Topic

Apex Quilt Seam Construction Feedback

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Apex Quilt Seam Construction Feedback

- This topic has 5 replies, 2 voices, and was last updated 8 years, 4 months ago by

Jerry Adams.

Jerry Adams.

-

AuthorPosts

-

Sep 10, 2016 at 7:20 am #3425318

I am making a synthetic quilt using Apex 2.5 for insulation. I selected very light fabric for the inner and outer fabric – 0.66 oz/yd Membrane 10 from Ripstop by the Roll. The quilt is going to have the drawcord type design (like the Enlightened Equipment Prodigy and Enigma) and I will use a fabric flap with snaps to close up the foot box about 18″ the bottom of the quilt.

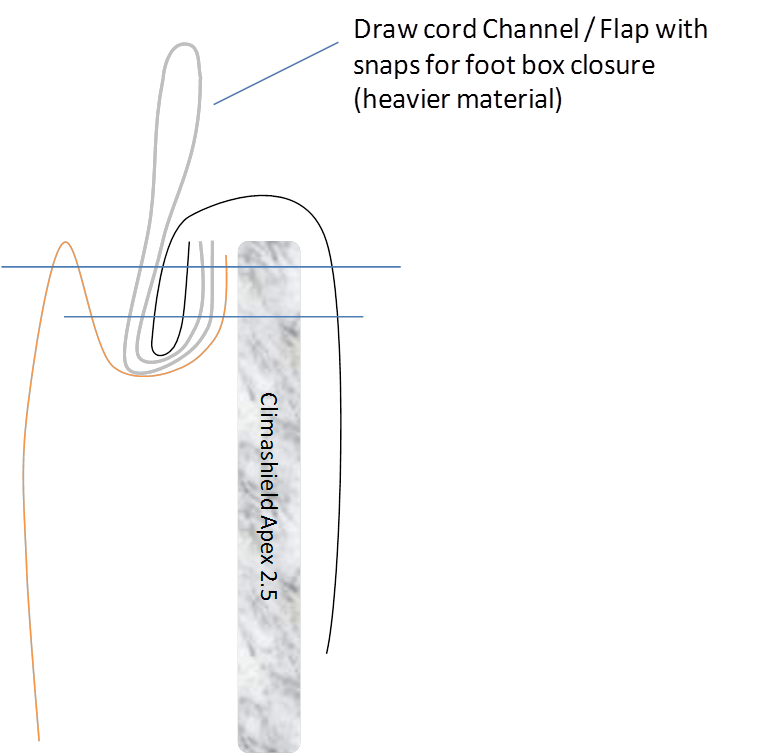

Since this fabric is so light, I wanted to reinforce the seams and use a heavier fabric that I picked up from my local fabric store for the drawcord channels since these will have some abrasion from the drawcords. The fabric is a ripstop nylon that I estimate to be about 1.5 oz/yd. I am also a bit obsessive about protecting the raw edges of fabrics so I wanted to design a seam where the raw edges are tucked inside. Here’s what I cam up with:

Seam for drawcord channels and the footbox flaps:

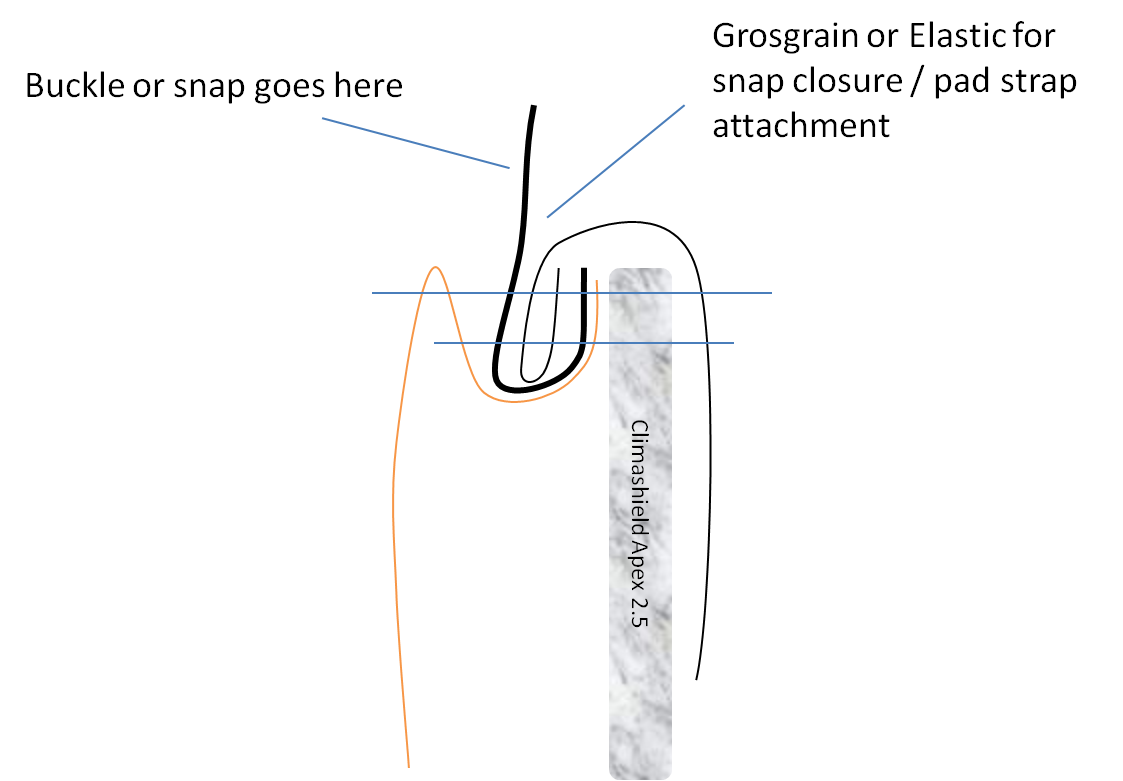

And here’s the design for where the pad straps and other snap closures will be attached (using grosgrain or elastic):

I wasn’t sure whether the two lines of stitching shown in the picture will disperse the tension on the grosgrain/elastic enough to prevent the Membrane fabric from tearing. I could sew a box with an x to provide additional reinforcement.

Hoping for feedback on this point and on the general seam design.

Sep 10, 2016 at 7:53 am #3425326Do the first row of stitches through fabric/insulation/fabric with raw edges hanging out.

It’d difficult to keep them aligned. Use some pins, or I find it easier to do some hand stitches to keep them aligned. It’s maddening to start with everything lined up at a corner, then sew your way to the next corner and they’re all misaligned.

Then fold the raw edges under and put your draw cord channel/strap in and sew through all of them with a second row of stitches.

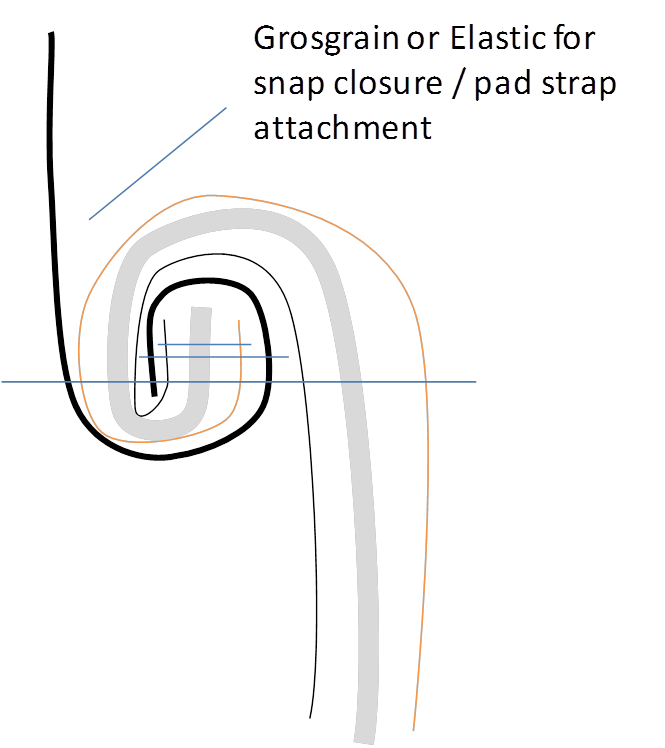

Sep 10, 2016 at 10:25 am #3425369Thanks Jerry. So would it look something like this then? …I guess this would put the fold on the outside of the quilt then right?

Sep 10, 2016 at 12:06 pm #3425380

Sep 10, 2016 at 12:06 pm #3425380 Oct 17, 2016 at 6:37 pm #3431626

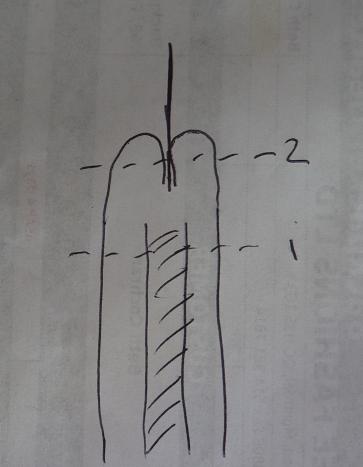

Oct 17, 2016 at 6:37 pm #3431626I ended up going with the seam design below. It worked out well, but was a bit difficult to pin together. The drawcord channels and various flaps and snaps are attached really securely and all the raw edges are nicely tucked away.

Here are few pics of the finished construction:

Flap closure for footbox:

One of the grosgrain snap attachments:

Oct 17, 2016 at 6:39 pm #3431628

Oct 17, 2016 at 6:39 pm #3431628that looks really good

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Trail Days Online! 2025 is this week:

Thursday, February 27 through Saturday, March 1 - Registration is Free.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.