Topic

Evaluation of Thermal Performance of Five Synthetically Insulated Jackets

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › Evaluation of Thermal Performance of Five Synthetically Insulated Jackets

- This topic has 29 replies, 12 voices, and was last updated 4 years, 11 months ago by

Richard Nisley.

Richard Nisley.

-

AuthorPosts

-

Mar 5, 2020 at 4:28 pm #3634424

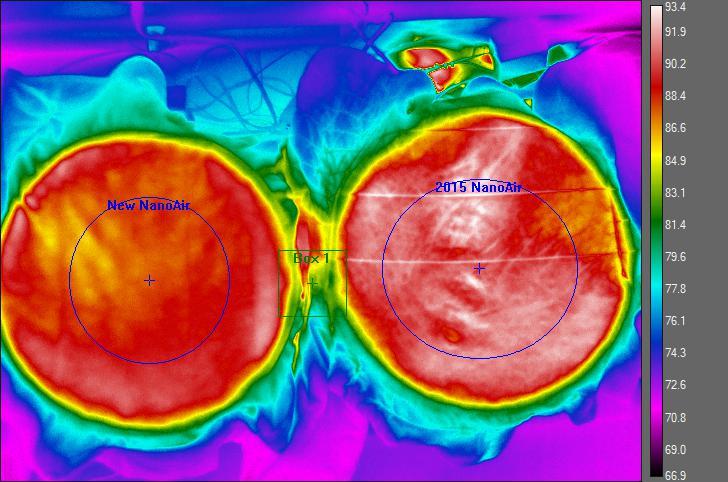

Here is one view of synthetic aging.

On the left is a brand new NanoAir, fresh from the Patagonia store. On the right is my 2015 Nano Air. It is old, washed many times, stuffed many times and still going strong. The calculated R value for the new jacket is .9. The R value for the old jacket is .73. About a 19% reduction in about 5 years. The jacket construction has changed. You can see seams in the old jacket. None in the new jacket. These are not through seams. In the new, more stitching is moved to the liner fabric from the face fabric. The insulation specification remains the same. Permeability of the new is 29 CFM/Ft2. Permeability for the old is 37 CFM/Ft2. The permeability of the new may increase with age. This, of course is one type of insulation. Others may behave very differently. However, if members have old and new versions of garments with the same insulation, I can perform this type of test to evaluate aging. PM me if you have a pair of garments to test this way.

Mar 5, 2020 at 4:55 pm #3634428Here are some more insulation measurements to answer questions raised above.

How does a wind layer impact a puff midlayer?

As I explained in my post on this subject above, this is a complicated question when the garment is in use. Review my prior post for a discussions of issues that will impact performance in the field. Here is a simple finding for still air.

I placed a MB Versalite over an MB Alpine Light down jacket. The R value increased by 21%. Surprisingly, the R value for the high loft areas dropped down a bit and the R value of seam areas rose up 287%. The R value of high loft areas reduced a bit because the down in this areas was compressed a bit by the weight of the Versalite.

If you stuff your down puffy under your wind layer, you may loose a fair amount of insulation capability.

So, that raises the question of how compression may impact insulation. I did a quick experiment. I placed a 2 square inch, 2 oz weight on the Alpine Light in an area of high loft and measured the R value loss at 68%. Next, I did the same experiment on my Pat MacroPuff. Here, the insulation loss was 55%. I am guessing the MacroPuff insulation is more resilient than the down. I suspect that when used in a situation where compression might be an issue, lower fill down may perform better than higher fill down. Just a theory, I have not checked.

Mar 5, 2020 at 6:06 pm #3634432Mar 5, 2020 at 7:56 pm #3634448I think designing and making for extreme cold and high winds take things out of the Ultra Light area but my down parka designed for Everest [ and now over 30 YO] was deliberately made using lower FP down and over stuffed by 50%.

The parka was never used on Everest tho, the design was changed to remove the need for a separate wind suit to incorporate a secondary shell of Goretex fabric.

I never made it to Everest due to the arrival of a baby/babies; mortgage etc

However there must be a point where the benefits of overstuffing are exceeded by the move to full baffled construction, with or without a wind barrier

Mar 5, 2020 at 10:36 pm #3634457I see a parallel in degradation testing and shell over insulation air gap testing; you will get very different test results based on the assumed knowledge and resultant use case of the presumed user.

An expert will know the optimal sizing to capitalize on air gap insulation and the novice will not. A shell stretched over insulation would simulate a novice’s use and provide the lowest possible clothing system air gap insulation benefit. A shell optimally air gapped over insulation, primarily for below tree line use, will provide the highest possible system insulation value. A shell optimally air gapped over insulation, primarily for above tree line use, will provide a mid-point system insulation value.

Regarding insulation longevity testing, an expert is more apt to carry a small pack, necessitating stuffing, and a lighter sleep system augmented, by their jacket insulation. Both these factors will maximize the degradation of synthetic insulation. In contrast, a novice would unlikely do either.

UL is most closely associated with expert users and insulation tests should reflect their equipment use patterns.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

HAPPENING RIGHT NOW (February 11-21, 2025) - Shop Hyperlite Mountain Gear's Biggest Sale of the Year:

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.