Topic

A good alternative to WPB gear for ACTIVE backpacking

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › A good alternative to WPB gear for ACTIVE backpacking

- This topic has 367 replies, 46 voices, and was last updated 6 years ago by

Stumphges.

Stumphges.

-

AuthorPosts

-

Apr 3, 2017 at 6:42 am #3461230

Roger,

How about fluorocarbon and wax-based? E.g. factory fluorocarbon finish with Nikwax applied by unwitting consumer a year or two down the road.

Apr 3, 2017 at 7:00 am #3461231My idea would be that since these two have a different chemistry, they at least don’t cooperate well and likely don’t work well together.

Apr 3, 2017 at 8:19 am #3461239Yeah, I find it curious that so much Nikwax is sold to the aftermarket, but that only Paramo gear is sold with Nikwax as the factory finish. It would seem that ~95% of the Nikwax sold is applied to garments that originally carried a fluorocarbon finish. Some of these finishes will be well and truly stripped by years of abrasion and washing cycles, and so the fabric might be ready to be ‘converted’ to Nikwax. But I would guess a substantial number of garments are “re-proofed” with Nikwax well before the fluorocarbon DWR is gone from the fabric. Many consumers don’t know about pure soap and double rinsing, drying at 120 degrees, etc., and these folks, assuming that “doesn’t bead up anymore” = DWR is gone, probably dump Nikwax onto still-adhered fluorocarbon finishes. How does that work for them?

Apr 3, 2017 at 9:57 am #3461248Stumphges,

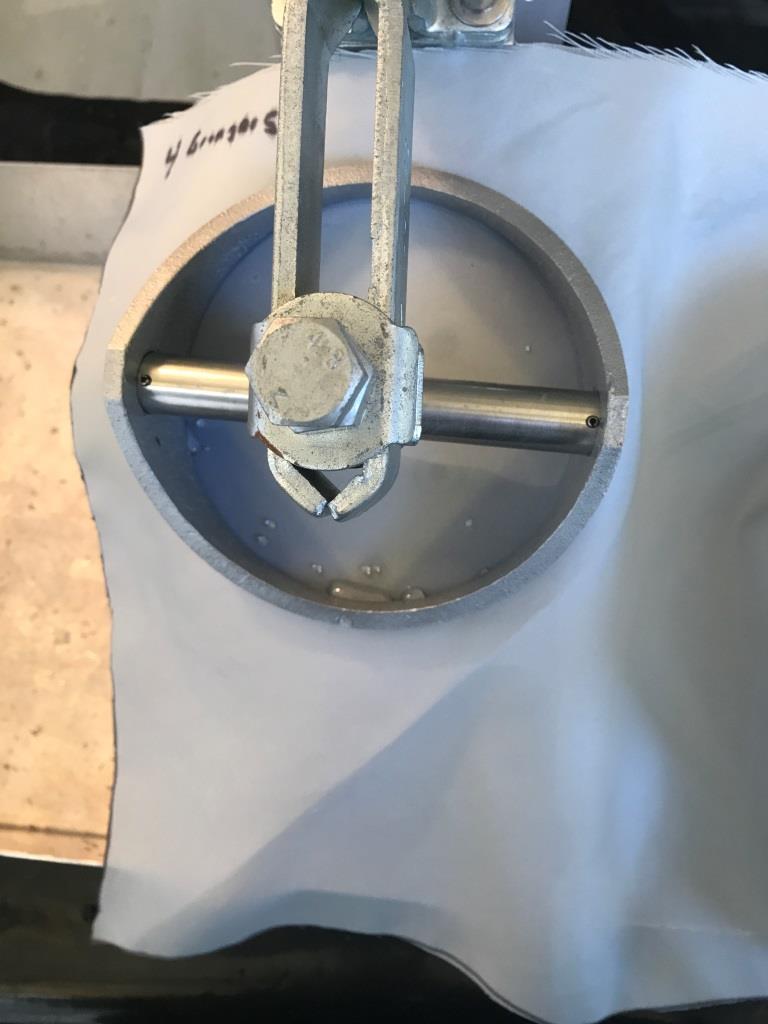

50 or 0 as a starting point is fine. What is relevant is the delta post DWR.

Woubeir,

I purchased the Nikwax at my local REI store last year.

I purchased the Grangers from MEC on 5/7/16 via mail order. I thought they may have been still selling the old C8 stuff but it was a different bottle. It was listed as their product # 5007404 but the picture showed the old C8 bottle.

I purchased the can of Revivex yesterday at my local REI retail shop in San Carlos, CA. They currently offer only this Revivex container option and only had a couple of cans on a portion of a shelving area allocated to McNett repair parts. The Primary REI DWR display was huge and was exclusively stocked with Nikwax DWR.

The surface tension of water in contact with air, at my test environment of 70F, is equivalent to about 3.49mm vs the 300mm value the green value DWR shows.

Apr 3, 2017 at 10:29 am #3461249Richard,

as it seems Granger’s has no Xtreme-productrange anymore, I assume your bottle contains FC’s.

Apr 3, 2017 at 10:32 am #3461250Roger,

just out of curiousity, what elements in my reasoning are not exactly true ?

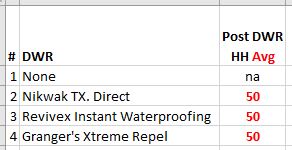

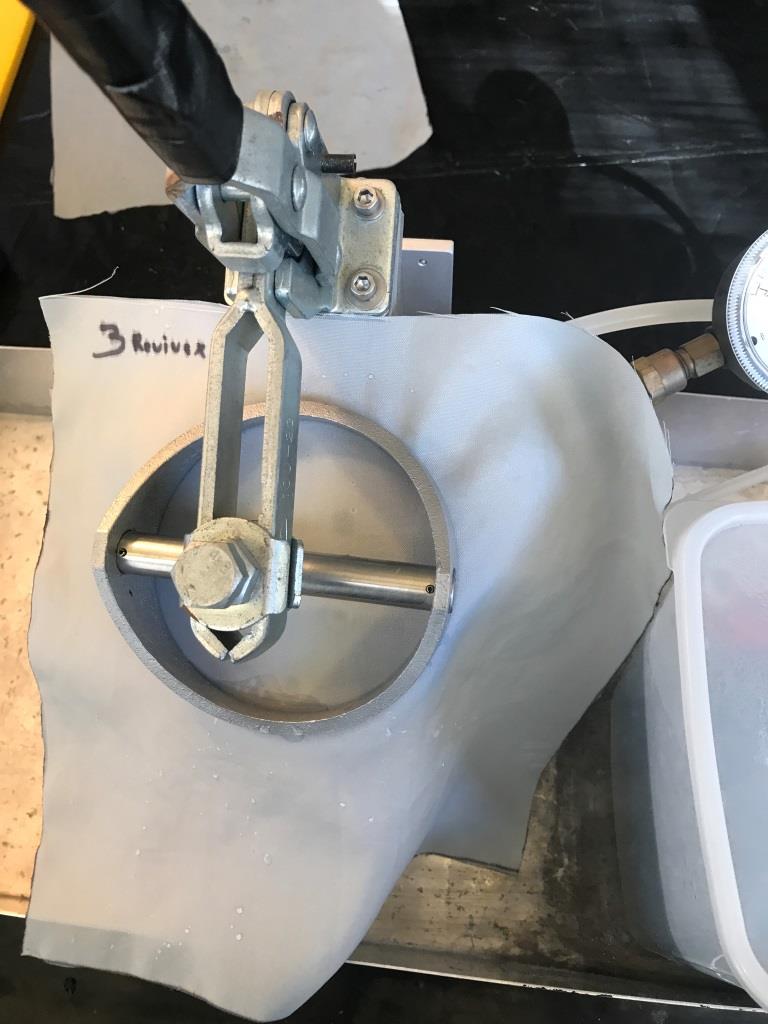

Apr 3, 2017 at 11:12 am #3461255Two of the samples air dried for 12 hours and Granger’s was machine dried per instructions. All three DWRs imparted excellent reduction in surface tension to achieve a 5 spray rating (best) versus 0 prior to the DWR applications. Next samples were hydrostatic head tested and none of them exhibited any significant increase in HH (showed about 50 mm which is my machine tolerance). The test results are below as well as updated in my yesterday post.

Each sample was tested with the DWR surface facing the water pressure.

Apr 3, 2017 at 11:52 am #3461258

Apr 3, 2017 at 11:52 am #3461258Woubier,

You said, “as it seems Granger’s has no Xtreme-product range anymore, I assume your bottle contains FC’s.” Also the fact that the Xtreme instructions say to use a dryer after applying the product significantly reinforces the probability that this is C6.

Since most consumers don’t know what DWR was applied to their DWR garment when manufactured and the DWR vendors don’t label the contents of their aftermarket DWR products… lots of WPB jackets are probably being discarded under the assumption that since they wet out they are worn out.

Apr 3, 2017 at 12:14 pm #3461263https://grangers.co.uk/products/clothing-repel

Grangers Clothing Repel is a fluorocarbon-free waterproofing treatment, based on Grangers’ unique Acrylic Polymer Technology. APT provides a highly breathable finish while maintaining excellent water-repellency and durability.

This product is an updated/rebranded version of Grangers Performance Proofer. Usage instructions are as follows:

- Use two 50ml capfuls per garment. For best results, we recommend reproofing garments separately.

- For each additional garment washed, add an extra 50ml capful of Clothing Repel to the washing machine.

- Wash on a full cycle (wash, rinse, and spin) at 30°C or 86°F.

- Treated garments can be left to dry naturally. Performance/longevity may be improved through tumble drying.

Apr 3, 2017 at 12:32 pm #3461267Grangers offered both C6 and non-C6 when I ordered the product used to test

This is how MEC listed the product I ordered and used for this test. Notice that the bottle is an image of the C8 bottle but they shipped the C6 bottle shown previously.

Apr 3, 2017 at 1:07 pm #3461274I purchased 2 linear yds of test material. Until it is used up, I will ship free untreated 1’sq fabric samples to anyone who has access to a HH tester and wants to do their own DWR tests. All that is required is sending me a postage prepaid (SF, CA area) envelope to that is large enough to contain the number of samples you are requesting (4 max).

Apr 3, 2017 at 1:54 pm #3461283Richard,

Thank you very much for taking the time and trouble to run these tests.

Now, I suppose, we have to reconcile your results with Dr. Gibson’s. I have some ideas but doubt they would hold any water.

Anyone know if there is a way to share pdf files on this forum without file sharing sites?

Apr 3, 2017 at 2:10 pm #3461285Richard,

interesting. Now, I could be wrong but I think that in the Natick-study the two sides of a fabric were treated with a repellant, Not that I think this will create a huge difference but you never know.

Apr 3, 2017 at 3:52 pm #3461304Why did Betamax lose out to VHS? Or why did the superior French Campingaz connector lose out to the technically-inferior UK Epigas screw-thread?

I suspect that Paramo and Nikwax have a nice UK market which keeps them happy, and there has not been the pressure to take over the world. So they did not try. I also suspect that the marketing spin and budget of the American membrane companies (especially Gore), coupled with the willingness of the consumer to want ‘100% waterproof’ rather than more realistic ‘water-repellent’ rainwear, may have something to do with it.

It turns out that fluorocarbons are being deprecated fast for environmental reasons, which may see Nikwax (and the new Graingers) rise in prominence. At the same time, 100% waterproof ponchos made of silnylon can offer what many want – but not as jackets with their condensation problems.

Can you apply Nikwax over fluorocarbon? I believe so. A wax/EPDM mix should stick to it. I would not try applying fluorocarbon over Nikwax though: it would not be able to bond to the fabric fibres anymore and would wear off very fast.

Woubier – I forget the details. I am sorry – remind me please?

EDIT: Oh, I see. Cultural problem only (we get these). ‘Close enough’ means that I cannot see any problems in what you were saying. I was agreeing.Cheers

Apr 3, 2017 at 4:21 pm #3461310Roger,

OK. You never know how you could be wrong in just a tiny error. For someone else it might not matter but I always want to improve what I already know or think I know, even if it’s just in details.

Apr 4, 2017 at 8:44 am #3461434Hi Roger,

Thanks for your thoughts on Nikwax and flour/wax compatibility. Do you think that a wax impregnated inner fleece worn under a fluorocarbon DWR-treated windshirt would mess up the later? From your post I’m guessing it should be OK.

Eventually, I’d like to switch from fluoro to wax/Epic (depending on conditions/terrain) entirely, for the health and environmental reasons you’ve mentioned, at least until something better comes along (which must be around the corner, surely, with all the research being done on super-hydrophobic surfaces.) But I’ve got several flurocarbon-DWR windshirts and a standalone Paramo “pump liner” that I’d like to pair in the meanwhile.

BTW, do you bother putting DWR on your Taslan wind shirts?

Apr 4, 2017 at 3:13 pm #3461483Do you think that a wax impregnated inner fleece worn under a fluorocarbon DWR-treated windshirt would mess up the later?

Should have no visible effect whatsoever. Windshirts and pump liners should go fine together.which must be around the corner, surely, with all the research being done on super-hydrophobic surfaces.

Plenty of them around, and they work excellently in the lab. So far they have all be a total failure in the field, especially on fabrics. For some reason a shirt on your back on the side of a mountain does not behave the same as a smooth test surface in the lab …do you bother putting DWR on your Taslan wind shirts?

Nope. Would not work. We get sweaty in the Australian summer, and all DWRs are killed by sweat and body oils. Quite pointless.Cheers

Apr 4, 2017 at 3:31 pm #3461493Thank you very much, Roger. Cheers

Apr 17, 2017 at 3:56 pm #3463628Anyone have the specs on the Tyono fabric used in the Arc’teryx Nodin jacket?

EDIT: never mind. I just realized it is the renamed Gossamera and not a new fabric.

Anyways, would be great to build a list of 300+ mm HH jackets in the 25+ CFM range.

Apr 19, 2017 at 8:56 pm #3464099Paul,

Very few on that list. Unicorns:

BD Alpine Start

Wild Things Multicam Windshirt 1.0

Luke’s Ultralight Argon 90 windshirt

Regarding Nodin, it may or may not be a previously used fabric. The Toray fabrics Arcteryx uses for their windshirts can and have had very thin polyurethane coatings on their inner surfaces, which dramatically change their hydrostatic head. The face fabrics might be identical but the coating specs might vary by year and jacket model. Nodin looks nice and full featured, but for the hood – it lacks a proper brim.

Apr 20, 2017 at 6:48 am #3464140I think you can add the Patagonia Level 4 to the above short list as well

Apr 20, 2017 at 8:03 am #3464150The Tyono used in the Nodin is the 20D-version so the old name is Luminara.

Apr 20, 2017 at 8:08 am #3464152Mike – Patagonia Gen 2 (PCU) Level 4 or Gen 3? Or does it even matter?

Apr 20, 2017 at 8:19 am #3464154Mike, I think R. Nisley tested the HH of the Patagonia Level 4 at < 100mm. https://backpackinglight.com/forums/topic/108524/page/2/#post-2238895

Have you found its performance to be better than that figure would suggest?

Apr 20, 2017 at 9:13 am #3464164not sure what gen mine is, circa 2009-ish

I have an Alpine Start and in real world use, I would say the Patagonia level 4 performs equally to it in both breathabilty and water resistance. It’s possible Richards sample was under performing or a different gen????

I use the level 4 big game hunting and the Start backpacking

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Trail Days Online! 2025 is this week:

Thursday, February 27 through Saturday, March 1 - Registration is Free.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.