Topic

DIY Quilt Batting Foot

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › DIY Quilt Batting Foot

- This topic has 2 replies, 2 voices, and was last updated 8 years, 5 months ago by

R.

R.

-

AuthorPosts

-

Sep 10, 2016 at 8:52 pm #3425452

I recently found myself faced with the task of sewing a dozen or so yards of quilt batting for an art project.

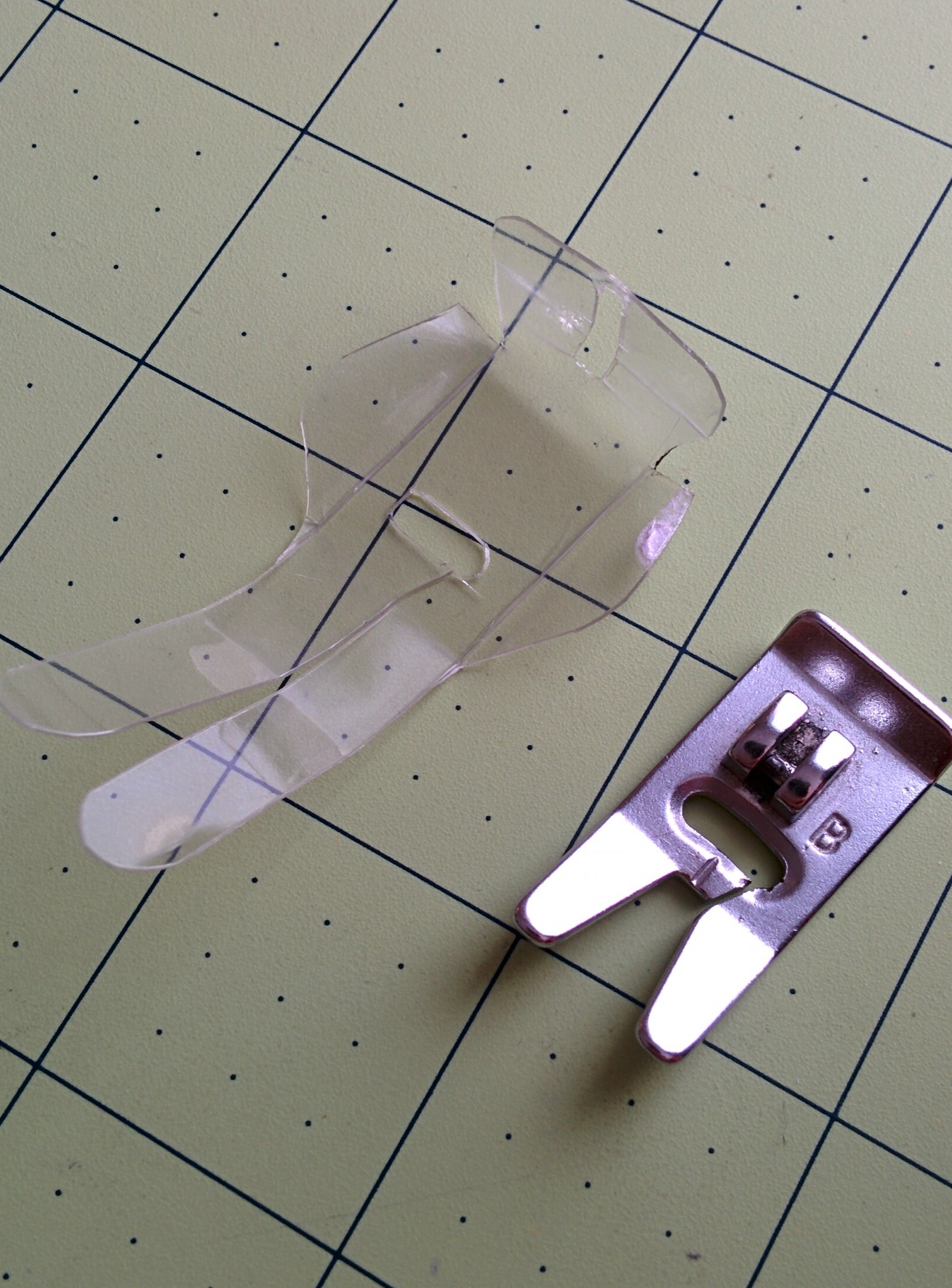

I cut some flat plastic sheet from a produce container and made what I’d call a ‘batting sole’. It goes under the normal foot of your sewing machine, like the sole of a shoe under your foot. Took me about a half hour to make the first one, and only 5 – 10 minutes to trace the pattern to make another. Worked like a charm – I could run 1″ batting through the machine like ordinary fabric. I expect this to scale well to thicker stuff.

The only trouble I got in to was when I had the machine set to a wide zig-zag and zero length – I did this to anchor a new stitch – and lay down enough horizontal layers of thread to create a lump. Then when I ran the foot over that, it pulled the batting sole, which bent and got dragged with the fabric under the needle and I sewed right through it – hence, making a second one.

Tools used: cutting wheel (optional), xacto blade, scissors.

Strangely, a google image search shows nothing similar. Nearest options are wheel-based gadgets.

The rear flap has a hole cut in it to accept the leg (?) of your machine. The side flaps have straight rear edges which press against the folded up rear flap – this is what prevents the sole from being dragged under the foot by the fabric.

Sep 11, 2016 at 10:50 am #3425533

Sep 11, 2016 at 10:50 am #3425533You might consider a walking foot attachment (not a walking foot machine, that’s different). I see them on Ebay in various sizes (maybe two, long and short arm). I find they work much better than a fixed foot, on everything from thin silnylon to thick insulation.

Sep 11, 2016 at 4:15 pm #3425594Thanks for clarifying that distinction. I may go pick one up.

The problem I solved for myself that a walking foot attachment wouldn’t (at least as far as what I saw in my quick search) is the ‘toes’ of the foot snagging strands of fiber from the upper layers of insulation. My gadget ensures the foot stays on top.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Trail Days Online! 2025 is this week:

Thursday, February 27 through Saturday, March 1 - Registration is Free.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.