and comment about in a later post.

First, I want to do some additional tests, albeit primitive, to get an idea of how much of a problem is created by the areas that are loosely woven. Note this is a ripstop fabric, and not sure how this appears on the micrograph image.

Until more evidence is presented, will withhold any judgment about the fabric’s potential. In view of the bomber HH on a barely over 1 oz/sq/yd silnylon (1.08 osy),

am clinging to hope.Sep 11, 2019 at 3:37 am #3609762Hi Sam:

As I mentioned above, I retested the aged sample without the screen. The HH came down a bit.

You asked about the ripstop in the photo

micrographs. I am attaching two more with less magnification that clearly shows the ripstop. I have not yet recieved the other samples to test but will let everyone know what I find when they arrive.Sep 19, 2019 at 5:45 am #3610863

micrographs. I am attaching two more with less magnification that clearly shows the ripstop. I have not yet recieved the other samples to test but will let everyone know what I find when they arrive.Sep 19, 2019 at 5:45 am #3610863Stephen,

Thank you for the clarification and added micrographs. For me, they resolve James’ and my concerns.

Sep 30, 2019 at 4:15 am #3612150I just published some more tent fabric HH test results here:

Oct 2, 2019 at 2:54 pm #3612400Wow, Stephen, you’ve been busy! Thank you for posting these results.

The ExtremTextil fabrics are looking very good. Both the 20D and 40D silnylons test very well. The 20D looks ideal for a tent or tarp canopy fabric.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Trail Days Online! 2025 is this week:

Thursday, February 27 through Saturday, March 1 - Registration is Free.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.

micrographs. I am attaching two more with less magnification that clearly shows the ripstop. I have not yet recieved the other samples to test but will let everyone know what I find when they arrive.

micrographs. I am attaching two more with less magnification that clearly shows the ripstop. I have not yet recieved the other samples to test but will let everyone know what I find when they arrive.