Topic

Compact/light weight propane canisters

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › Compact/light weight propane canisters

- This topic has 126 replies, 17 voices, and was last updated 6 months, 1 week ago by

Bill Budney.

Bill Budney.

-

AuthorPosts

-

Oct 26, 2016 at 10:38 pm #3433036

Recently I began looking at options for running my isobutane stoves/lantern etc on propane. Rather ironic that I ended up here, as I was thinking in the context of car camping on a multi-month road trip coming up next year. The goal being cheaper and greater availability of fuel, but avoiding the bulk of full size propane gear. I also want to get back in to winter hiking and camping so the low temp/high altitude prospects are a secondary goal for me but likely the primary for most of you I imagine.

Initially I thought of just refilling the isobutane cans, and in searching that came across the article on pressure testing an isobutane can to failure (https://backpackinglight.com/exploding_gas_canisters_the_hazard_of_overheating/), which was informative.

Anyway, I thought I’d post about this as I’ve come up with an approach that doesn’t seem to have been discussed here as far as I can tell from searching.

[IMG]http://i64.tinypic.com/168vqqs.jpg[/IMG]

Green gas is propane and a small amount of silicone oil, used in some airsoft guns. It appears to come in aluminum or steel cans, and I tracked down some aluminum ones (250 + 1100 ml). I thought the seamless aluminum would be a better bet given the point of failure being at the seam in the above test. The cans have the same style of nozzle and top diameter as the butane cans used to refill lighters. Adapters for this style of can to threaded lindal are cheap ($5+), or a bit more if you need a stand and hose, which would likely be necessary with these tall cans unless you already have a remote stove.

I assumed the propane can would be stronger, but they both have DOT 2Q rating (minimum wall thickness 0.008″, tested to 270 psi without bursting) so I decided to cut them open and find out. For fun I threw a can of sunscreen in to the mix, also with a DOT 2Q rating.

[IMG]http://i68.tinypic.com/2dvl8nn.jpg[/IMG]

The butane and green gas both have a wall thickness of 0.016″ and the sunscreen is 0.013″. The bottom of all three cans is thicker than the sides. Butane 0.038″-0.064″, green gas 0.052″-0.08″, sunscreen 0.029″-0.058″.

I was surprised how thin the wall was especially on the green gas can, and that it was the same as the butane can. If I use this I would be inclined to sleeve it with some inner tube or a coat of plasti-dip, bed liner, etc. to prevent drops or scrapes from weakening the wall. Without knowing the exact specs on the aluminum it’s hard to calculate the theoretical burst pressure, but if .013 can pass the 270 psi test then .016 should clear 330 psi if it’s linear. This would be reached around 60 degrees C, and it’s hard to imagine how it would get that hot unintentionally if it’s not used directly under a stove. Maybe sitting out in the sun all day? I’m not involved with airsoft so I don’t know if many of them are missing fingers from using these cans, but I can’t imagine it would last on the market if it was a big problem.

So…thoughts?

Oct 26, 2016 at 10:46 pm #3433038Doesn’t look like I can edit the post to fix those links… will try again.

A few things I forgot to include: the 250ml green gas weighs 175g full and contains 125g of propane (silicone is minimal, I would guess less than 1% based on what I saw emptying in to a container). The larger 1100ml does not have the DOT 2Q designation, likely because it is larger than the 1 liter limit. I will dissect it once I use the fuel or am somewhere remote enough to dump 1 lb of propane safely :P

Oct 26, 2016 at 11:22 pm #3433040I see that Green Gas is some sort of propellant for guns so not specifically designed to be burnt but for all I know it may not be a problem.

First thing that came to mind, after the safety bit, was : how does it smell when burnt ?

Oct 26, 2016 at 11:39 pm #3433041I haven’t tried it yet, waiting on the slow boat for the adapter. Could also clog the jet maybe if the silicone builds up? But once it’s refilled with straight propane that wouldn’t be a problem. I wouldn’t suggest just burning the green gas and not refilling as it would get expensive. But if you just wanted it for occasional winter use that might make sense. The cans were $7 for the small and $15 for the large, on sale.

Oct 27, 2016 at 12:03 am #3433046I’ve played a little with some of those adaptors off of eBay and the cigarette-lighter ports worked better in discharge (into a lighter) then as refill ports. Propane is pretty high pressure so you want to be very careful about any spark hazards as well as potential frost-bite to exposed skin.

Also, since you won’t be using a pump to move liquid propane from one tank to another, your donor tank will have to be a higher temperature/pressure than your receiving tank. I usually do that with the donor at room temperature and putting the receiving tank in the freezer a few hours beforehand.

Oct 27, 2016 at 12:07 am #3433047And you’re going to have carefully weighed everything before and after and if you overfill anything, vent it until it is at or below factory fill weight, right? With very clear “empty” and “full” weights written on every container. That’s really important because liquid hydrocarbons expand more than the metal container and if there is not enough gaseous headspace inside the canister, the liquid can expand to fill all the volume and then the pressure goes up VERY rapidly with any additional temperature increase.

Oct 27, 2016 at 7:34 am #3433070I was aware of needing a temperature difference to transfer, but I hadn’t considered the challenge of doing that on the road. Maybe the cooler with ice would be enough, or plan ahead and do it on one of the nights we get a hotel. Or put the filler tank in warm (not hot) water.

I was hoping to use a float test to fill it without having to bring a scale. I’ll see how accurate that is by comparing with a scale first, before relying on it. Maybe drop the line 5-10% to compensate for lower accuracy.

Thanks for the safety reminder though, can’t be safe enough with this stuff!

We should also mention that even if the canister is safe, it doesn’t mean your stove or supply line can handle the higher pressure of propane. Especially if you are using vapor feed on a remote stove with a valve at the stove instead of the can, or liquid feed with a valve at either end. This would expose your hose and crimped connections to the full pressure of propane.

I focused on the canister in my initial post because the consequences of a canister rupture are more severe, but a downstream failure could still result in serious burns! So test your stove at the highest summer temperature it will be exposed to, and monitor it for loose parts and hose wear.

Forgot to include this initially – explains why canisters fail without the bottom first deforming as they say it should: https://www.chemaxx.com/real-world-aerosol-testing/burst-pressure-testing.html. This is why I decided to go with once piece aluminum vs two piece steel, the bottom will hopefully evert without failure. In theory…

Oct 27, 2016 at 8:19 am #3433075Thanks for the safety reminder though, can’t be safe enough with this stuff!

No way in hell I’m going to put straight propane in that can under any circumstances.

Oct 27, 2016 at 5:58 pm #3433165Can someone explain greengas to me? It is bottled and manufactured for Airsoft guns? But…. it doesn’t have a safety valve and some people think it is really dangerous? How is this thing being produced? What is the DOT rating for the standard isobutane/propane mixture canisters for backpacking?

Oct 27, 2016 at 6:46 pm #3433169A cooler with ice might well be enough to cool the receiver canister. Because the totally empty metal canister doesn’t weight much it can warm quickly from vapor propane condensing in it and from ambient air on the outside. Sometimes, I’ve had to do two or three coolings. Each subsequent cooling had more propane in it. So it took more new propane.

If you want to make things cold than 0C / 32F on the road, take common ice and add salt (20-25% by weight). I’ve kept ice cream cold for more than a day that way, but be cautious about salty water around any metals. Depending on the aluminum alloy, it may start to corrode (thin aluminum corroding with high-pressure propane inside = bad) and it could corrode very quickly if there are any dissimilar metals in contact with each other (the LIndal valve? your adaptor?). Then I would definitely avoid the use of any salines.

Oct 27, 2016 at 7:51 pm #3433183If you’re on the road you can just fill as often as needed. Cool the receiver a little and/or warm the donor a little.

You could heat up some water to a little more than body temperature which would cool down the receiver some. Then put the donor in the warm water for a while before transferring.

Or leave out the receiver over night and put the donor inside a warm place like your sleeping bag, or you could put it under your jacket to warm up for 10 minutes.

If you were going to transfer for a multiple day trip then you’d want to do large temperature difference to completely fill, so you should put receiver in freezer, etc.

Oct 27, 2016 at 10:17 pm #3433200Oh Boy! Here be Dragons!!!

OK, my opinions, strictly my own.Once upon a time we had compressed air pistols and rifles. You pressurised them with a lever action.

But some bright spark thought he could use CO2 sparklet bulbs instead – and they worked. But the CO2 bulbs are small.

So then someone thought of using a refridgerant gas in a larger container, and that worked – until the gas was declared to be a serious greenhouse gas and banned.

The refridgeration industry found you could replace the banned gas with propane, and that worked – except that you now have a container full of an explosive gas. I think they got away with that for a while until ‘the authorities’ cracked down on the safety aspect. I am not sure what the current status is.In the meantime, the air pistol fanatics started using the refridgerant gas, until it was banned, and then they too switched to propane. It would appear that there are now ‘air pistol’ companies which are shipping containers of propane around America as ‘Green Gas’, without declaring the contents. Do they have a DOT approval? I very much doubt it, but maybe they do. I don’t know.

As far as I can see, it is a wildly unregulated industry, run by people who either do not realise the dangers or wish to ignore the dangers – either for profit or fun with pistols.

Could you use these canisters with a stove? There are several problems.

* The first is the fitting on the end: it is NOT a Lindal screw thread. However, I believe one can buy adapters which convert them: the Japanese seem to have zero regulations on this. How safe are they? A good question.

* Then there is the small problem that the canisters contain a little silicone oil as well as propane – that’s to lubricate the gun. Does this mean your stove could be spitting out . . . sand? Possibly. Or it may block the valve or jet up – maybe. We don’t know.

* The cans are of the ‘hair spray’ format, so you have to lie them down. But the valve has no filler tube on the inside (the Coleman powermax canisters DID have them), so you can get gas or liquid fuel down the hose, depend on how full it is. This presents some problems with the valving.

* The use of straight propane in a stove designed for a propane/butane mix can be tricky. The stove would need a different fuel/air mix, so the jet or the air inlets would be a (little) bit wrong. How well it would work would depend on the stove: some would work better than others.The advertising on some of the ‘green gas’ web sites contains a lot of wonderful marketing spin – and is often just plain wrong.

Using propane with a silicone adapter can lead to uneven amounts of silicone oil being distributed into your gas airsoft gun, which may cause increased wear over time. FirePower Green Gas already has silicone mixed into the gas, providing a constant and even dispersal of lubricant.

Pure marketing spin. ‘Uneven’ amounts … snerk.Scented, does not have the same odor as propane

They have left out the mercaptan which is meant to be there to WARN you that the propane is leaking out. Instead you get a fresh lemon smell ? ? ?An additional mandatory HAZMAT shipping fee ($27.50) is not included in the list price but will be added once you check out to cart. This fee is mandated by UPS and paid for in advance by Airsoft Megastore to UPS, and is separate from the actual shipping cost.

Well, this bit is probably RIGHT!DO NOT expose to heat or temperatures above 120 F

Ah – and on a hot day inside a parked car?I could go on, but I won’t. You use this stuff at your own risk ! ! !

Cheers

Oct 28, 2016 at 8:01 am #3433238I appreciate everyone weighing in. It looks like I may have jumped the gun a bit here, should have done a bit more searching on airsoft forums:

http://www.airsoftforum.com/board/topic/46472-green-gas-heat-bang/

https://www.youtube.com/watch?v=72bSUCB_bqI

I guess in my excitement of thinking I found a solution I made the naive assumption that a commercial product would meet a safe standard. It appears that these cans may very well meet the DOT 2Q standard, but since that doesn’t seem to specify what you can put in them, just a test pressure, it is a bit of a grey area. They might all pass at 270 psi and all blow at 280 which could be reached when heated by the sun apparently.

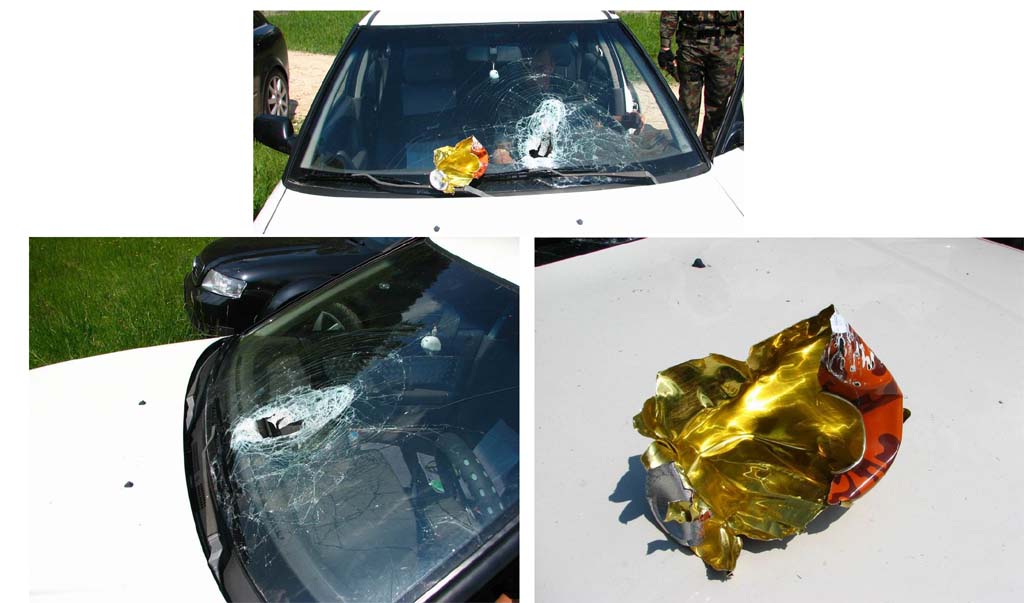

These images are interesting showing the different types of failures. When I saw the first one I thought, ok the side is the weak point, maybe a fiberglass wrap would solve that. But the second image shows that some cans may evert the bottom and then blow the top before the side goes. And the steel can blows the bottom off much like the isobutane cans do.

I guess it’s not worth the time and $ trying to reinforce these and do the necessary pressure testing to failure. Back to the drawing board. Anyone want to buy some green gas cans? I’ll give you a good price :)

Will look in to a few other options I’ve thought of – paslode fuel cells and small CO2 canister. Paslode sounds like it is 2 component with propene pressurizing butene in a bag to keep it liquid for accurate metering, based on patent info. Could pose a challenge for refilling.

Oct 28, 2016 at 2:24 pm #3433280I examined a Paslode fuel cell today. It does indeed have a foil bag inside separating the 2 gases. There are a few msds online listing different ranges of ratios of propene to butene, but my guess is we are looking at approximately 80/20 butene/propene when full and the opposite end of the range is for an empty can.

Here are my measurements:

Weight: 89g full, 51g purged, 44g after can cut (38g butene, 7g propene)

Vapor pressure: 155 psi @ 18 deg C

Wall thickness: 0.022″ side, 0.08″ bottom, they are noticeably stiffer than the cans above.

I think this is promising, because if it is designed for propene which has a higher vapor pressure than propane, that should give us an extra safety margin. However there is no DOT or other rating, other than something about a small volume exemption on the msds. It does say do not allow it to get above 49 C, so perhaps they have tested it to that pressure.

I’m not sure if the lindal adapter will fit, as the nipple appears shorter and wider than on a butane can.

I’m assuming refilling with propane would force you to always be in liquid mode because it would act the same as butene in this respect. I guess a positive of this would be you wouldn’t need a stand to hold the can inverted, it could just lie flat.

Oct 28, 2016 at 3:48 pm #3433294“because if it is designed for propene which has a higher vapor pressure than propane”

*** Edit: mostly ignore my response below. I didn’t catch the bit about the propene being in a separate foil bag***

***This response would apply if the propene and butene were mixed together:***

While propene does have a higher vapor pressure than propane, you report the canister is 80% butene and 20% propene (by weight). So it is 25% propene by mole fraction and 75% butene by mole fraction. To estimate the vapor pressure of the mixture take .25 x propene v.p. and add .75 x butene v.p.

At 18-ish C, I get .25 x 159 psi + .75 x 37 psi = 67 psi.

Where you get “Vapor pressure: 155 psi @ 18 deg C”? Measured from the canister, from the MSDS, or your own calculations?

My concern is that it wasn’t designed for pure propane nor for a gas with a propane-like vapor pressure. It is closer to a butane (butene in this case) canister, albeit a little higher pressure due to the 25% propene fraction.

Alas, TANSTAAFL (There ain’t no such thing as a free lunch). You want a higher vapor pressure gas for its better cold-weather performance (and in this case, for its lower cost and bette availability), but a higher vapor pressure gas needs a stronger container. Now, aluminum containers and some composite containers are lighter than steel, yes. And that’s useful for larger (> 5 pound fuel weight) propane tanks that hauled as a air freight (or are exposed to salt water) so those are available off the shelf (at a significant price premium). If you find the right pressure rating in a small aluminum container, there is the potential to save maybe 40% of the container weight versus steel. Beyond that, you’re giving up safety to go a lighter/thinner-walled container. Maybe that’s okay with you if you can assure the container never sees high temps in transport (snow camping?) or IN USE (which is harder to assure when it sits next to a burner!).

Oct 28, 2016 at 3:51 pm #3433295I know a lot of this comes across as a being a naysayer, while I have myself dabbled in canister refilling for many of the same reasons. Just wanted to double-check your assumptions and your calcs. And to point out that is it really tough to beat mass-produced butane/propane canisters for cost, convenience and safety.

Oct 28, 2016 at 4:12 pm #3433300I am a bit keen on the safety aspect, as you know. But what I found very interesting was that someone (elsewhere) claimed to have cut open some different ‘hair spray’ shaped containers and found that they had different wall thicknesses. Actual hair spray was low thickness, butane/propane was mid-thickness, and straight propane in the form of ‘green gas’ was high-thickness. This suggests that you CAN get stronger ‘hair spray’ canisters which would meet the DoT regulations.

On which score, I note that Sievert in Europe sell straight propane in the hair-spray format canisters. A respectable company, so I assume they have done their checking for safety. Interesting.

But you would still need to ‘tune’ the air inlets on a stove to adjust it for a straight propane fuel. That is of course possible.

Cheers

Oct 28, 2016 at 5:30 pm #3433309

(Kids don’t try this at home, you might get frostbite)

155 psi was my initial reading. Here it’s reading about 135, not sure if that’s because my hokey connection isn’t sealing properly now or because there’s less gas left.

Happy to have you guys question my numbers and theory. My understanding is that the pressure is only calculated like that when the gases are mixed. Here they are separated by a foil bag, creating an inner and outer chamber. The propene outside compresses the butene inside completely to liquid form, which is then at the same pressure of the propene. They do this to ensure the nail gun gets liquid metered with each shot to have an accurate fuel air ratio at any temperature or angle.

This gauge may not be highly accurate but I don’t think it’s off by 70-80 psi and it checks out against a second gauge.

However I should correct something from my last post where I said refilling with propane would make it safer as it would be lower pressure. Because the propene would remain in the canister the propene would determine the pressure not the propane. This could also pose a challenge for refilling.

Oct 28, 2016 at 5:34 pm #3433310You are going to run a nail gun off a propane canister? And when the nail hits something hard and makes a spark?

Blimey.

Oct 28, 2016 at 6:31 pm #3433313It’s not just running propane through a pneumatic gun, it’s a combustion gun. There wouldn’t be anything to ignite from a spark afterwards, just like your car exhaust. I haven’t used one myself but they seem to be an established company, in North America anyway.

Oct 28, 2016 at 8:03 pm #3433323Blimey!

Cheers

Oct 29, 2016 at 8:50 am #3433370Can someone explain greengas to me? It is bottled and manufactured for Airsoft guns? But…. it doesn’t have a safety valve and some people think it is really dangerous? How is this thing being produced? What is the DOT rating for the standard isobutane/propane mixture canisters for backpacking?

If you read the BPL article linked in my initial post, it has a good explanation of the ratings for isobutane canisters, or you can check the primary sources:

The DOT rating for most aersol cans is 2P or 2Q, details here: https://www.gpo.gov/fdsys/granule/CFR-2011-title49-vol3/CFR-2011-title49-vol3-sec178-33a.

Standard isobutane canisters have individual exemptions by company, allowing for different diameter, wall thickness, test pressure and frequency, etc. You can look these up by company – snow peak, cascade designs (msr), primus, etc here: http://www.phmsa.dot.gov/hazmat/regs/sp-a/special-permits/search.

Oct 29, 2016 at 10:57 am #3433377Roger, Paslode is a GOOD brand of nail guns. They are commercial equipment, but, I have seen them dropped from a second story and simply handed back for use. Rugged does not begin to describe them. They are fairly air tight, except where it enters the combustion chamber. Then it fires producing a good *hammer* action on the piston. Then the exhaust is vented as a spring recoils the piston, ready for the next shot. It all takes less than a blink of an eye. I used these and several others, air powered, and hammer driven, wrenches, impacts, etc. I worked on the older ones…one of my first jobs was to keep air tools running at a plant.

Oct 29, 2016 at 2:08 pm #3433399Hi James

Fair enough. Compressed air nail guns we have, but I don’t think ‘they’ allow the propane ones into the country. It surprised me.

As for how Airsoft and GreenGas get away with it ??? Support from the NRA maybe?

Cheers

Oct 29, 2016 at 8:32 pm #3433438I believe the small size of the fuel cells (Paslode’s) makes them fairly strong. The limit of strength for internal pressure is infinite. As it gets larger, it gets weaker. Example: a 5mm tube of .05mm thick aluminum will hold a plenty of pressure. But expand it to a 10cm tube and it will not hold the same pressure. So, using a 3cm tube will actually make it stronger than using a 6mm tube. I seem to remember increasing diameter decreases strength for the same wall thickness. Hmmm, maybe I can look it up on the web… Yup.

Here is a link… http://www.engineersedge.com/calculators/pipe_bust_calc.htm

Unfortunately for the scientific crowd, it is all in inches and psi. That is all stuff I learned with anyway and doesn’t really effect the actual calculation, which is given, also. I used a 1″ tube at .005″ thickness and got a burst pressure of 300psi. (Zero out the other inputs.) A 2″ tube at .005″ thickness got a burst pressure of 150psi. A 4″ tube at .005″ thickness got a burst pressure of 75psi. Double the diameter, half the strength… Check it out…

Soo, I assume manufacturers know this, but a squared off tube will be more space and weight efficient than our standard canisters at the same diameter. Probably allowing as much as another 50-75gm of fuel in a standard diameter sized 230gm tank. Small diameter, but longer, propane bottles can be made safely, similar to the old Colemans. But, basically, you are substituting small diameter with it’s decreased fuel amounts (by a factor of pi) for larger diameter and reduced fuel efficiency. Basically, more metal per ounce of fuel. I don’t believe propane is THAT efficient of a camping fuel to make up the difference except for a few hard core winter campers. You actually pay a weight penalty: Metal/BTU content.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.