Topic

Does X-Pac really offer weight & performance benefits over Cordura?

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Does X-Pac really offer weight & performance benefits over Cordura?

- This topic has 45 replies, 11 voices, and was last updated 6 years, 1 month ago by

Roger Caffin.

Roger Caffin.

-

AuthorPosts

-

Jan 26, 2019 at 8:27 pm #3575202

The current thread on the new Seek Outside lightweight prototypes has got me thinking about fabrics for durable packs. I’m tending towards the idea that boring old Cordura is being under-valued in the rush towards the sexy new laminates, but please check my logic and challenge any wooly thinking.

You frequently see claims that X-Pac offers weight savings over older fabrics like Cordura – for example here on Carryology: https://www.carryology.com/insights/insights-1/dyneema-vs-x-pac-ultralight-fabrics/

But is this really true?

With a good Cordura, most of the weight is in the tough face fabric (with its proven weave of strong 6.6 nylon), with modest weight in the PU water-resistant coating.

With X-Pac, weight for weight you get a lighter face fabric (which in many versions is of unknown provenance), with more of the weight devoted to the waterproof laminate and optional internal lining.

If you’re concerned about abrasion and durability, this means that for the same performance dry Cordura will always be lighter than dry X-Pac. So as far as I can see, any edge for X-Pac is restricted to performance in the wet.

Neither pack will be fully waterproof, so you’re going to have to use a trash-bag liner in both. In my experience this is enough to protect your gear. I have an ancient Cordura pack that’s lasted literally 1000s of days on the hill. The DWR is long gone and the PU coating is degraded, but although it leaks a bit through the tight weave my gear has never suffered inside the liner This is an extreme boundary case – most people don’t use a pack for 40 years – but functionally the leaking has been pretty much a non-issue despite the less effective PU waterproofing.

So what’s the payoff for the weight of the laminate? Sure, the waterproofing is more durable, but as I’ve argued, I’m not convinced that provides a significant practical benefit.

That leaves weight – with many people claiming that X-Pac is lighter than Cordura when wet. With both Cordura and X-Pac the face fabric is protected by DWR which will wear off, so both will absorb water after some use. The X-Pac will absorb a bit less, but only because the face fabric is thinner and less durable than a Cordura PU of the same weight.

Has anyone actually tested whether wet X-Pac is significantly lighter than wet Cordura of equivalent durability? The Cordura PU starts lighter, so there would have to be a very large difference in their performance in the wet before it became a meaningful issue. I simply can’t see where that difference would come from.And what percentage of our time do we really spend walking in persistent rain? Even here in the UK it’s relatively small, while in the SW US, for example, it’s trivial. The rest of the time, Cordura is lighter at any given level of durability.

Quality branded Cordura is inexpensive and much of it meets stringent military standards, It’s easy to source in a wide range of weights and colours, doesn’t fade in UV, has a nice hand, takes stitching like a champ, self-heals if you need to rip a seam, has no abrasion points like the X-Pack ripstop, and in my experience, is pretty much indestructible (for any use short of canyoneering).

But if you look at the specialist pack makers and the MYOG packs here, Cordura is rarely used these days – it’s all Dyneema ripstop (which seems to offer no advantages at all over Cordura), X-Pac and a couple of companies offering woven Dyneema (which we can’t source). I know that Cordura is not sexy and the newer fabrics must be easier to market, But perhaps we’re being too quick to abandon it?

Jan 26, 2019 at 8:46 pm #3575204I think X-Pac is waterproof

Cordura is not – the large threads that make up the fabric have large holes between threads and no matter how much PU you put on it, it will leak

500D Cordura is 8 oz/yd2 (not including PU?)

1000D is 11 oz/yd2

I used 2.92 Dyneema for pack which seemed pretty strong, 2.92 oz/yd2

VX07 is 4.8 oz/yd2

VX21 is 6 oz/yd2

Jan 26, 2019 at 9:35 pm #3575211Hi Jerry

Not sure that it’s meaningful to compare VX07 with a vulnerable 70d face fabric with bombproof 500d Cordura. They aren’t aimed at the same applications. But an X-Pac with a 500d face fabric will always be significantly heavier than a 500d Cordura PU.

And much of my point is that even in my 40 year old Cordura daypack the slight leakage is an insignificant issue, so why bother with all the drawbacks of X-Pac such as cost, the additional weight of the lamination, the wear points on the X-grid, potential delamination, and (as some report) difficulty of sewing seams that don’t expand under load, if the only advantage is a bit less leakage?

What problems do you experience with leakage that would justify a heavier and more expensive fabric to mitigate the issue? That’s what I’m struggling to understand.

Jan 26, 2019 at 10:01 pm #3575217I made a pack 40 years ago out of Cordura that leaked. I made a pack a few years ago out of 200D that leaked, even though it had an extra heavy PU coating

uh oh, I over generalized in saying all Cordura will leak : )

and I’m just putting out data, not arguing any particular case, awaiting other information from other people : )

For my usage, I don’t need the strength of Cordura. That 2.92 Dyneema is strong enough. If you were making a bag to go through airport cargo people maybe Cordura would be the right product. Or rock climbing dangling a pack against a rock face. Maybe that’s the main message of BPL, don’t use heavier materials than necessary. Historically, manufacturers use heavier materials just because it’s annoying for customers to return broken stuff, there was little appreciation for minimizing weight. There’s also a 1.43 Dyneema, I wonder if that’s strong enough.

With a backpack, the total area of fabric isn’t that big. Not much more than 1 yd2. The difference between 1.43 oz/yd2 and 2.92 oz.yd2 isn’t that big. 8 or 11 oz/yd2 fabric – that might be significant.

With a laminate, the outside fabric can take the abrasion and the inner waterproof layer will maintain waterproofness.

I’m with you on skepticism of shiny new products with flashy lights, often more marketing than anything useful. An excuse to throw out all your old, perfectly good equipment and buy new stuff that’s supposedly better.

Jan 26, 2019 at 11:22 pm #3575234I’ve never thought of X-Pac as being a lighter option to Cordura. I simply want a durable waterproof laminate inside my pack to make it more waterproof and that’s worth an extra 1 oz/yd to me.

I would hope that X-Pac with 210D nylon holds up similarly to 210D Nylon cordura, and then X-Pac laminates make it a bit heavier in exchange for more waterproofness. Not every one values this enough to spend the weight, but for many uses it’s nice.

Since the laminates do add weight, I expect that they are less durable for a given weight than cordura since not all the weight is in the face fabric.

I wish Cordura would offer their nylons with inner laminates rather than PU.

Jan 26, 2019 at 11:30 pm #3575235330d Cordura is probably more of a replacement for the 210d Dyneema X than the X-Pac X21 or VX21.

X-Pac does have a 330d Cordura with a PET laminate X33 – Its 7.9oz per sqyd

Jan 27, 2019 at 12:37 am #3575246For my uses light Cordura is plenty tough; and I’ve never felt the need for a truly waterproof pack, since I don’t feel like it’s worth trying to effectively seal all the seams in a pack with all the stress they take. So I see no advantage for my own uses in any of the Dyneema or Xpac fabrics.

The only things made of Cordura that I’ve ever worn out are toolbelts used on the jobsite, which take a beating that few packs ever will unless you are caving or canyoneering.

The fabric I really like is 160d Cordura but It’s not easy to find. I used to get it from The Rainshed but they don’t have it any more. the 330d and the 160d that I have used are about the same weight; the 160d is a much tighter weave, nicer to work with. What I’d like is a coated Taslan. I think I saw some once but not sure where. That would be very similar to the 160d Cordura, as Taslan and Cordura are similar in yarn and weave from what I have read. Taslan is very tough. I have been through numerous pairs of Taslan shorts without managing to actually wear out any of the fabric, despite years of use. The elastic fails, the mesh liners wear out, the stitching sometimes wears out, but I have yet to wear a hole in the taslan despite sitting on many a granite boulder and wearing them day in and day out. Also had a pair of shorts from LL Bean that were 160d ripstop Cordura. Wore those to work doing carpentry for several years. Pocket linings wore out, zipper wore out, stitching on the surface wore out. I melted some holes in them cutting rebar with a an abrasive blade, but never wore a hole in the fabric. Finally gave up on all the pocket and zipper related repairs and tossed them. Supplex pants or shorts for the same use last about a year and they do have holes in them by then.

Dyneema is the new sexy thing, and when you say Cordura I think people think 1000 denier, 12 oz per yard cordura,

Jan 27, 2019 at 1:46 am #3575265Yeah, I use Taslan for our bushwalking clotthing. Not so much ‘years of use’ as decades. Torn it a few times – on barbed wire fences.

Cheers

Jan 27, 2019 at 2:25 am #3575271that’s funny, I’ve torn Taslan pants on barbed wire too. I really wacked the bush away so next time I don’t have to go so close to fence. Put seam grip over the hole. Maybe I’ll make a new pair of pants for cosmetic reasons. Yeah, that stuff does not wear out.

Jan 27, 2019 at 9:42 am #3575297Well, it seems that everyone agrees that Cordura offers the best durability for weight – so I guess it boils down to whether you find the leakage troublesome, like Dan and Dave Chenault, or whether you find it a minor irritant, like me and Paul. So far no one has come up with any other argument for the X-Pac.

Paul – very interesting post. Yes, in my experience heavy Cordura is over-specified for pretty much any use. I have a 40 liter 1000d Lowe climbing pack I bought around 1974. It did a few hard climbing seasons on Scottish ice and Alpine granite before it was relegated to my training pack. I reckon it’s done at least 3000 days in the hill, but the fabric is unblemished and the simply sewn straight seams are all intact. I use it as a seat or bushwhack through thorns without a second thought. And it’s not even that heavy, at around 1400 grams, despite being over-engineered in every feature. So yes – a much lighter weight should give a more than acceptable lifespan for off-trail backpacking.

The 160d sounds interesting – I’ll keep my eyes open, If you visit cordura.com you’ll see that they offer a wide range of weaves and finishes, but frustratingly few seem to make it onto the MYOG market.

There are plenty Chinese companies offering PU coated Taslans on AliBaba – some of them claiming to offer 1 meter min orders (would they really do that?). But Taslan doesn’t seem to be a standard like branded Cordura, so I’d imagine that the quality would be a lottery.

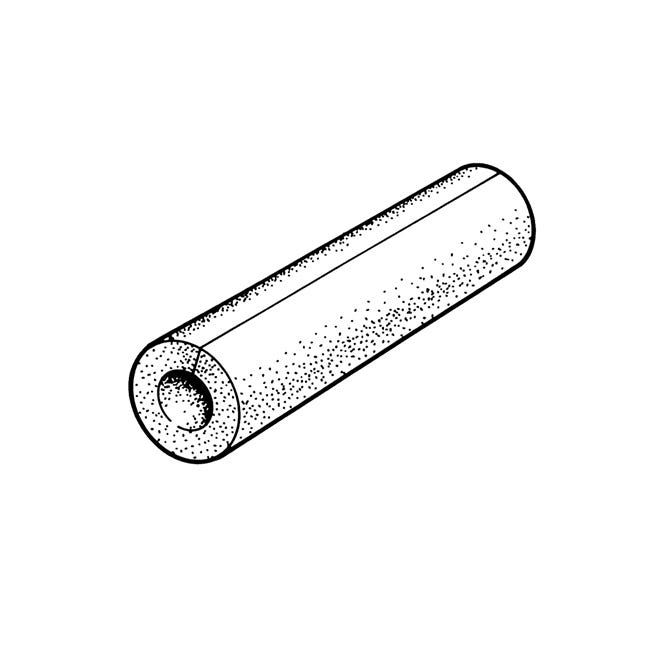

Roger – if you’re getting ripped up on barbed wire, here’s my little trick – if required I carry a couple of feet of closed cell pipe insulation and slip it over the top strand. Weighs next to nothing and offers reliable protection for your delicate bits:

.Jan 27, 2019 at 2:22 pm #3575308interesting about foam over barbed wire

when I have to go over a barbed wire fence that would be really useful

Jan 27, 2019 at 2:41 pm #3575309X-pac’s advantage over plain Codura is that it’s waterproof. I sealed the seams of my X21 pack and have noticed no leakage packrafting or backpacking in rain. I sill put my quilt, down jacket, etc in either a compactor or nylofume bag, as I would never rely on a backpack to be 100% waterproof all the time (too many seams-many high stress) but as a first line of defense it’s certainly an asset over Codura or Dyneema X.

That doesn’t mean 330 Codura might not be a good pack fabric, but to me it’s more a competitor to 210d Dyneema X. I see 210d Dyneema X yo have a lot tighter weave than 330d Codura. I’m not sure what advantage (or disadvantage) that might have.

Jan 27, 2019 at 3:44 pm #3575316Roger,

What is the approximate weight of this taslan of which you speak?

Is it nylon?

Jan 27, 2019 at 3:46 pm #3575317As a preamble I’d say that while it’s easy (and fun!) to geek out on pack fabrics, refinements in suspension and features are more significant when you’re actually in the woods. I’d gladly be stuck with the craptastic 210D gripstop GoLite used in 2011 (with the amazing, recycled, insta-delam PU coating) so long as I could also have modern lightweight suspension and evolved pocketing, as opposed to building a 2011 Pinnacle out of custom V33.

That said, I think for the home builder or cottage shop the biggest advantage of DP fabrics over PU coated fabrics is consistency. In this respect it is very much like Goretex WPB apparel relative to PU coated WPB; with the former you know what you’re going to get because of the in-house control. I’ve seen massive variations in the PU coating on Cordura. The best stuff really is waterproof, at least for a good decade or more, while the sketchy stuff is decidedly not. If you’re just ordering retail from Rockywoods there’s an inherent roll of the dice. If you’re buying 500 yards wholesale, or outsourcing to a Berry-compliant cut and sew house, you have a lot more control and certainty.

If I lived somewhere other than Montana DP laminates probably wouldn’t be worth the cost and weight premium. And now that the cargo fly has become standard practice the need for highly waterproof fabrics is significantly diminished even around here. In the past year I can think of around a dozen days, mostly drizzly fall days hunting with lots of bushwacking, where the DP fabrics really gave full value. The rest of the time it’s just the little things (added stiffness making packing easier) which make me keep using them.

A accessible fabric with a durable surface waterproofing would be more relevant for most folks. Something like the nylon Arc’teryx uses in their Alpha series of backpacks.

Jan 27, 2019 at 3:54 pm #3575319http://www.owfinc.com/Taslan-Breathable-Black-4-Ply/productinfo/TASBLK/

Taslan or Supplex comes in two weights, “4 ply” (4.2 oz/yd2) and “2 ply” (maybe 3 oz/yd2)

4 ply is good for pants, 2 ply for shirt

I don’t know what the “ply” they refer to is : )

I think the difference between Taslan and Supplex is just the name

Jan 27, 2019 at 5:04 pm #3575326Jerry,

Thanks for the taslan/Supplex

Jan 27, 2019 at 8:32 pm #3575387The worst barbed wire was an old fence which shouldn’t have been there. But then, maybe we were not supposed to cross it either. Ho Hum.

Taslan for clothing – see:

https://backpackinglight.com/make_your_own_gear_trousers/

and

https://backpackinglight.com/myog_shell_top/

for our MYOG articles.Afaik, all Taslan (and Supplex) is air-textured nylon: wiggly threads rather than dead straight ones. It is not a micro-fibre, which is why the fabric is so abrasion resistant.

I think I actually have three weights in Taslan: what I would call light, medium and heavy. The light is good for tops and summer-weight pants, while the heavy is our preferred choice for bad scrub.

Cheers

Jan 27, 2019 at 10:05 pm #3575400just choose a different color than Roger’s : )

my article has a couple different techniques for making pants, read both of them and pick and choose

also good about Taslan is bug and sun protection. Sunscreen has only partial effectiveness, better to cover up. Bugs can’t stick there little probosci through the tight weave

uh oh, thread drift, sorry : )

Jan 27, 2019 at 10:22 pm #3575402Ah, but I have at least 5 different colours of Taslan …

Cheers

Jan 28, 2019 at 4:44 am #3575463Who’s on first? For example, a quick visit with Dr. Google reveals that while Taslan often refers to polyester fabric, nylon fabrics are also marketed as Taslan. And X-pac covers a host of laminated DP fabrics with many different characteristics.

Giving Geoff the benefit of the doubt, and accepting that this is not just another of BPL’s false dichotomies that cry out for headache meds, I’m not sure he needs to limit the choices to DP laminates vs nylons marketed by Cordura that come in many weights, The best laminate I ever saw, in terms of durability for weight was the Cuben/polyester laminate used and sold by Zpacks, but it is stiff as a board. If you like loading up a pack baseket, it might appeal to you.

For those who prefer a material with a softer hand for a pack, nylon has it all over DP laminates. Even if you can live with the stiffness, there are the other drawbacks that Geoff mentions: 1) Stitch holes in laminates don’t self heal like nylon; 2) Cost; 3) Potential for Delamination; 4) Grid wear; and 5) Resistance to sewing.

I tried one DPL laminate around 5 oz that had a soft hand, but the stitches left gaping holes, and that was before load was applied. So tried a stiffer one that was lighter, and it leaked like a sieve. So tried a special order one around 5 oz that was solid green with a thick PET laminate – it flunked Richard Nisley’s aging tests by delaminating – needs the grid, they said. The only one I’ve seen under 5 oz that looks promising is the X-grid laminate, X-21 RC, and it is quite stiff. But I would not trust it with stitches, and who is to say that the PET film is more waterproof than modern PU coatings of similar weight? Haven’t seen any evidence of that.

So what we see from the forums is DP laminates being bonded rather than stitched. OK, if you are good with bonding and don’t mind the mess and the clamping, neither of which applies to me. So DP leaves me with a pack that will be unnaturally stiff and therefore more brittle after a while, that will not be WP for long if at all, that is not very abrasion resistant, and costs a lot. I think the person who posted that the DP laminates are made for sails that will be used by rich folks who will use and quickly discard them was on to something.

Giving the benefit of another doubt, that the discussion related to bomber packs and outerwear for bushwhacking was not just expressions of machismo, but based on real need, why not try chaps. They go on and off easily, and could even be bought snake bite proof for hiking in the thorny (New) Jersey highlands, crawling with rattlers and copperheads..

Nowadays, I tend to stick to trails here in New England; and due to the open terrain, going off-trail in the open country of the Rockies, which is way more of a lark than bushwacking. (I had the impression that except for the prison, Dartmoor was open country – maybe not). For backpacking light, the name of this site, a pack of nylon, woven with ripstop reinforcments, and a little under 4 oz with a durable PU coating seems just right. Unlike some other posters, WP is very important, to save the hassle with plastic bags, and protect ALL the pack contents, including even limited electronic gimmickry, from water. It can be done, and have never gotten gear wet (in this century anyway) backpacking. The only advances technology offers in this area , IMO, are much better PU coatings and double ripstop weaves that better resist abrasion.

If this post sounds a little more rantish than usual, it’s because I’ve been out on the barricades for the last few weeks, and am suffering from political exhaustion. Guess which side of the barricades.

Jan 28, 2019 at 2:23 pm #3575492I made a pack with 2.92 Dyneema laminate and like it, I think that’s my favorite fabric right now. But I’ve only used it for a few months.

I sealed the stitches with seamgrip. I haven’t had a really good rain test yet though.

I like the stiffness. It holds it’s shape better when I put stuff in it. It holds it’s shape better when I’m carrying it, when it droops it doesn’t carry the weight of the pack as good.

The stiffness is difficult to sew, like towards the end when I’m sewing on the bottom or shoulder straps. As always, with a pack, you have to plan it out and sew everything you can when it’s flat.

I want my pack to be waterproof, but also I have waterproof bags for stuff that’s critical like down or electronics. As said previously. Belt and suspenders. Sometimes some unusual event will happen, like falling in a stream or ripping the pack or forgetting to close the top, so having two layers of defense is good.

I don’t like to just give up on the pack being waterproof in the first place. Seems like there’s something wrong with that. If I had a pack liner I’d still want to put critical stuff into waterproof bags.

I’m not sure exactly what barricades you’re talking about but it seems like we go in phases, sometimes more conflict, other times more peaceful, I’m looking forward to going back to a peaceful phase. Unless we self destruct : )

Jan 28, 2019 at 10:09 pm #3575549Sam,

I feel your pain Bro.

Jan 28, 2019 at 10:30 pm #3575553Looks like the fabric discussion has broadened a bit so I’ll throw in my standard 2cents worth.

I like packs that aren’t waterproof. Allows me to throw them in washer/dryer between trips and thereby reduce some of the sweat induced stink.

I rely on plastic bags to keep dry what needs to be dry. Food’s already prepared to hang from a tree so it doesn’t need to be kept drier than I’ve already prepped it. Stove, fuel, pots, pans, dishes don’t need it. Water purification and bottles don’t need it. Tent doesn’t need it. Raincoat (or foam coat) doesn’t. I think you get my drift.

I don’t want the pack fabric to burst or rip . Don’t mind small pin holes. I don’t drag the pack on granite and I don’t carry over 30 lbs.

So with the above criteria in mind I’ve made and tested at least a dozen frame packs using fabric weights in the 1-2 ounce per square yard range over the last 20 years. All the fabrics have worked. To provide a little margin of error I’ve gravitated to the roughly 2 ounce per square yard range of uncoated ripstop nylon these days.

Jan 29, 2019 at 12:24 am #3575573Daryl – we’re on the same wavelength as regards waterproofing, though it seems we’re in a minority. I put anything that would be damaged by wet in a trash bag, and my down gets double-protected in a drybag (probably overkill, but I like the peace of mind). After that, a bit of leakage is inconsequential to me.

On a multi-day I’d never trust a so-called waterproof pack and ditch the inner bags – just too much that could go wrong on the trail. So I’m using the inner bags anyway – nothing lost. And if you do want proofing, how long will the X-Pac laminated film really outlast the PU on a high-spec modern Cordura? I don’t think we’ve got much hard evidence.

We part company on the durability issue though – I just don’t like to have to baby my pack. I want something I can scramble with on granite, drag through a thicket or over windfall, chuck in the hold of a plane, or sit on if I’m in a bog or on a snowfield. Something that will last a thru-hike without issues. Given that there’s under 1 sq yard of fabric in an ultralighter’s pack, to get the benefit of a tough 360d Cordura I’m only paying a penalty of around 3.5 oz vs your uberlight approach. Well worth it for a klutz like me…

Jan 29, 2019 at 2:22 am #3575593Geoff,

I hear you. All good points.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Trail Days Online! 2025 is this week:

Thursday, February 27 through Saturday, March 1 - Registration is Free.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.