Topic

Folding Wood Saw – Was 6.6oz Now 1.98oz

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Folding Wood Saw – Was 6.6oz Now 1.98oz

- This topic is empty.

-

AuthorPosts

-

Feb 11, 2006 at 10:30 pm #1217758

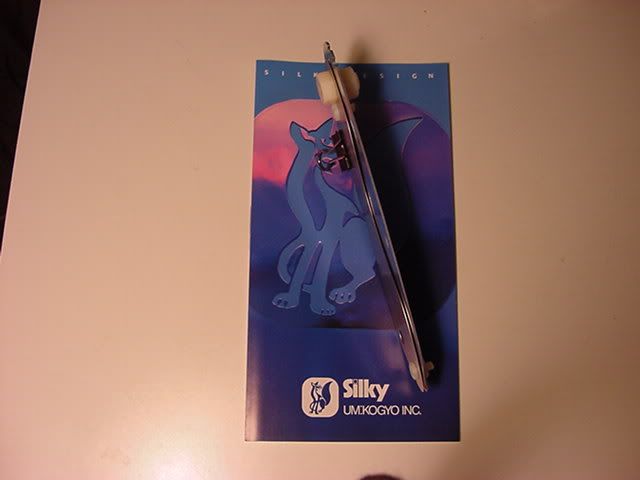

There was a thread here about wood saws. Several different saws were talked about. Some were folding and some were not. Of the different saws I liked the Japanese Silky “Pocket Boy” Folding Saw. I ordered one. I got one of the Large Teeth versions. It has a 5 inch saw blade and the complete saw weighs 6.6oz. But not for long.

I decided that if I gave up the Folding Part I could save a lot of weight. I also didn’t expect to ever carry the folding saw in my pockets anyway so that part could go. I removed the stock handle and weighed the Saw Blade, the Blade weighs 0.98oz. I made a new set of handles out of some of my Titanium.

The finished Saw now weighs 1.98oz.

I am going to make a carrier for the saw out of plastic soda bottle material and make a way to attach it to my pack frame. I want to do a long hike and use one of my 1oz wood stoves and the saw might come in handy.

Feb 11, 2006 at 10:43 pm #1350398

Feb 11, 2006 at 10:43 pm #1350398where did you get the titanium & how did you prepare it?

that’s the neatest little saw I ever, uh – have seen!

Feb 11, 2006 at 11:41 pm #1350399Thanks Cary,

The Titanium comes from

Thru-Hiker.comIn some ways Titanium is very easy to work with in other ways it is very hard.

I use 0.016inch – 6A14V -This is military grade titanium sheet and is extremely strong. It combines a high strength to weight ratio with corrosion and heat resistance. The pictures shows most of the tools I use when working with Titanium. The picture is from when I made a Titanium Potty Trowel. The piece for the Ti Trowel was from some scrape left over from my Ti External Pack Frame.

I cut the Ti to shape with a pair of WISS Tin Snips. These work really well for Titanium. I Punch my holes with a "Hand Punch". This is also easier than drilling in Titanium. You can drill Ti but where the punch will work it is easier to use. I do a lot of filing and some sanding. The forming for the Potty Trowel was done by what I call my primitive "'blacksmith" skills. Heat and pound. File and sand, a lot.

Feb 12, 2006 at 12:48 am #1350405

Feb 12, 2006 at 12:48 am #1350405Bill, great job. Didn’t realize how relatively easy it can be to work with Ti. Thanks for explaining how you did it. Tin snips, huh? Remind me not to shake hands with you; you must have some grip strength! Since only my fingertips are calloused from typing long posts, I’d need some padding on the handle not sure if you will though. The design of your handle looks like it would be easy to wrap with a couple-to-few layers or bandana or pack towel while sawing and not have your hand slip while sawing.

Feb 12, 2006 at 12:49 am #1350406.

Feb 12, 2006 at 2:31 am #1350411Hi Paul, Thanks for the nice comment. You are right about a little padding for the handle. I always carry a pair of light weight gloves and figured I can use them if necessary. Your ideas for a little padding are also good ones along with a possible sock or any number of other things a person might have with them.

I don’t expect to be cutting a lot of wood but a really light saw would sure earn its keep this weekend a lot of places along the AT. The snow falling right now would be easy to take with a nice small fire.

Feb 12, 2006 at 7:59 am #1350416Can’t one side be made still lighter for aluminum or a plastic?

、、、、、、、、、、、、、、、、、、、、、

Billさんへ

とても感心しました!

私も使っている道具ですので興味あります。

せめて、片側を軽いアルミ、プラスチックにしてみたら使えますか?両側ともアルミでは強度が不足しますか?カーボン繊維を貼り付けると重くなり過ぎるのかな?Feb 12, 2006 at 8:30 am #1350420Very nice Bill,

it is funny how us ultra lighters will modify something before hardly using it,:-)

I like Yukio`s idea, I guess something can always be lighter

Feb 12, 2006 at 7:03 pm #1350461You did it again, Bill.

Now I gotta make one.Feb 12, 2006 at 7:29 pm #1350463Yukio-san, Thanks for your comment.

Part of what Yukio-san is asking is about using Aluminum and or Carbon Fiber. Three pieces make up the handle. The inside piece is Aluminum and used as a gasket of sorts as it is the same thickness as the saw blade. The Titanium is lighter than the Aluminum I have and I don’t have any flat sheet Carbon Fiber. It is possible to get flat sheet Carbon Fiber but it seems to be in short supply. I may send for a sample pack and see what it is like. I email the company once about the flat sheet material and I believe it might have been lighter than the Titanium I use. It has been a long time ago and I will have to look for their web address.

Ryan if it can be made lighter I want to try.

Vick, you can buy just a replacement saw blade like I used for $16 plus S&H. If you want to try one like mine I can post a 1-800 number for you.

Feb 12, 2006 at 11:50 pm #1350479Lighter? Without switching materials, use the old drag racer’s trick from the 50’s. Drill holes in your frame/handle. Yes, I remember you said drilling is hard, so maybe, you disassemble it and punch the holes; then reassemble.

Use descretion as to the number of holes you punch though, or you can end up with a failure due to insufficient material remaining to take the stress of use. Obviously, the holes would make padding the handle with a sock (as you suggested), or a bandana or packtowel, more important.

Feb 15, 2006 at 6:52 am #1350595 日本の箱根地域では各種の木材を繊細に切り込んで組み合わせた「指物細工」が有名です。

日本の箱根地域では各種の木材を繊細に切り込んで組み合わせた「指物細工」が有名です。その加工には、カミソリのようにとても薄い鋸刃を使います。刃の弱さを補うために峰の部分にU形に折り曲げた金属板を取り付けて直線にしています。(胴付き鋸)

このアイディアを応用したのが、写真のものです。基本的には、穴は1箇所です。

お尻部分の穴は紐を付けたり壁に吊り下げるためです。

A=刃の剣先がようやく収まる隙間にする。携帯したときに刃が飛び出さないように。

B=刃の2倍ぐらいの内幅にする。刃先は薪以外に当てないためです。

C=B部分に物を挟んだままで、さらにC部分に刃厚のものを挟んでバイスで締め込む。

鞘の前方はやや延長させると、使うときに鋸刃が暴れにくいです。

B’-B” 断面図 鋸刃が収納された様子です。

チタン板が、折り曲げ加工しても折れないことを希望します(笑)

Feb 16, 2006 at 2:38 pm #1350653I changed my saw a little and it will now fold up and has a locking device to keep the saw blade from coming open when it is folded. In making the change I also dropped a little weight and the Folding Saw now weighs 1.83oz.

Feb 16, 2006 at 3:15 pm #1350657

Feb 16, 2006 at 3:15 pm #1350657Great Job, Bill. Very impressive to say the least. Too bad you don’t want to be an entrepreneur. You’ve made a number of items that I wouldn’t mind purchasing from you and be proud to own. Excellent weight for a decent sized saw. I think a lot of companies could learn something from you. Thanks for sharing your secrets.

Feb 16, 2006 at 5:13 pm #1350668Paul says it is too bad Bill doesn’t want to be an entrepreneur. I disagree. Once he has invented/developed something like the folding saw I want him to move on to something else and not waste his time on production.

On the other hand, if there is someone out there with the skills and inclination to produce and sell some of Bills designs (by arrangement with Bill) that sounds like a good thing. Any offers?

David

Feb 17, 2006 at 12:07 am #1350686David, good point you make. You’re absolutely right, I, too, want to see more from Mr. Fornshell. I just wish that I could buy some of his “creations” for my own use.

Feb 17, 2006 at 6:35 am #1350693Paul and David. I appreciate your nice comments. I once thought about making short runs of some of my ideas. I decided that the product liability with todays consumers isn’t worth the hassle. Anyway most good ideas just get stolen by others so I don’t show everything I make for myself anymore.

Paul, I have a new design for a more “arty” version of the handle for the saw. Not as wide and holes to make it a little lighter but in a artistic sort of pattern.

Feb 17, 2006 at 7:15 am #1350694Bill, can’t wait to see it. Now that you’ve mentioned it, once you think that it is ready, pics are obligatory.

Feb 17, 2006 at 7:39 pm #1350735Hi Paul, Here is the new Folding Saw Handle. I am going to retake the pictures and see if I can get rid of the green tint.

The complete saw now weighs 1.68oz.

Old Handle / New handle.

Feb 17, 2006 at 7:49 pm #1350736

Feb 17, 2006 at 7:49 pm #1350736Very neat!! I like it. Let me know how it works out for you. BTW, the green tint in the pics is very nice too – very outdoorsy.

Like you said, wrap the handle with a dual-use piece of cloth that one is carrying anyways, and this should cut you some fine small deadfall for your wood cook stove. Certainly your creation will cut faster than a mouli (wire) saw, which IME, is not too gentle on the fingers after endless minutes of sawing with those very tiny mouli saw teeth. My mouli saw weighs just under 1.0 oz, but you will be done eating and cleaning up by the time I finish cutting. Nice job.

Feb 17, 2006 at 8:37 pm #1350739Hi Paul, Thank you. If I ever see you along the trail I will let you use my saw or better still I will cut you some wood. The green doesn’t really look that bad.

I have a couple of the wire saws. They came with something I got while in the army and were part of a pilot or air crew survival kit. One of the funnier items in the kit were what the army called a water proof receptacle. They looked a lot like a non-lub’ed condom. You could roll a pair of socks up in one and keep them dry. Very light weight and a great way to keep a pair of socks dry during the monsoon season.

Feb 18, 2006 at 8:27 am #1350756Bill, very nice work, as usual. I think with titanium you can actually make the holes bigger and not lose a lot of strength. You have two plates of titanium in there, right? You could drill offset holes in either plate, as well, maybe that would preserve strength of the handle as a whole.

When I take a wood stove in Yellowstone, I cook on willows. Most of the time they are green. I’m using a Kelly-Kettle so the wood sizes are pencil sticks. A saw doesn’t work so well, and takes a long time. For efficiency, I brought a pair of garden shears (pruning type) for “making wood”. They are way heavy – 8 oz. If you could get a set of these below 2 oz it would be a great addition to the wood fire builders cook kit.

Feb 18, 2006 at 8:40 am #1350757DrJ, good point on the offset holes – wish I had thought of that. …and..the pruning shears…good one also…I’ve got a pair of Cutco racheting pruning shears that weights “only” 6.5 ounces. Never thought about carrying them, but might consider it now. They can handle the hardest of woods up to just over 1″ in diameter. Four quick, relatively easy racheted squeezes (even my 102lb wife can prune a 1″ oak branch) and the branch is “pruned”. It’s actually faster and requires less effort than sawing. Now, all I’ve got to do is sneak the pruning shears away from my wife’s gardening gear and into my gear closet…

Feb 18, 2006 at 12:25 pm #1350767Thanks Ryan for your comments:

Yes, both sides of the handle are made of Titanium. I sort of liked the design made by the holes. Shame on me. The holes are punched out with my Harbor Freight punch tool so that part is easy. I will make another (one) handle side and punch more and larger holes to see how much lighter I can get one handle. Then decide if I want to make another set of handles, Yes.The saw blade is the “Heavy” at 0.95oz. The two sides of the handle only add 0.34oz each per side. The steel or what ever the Japanese used for the saw blade is a killer on drill bits. I had to drill one hole and about ruined everything I used to include my drill. I will go Monday to my Screw Store and let them look at the blade and see what kind of drill bit I need. If I can get a few different sized drill bits that will work on the saw blade I can lose more weight there faster than with the handles. The handles just don’t have much to give up. The magic 1 ounce number might be possible. That would be nice, go from 6.6oz to 1oz. I better order a new blade just in case I have a melt down.

As for the Kelly-Kettle, I like the idea but not the weight. I and a few others I know are looking for aluminum cans or things that would let use make something like it but much lighter. We have found a few things that might be workable to modify into the parts but the things are a little expensive. The small double walled Sake can will work but it is really to small.

Small Shears: I have looked for small shears for something else and the smallest I have found were a pair of what they called scissors but with serrated blades. They weighed 0.8oz. I didn’t buy them but they might cut pencil size sticks. They were $22.

There are made by

Kershaw

a real high end knife maker. At 0.8oz they might be worth a test.Paul: Just for you and Ryan I am going to make “Swiss Cheeze” out of the Titanium handles, at least one as a “how low is low” weight test.

Mar 9, 2006 at 6:51 pm #1352216Some notes about Japanese saws. They cut on the pull stroke, so blades can be much thinner than western style blades – and they are quite flexible. High teeth/inch blades cut faster and through more different types of material than someone would assume at first glance. Saws are often high carbon steel with impulse hardened teeth. But outdoor/gardening saws may be plated or stainless steel. One of my favorite little saws is a 25 teeth/in detail saw.

That little detail saw has been used/abused primarily on garden chores. I have trimmed down 7″ stumps but mainly used it for light pruning. It cuts very fast on all material – green or dry, thick and thin. Not quite working like pruning shears, of course – but it cuts similar material. I have not had a rust problem with this blade eventhough it is high carbon steel. I have only quickly wiped out the wet pulp from the teeth before putting it away. Coarser tooth Japanese saws, because they have fewer and deeper cut teeth, do cut faster however. The alternating cut pattern of the ‘cross-cut’ style saw, cut much cleaner than other saw tooth patterns.

One of the better types of drill bits that can go through tougher material are cobalt bits. Better hardware stores (ones for the “trades”) or metal suppliers sell them.

Japanese saws can be sharpened by special files.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.